Nissan Murano: Sheet Metal Work / Sheet Metal Work Tools

This section explains various tools used in body repair work.

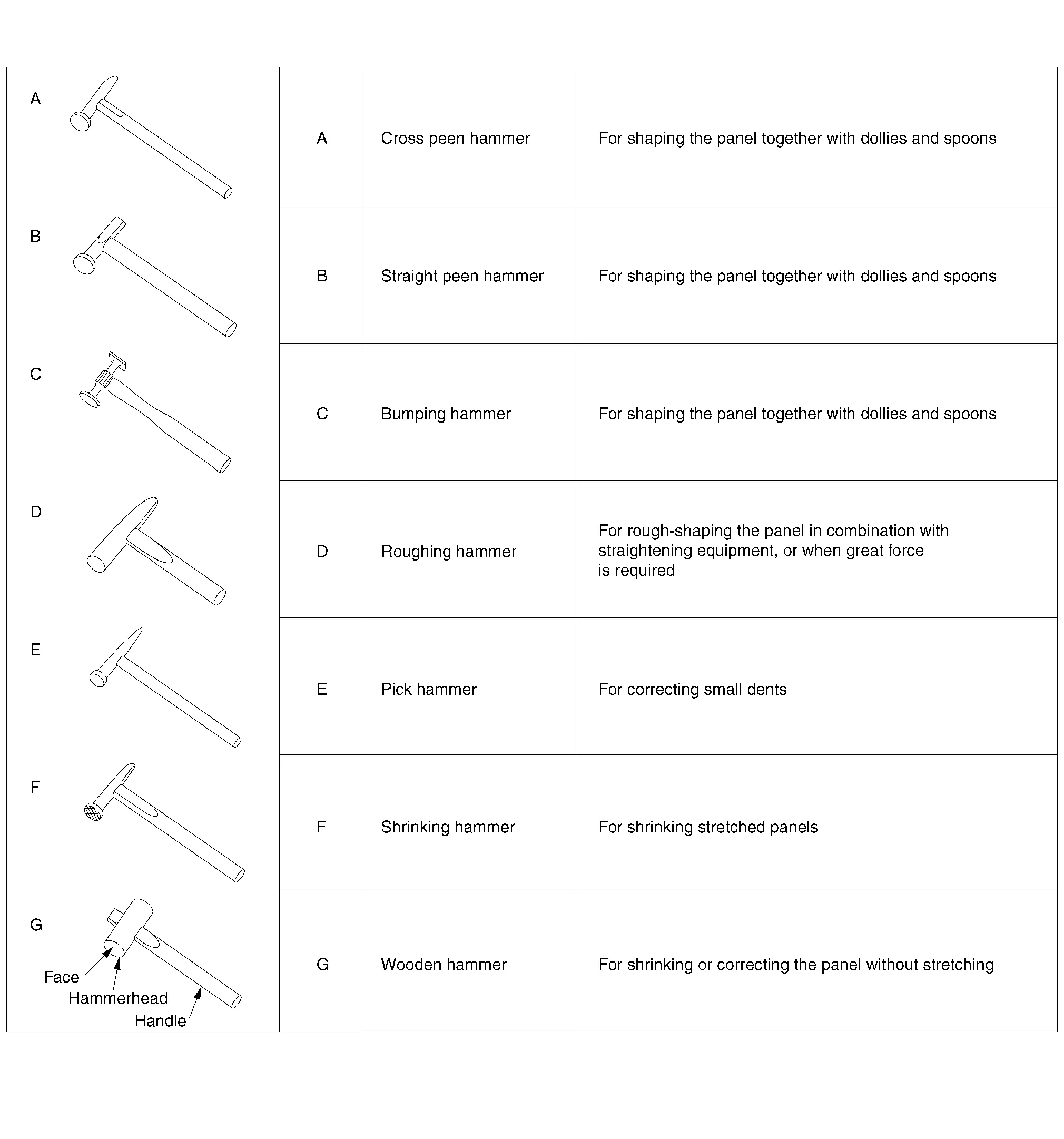

A hammer is used to correct dents, projections or other deformations. Various shapes have been designed according to their purposes.

(1) TYPES AND FEATURES OF HAMMERS

(2) SELECTION AND MAINTENANCE OF HAMMERS

It is necessary to choose lighter or heavier hammers according to application or purpose.

Hammer weight should be selected according to the user's physical strength.

Hammer maintenance is important. In particular, the hammer face must always be kept clean. A distorted or damaged hammer face will lead to distorted panels.

Accordingly, hammers for sheet metal work must not be used to hit other objects such as a chisel. Do not mix sheet metal hammers with ordinary hammers.

Repairing the face of a sheet metal hammer is explained below.

NOTE:

NOTE:

To avoid damage to the vehicle, always use separate hammers on aluminum and steel.

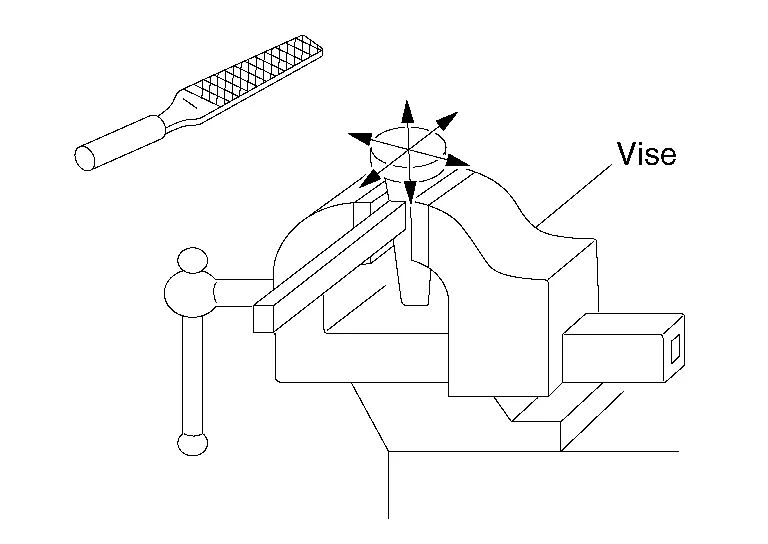

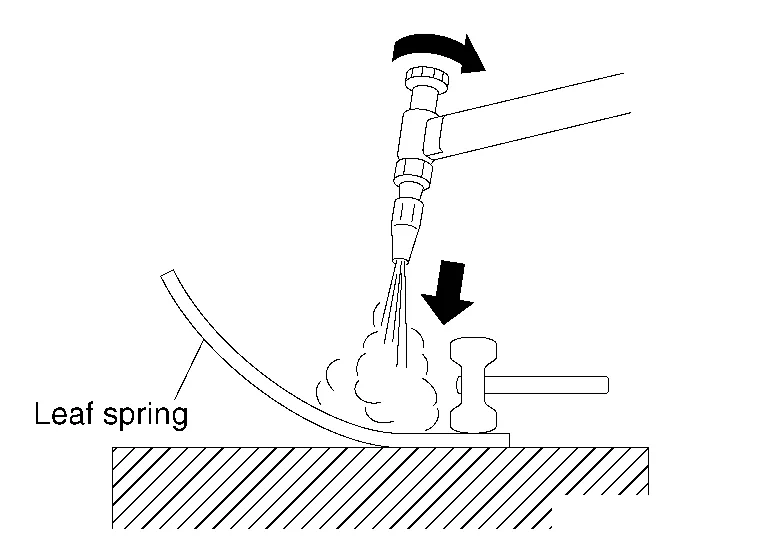

(a) Clamp the hammer in a vise with the hammer face up.

If the hammer face is deformed, use a hand file to smooth it.

(b) File the face in all directions. Do not file in only one direction.

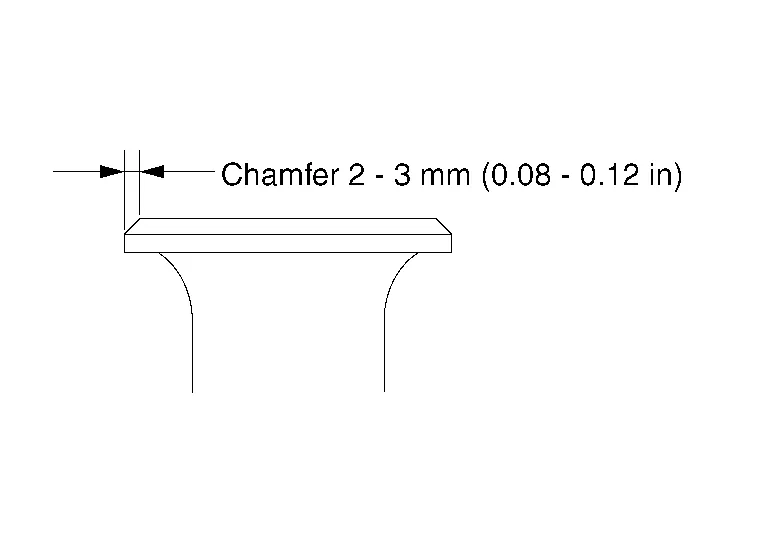

(c) Chamfer the edge of the face to prevent it from nicking or distoring the sheet metal.

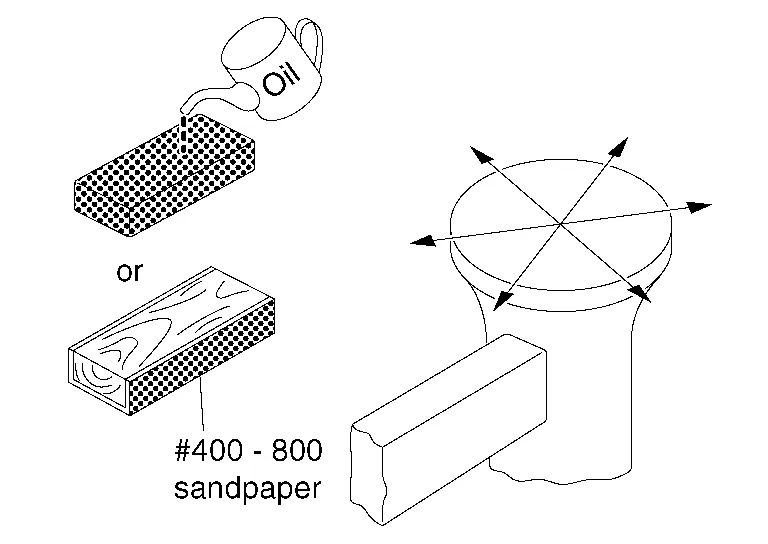

(d) After smoothing the hammer face, polish it with an oil stone or #400 - #800 abrasive paper wrapped around a wooden block. Polish the face in all directions.

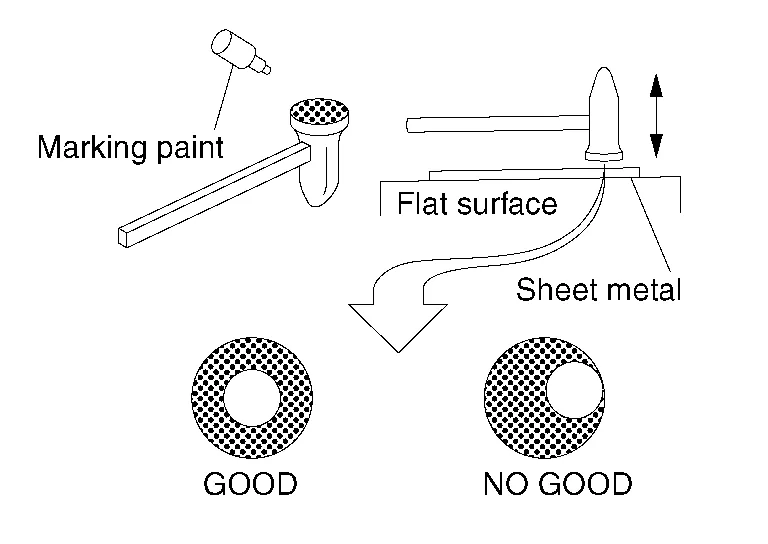

(e) To check the finish, apply marking paint to the hammer face . Hit a piece of flat sheet metal on a flat surface.

| GOOD | : The paint comes off the center of the face. |

| NO GOOD | : The paint comes off at a section other than the center or the face. Grind the surface again. |

(3) HOLDING AND HITTING WITH THE HAMMER

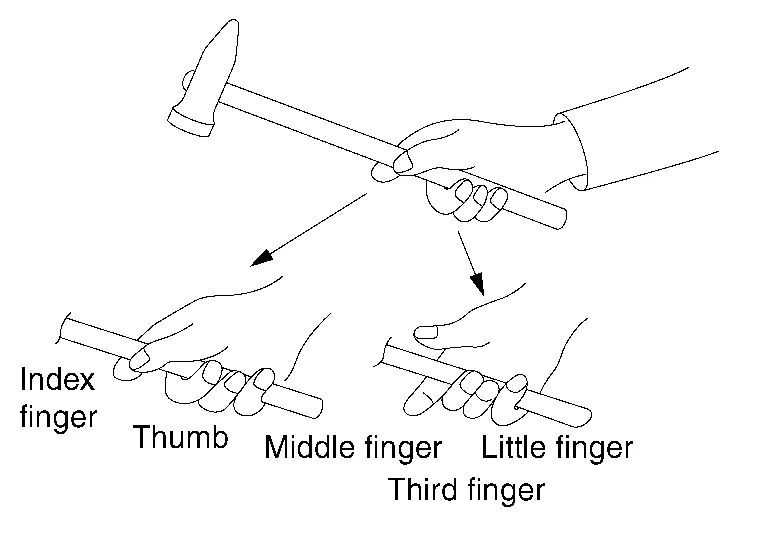

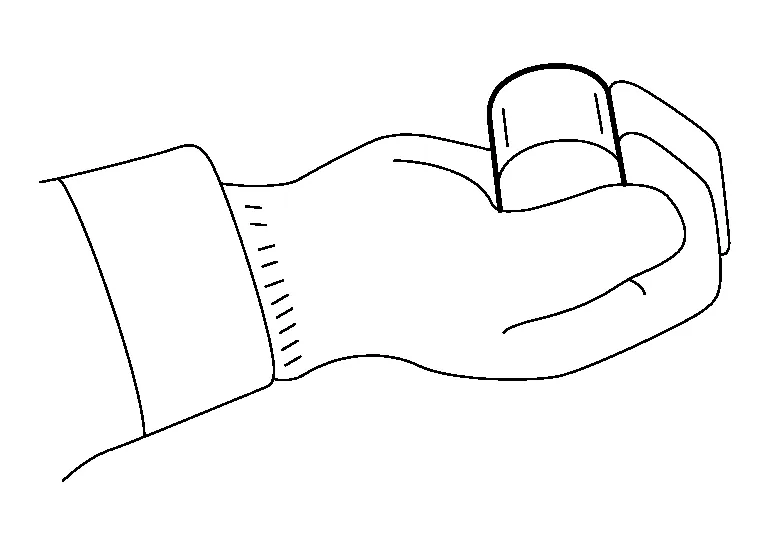

(a) Holding the hammer

-

Hold the hammer handle tightly with the middle, third and little fingers so that it will not slip when it is swung.

-

Hold the sides of the hammer handle lightly with the thumb and index finger to prevent sideways movement.

(b) Hammering

-

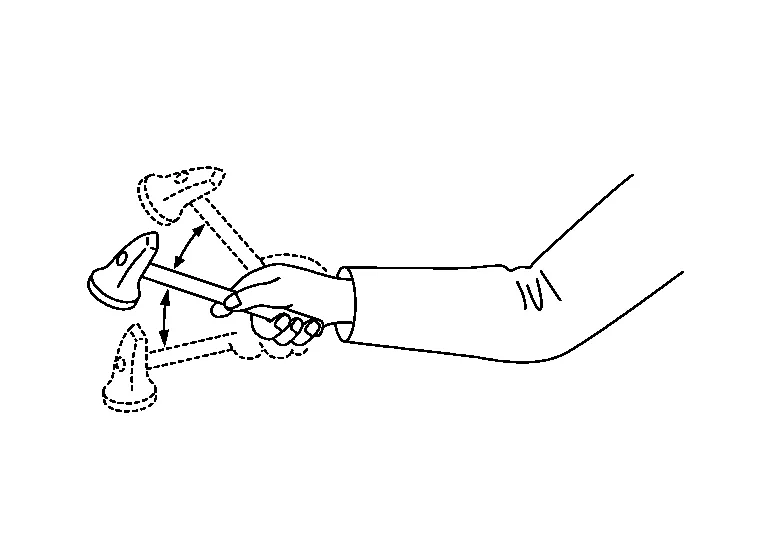

For rough straightening work, strike strongly.

For ordinary correcting work, swing the hammer using the wrist. In this case, the arm serves as a guide to determine the hammer direction.

