Nissan Murano: Sheet Metal Work / Correcting a Deformed Exterior Body Panel

CAUTION:

This repair method should not be used on rails and reinforcements.

Panel damage must be examined carefully to select the most suitable repair method.

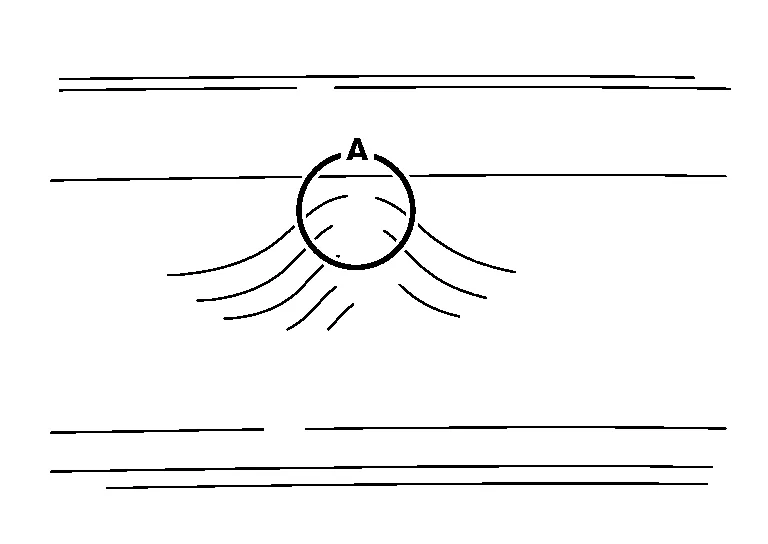

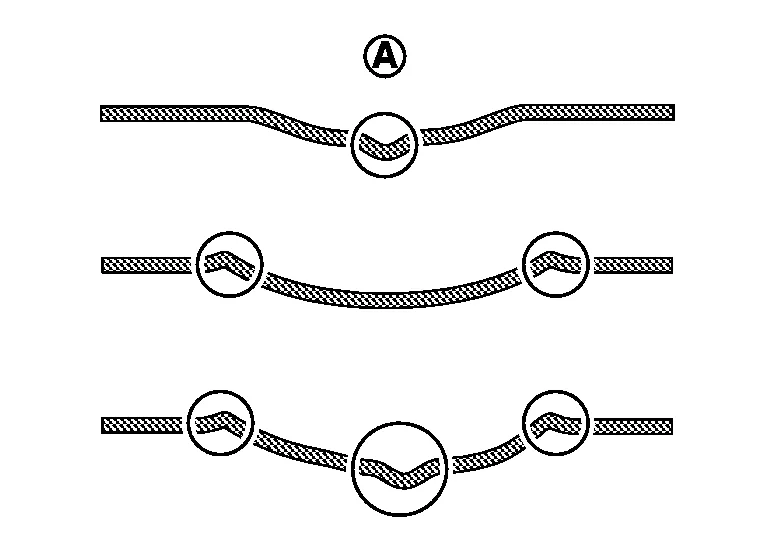

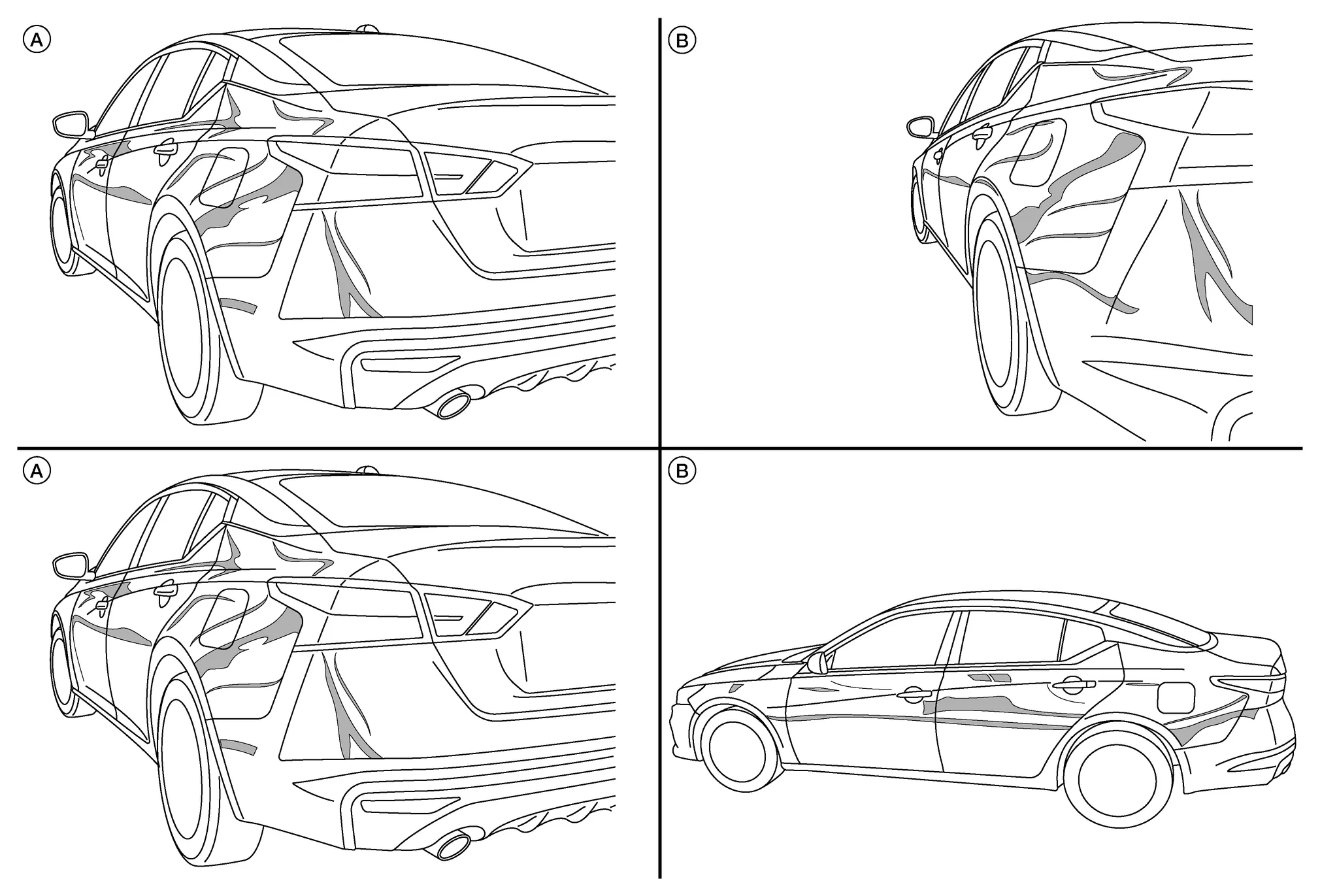

(A) In the figure is the plastic deformed area and the surrounding portions are elastic deformed areas.

