Nissan Murano: Sheet Metal Work / Shrinking the Sheet Metal

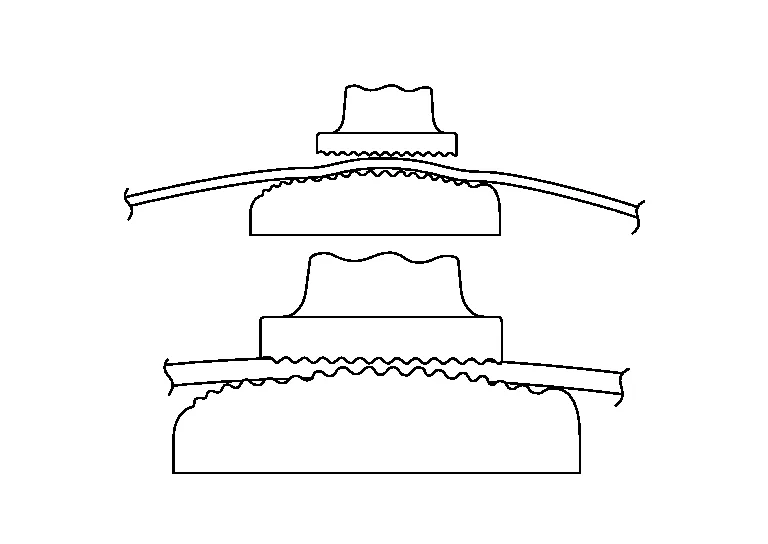

Plastic deformation may cause reduced panel thickness and the panel may stretch. Even when it is repaired using a hammer and dolly, the panel tends to bulge, losing its original shape.

In such cases, it must be shrunk to its original shape. This is called shrinking the sheet metal.

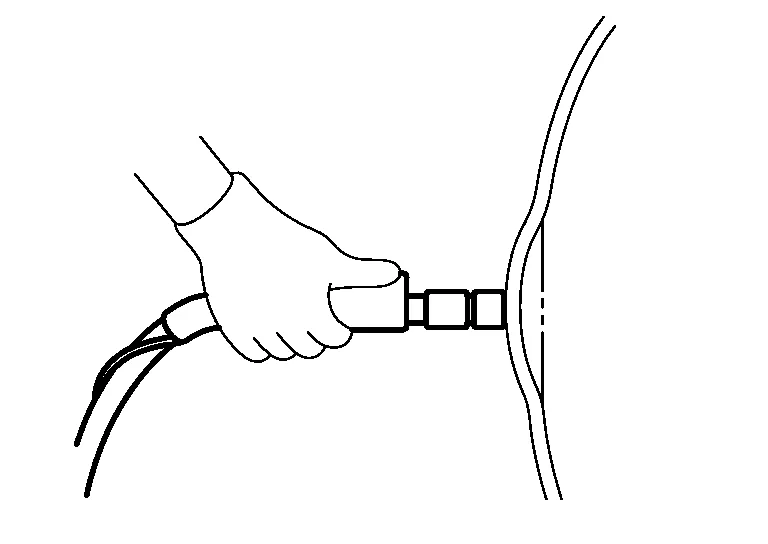

(1) ELECTRIC WELDING MACHINE

The body panel is connected to the negative power supply terminal and the tip is connected to the positive terminal. Then, an electric current is supplied to heat the panel. The shrinking principle is the same as that of gas welding. This method features no hammering and greater workability than gas welding and is suitable for repairing local panel deformations.