-

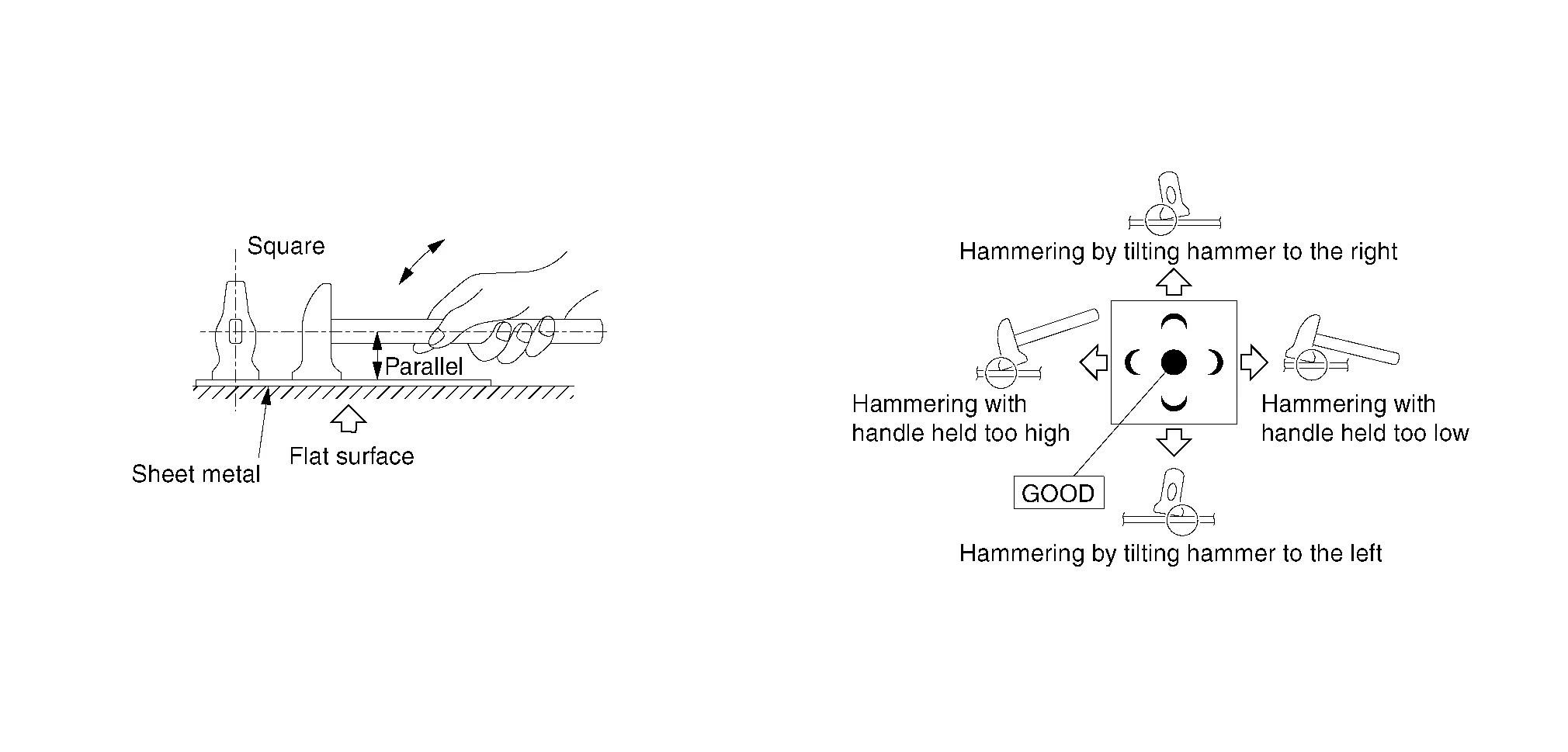

The hammer face should be flush with the panel surface when hitting. If the hammer edge strikes the surface, it will nick the panel.

-

Hammering should be approximately 100 hits a minute, and should be kept constant. An irregular hammering rhythm will lead to an uneven hammering force. Sheet metal will stretch when it is hammered. Irregular hammering also makes sheet metal correction more difficult.

Dollies are used in combination with a hammer. They are a 1 kg - 2 kg (2 lb - 4 lb) steel blocks, heavier than a hammer, with various curves and planes.

(1) USE OF DOLLIES

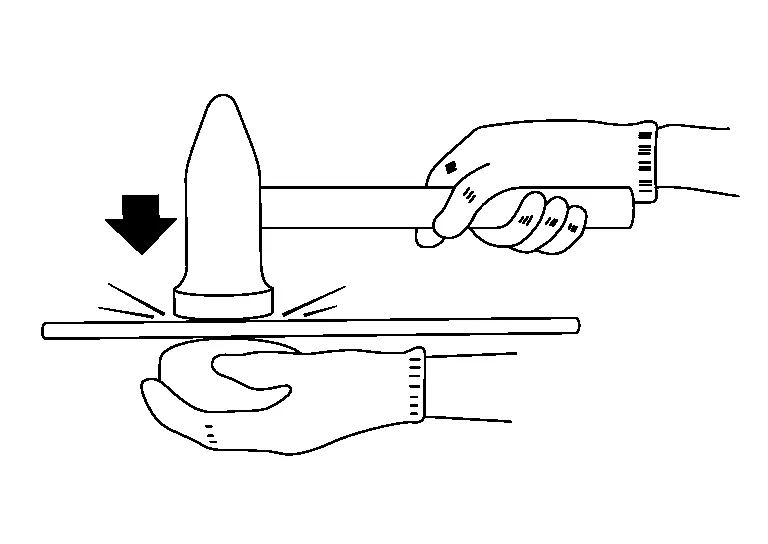

(a) Place the dolly on the underside of the deformed sheet metal.

Strike the deformed section of the sheet metal with the hammer to stretch it.

(b) Move the hammer and dolly as necessary, and direct the hammer blows so as to bend the sheet metal.

(c) If ordinary hammering is impossible due to limited space, substitute a dolly for the hammer, and strike the dented portion with the dolly.

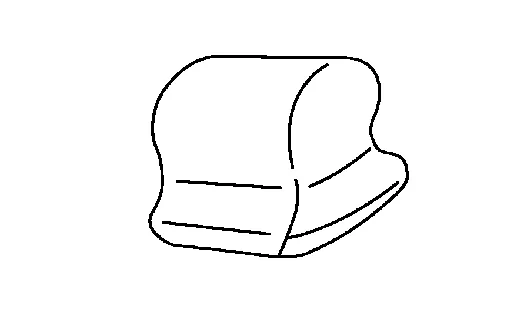

(2) TYPES AND FEATURES OF DOLLIES

|

|

General purpose dolly | This is also called a rail dolly. It has both wide and narrow curved faces. |

|

|

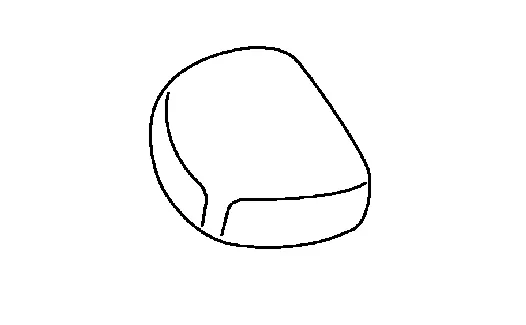

Utility dolly | This type of dolly features various curved surfaces and has wide applicability to automobile body repair work. It can be handled easily in narrow spaces. |

|

|

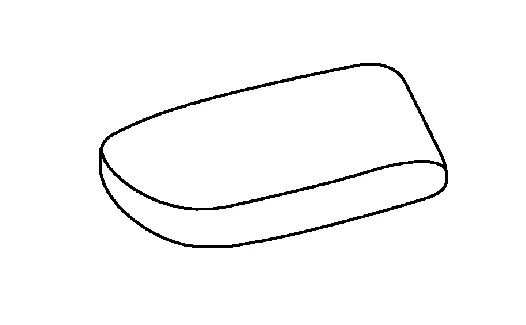

Heel dolly |

One side is flat and the other side is curved slightly. This is suitable for correcting flat and slightly curved surfaces. |

|

|

Toe dolly | This dolly is formed by two flat surfaces and a connecting curved surface. It can be used in narrow places. |

|

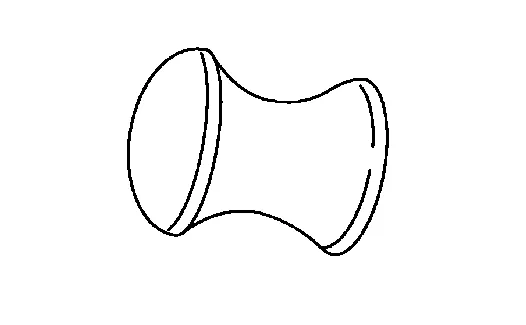

|

Round dolly | Both sides are curved. This dolly is used for repairing small dents. |

|

|

Wedge dolly | This dolly has a curved surface which changes gradually from sharp to gentle. Its sharp end can be inserted into narrow portions. |

|

|

Shrinking dolly | The surface is like a file. This dolly is used in combination with a shrinking hammer. |

(3) SELECTION AND MAINTENANCE OF DOLLIES

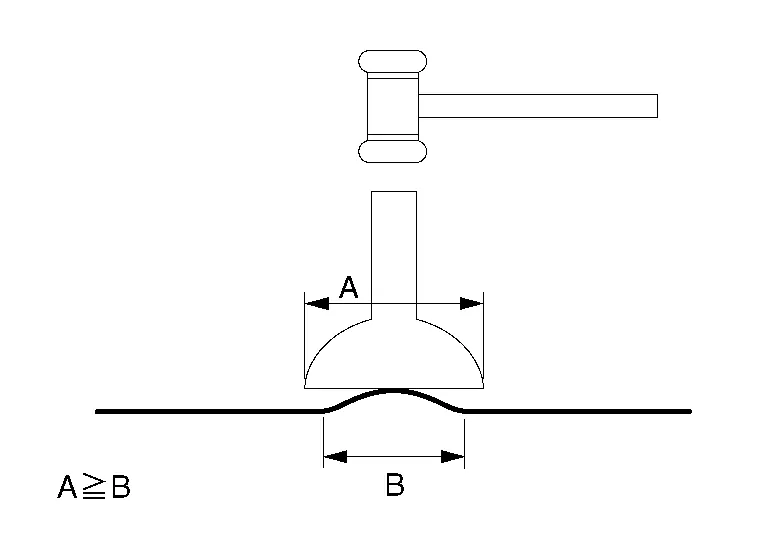

Ideally, a dolly whose curved surface just fits the curvature of the panel should be used. However, this is often difficult. In most cases, a dolly whose curvature is slightly smaller than that of the panel should be selected.

Generally speaking, four types of dollies (general purpose, utility, heel and toe dollies) are sufficient for ordinary panel work. However a special dolly can be designed for unique shaping.

The size and weight of the dolly must be easy to handle.

The maintenance procedures and cautions described for the hammer also apply to the dolly.

The entire surface of the dolly must be free from damage.

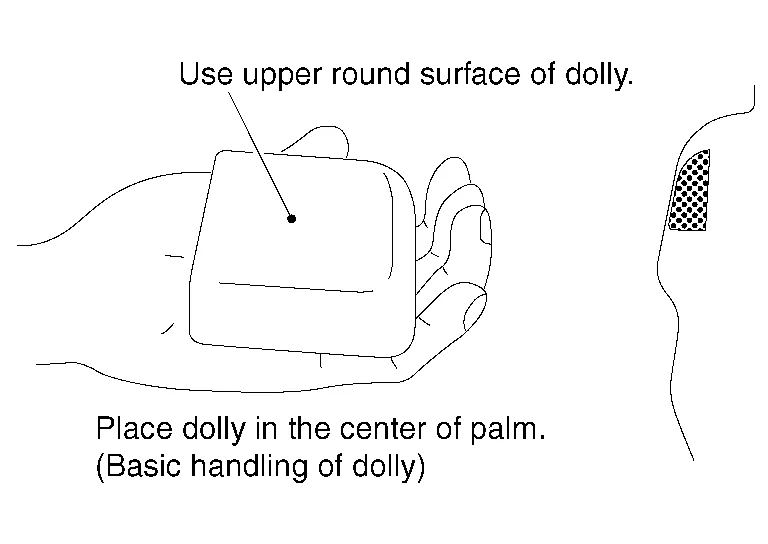

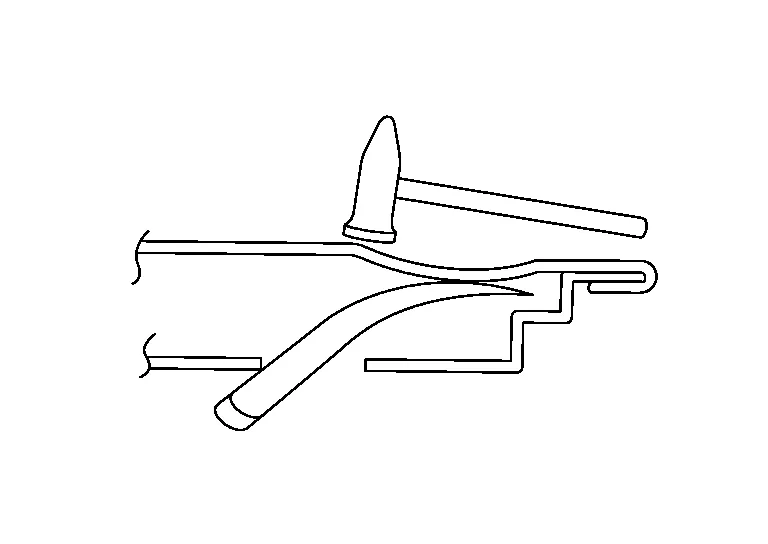

(4) HOW TO HOLD THE DOLLY

Basic handling of the dolly.

(a) TOP:

Place the dolly in the palm of your hand.

Holding it lightly, place the curved surface against the curved surface of the panel.

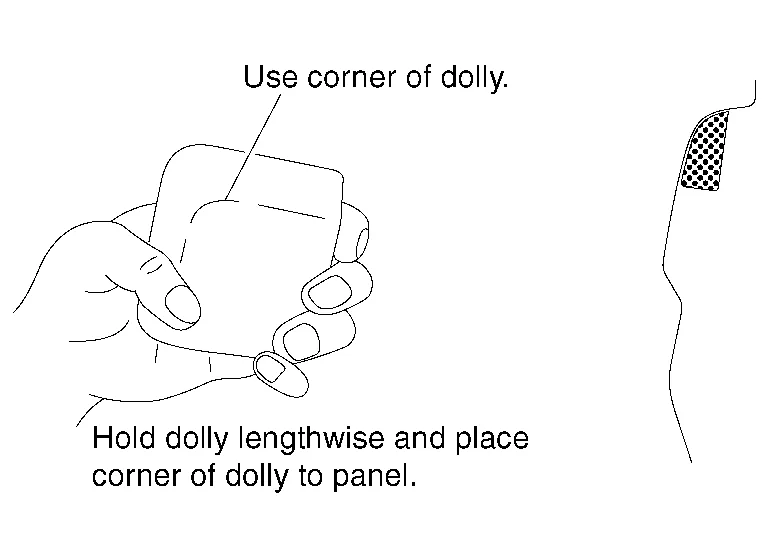

(b) CORNER:

Hold the dolly lengthwise, and place the corner in the sharply bent portion of the panel.

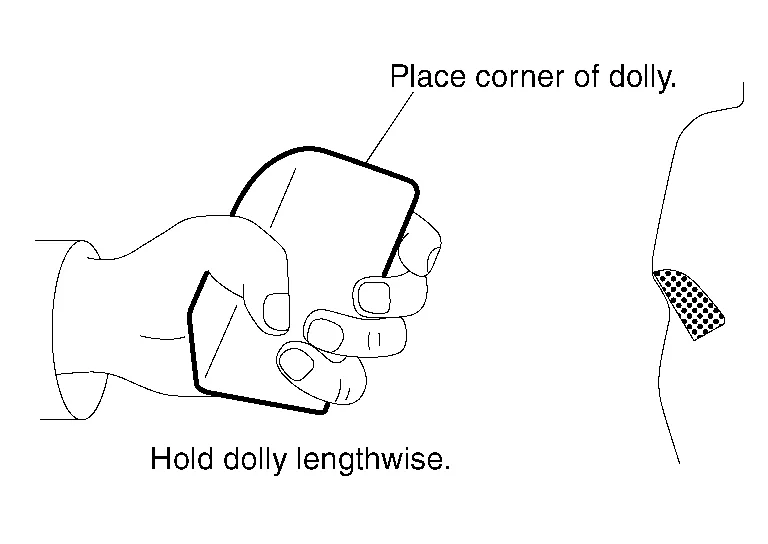

(c) EDGE:

Hold the dolly so that the edge faces upward.

Place this edge to the press line of the panel.

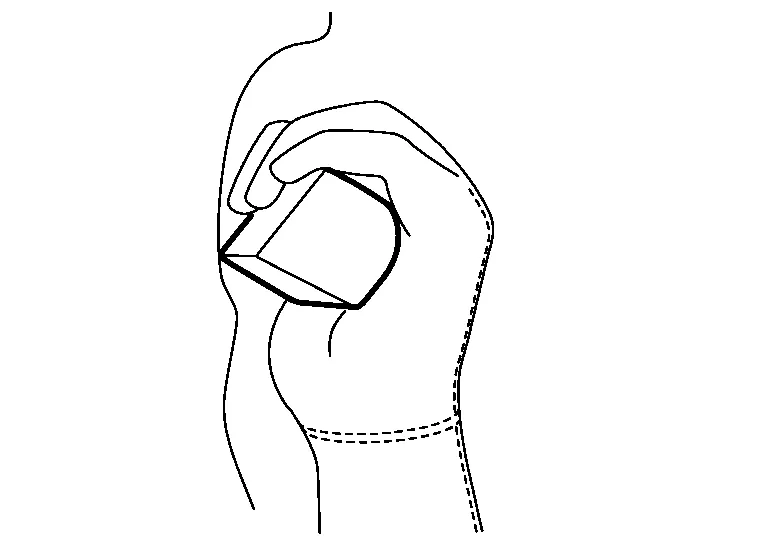

(d) CORRECTING THE PRESS LINE:

To correct a concave press line in a narrow space on the back of the panel, use a dolly as shown in the figure and strike the press line with it.