Correction of (A) will automatically remove the elastic deformation.

Removing the cause of the dent can simplify the entire repair operation. Plastic deformation can be recognized by sharp bending, a nick, or cracked or peeled paint.

SHEET METAL DEFORMATION ANALYSIS

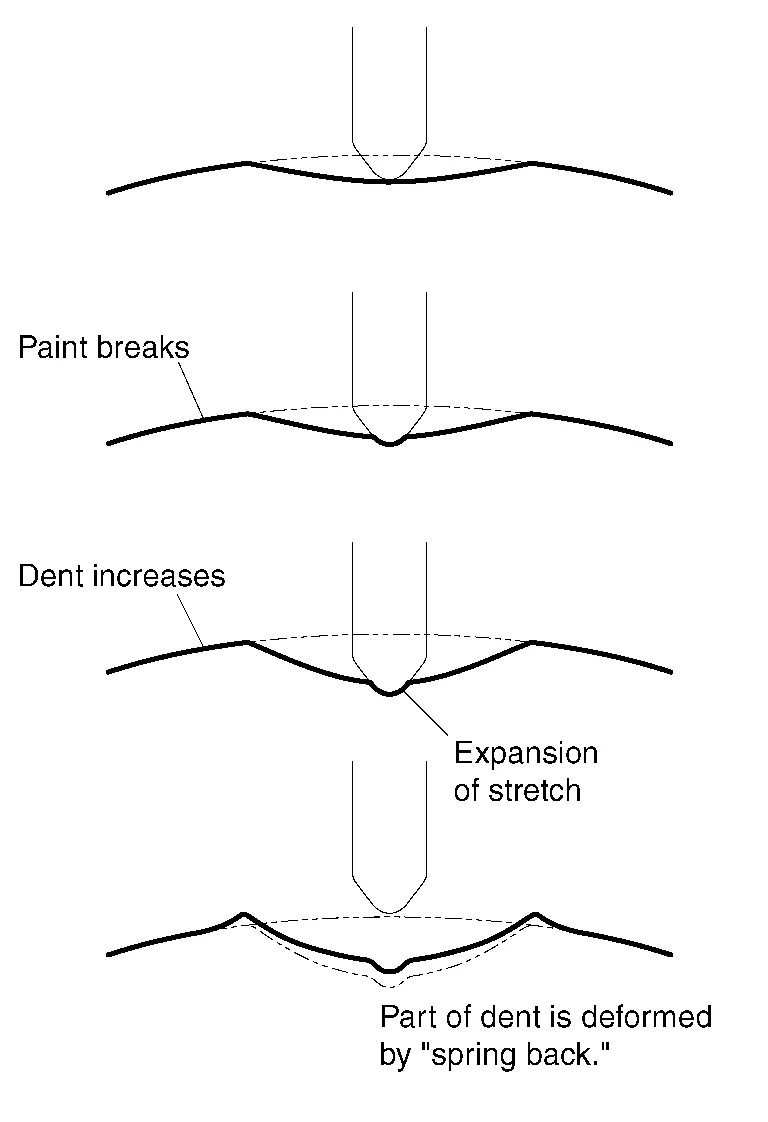

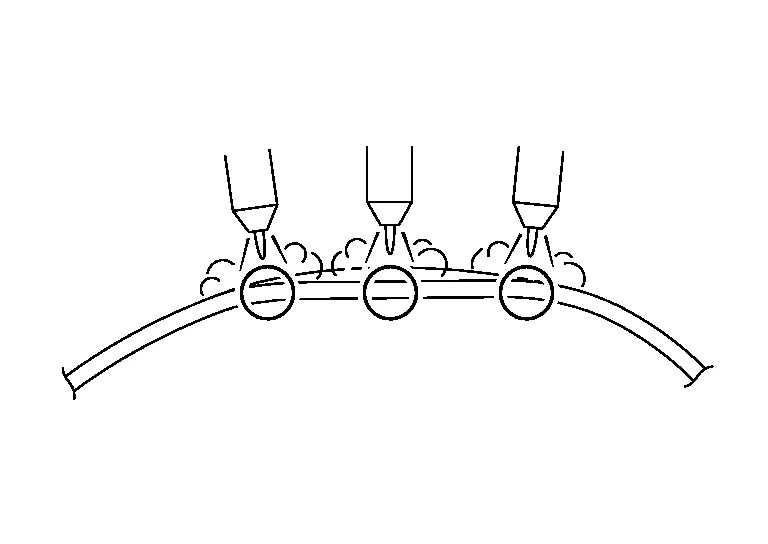

(a) When external force is applied, sheet metal deformation begins. Elastic deformation is generated around the point where the external force is applied.

(b) As the external force increases, areas surrounding the dent yield to the pressure, and local cracking or small breaks in the paint occur. This indicates plastic deformation.

(c) If the external force continues to increase, breaks around the dent enlarge, and the sheet metal at the center of the dent stretches.

(d) When the external force is removed, the “spring back” causes the plastic deformed portion of the dent to swell above the original surface.

The first thing we look at is the dent. This is also the case when you repair a dent. You always should look at the damage first. The important thing to look at is the center of the dent. The depth of the dent is the important part. It tells you the following:

-

Difficulty of the repair

-

Time of the repair

-

Type of repair method

There are many different aspects to dents but the depth is the most important part. On one side it is the depth and on the other side the sharpness, but in most cases a deep dent is also a sharp dent. Basically there are two types of dents.

Depending on the type of dent you want to repair, consider the following information:

| Sharp Dents | Soft Dents | |

|

|

|

|

| Repair Time: | 2x (twice as much time as soft dents) | x |

| Repair Method: | Levers | PDR, Glue System |

| Technical Experience: | Medium to high | Low to medium |

| Cause of Damage: | Park, medium to big hail | Soft park, small to medium hail |

-

Soft or Shallow Dent

Most of the shallow dents have a low depth. They are also called elastic dents.