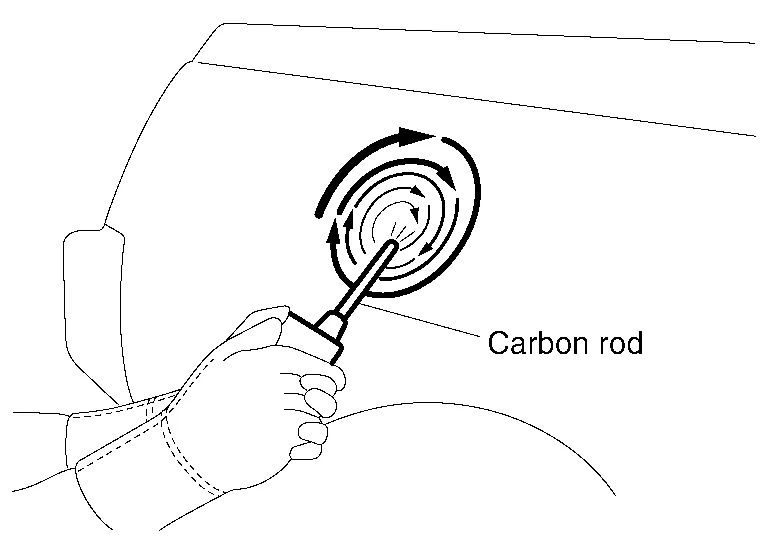

(2) CARBON ROD

The panel is connected to the negative power supply terminal and a carbon rod is connected to the positive terminal. The panel is heated so that heat is conducted from the outside to the center of the dent. Wet rags are then applied to cool it quickly, thus shrinking the panel.

This method is suitable for repairing wide, shallow panel deformations.

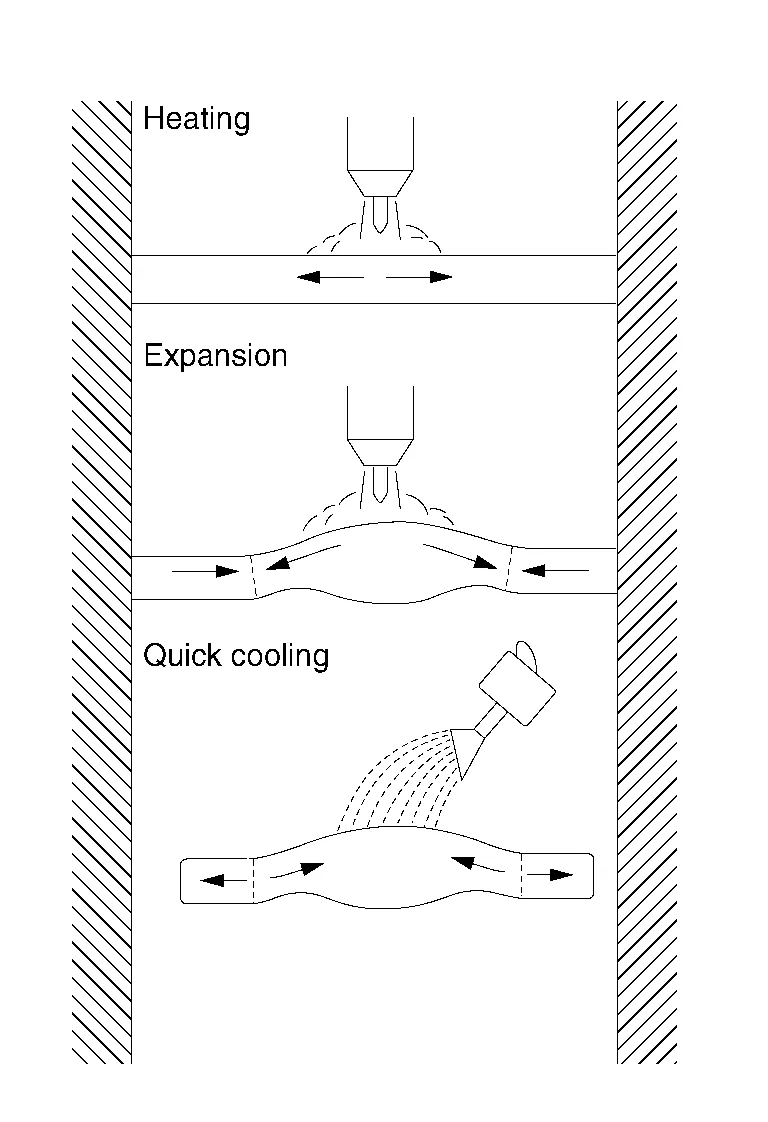

(3) GAS WELDING (OXY-ACETYLENE TORCH)

(a) Heating and expansion

As the sheet metal is heated with a gas welding torch, it stretches.