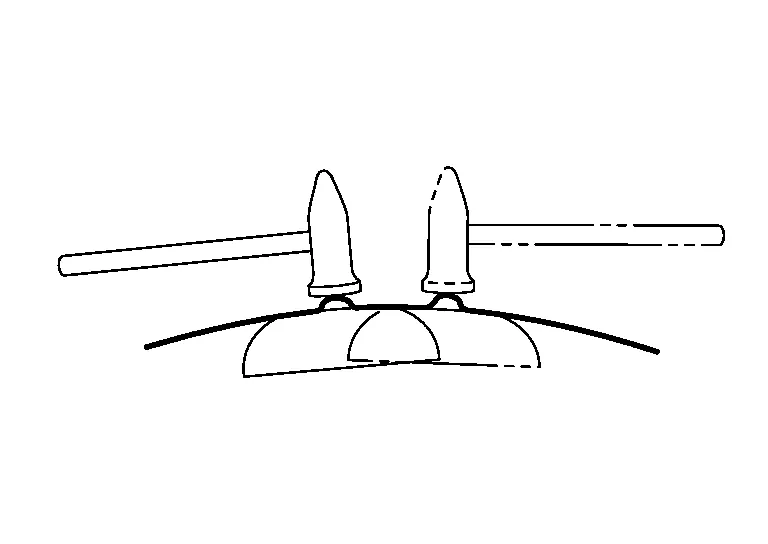

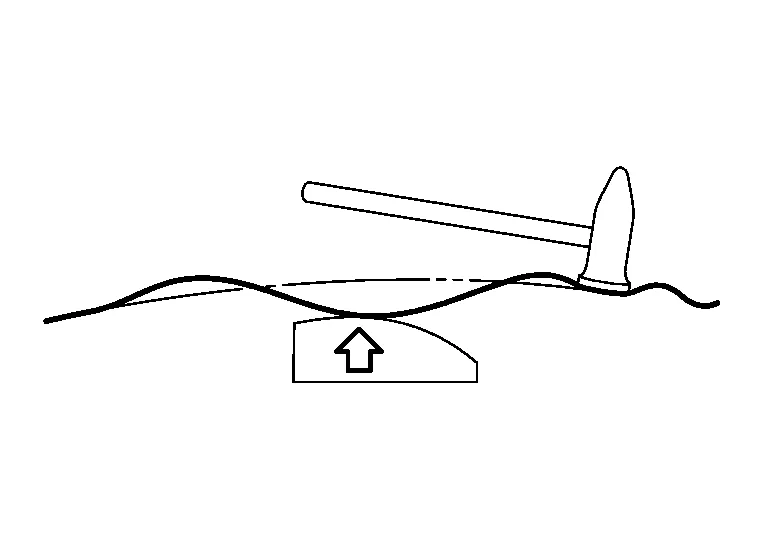

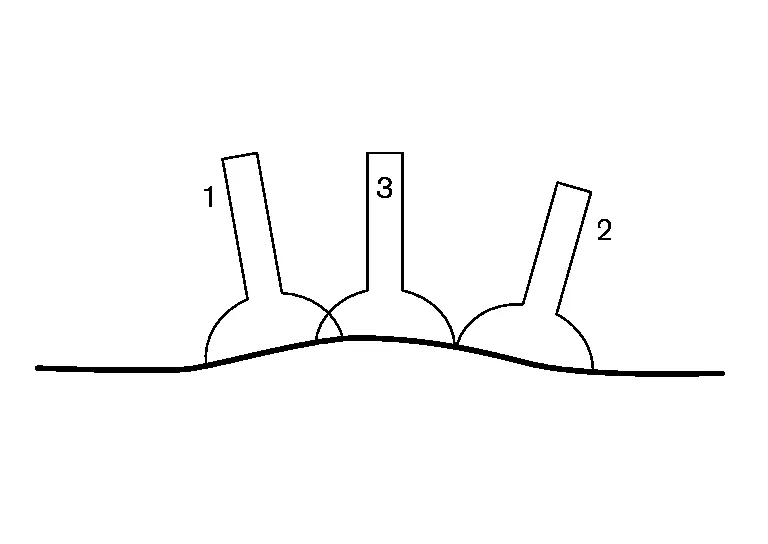

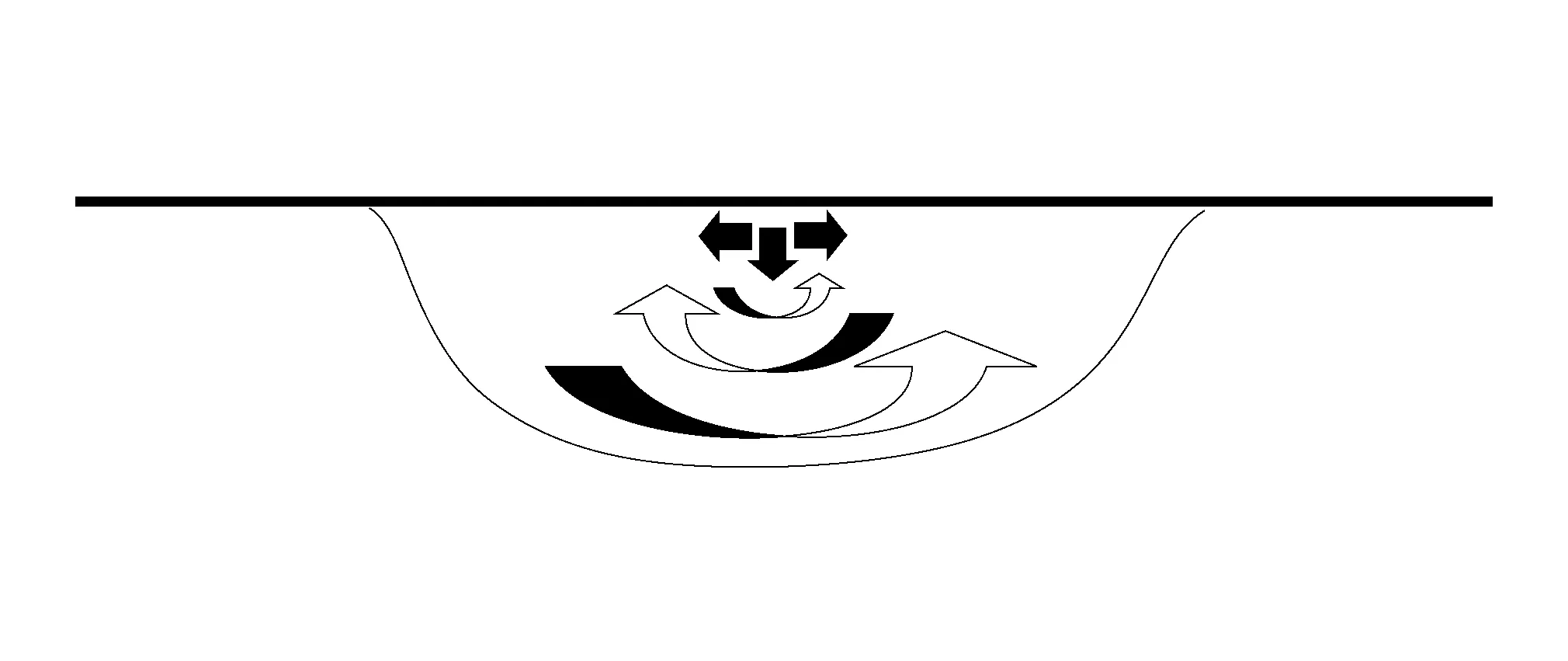

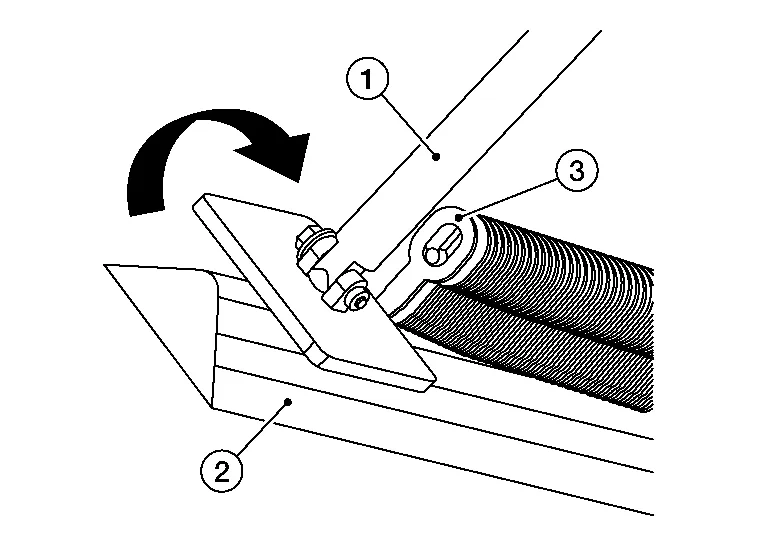

(1) HAMMER-ON-DOLLY

This is also known as dinging on the dolly. The dolly is held directly under the area being struck with the hammer. Hammering smoothes the dented metal between the dolly and hammer. This method causes the sheet metal to stretch.

Hammering on a dolly is most effective for repairing shallow dents.

(a) The hammer strikes the sheet metal, causing the dolly to bounce against the metal surface. Thus the damaged portion is worked out from both inside and outside.

(b) The sheet metal stretches between the hammer and dolly, and deformation is distributed around the strike area.

(c) Continuously move the dolly under the shifting deformation so that it can be struck properly.

(d) The sheet metal gradually stretches and returns to its original shape.

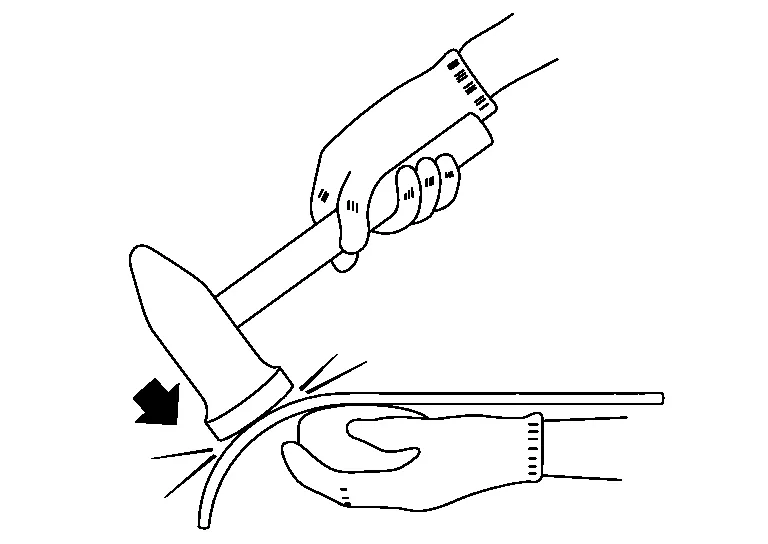

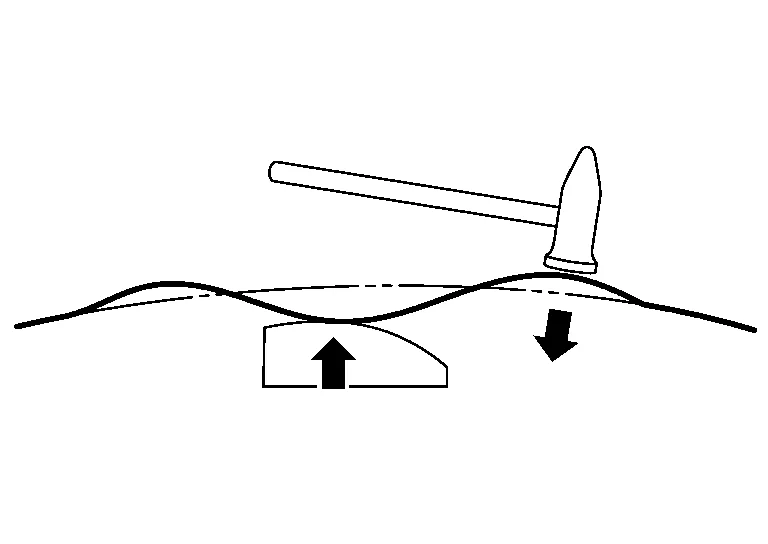

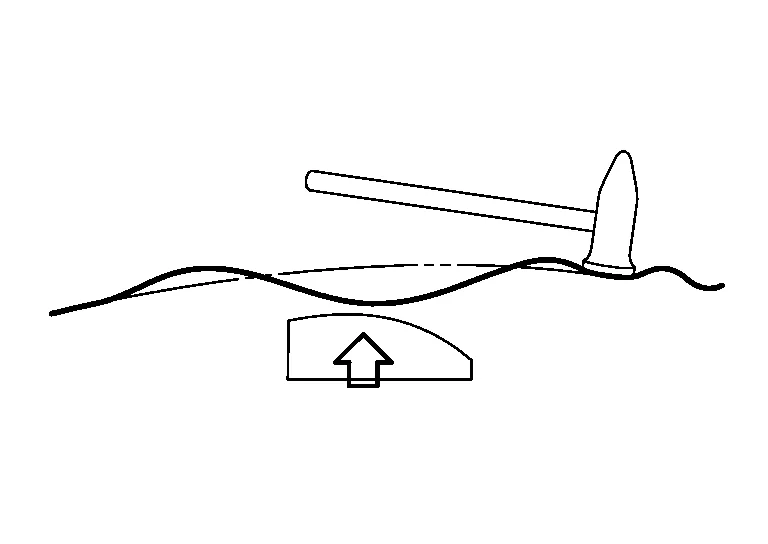

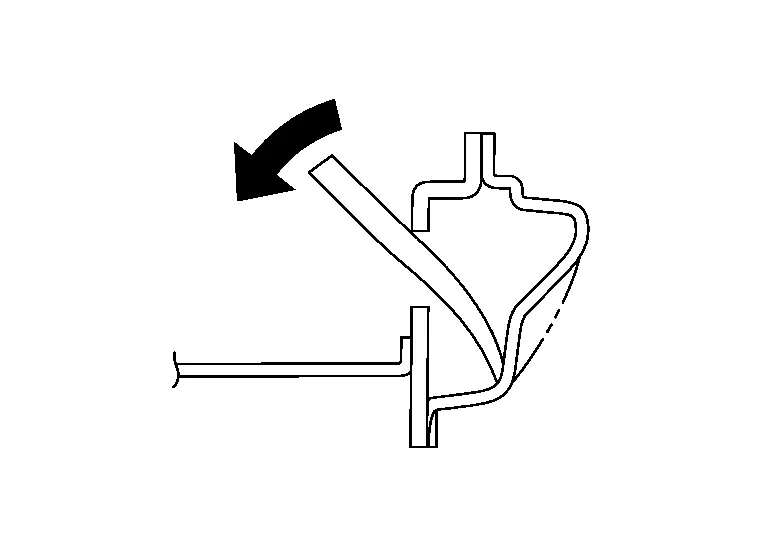

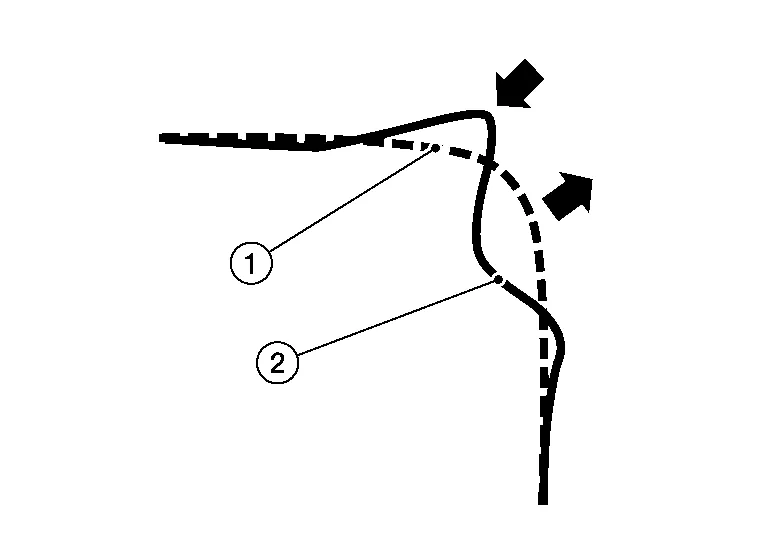

(2) HAMMER-OFF-DOLLY

This is also known as dinging off the dolly.

Place the dolly directly under a dent, and hammer against the edge of the dent. The hammer drives one area downward while the reaction of the dolly drives the adjacent area upward.

An example of the hammer-off-dolly operation is given below.