-

Sharp Dent

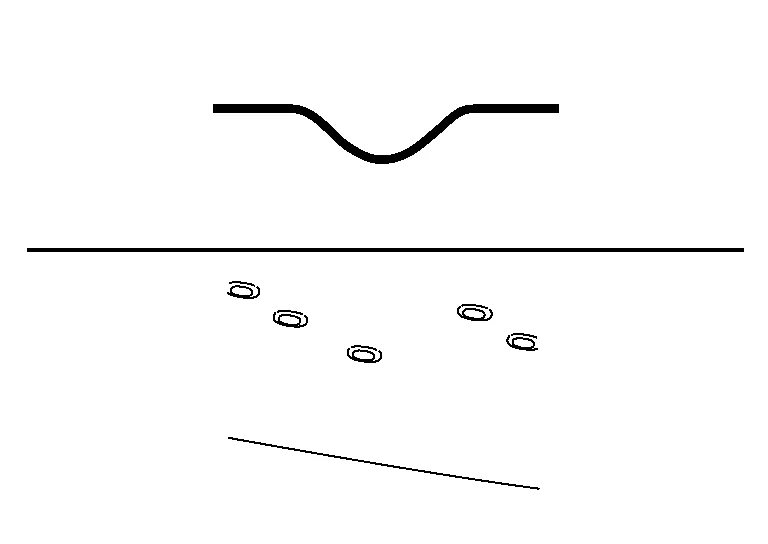

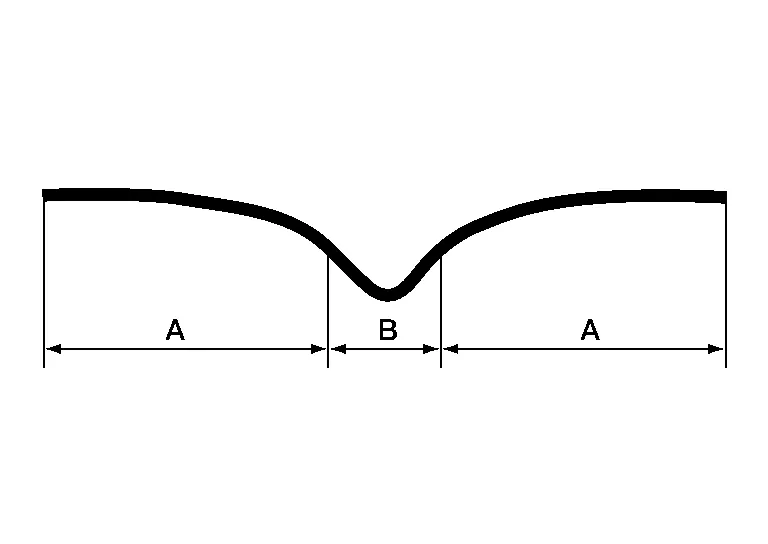

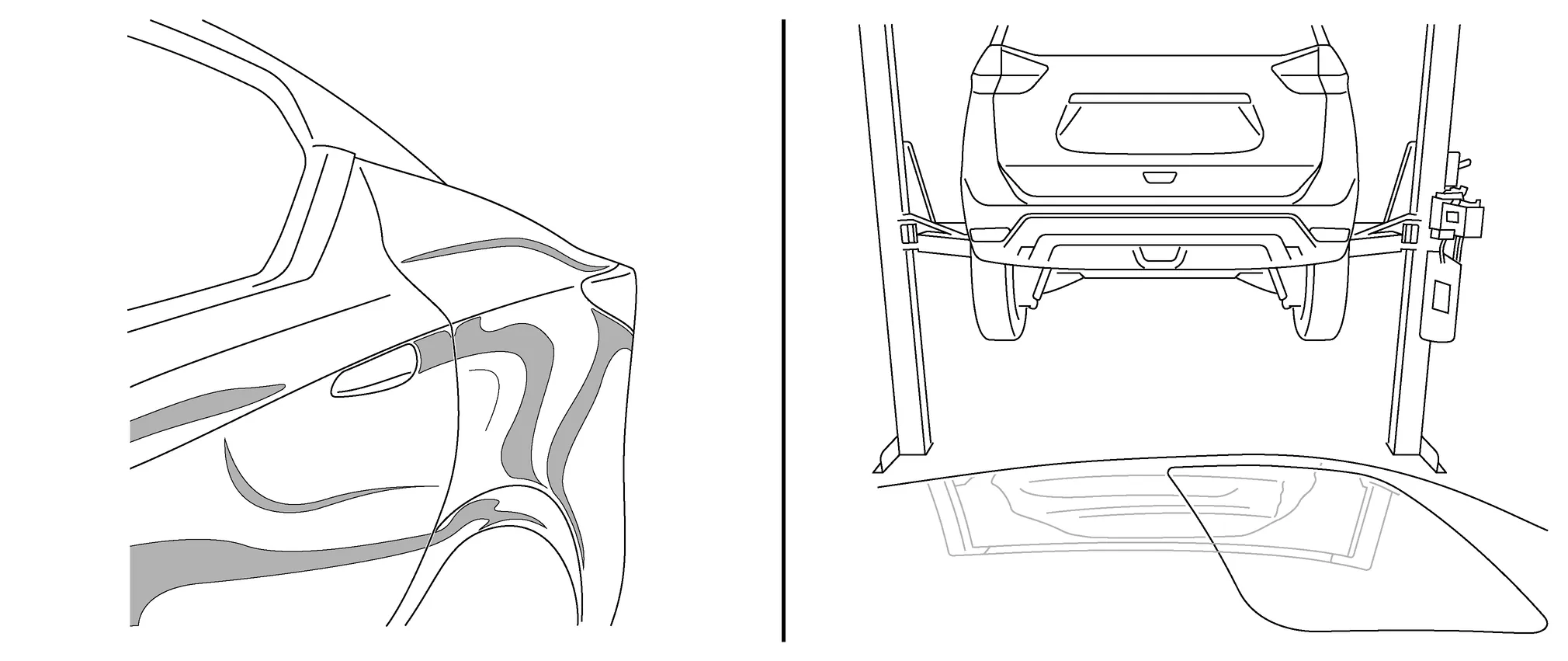

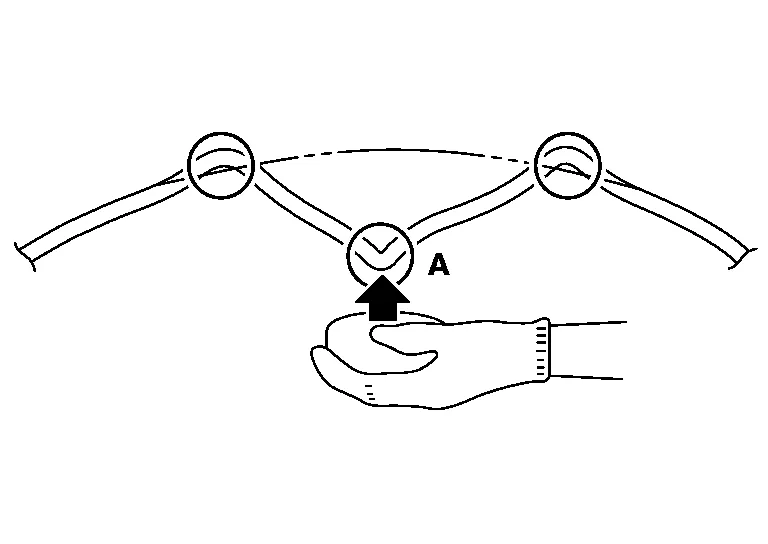

A sharp dent is made out of two parts: The Center (A), which is formed by the object which made the dent (stretched metal) and the second part of the dent (B), which is from the energy of the hit.

-

Energy of the hit

A: Primary Damage - Stretched center plastic deformation B: Secondary Damage - Energy of the hit elastic deformation

The outside part (A) of the dent is removed quickly. That is the easy part. To remove the center (B) is more difficult and needs more experience.

CAUTION:

This repair method should not be used on rails and reinforcements.

-

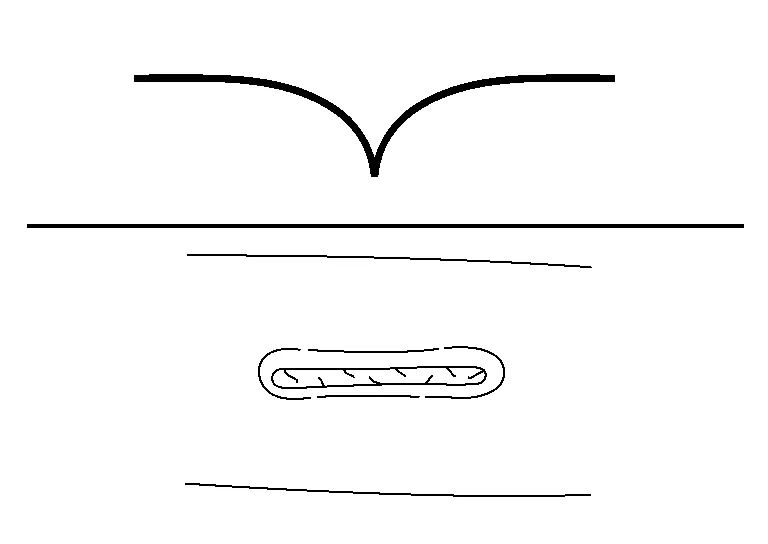

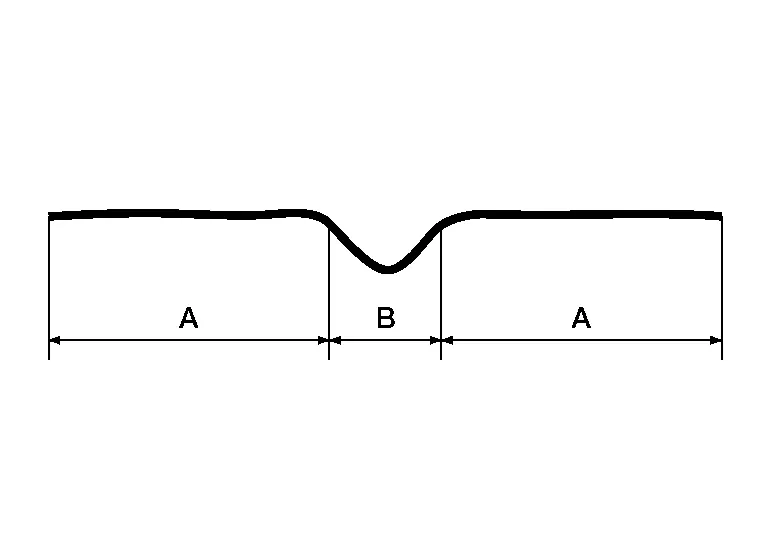

Plastic deformation forms at the center of portion (A) of the dent. The surrounding area remains in elastic deformation.