However, stretching is restricted in the unheated surrounding portion. As a result, the heated portion bulges.

(b) Sudden cooling

When the bulge is cooled suddenly, it shrinks.

This shrinking is accelerated by tapping with a wooden hammer.

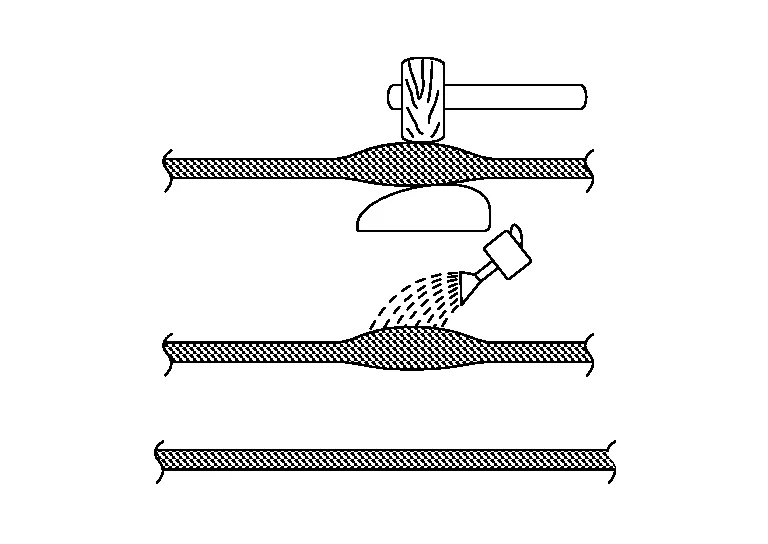

(4) HAMMER AND DOLLY

A shrinking hammer and shrinking dolly are used by the hammer-on-dolly method. Many tiny dents are formed on the panel surface. This method is suitable for shrinking comparatively small areas of panel deformation.

-

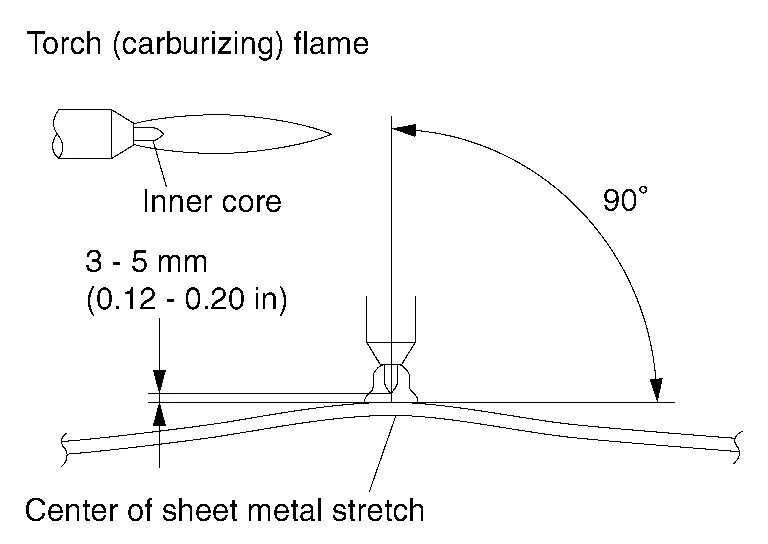

Use a carburizing flame when shrinking sheet metal with a gas welding torch.

-

Hold the torch at a right angle to the center of the sheet metal.

-

Maintain a distance of 3 mm - 5 mm (0.12 in - 0.20 in) between the inner core and sheet metal.

-

Heat the sheet metal to approximately 800°C (1,472°F) (until the heated portion turns red). Increase the temperature if sheet metal stretching is insufficient.