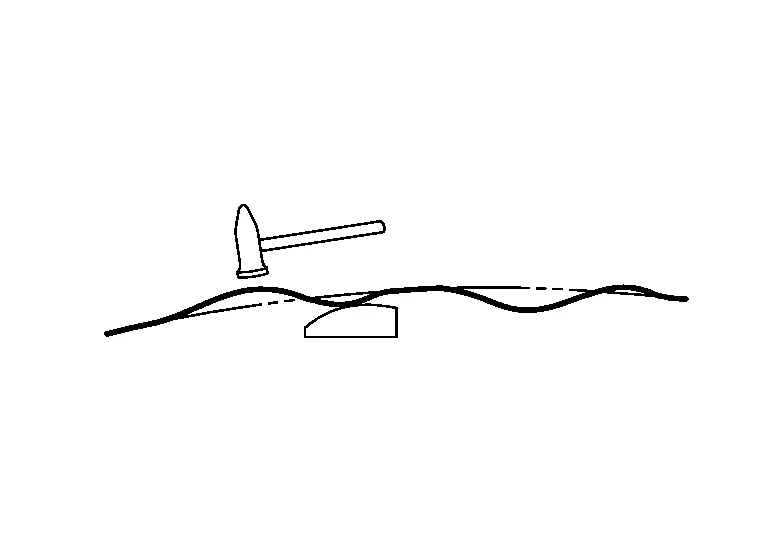

(a) Place the dolly under the deepest dent, and hammer the highest portion of the top surface.

(b) The raised portion of the surface lowers as it is struck with the hammer.

(c) Hammer blows are transmitted to the dolly, creating a reaction force.

(d) This reaction force pushes the dent.

(e) Repeat steps (a) - (d) until the surface is smooth.

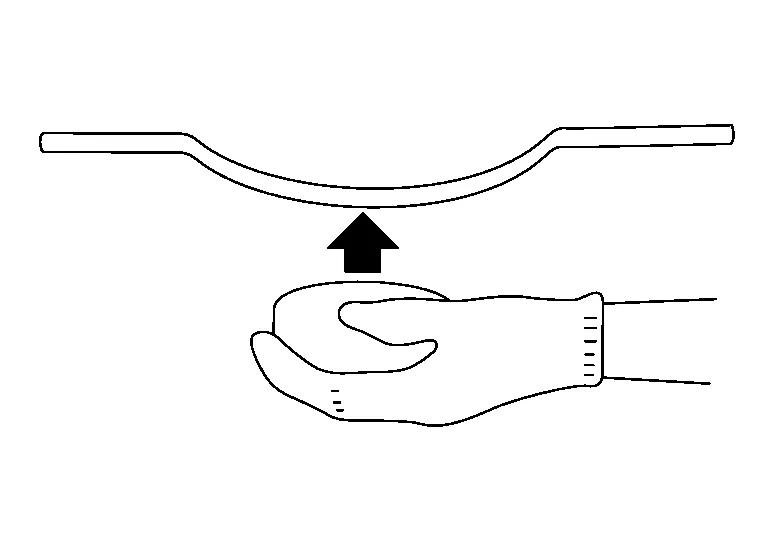

Spoons are made of steel, and one or both ends are flat. Spoons are used as dollies in narrow spaces or as pry bars.

(1) TYPES AND FEATURES OF SPOONS

|

|

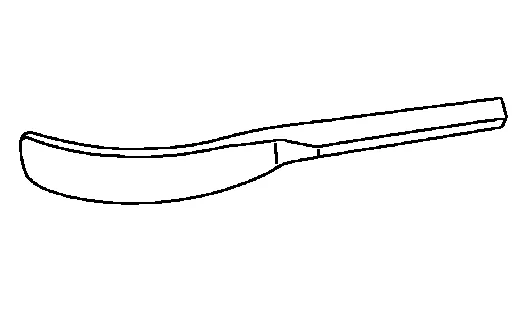

General purpose spoon | This spoon has a gently curved surface and sharply curved ends. It is widely used in automobile body repair work. |

|

|

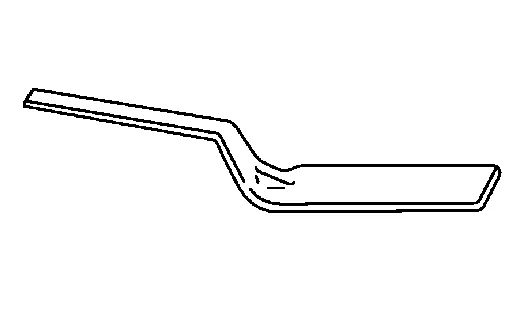

Long spoon | This spoon has a long handle and thin, rigid faces. It is used primarily for prying. |

|

|

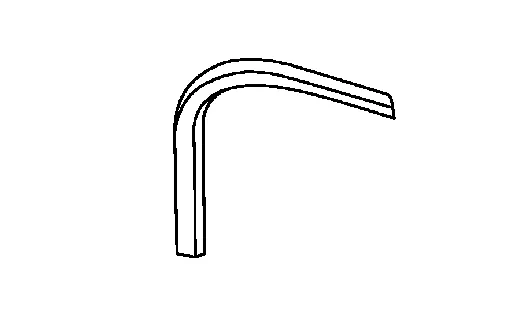

Curved spoon | The handle of this spoon is comparatively short. It has a wide curved blade. This spoon is used for smoothing. |

|

|

Flat spoon | This spoon has a short handle and a wide, flat blade. When the spoon is placed on the panel and hammered, the force disperses over a wide area. |

|

|

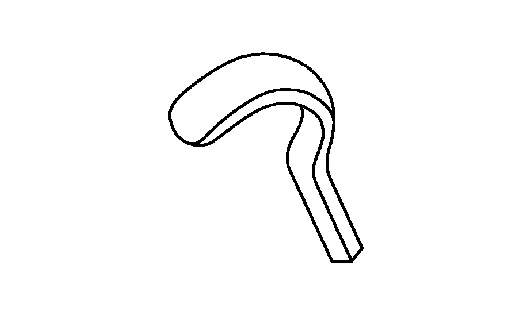

High crown spoon | This spoon has a wide hooked blade. It is used for repairing narrow body panel spaces such as inside of outer sill panel. |

|

|

Sickle-shaped spoon | This spoon has a wide, gently curved surface with a thin end. It can be inserted into very narrow gaps between panels. |

(2) SELECTION AND MAINTENANCE OF SPOONS

Select spoons suitable for the particular panel shape and internal structure.

The precautions described for the hammer and dolly also apply to spoons. Do not damage the surface which comes into direct contact with the panel during repair work.

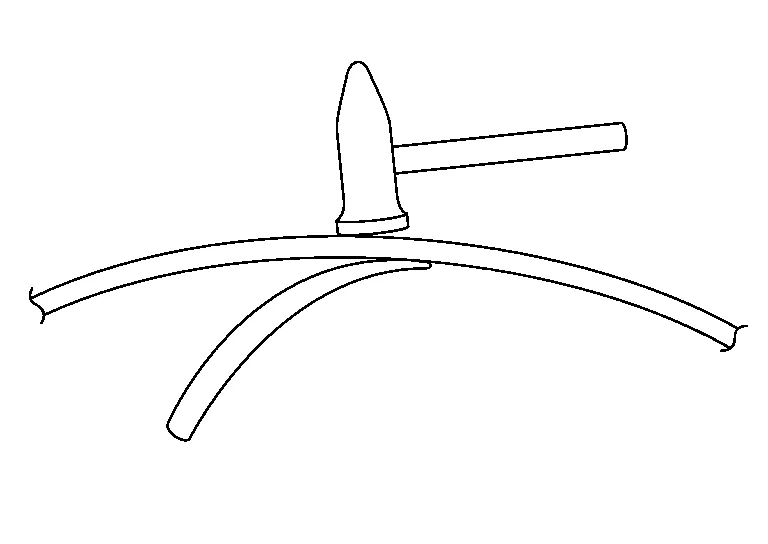

(3) HOW TO USE SPOONS

(a) Insert the spoon into tight spaces such as inside of door, and use as a dolly.

(b) Place a spoon between two panels and pry out the concave portion.

(c) Hammer directly on the spoon to disperse the force of the hammer blows.

(d) The figure to shows an example of incorrect spoon usage. There is no fulcrum point for the spoon.

If a spoon is used in this way, insufficient force is applied to the mating face, and the spoon cannot act as a dolly.

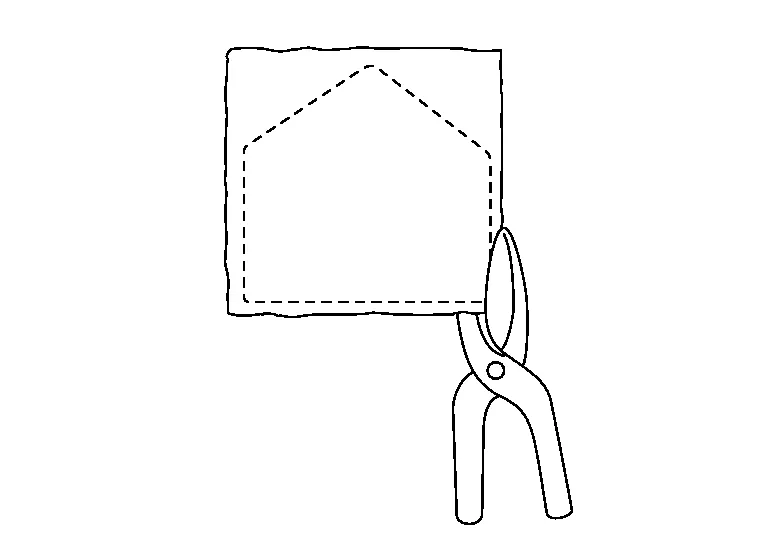

Chisels are generally used to cut sheet metal.

They are also used in body repair work. There are numerous types of chisels. This section, however, describes scribing chisels used exclusively for bending sheet metal or for shaping panel press lines.

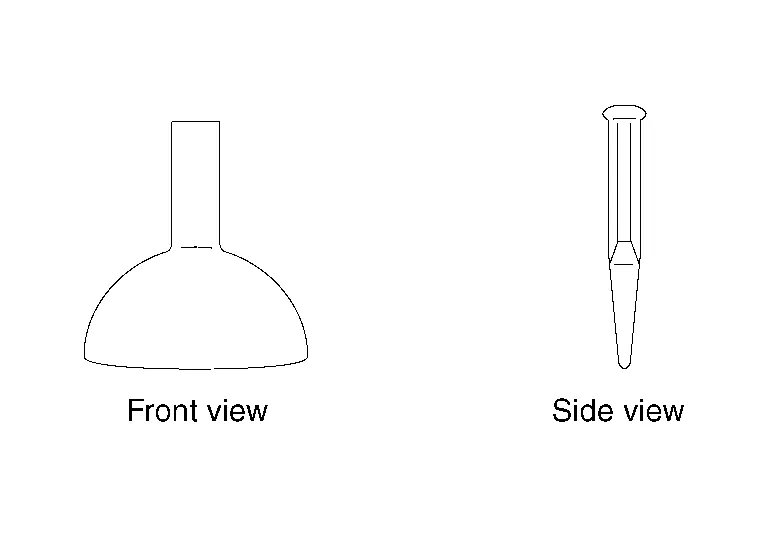

This type of chisel must have a smoothly rounded edge as shown in the figure. If the edge is sharp, the body panel will be nicked.

HOW TO USE SCRIBING CHISELS

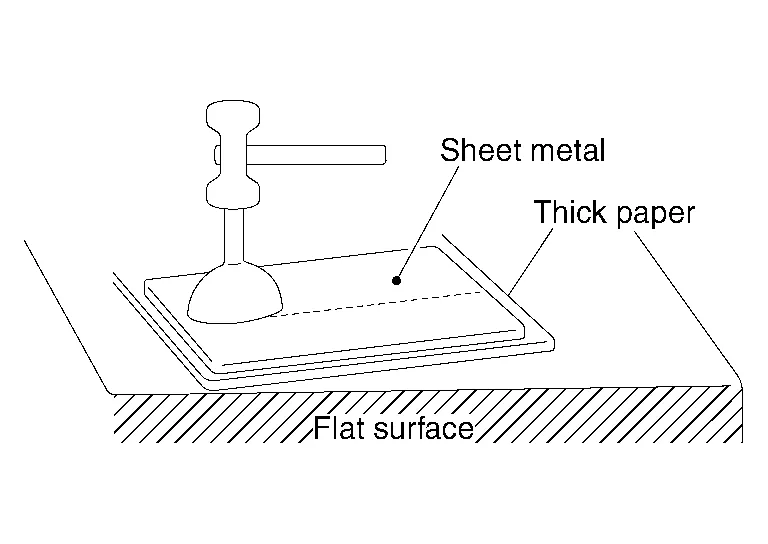

(a) For bending sheet metal

-

First scribe a line on the sheet metal.

Place thick paper or cardboard under the sheet metal.

Place the scribing chisel on the line and hammer it.

-

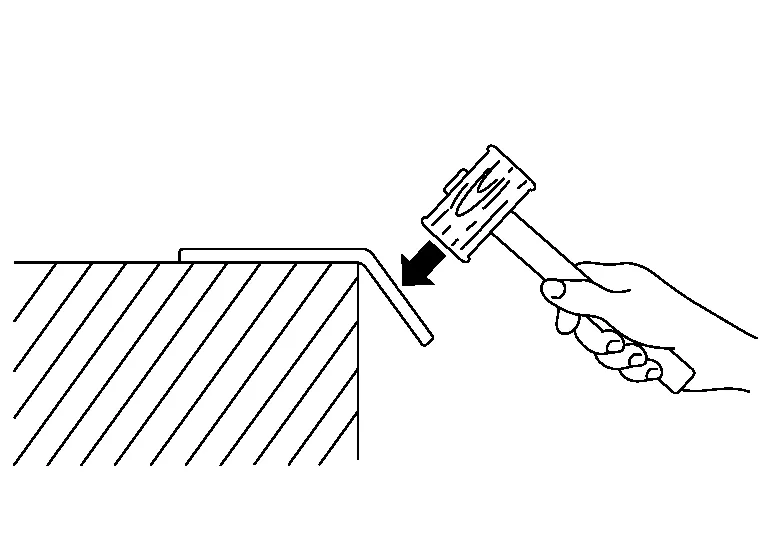

Place the sheet metal on a flat, angled surface scribed-side down, and bend the sheet metal with a wooden hammer.

-

Using a hammer and the scribing chisel, neatly bend the sheet metal squarely. Do not bend all at once.

Bend the sheet metal gradually by gently hammering against the chisel head.

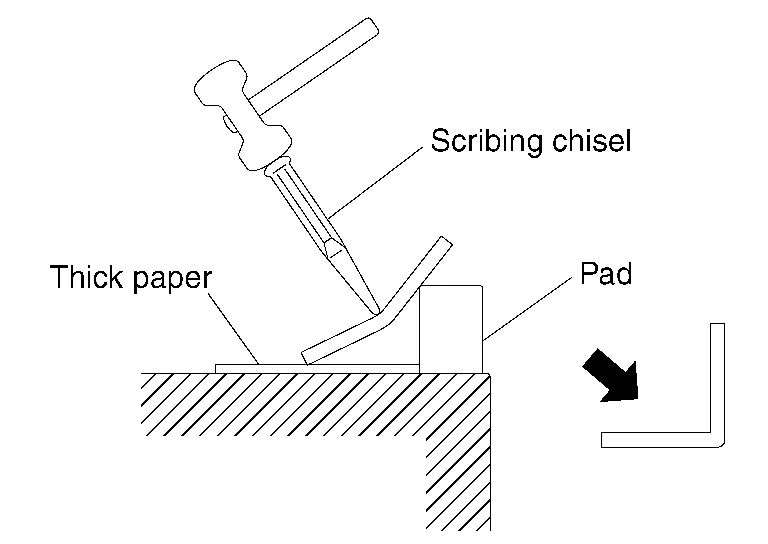

(b) Shaping the press line

-

If the dent in the press line is smaller than the width of the chisel, apply the chisel to the center of the dent. Hammer to flatten. Hammer gently so that the dent can be removed gradually.

-

If the dent is larger than the width of the chisel, do not strike the dent in the center. Apply the chisel at the edges of the dent.

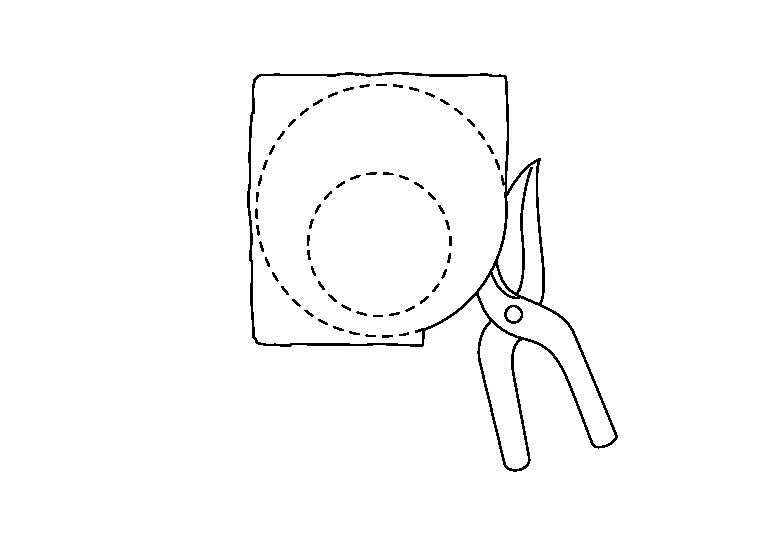

(1) STRAIGHT BLADE SHEARS

For cutting straight lines.