-

Plastic deformation occurs at one or several portions around the dent. Other areas remain in elastic deformation.

-

Both plastic and elastic deformation are generated throughout the damaged panel.

CAUTION:

This repair method should not be used on rails and reinforcements.

It is difficult to find minor deformation or panel irregularity, particularly, at the final stage of repair. This section explains how to determine if a Nissan Murano vehicle has minor panel deformation.

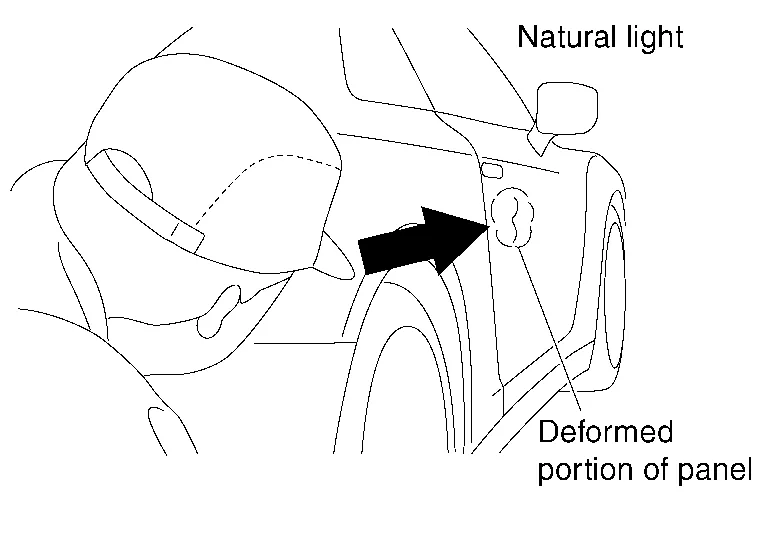

(1) VISUAL CHECK

Check the affected portion of the panel by carefully examining the deformation in the light reflected on the surface.

(2) What is Light? (General Contrast)

One of the major weak points is not being able to see the extent of the damage and correctly analyzing the damage and repair process.

For this it is necessary to look at the panel correctly.