-

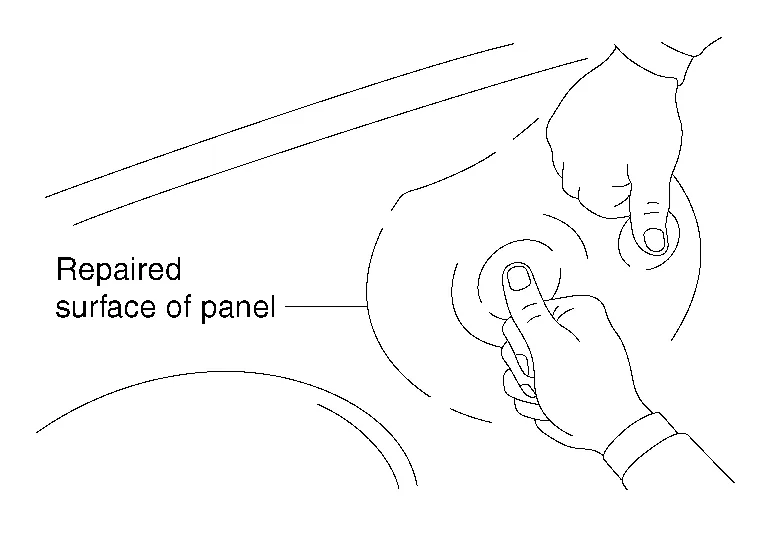

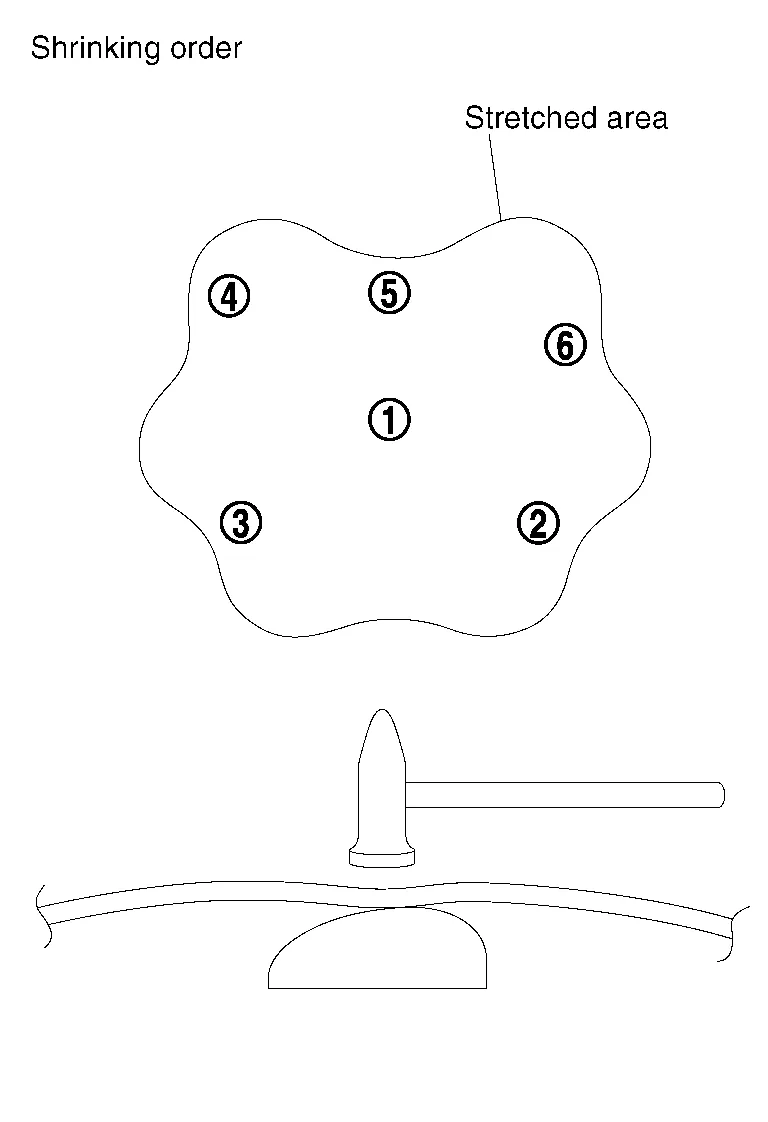

Locate the stretched portion of the panel.