(2) CURVED BLADE SHEARS

The blades are smoothly curved. Suitable for straight or curved cutting.

(3) SCOOPED BLADE SHEARS

The entire blade is bent to one side. Suitable for cutting along a sharply curved line.

If it is impossible to gain access to the damaged area, dents can be pulled out and repaired.

METHODS

There are many techniques to repairing a dent, but there are basically two methods. Both methods can be used depending on the type of damage. Each method has its own advantages and disadvantages.

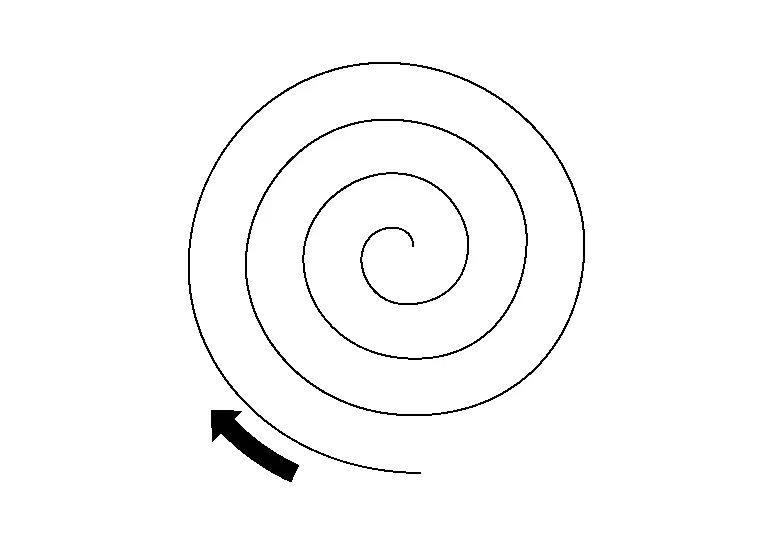

| Outside in | Inside out |

|

|

|

| The traditional method is from the outside to the inside in a spiral from. This method has the advantage that the single spots will harden and stabilize the area as you are working into the center. The disadvantage is that the center will be stiffened up and will not be easy to bring out. | The inside out method is to start in the middle and as it comes out the surrounding area can be worked. Also the hammer can be used at the same time to stress relieve the metal around it. |

If the damage is influenced or affected by an edge or bodyline, you have to go away from the edge - feathering away from the edge with small single pulls.

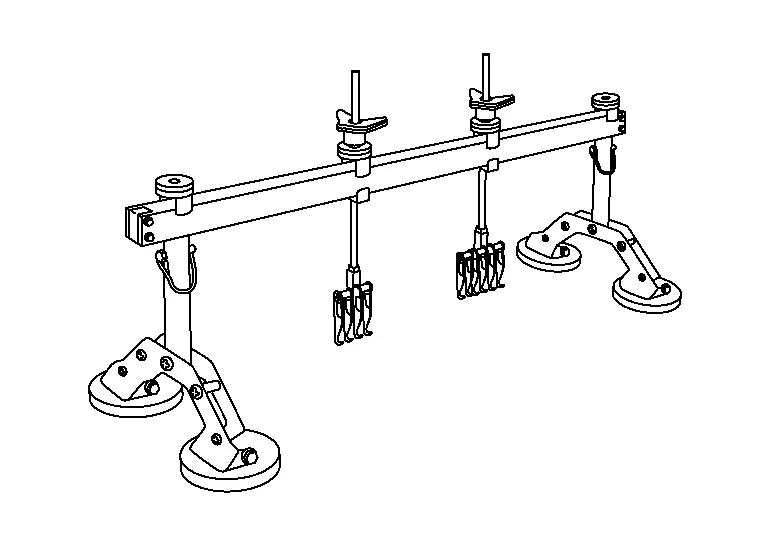

DENT PULLING TOOLS

| Damage Level | Recommended Tool | |

|---|---|---|

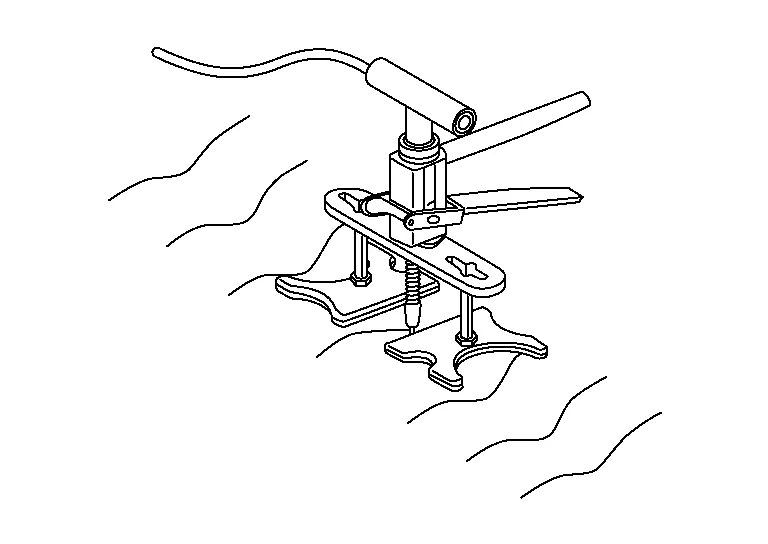

| Heavy |

|

Dent pull bar |

|

|

Dent pull bar Long bridge |

|

| Moderate |

|

Dent pull bar Short bridge |

|

|

Slide hammer | |

| Light |

|

Dent Pulling Rod and Hammer |

|

|

Dent pulling rod | |

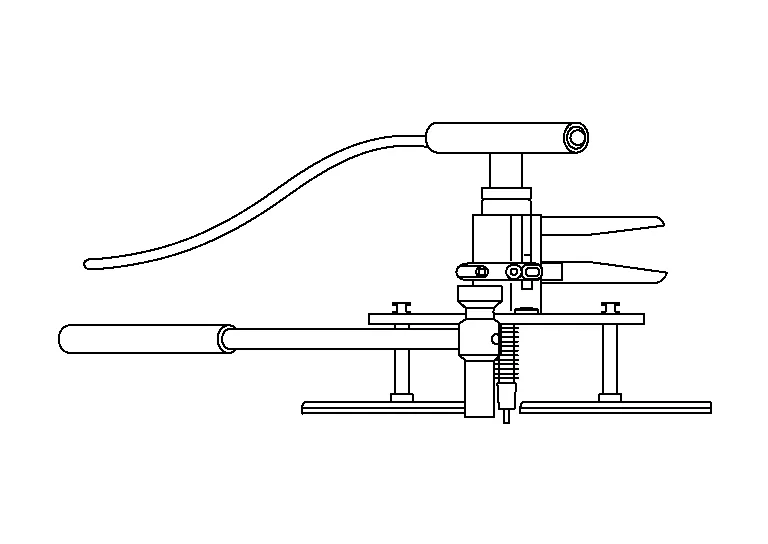

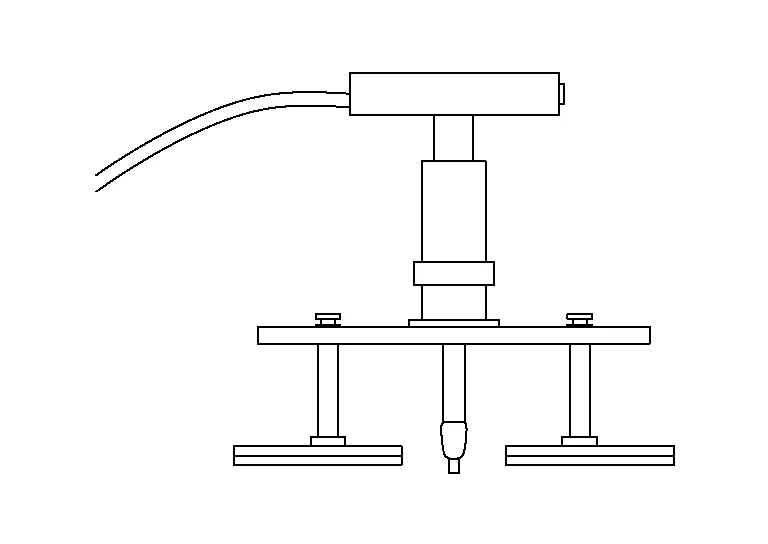

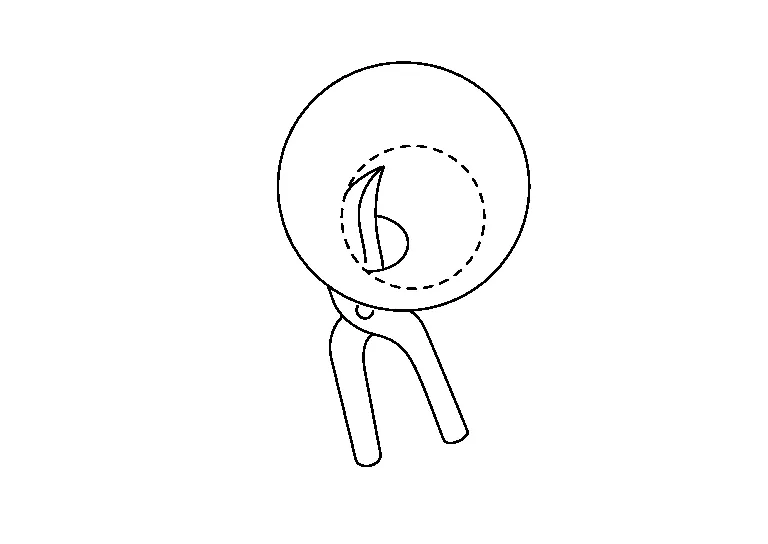

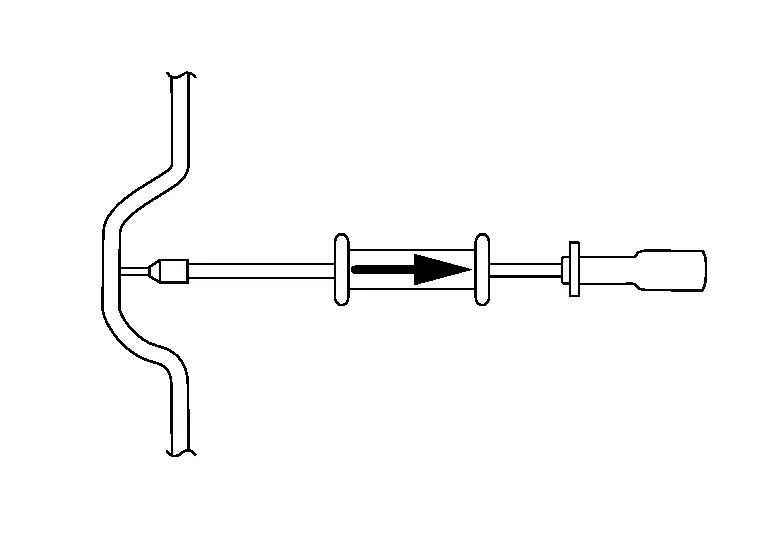

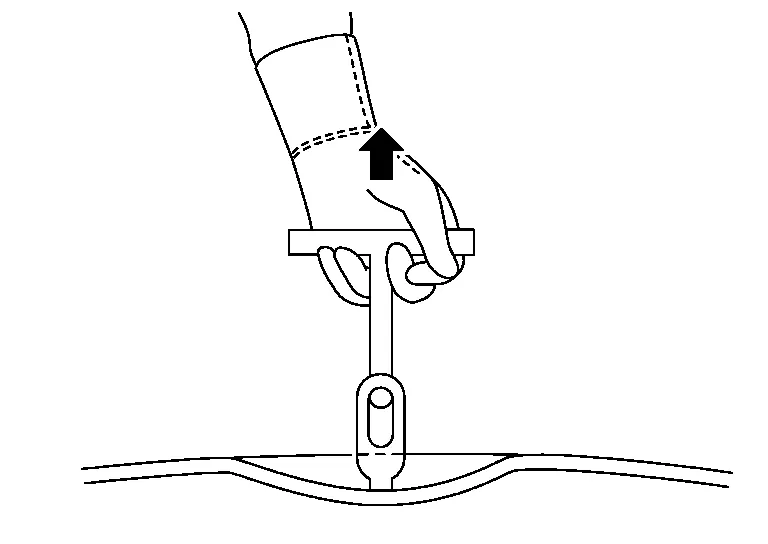

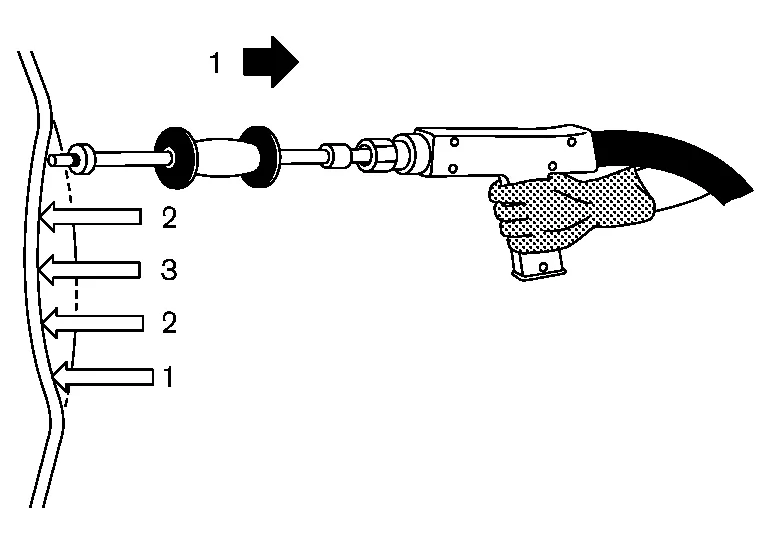

(1) SLIDING HAMMER

The sliding hammer is used for repairing large, deep dents. Since it provides greater force than an ordinary hammer, it is used to repair dents in thick panels.

(a) When the panel is thin. Instead of a hole, a metal pin or washer is welded to the panel. Great force can be used for pulling.

(b) When the dent is deep and narrow, pull it with a single blow.

(c) When the panel dent is shallow and wide, hold the end of the sliding handle. Repair the dent by gradually tapping the edge of the dent.

(d) Deeper Damages are pulled out with a hand puller. It allows more of a control and it allows pressure to be applied and at the same time the pressure can be applied with the hammer.

A hand puller has the advantage with a line damage. The damage can be pulled up with more control and will reduce the repair area.