The basic of a light is the contrast and a line. The bigger the contrast the better you can see the damage. At first use a light contrast in the distance to see the damage. Use the contrast as a scanner which you can move over the surface.

Once you have found a good contrast line (A) it can be used to see the damage precisely (B). The most ideal would be to use a PDR type light as with it you will be able to see the full extent of the damage.

At first use a light contrast in the distance to see the damage.

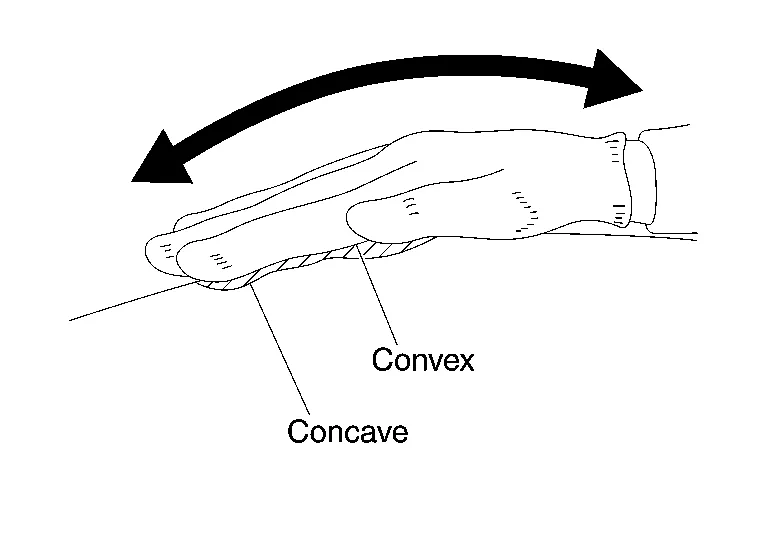

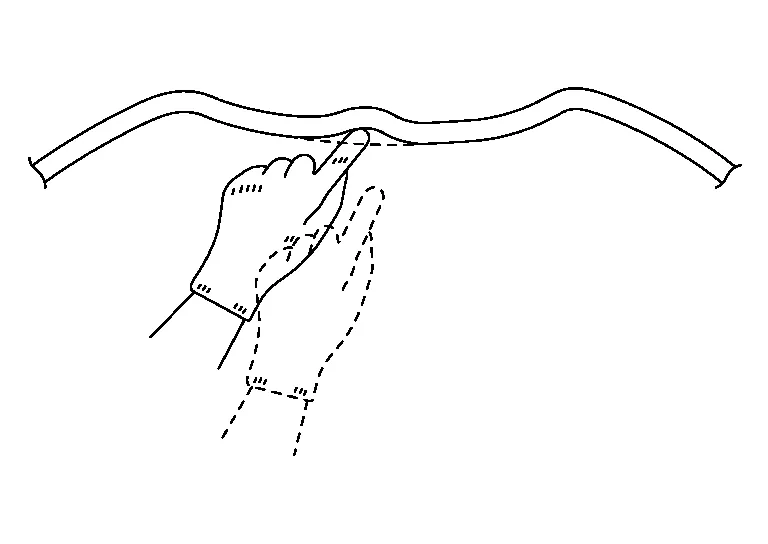

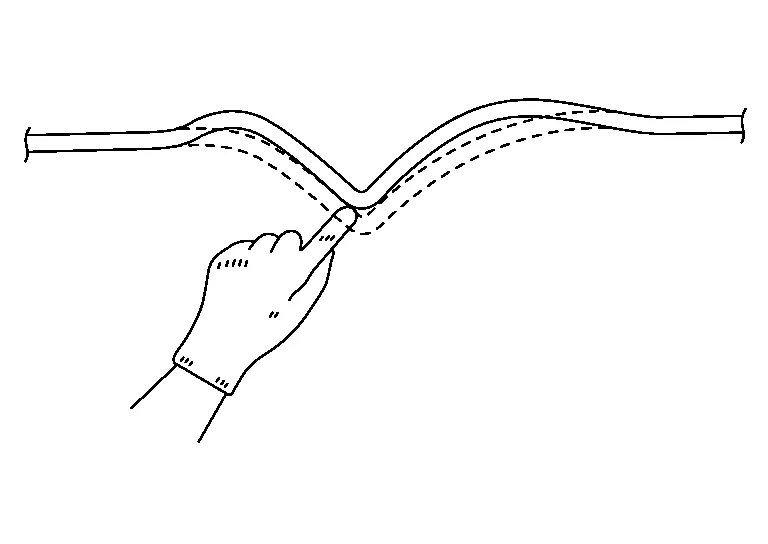

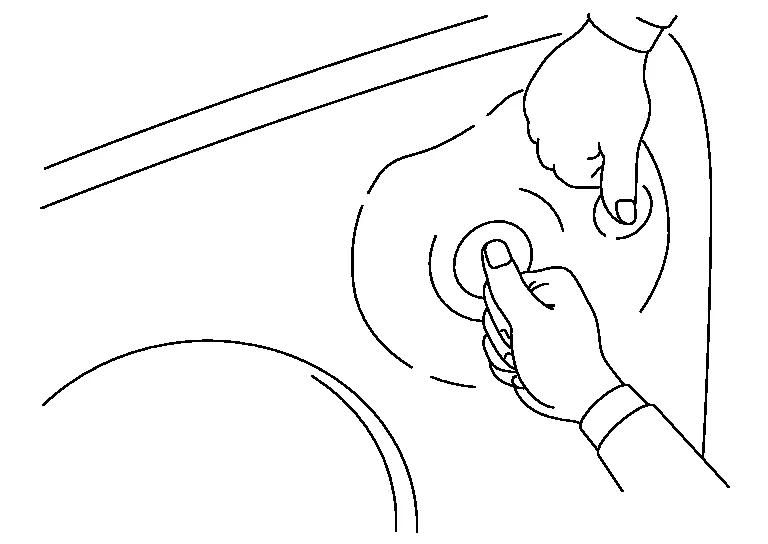

(3) TOUCH CHECK

Lightly place a hand on the surface of the panel and move it forward/backward and right/left to judge by touch with the palm of a hand. Slide and move a hand from an undamaged surface to a damaged part, all the way to the undamaged surface on the other side.

NOTE:

NOTE:

Wearing work gloves makes it easier to tell the difference.

(3) CHECK WITH PAINTLESS DENT REPAIR (PDR) LIGHT

Refer to Light Stand.