Press the surface being repaired in several places.

The point where the largest elastic dent is formed is the center, where the stretch is the maximum. The highest portion of the panel being repaired can also be considered the most stretched portion.

-

The area heated with a welding torch must be approximately 3 mm - 5 mm (0.12 in - 0.20 in) in diameter if the panel shape is complex, and approximately 6 mm - 15 mm (0.24 in - 0.59 in) in diameter if it is flat.

-

Small stretch

-

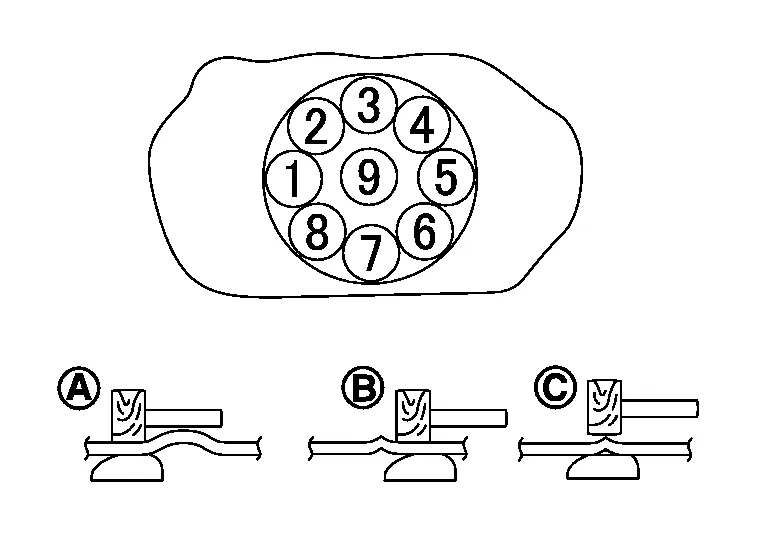

Apply a dolly to the back of the heated panel. Tap the panel with a wooden hammer using the hammer-ondolly method in the sequence shown in the figure.

(A) and (B) → 1 - 8 (C) → 9 -

Excessive stretch

Shrink the panel, starting with the most stretched portion, and proceed toward the edge of the dent so that the dent surface is lower than the original surface.

Using a gas welding torch makes the panel concave.

To correct this, strike the concave portion using the hammer-on-dolly method to stretch the panel bit by bit until the original surface is restored.

-

Apply wet cloths to the shrunken portion of the panel to cool it quickly.

Sheet Metal Work Tools

Sheet Metal Work Tools

Sheet Metal Work Tools

This section explains various tools used in body repair work.

Hammers

A hammer is used to correct dents, projections or other deformations...

Correcting a Deformed Exterior Body Panel

Correcting a Deformed Exterior Body Panel

Determining Panel Damage

CAUTION:

This repair method should not be used on rails and reinforcements.

Panel damage must be examined carefully to select the most suitable repair method...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Vehicle Information. Body Exterior Paint Color

Body Exterior Paint Color Component Color code KH3 K23 KAD KBY NBL QAB RCJ Description Black Silver Gray Gray Red White Blue Paint type S 2M 2M 2P 2PM 3P 2P Hard clear coat x x x x x x x 1. Door mirror Body color KH3 K23 KAD KBY NBL QAB RCJ Black KH3 KH3 KH3 KH3 KH3 KH3 KH3 2...

Nissan Murano (Z52) 2015-2024 Owners Manual: Trailer frontal area

CAUTION Exceeding the maximum trailer frontal area specification may exceed the towing capacity of the vehicle. This may affect the towing performance and lead to vehicle damage. The trailer frontal area affects the towing load of a trailer. The frontal area is the total area of the vehicle and trailer that is affected by air resistance while towing...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Jacking up vehicle and removing the damaged tire

- How to enable/disable the LDW system

- Intelligent Forward Collision Warning (I-FCW)

- New on site

- Most important about car

Seatback pockets

Theremaybe one or two seatback pockets located on the back of the driver and passenger seats. The pockets can be used to store maps.

WARNING