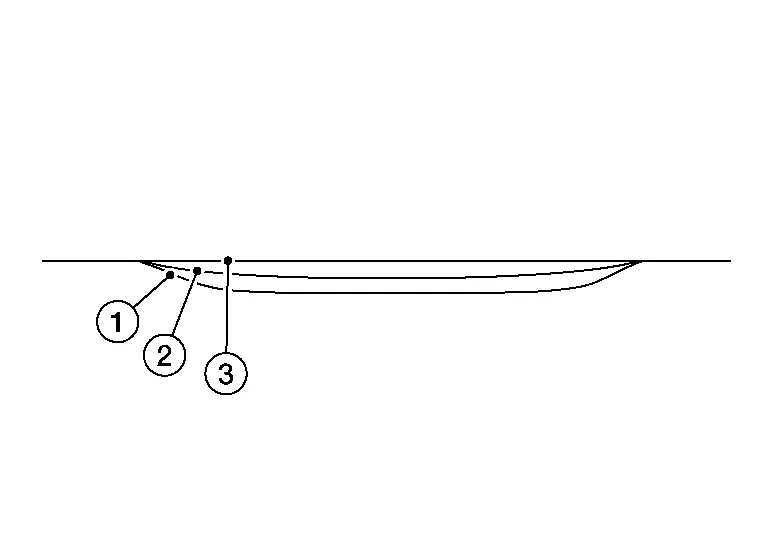

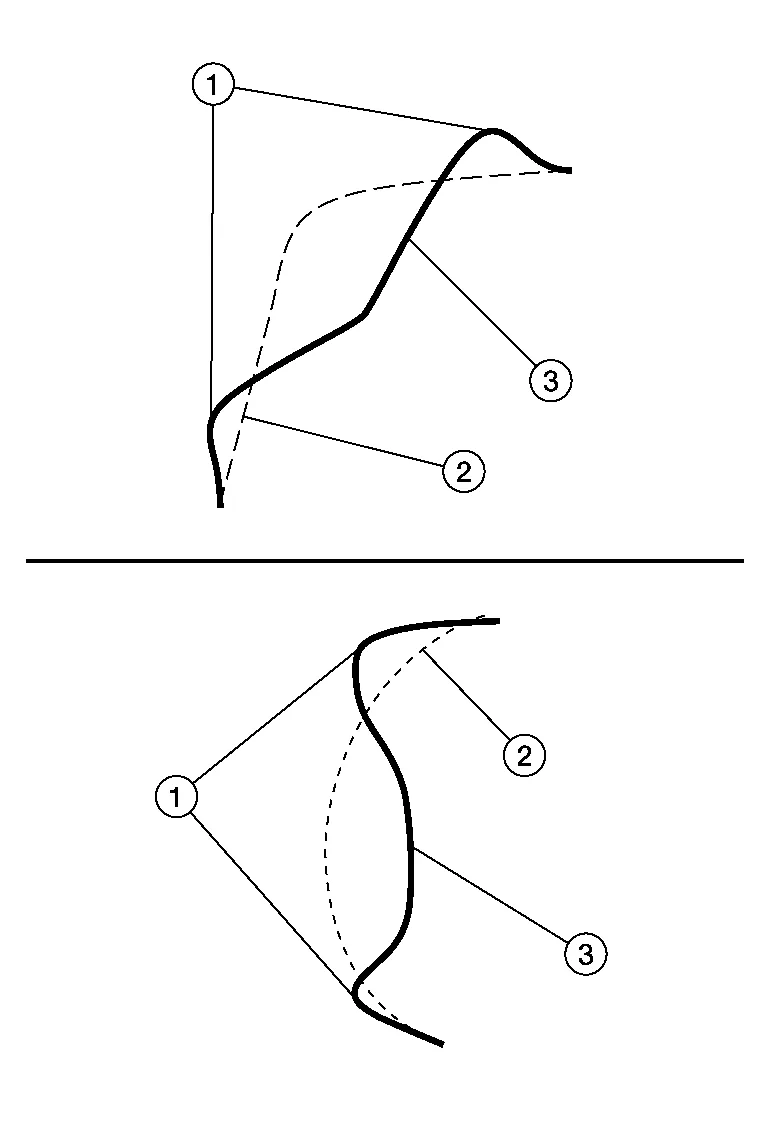

Repairing long dents or deep dents

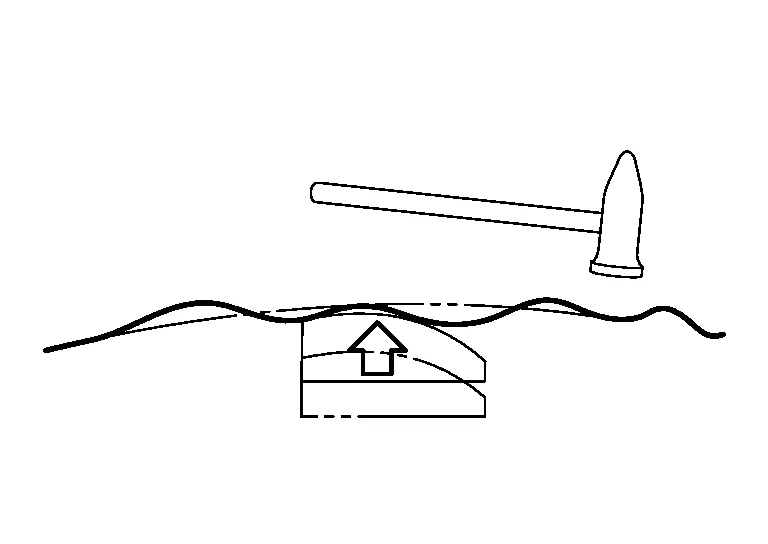

If the damage is deep don't try to pull up the damage completely. Do it in increments until the desired level is achieved .

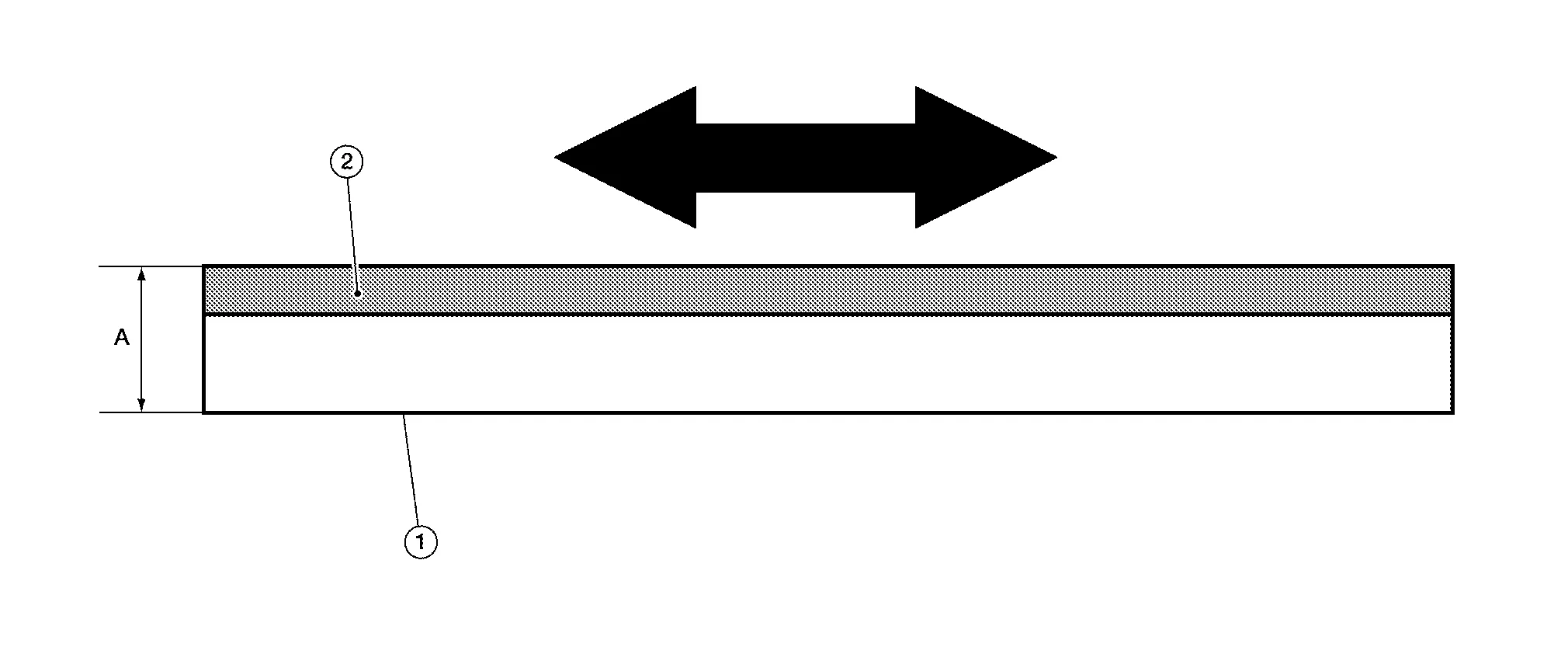

| 1 | :Panel surface |

| 2 | :First pulling distance |

| 3 | :Finishing pulling distance |

Pull first in the middle with a light pull. Then continue by halving the distance between the pulls always pulling a little every time. Don’t try to pull it all at once, because the metal will be too high at the end.

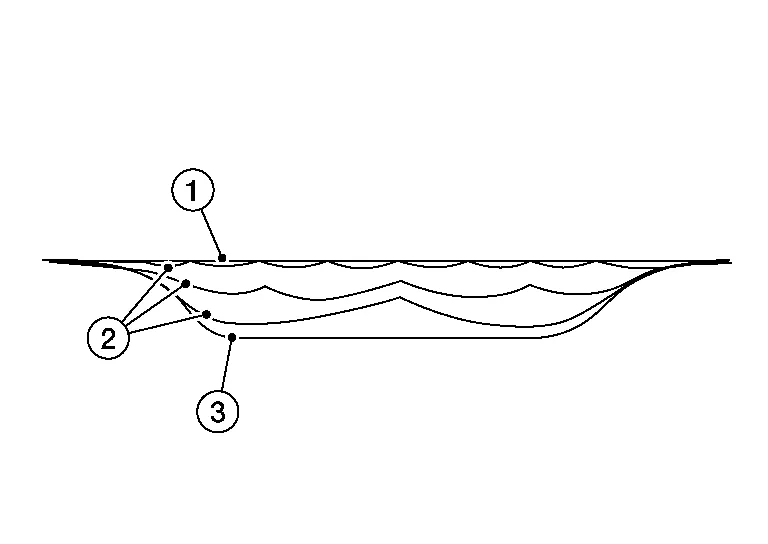

| 1 | :Finishing pulling distance |

| 2 | :Pulling distance by halving |

| 3 | :Panel surface |

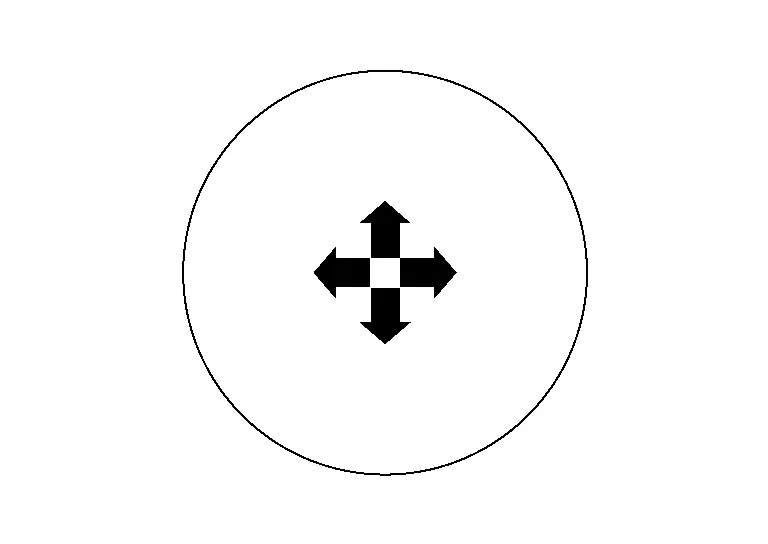

When using the hand puller, place the feet cross to the bodyline.

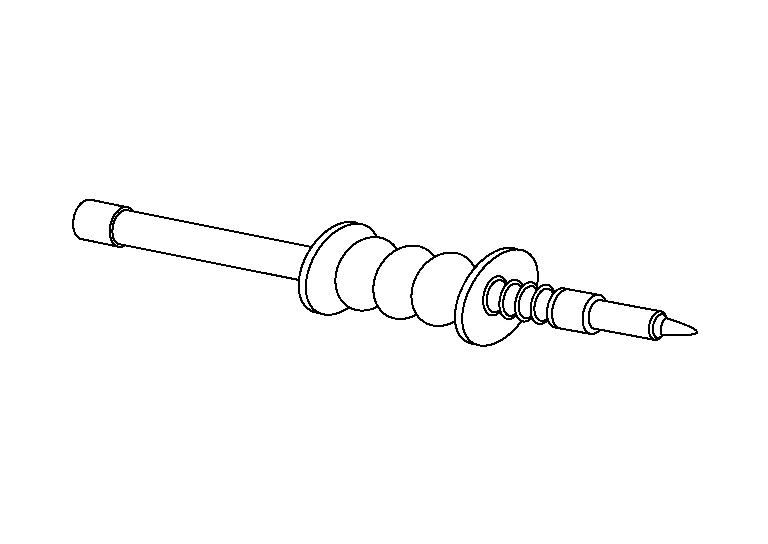

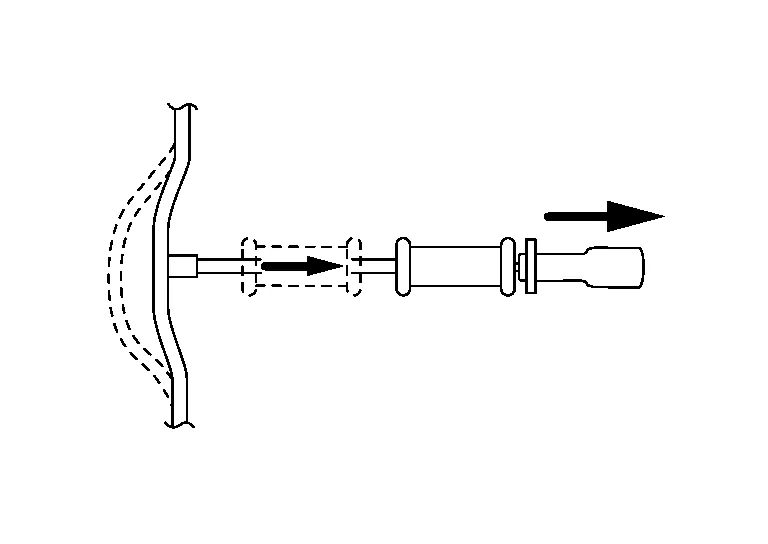

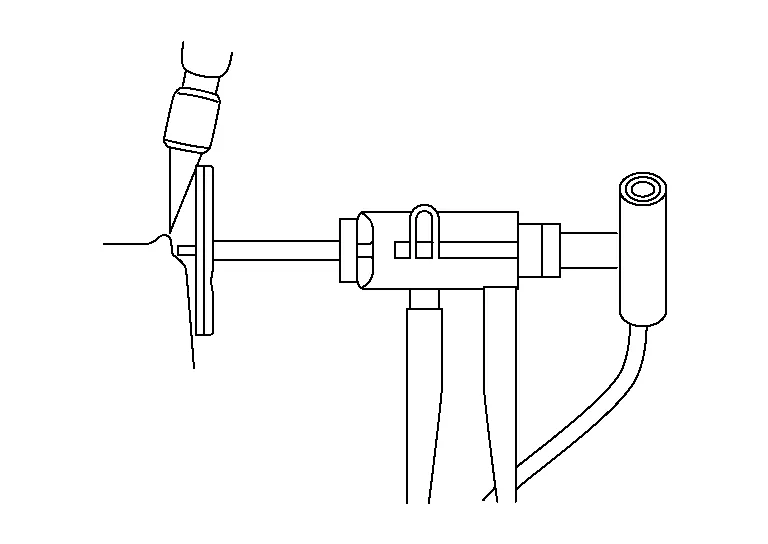

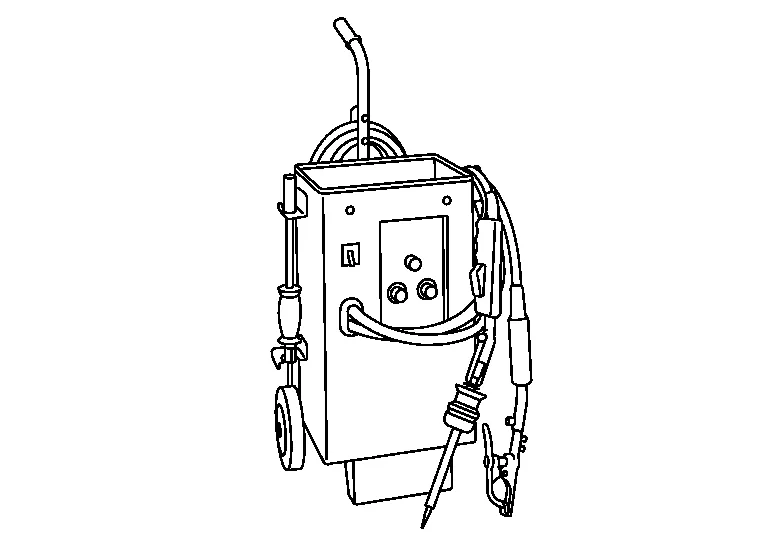

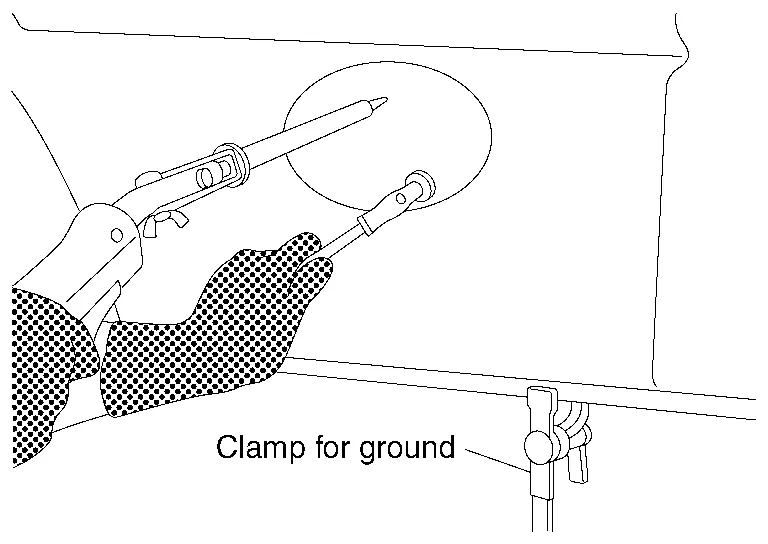

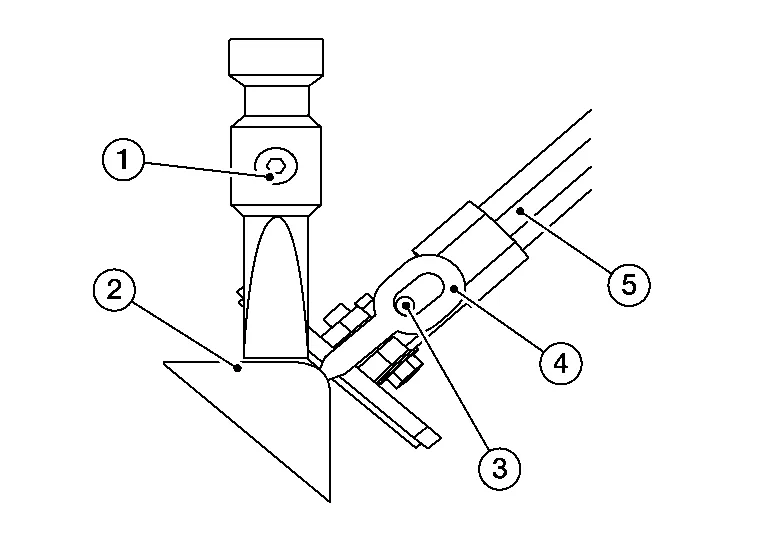

(2) STUD WELDER (BODY REPAIR STATION)

A pin or washer is welded directly to the body panel dent without drilling. The panel dent area is then pulled outward with the sliding hammer. Because no drilling is required, panel strength is unaffected. Corrosion problems are also reduced.