-

Elastic deformation: If pressed, the deformed portion will move or further deform.

-

Plastic deformation: If pressed, the deformed portion will remain unchanged, and other portions will move.

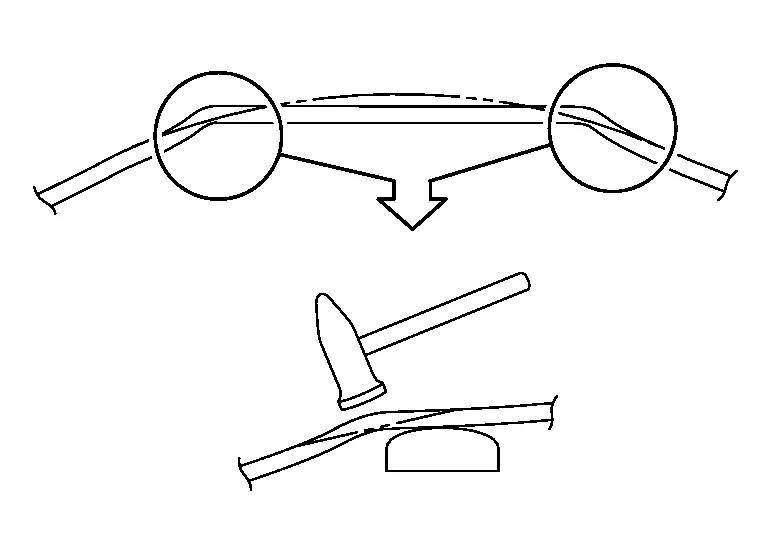

(1) WHEN PLASTIC DEFORMATION OCCURS AT THE CENTER OF THE DAMAGED PORTION

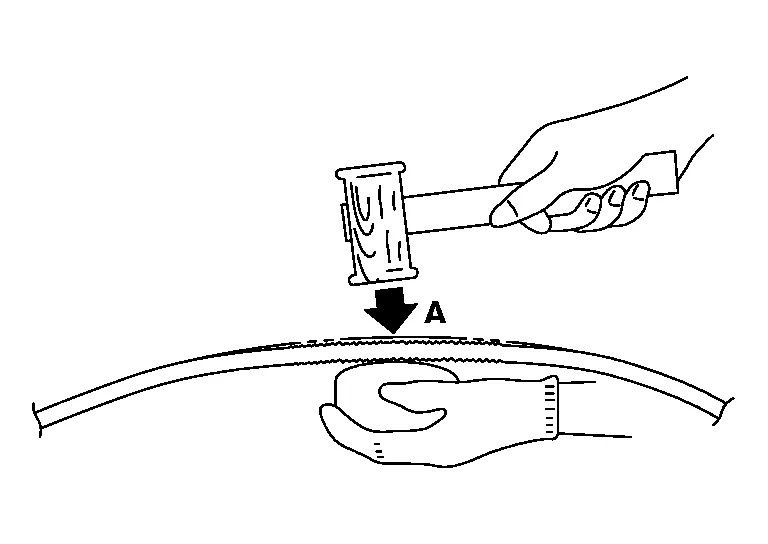

(a) Using a hammer or dolly, strike the lowest portion of the dent from behind until it becomes flat.

(b) Using the hammer-off-dolly method as shown in the figure, raise the concave portion and lower the convex portion.

Then smooth the surface a little lower than the original. Using a wooden hammer and dolly, correct the irregularities in the panel.

(c) Existence of plastic deformation can be determined by the stretched panel. The original surface can be restored by shrinking that portion with a gas welding torch.

(d) Use a hammer and dolly by the hammer-on-dolly method. Stretch the panel while striking the outer area of the damaged portion. The entire panel surface should be formed somewhat higher than the original surface. Note that, in this case, the stretched portion of the panel must not be hit with the hammer.

If the concave portion is shallow and if the working face of the wooden hammer matches it, the repair work can be completed quickly by directly shrinking the portion with a gas welding torch.

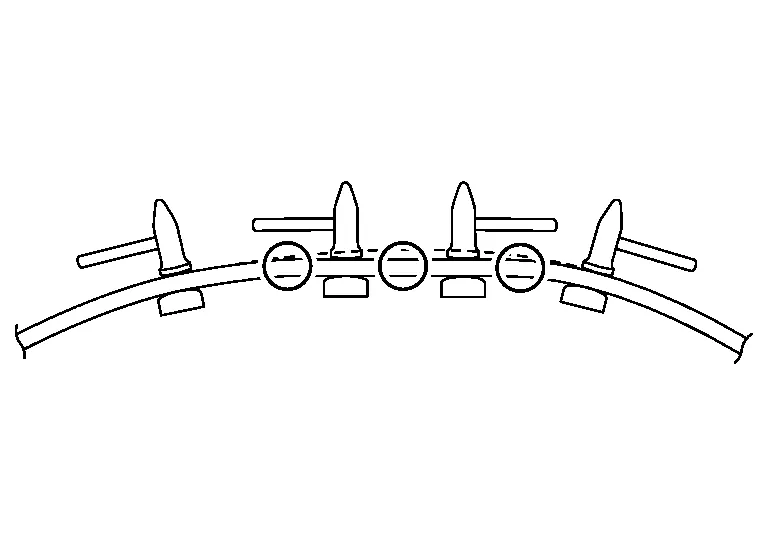

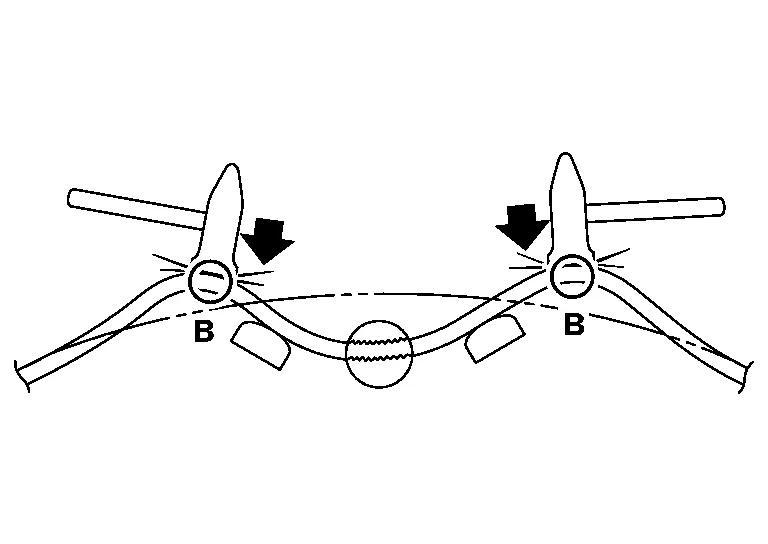

(2) WHEN PLASTIC DEFORMATION EXISTS AROUND THE DAMAGED PORTION

(a) Apply the dolly to the elastic deformation area behind the panel. Hit the plastic deformation area with a hammer so that the elastic deformation area is lower than the original surface.