Application of the clamp for ground will increase the painting area in the repair process. A different ground could be used which can be applied next to the damage and will reduce the repair area.

Because the stud welder welds pins directly, the paint must be removed from the dent surrounding area and the area where body ground is established.

As shown in the figure, the ground can be established at the flange area or in the dent surrounding area using a magnet.

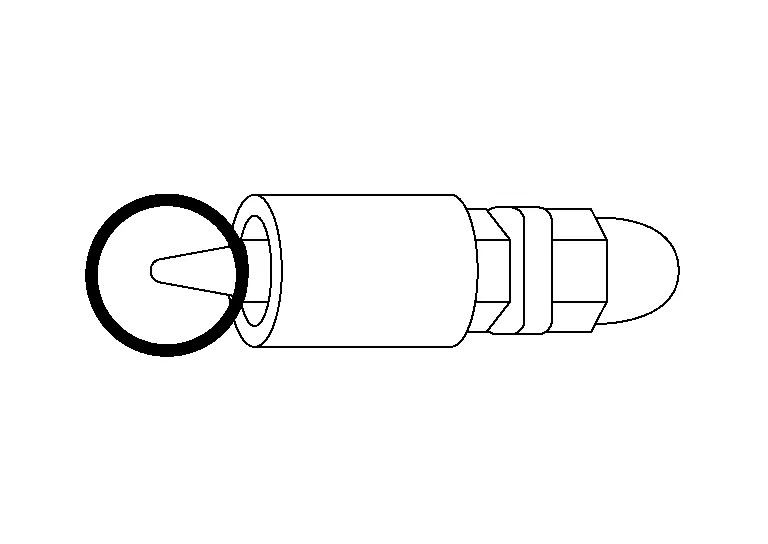

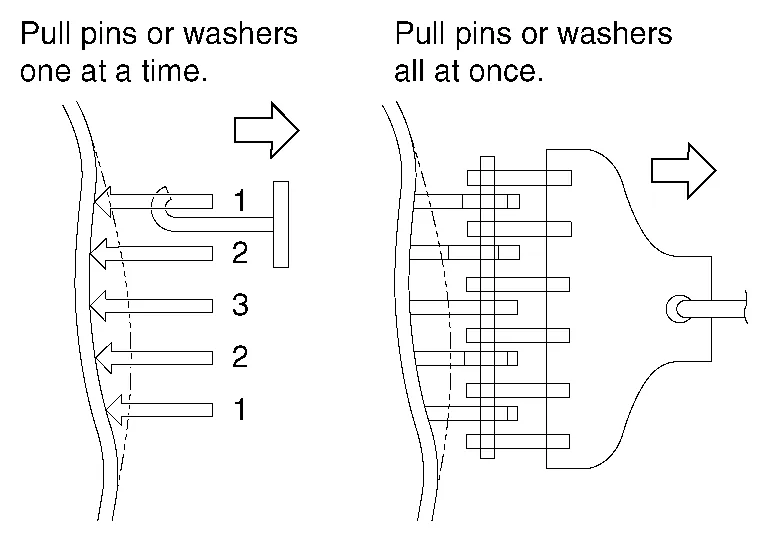

(3) WELDED PIN OR WASHER

A pin or washer is welded to the dent without drilling. It is then pulled to repair the dent.

Several pins or washers are welded to the dent. They are then pulled together or separately to repair the dent.

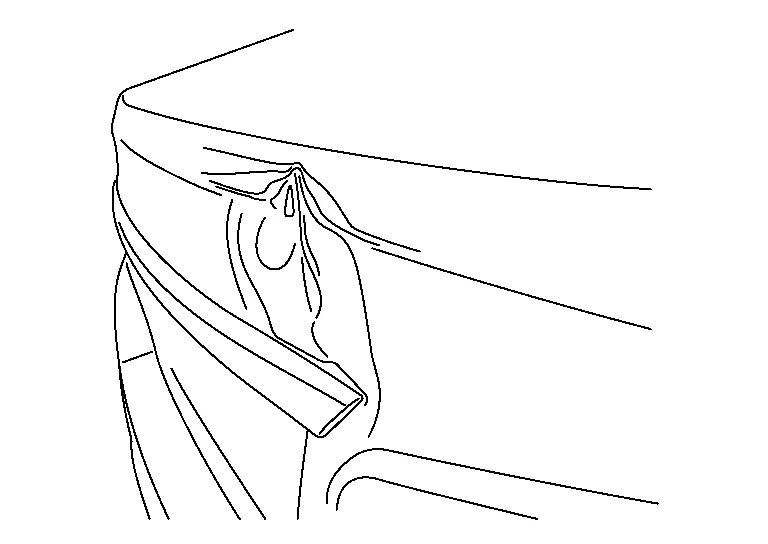

Analyze

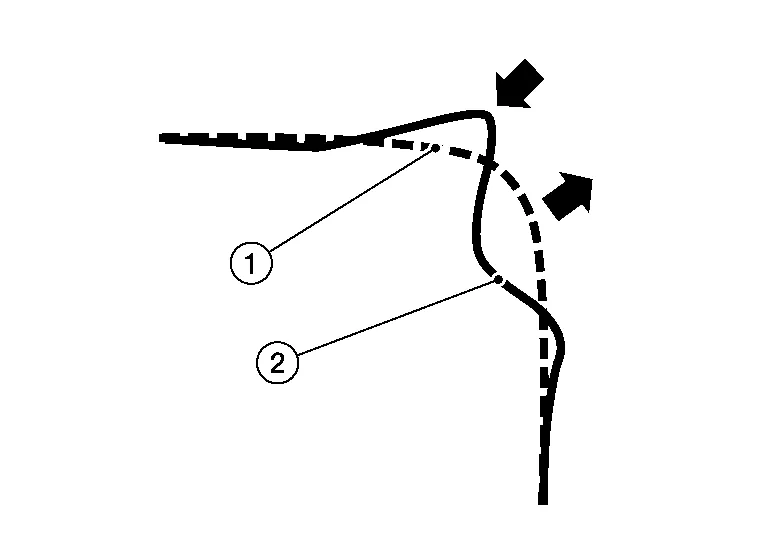

Look at the damage. See from which direction the hit came from and the extent of the damage. Also look for the different zones.

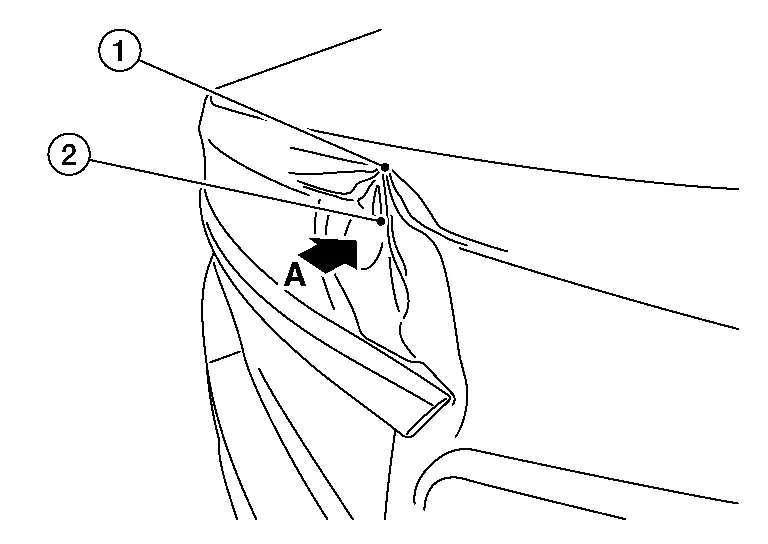

| 1 | :Crown (metal pushed up) |

| 2 | :Damage |

| A | :Direction of impact |

If there is an edge or bodyline within the damage area, it is important to focus on straightening it first as shown.

| 1 | :Finishing pulling distance |

| 2 | :Panel surface |

In most cases, there is also a crown (1) in the damage. The crown is the area where the metal has been pushed out. Depending on the shape of the metal and the direction of the hit the crowns are in different areas.

| 2 | :Finishing pulling distance |

| 3 | :Panel surface |

To bring out the edge or the bodyline a bridge system is ideal. The advantage of a bridge system is that you can bring out the edge first and relieve pressure on the crown.

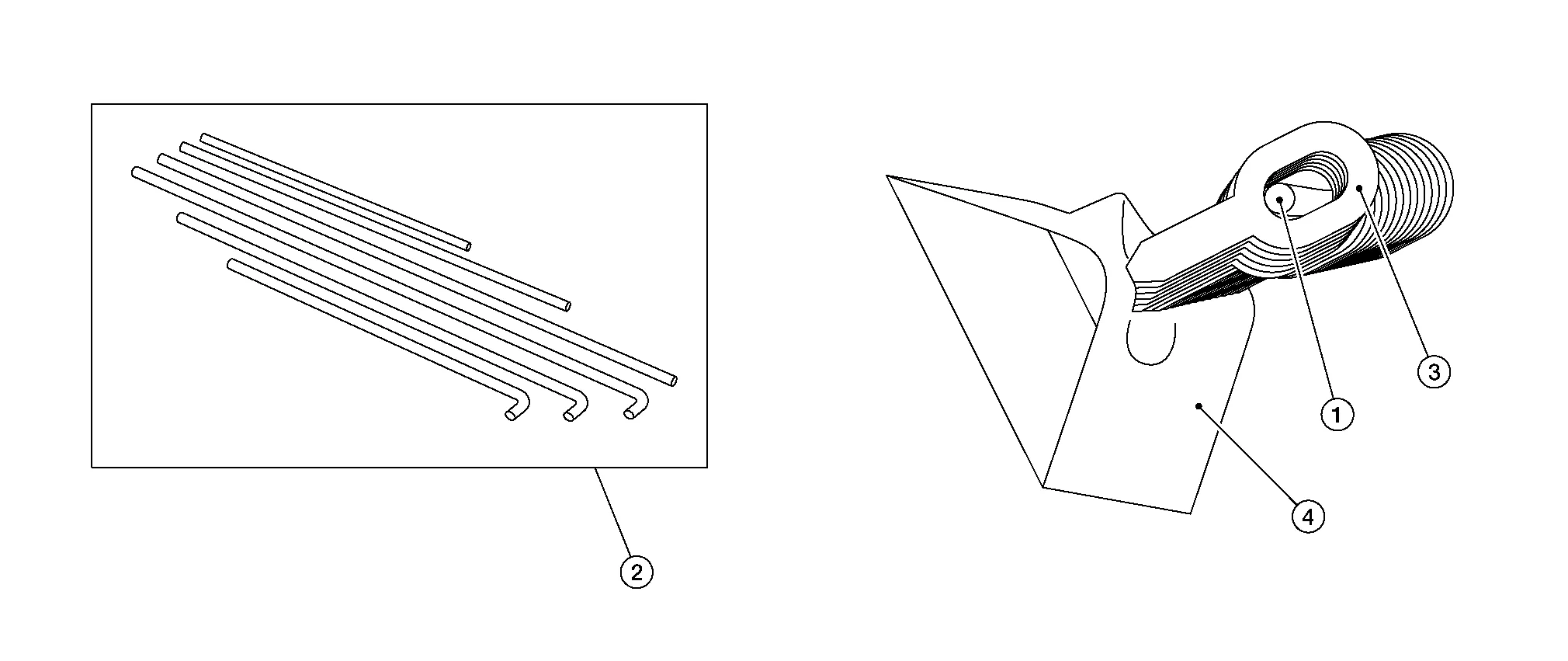

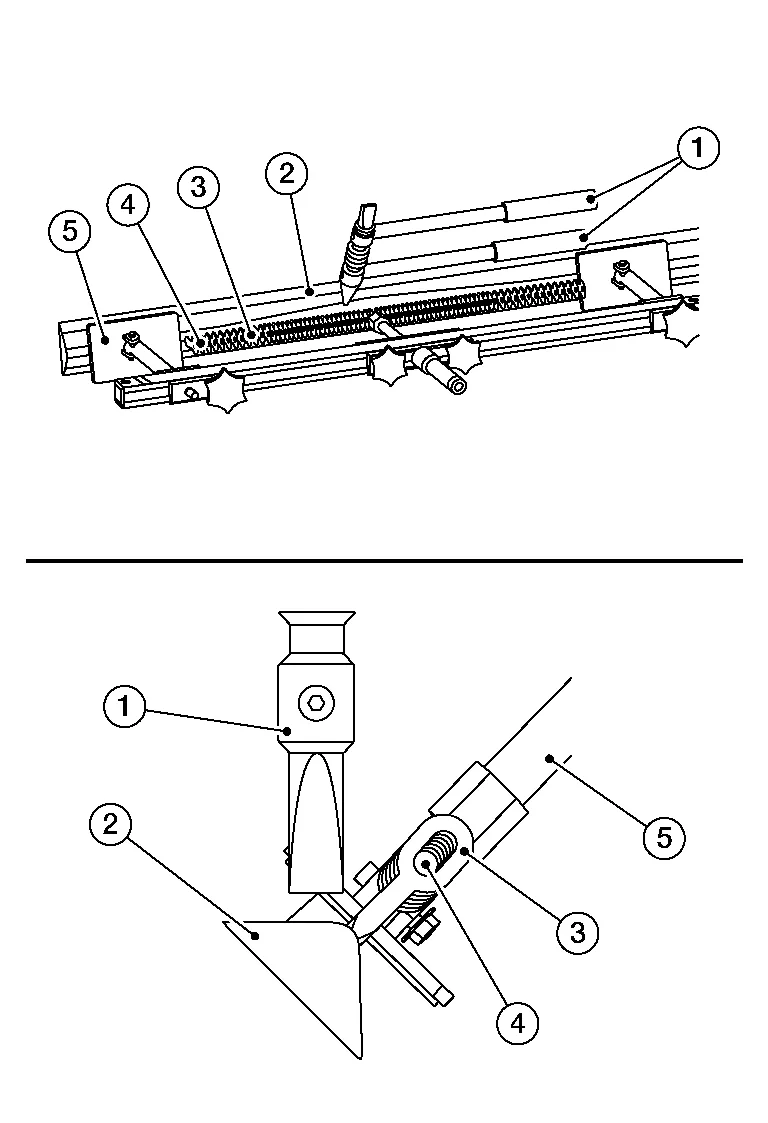

Welding on the Bits

It is important to weld on the line. Therefore, first mark the line by using the pulling bar and making a scratch on the bare metal. You can also use the Flatliner Laser to make the line. Welding of the bits is done most of the time on the tangent point (2) of the line. This depends on the direction of the hit. Try not to weld on the radius area (1) or round area of the bodyline. This will increase the risk of making a hole in the panel.

Welding on the bits is easiest done with the Bit Gun. You can also single weld this. On the Digispot, change to manual welding mode, this way you can first place the bit and then weld. In the area where you don’t need a lot of pulling force you can place the bits further apart. In the center where more pulling force is needed try to weld the bits as closely together as possible. The more bits you weld on and the closer they are, the fewer waves you get in the repair.

Insert the pulling bar (1). There are 6 different types of pulling bars (2): three different lengths and also either straight or bent at the end. The bent pulling bars are for vertical applications.