(b) Repair the plastic deformed portion using the hammer-off-dolly method. If a shrinking hammer is available, the stretched portion can be easily shrunk.

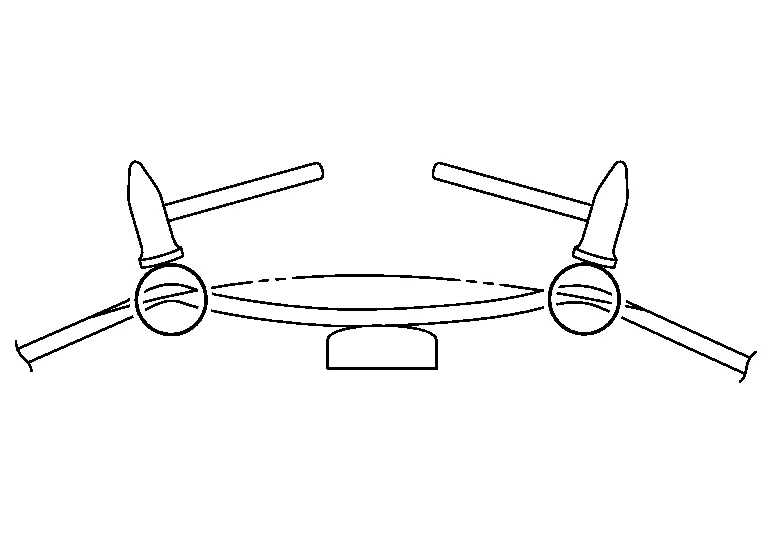

(3) WHEN PLASTIC DEFORMATION EXISTS AT THE CENTER AND AROUND THE DAMAGED PORTION

(a) Using a hammer and dolly, flatten the lowest portion (A) where the plastic deformation exists, so that the flattened surface is not higher than the original surface.

(b) Flatten the highest points (B) where plastic deformation exists.

(c) Flatten portion (A) so that the panel surface is not higher than the original surface.

Correct irregularities using a wooden hammer and dolly. If the panel has been stretched, repair by shrinking.

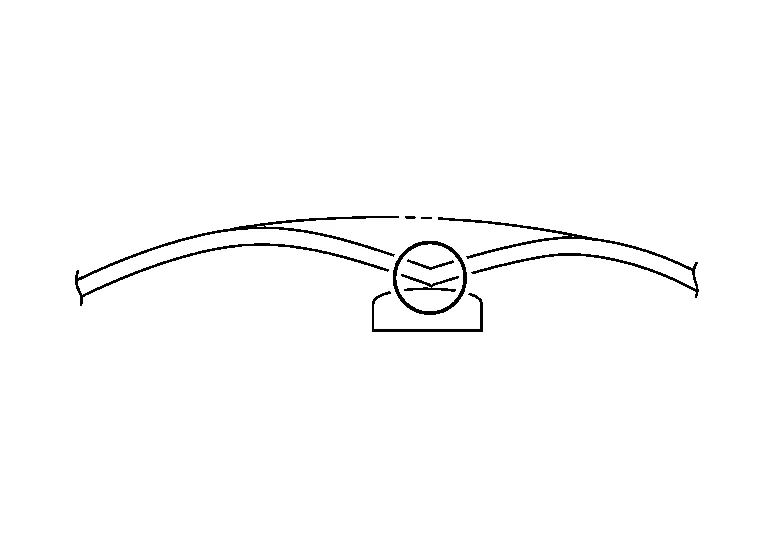

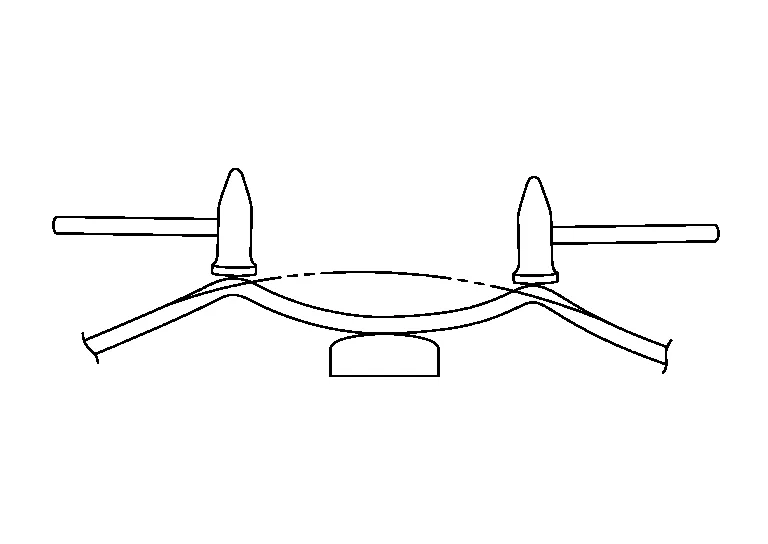

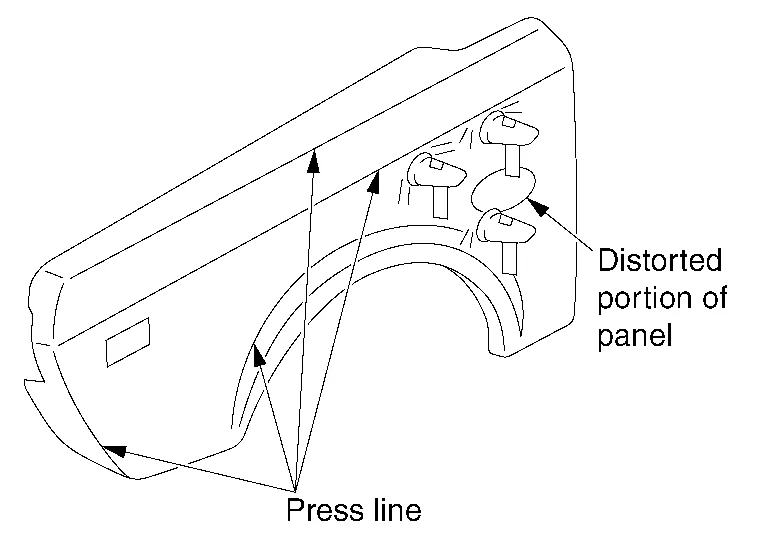

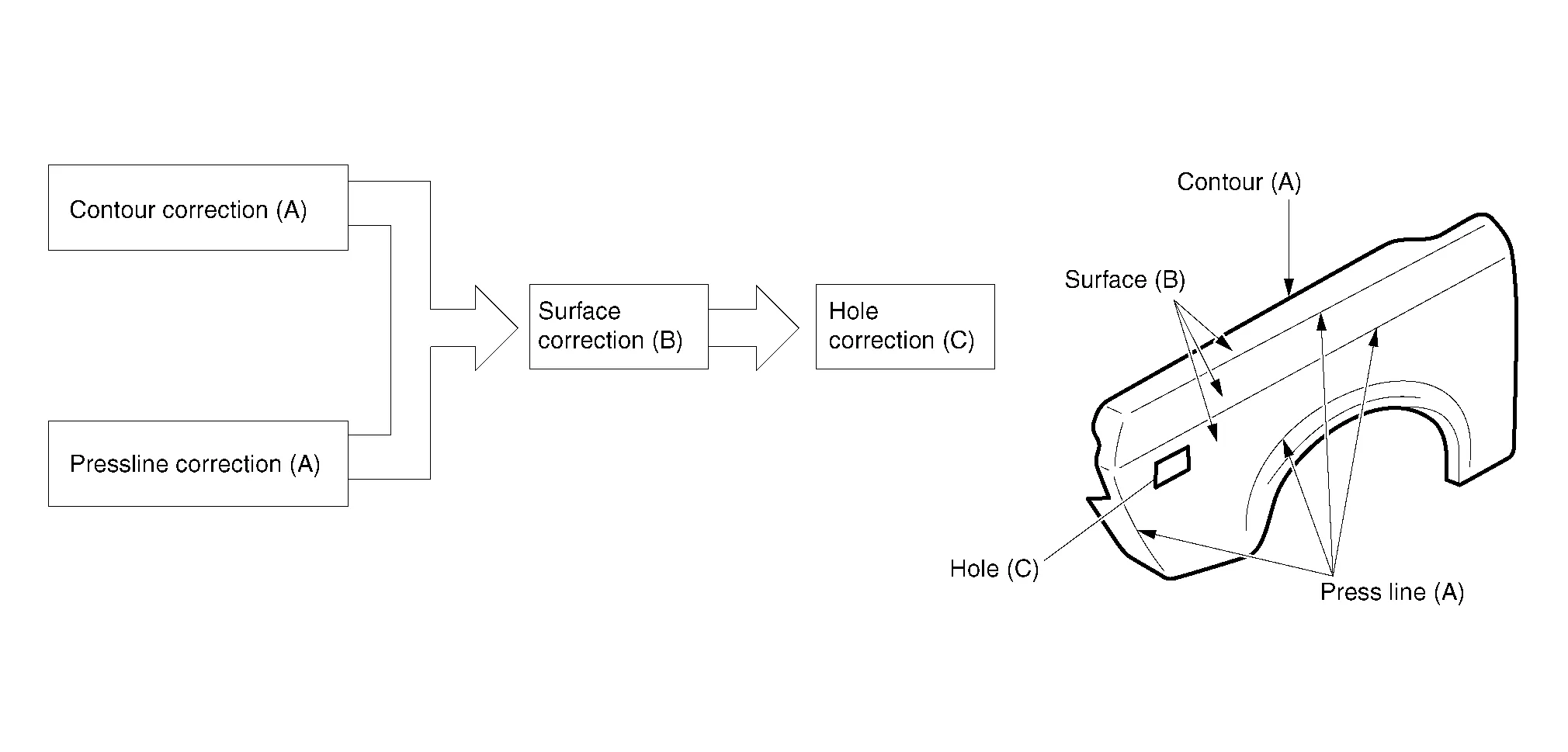

(4) CORRECTING PANEL DISTORTION

(a) Panel distortion occurs when panel damage is repaired. The panel is deformed within the range of elastic deformation. If pressed with a finger, the deformed area bends inward and outward. Panel irregularities occurring over a wide range other than the repaired portion may also indicate panel distortion.

(b) Cause of panel distortion

Expansion stress due to damage repair is confined inside the panel because the outer area is bent and work hardened. Thus, it does not allow the panel to expand. The stress is released in the form of panel distortion.

(c) How to correct panel distortion

Panel distortion can be removed by shrinking the stretched portion or by stretching the side of the press line using the hammer-on-dolly method.

The front fender repair procedure is explained below:

When repairing the body panel, paint and anti-corrosive wax must be thoroughly removed from the damaged area by sanding.

Shrinking the Sheet Metal

Shrinking the Sheet Metal

Shrinking The Sheet Metal

Plastic deformation may cause reduced panel thickness and the panel may stretch. Even when it is repaired using a hammer and dolly, the panel tends to bulge, losing its original shape...

Paintless Dent Repair

Paintless Dent Repair

Paintless Dent Repair

Paintless dent repair is one type of panel repair technique. This technique is used to repair irregularities on painted outer panels without damaging the painted surface...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Fuel Filler Lid Lock

Removal and Installation REMOVALRemove luggage side lower finisher (LH). Refer to Removal and Installation. Disconnect the fuel filler lid release cable from the fuel filler lid lock. Rotate fuel filler lid lock to release pawls and remove.INSTALLATIONInstallation is in the reverse order of removal...

Nissan Murano (Z52) 2015-2024 Service Manual: Diagnosis System (ipdm E/r)

Diagnosis Description AUTO ACTIVE TESTDescriptionIn auto active test mode, the IPDM E/R sends a drive signal to the following systems to check their operation: Front wiper (LO, HI) Front fog lamps Parking lamps Side marker lamps Tail lamps License plate lamps Headlamps (LO, HI) A/C compressor Cooling fans (LO, HI) Operation ProcedureCAUTION: Do not start the engine...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- All-Wheel Drive (AWD) (if so equipped)

- Checking engine oil level

- Tire rotation

- New on site

- Most important about car

Unfastening the seat belts. Checking seat belt operation

Unfastening the seat belts

To unfasten the seat belt, press the button

on the buckle  . The seat belt

automatically

retracts.

. The seat belt

automatically

retracts.