NOTE:

NOTE:

For a low pulling force, individual weld on tabs (3) can be pulled. For a high pulling force, multiple weld on tabs can be pulled.

| 4 | :Panel surface |

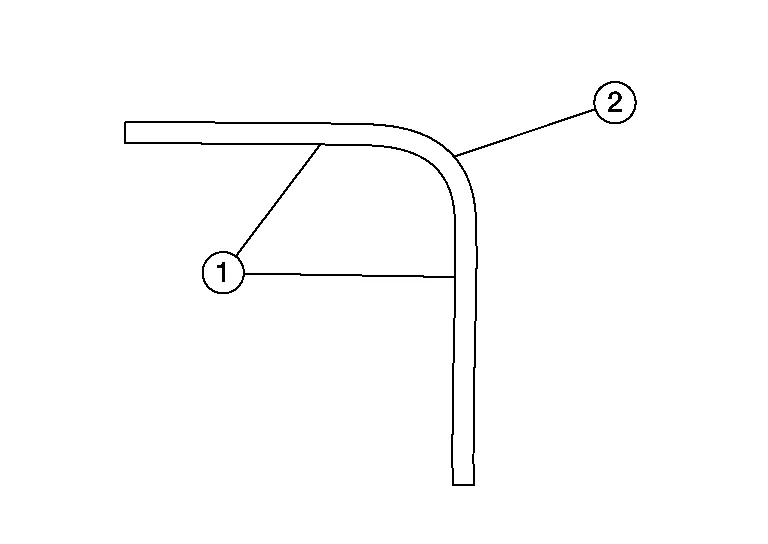

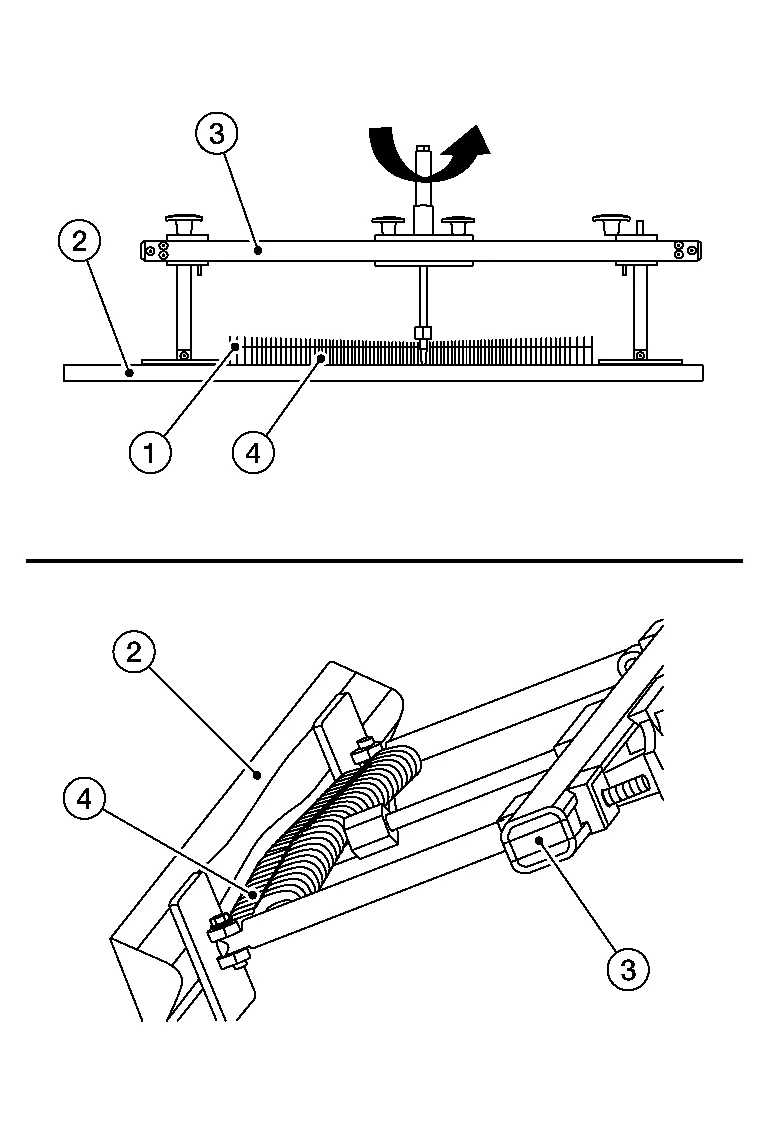

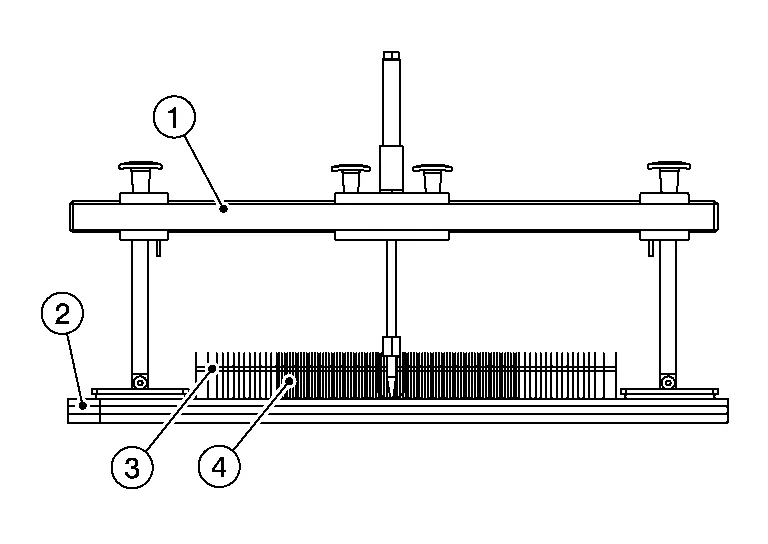

Applying the Bridge

For small areas, it is best to use the FL80-bridge. Also use the 2 angle directional feet (1). This way the bridge will not tilt down during the pull.

| 2 | : Panel surface |

| 3 | :Weld on tabs |

Open up a space for the pulling bar (1) in the middle of the panel surface (2).

Place the feet on the outside of the damaged area and apply a little pressure by rotating on the pulling mechanism.

| 3 | : Bridge |

| 4 | : Weld on tabs |

When you pull up the damage, don't pull it out completely. Once you get a little tension on the pulling mechanism it is important to start to relieve the tension on the crown. This means that you are pulling a little and knocking down on the crown in direction shown.

| 1 | :Panel surface |

| 2 | :Finishing pulling distance |

It is easiest to use two hammers (1) at the same time. One is for placing and the other for hitting. If you use the vertical fin of the hammer and place it on the crown (2) you can see the crown much better from the side, even if it is a small crown. The other advantage of using two hammers is that it will reduce the vibration, which can loosen the bits.

| 3 | : Weld on tabs |

| 4 | : Pulling bar |

| 5 | : Bridge foot |

Try to pull out the damage a little and knock down the crown again. You will feel the pressure on the pulling mechanism releasing once you take away the tension from the crown.

| 1 | : Hammer |

| 2 | : Panel surface |

| 3 | : Pulling bar |

| 4 | : Weld on tabs |

| 5 | : Bridge foot |

Once most the damage is pulled up and the crown is knocked down, check if the line is straight. You can do this with a pulling bar or with the laser.

| 1 | : Bridge |

| 2 | : Panel surface |

| 3 | : Pulling bar |

| 4 | : Weld on tabs |

The next step is to bring out the remaining area and to stabilize the edge. This is normally done on both sides of the damage. This is done while the bridge is still in place. It will hold the line and facilitate the repair process of the area.

| 1 | : Bridge |

| 2 | : Pulling bar |

| 3 | : Weld on tabs |

| 4 | : Panel surface |

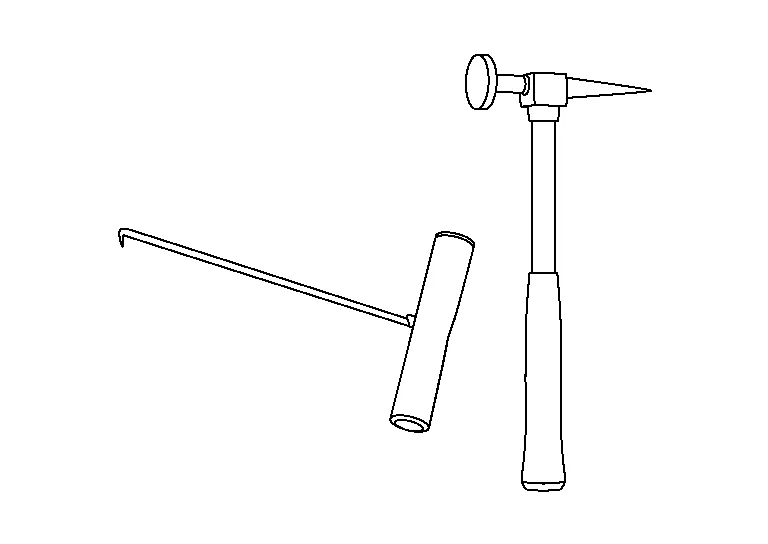

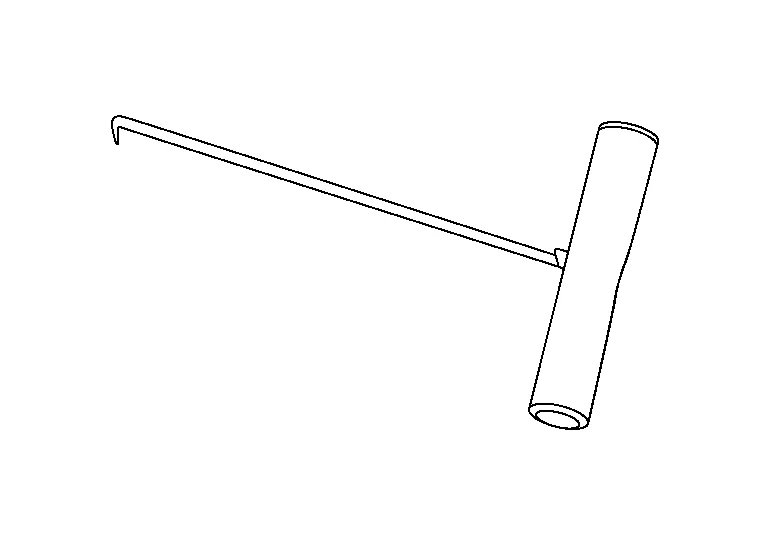

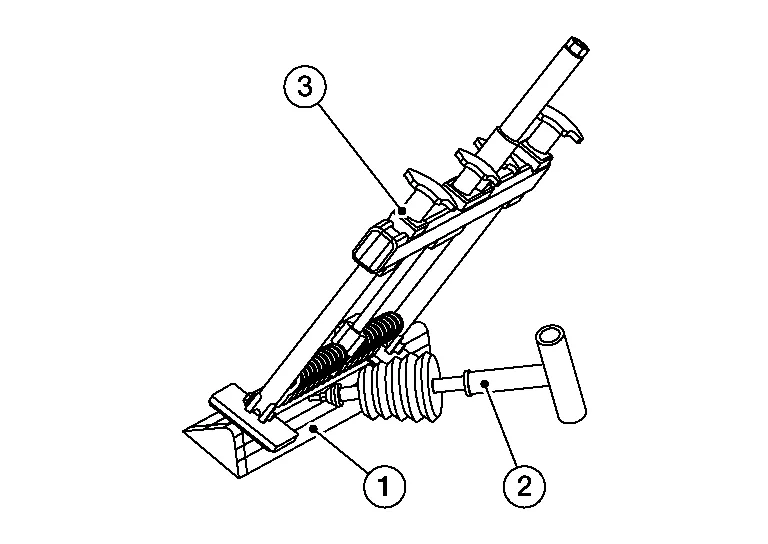

Depending on the depth and strength of the remaining damaged area (1) different tools maybe be used. It is best to use the T-Handle (2) or if needed the small sliding hammer of the Innopuller. Normally not much force is required.

| 3 | : Bridge |

The rest of the finish can be done with the Innopuller or the hand puller (1). Another option, if the damage (2) is still deep, is to use the Innopuller with the hammer (3).

Bridge Application Short

On rocker panels and edges or in small places most of the time the FL80-bridge is being used.

Bridge Application Long

On larger areas or where the damage is in the middle of the panel the FL120-bridge is being used.

(4) SPOT HAMMER WELDING

The sliding hammer tips are welded to the dent.

They are then pulled separately to repair the dent.

After the tips are pulled, they are twisted to separate them from the panel.

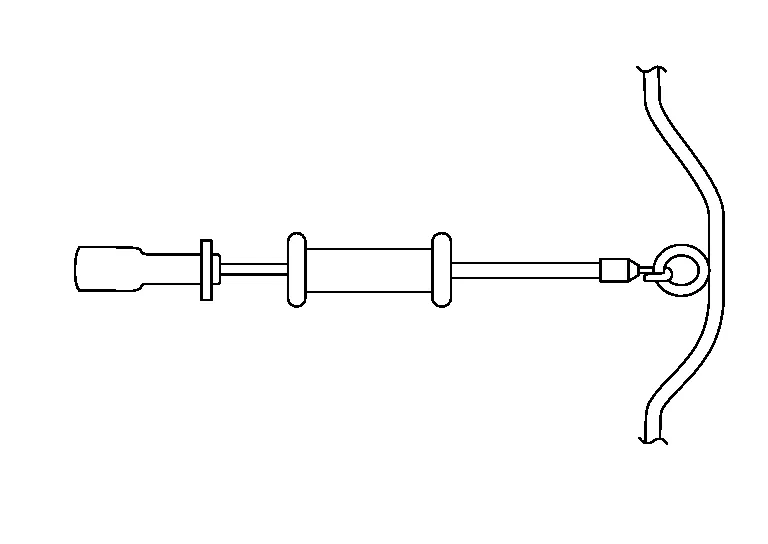

(5) HAND PULLER

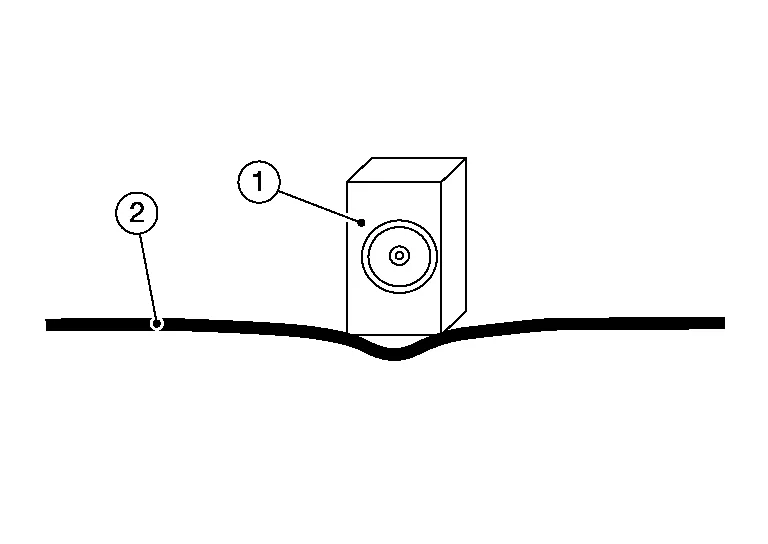

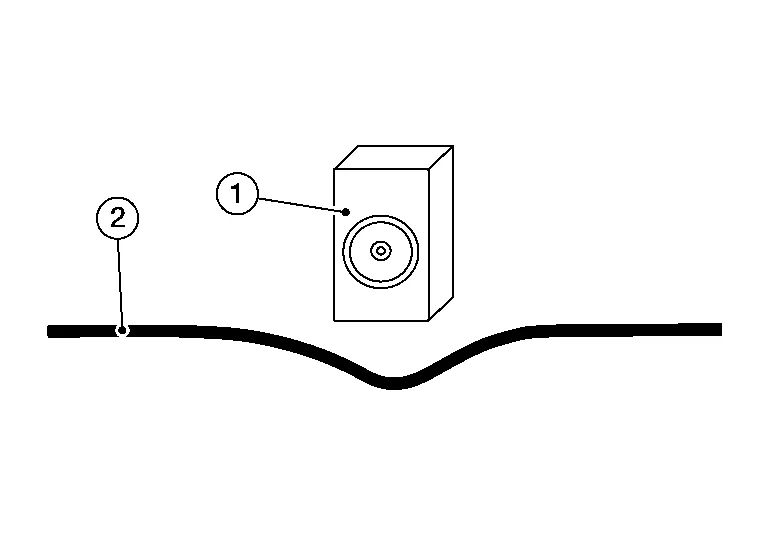

The hand puller (1) can also be used together with the hammer (2). By applying a little pressure on the handle and with little hits from the hammer the stress can be relieved. This can also help with frogs/oil canning in the metal.

| 3 | :Panel surface |

The finish is best done with the hand puller/T-bar and the hammer. Start from somewhere on the outside and work your way in. It is also helpfull to place the Flatliner Laser further away and to run the light over the surface.

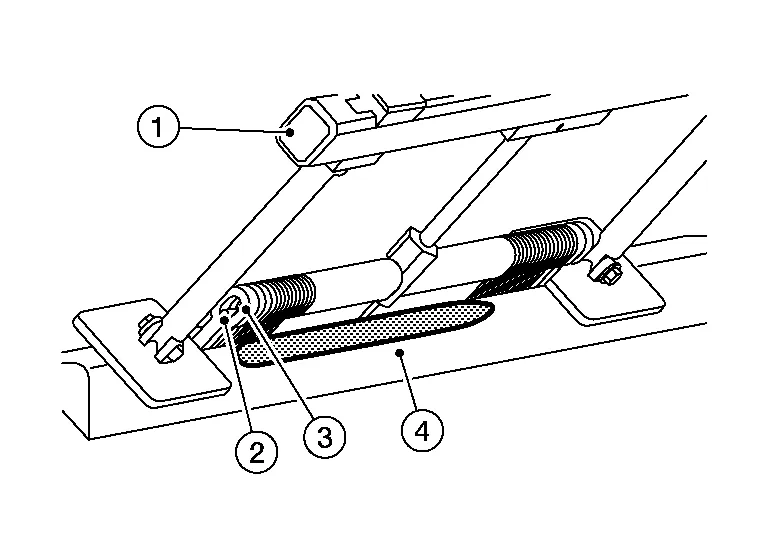

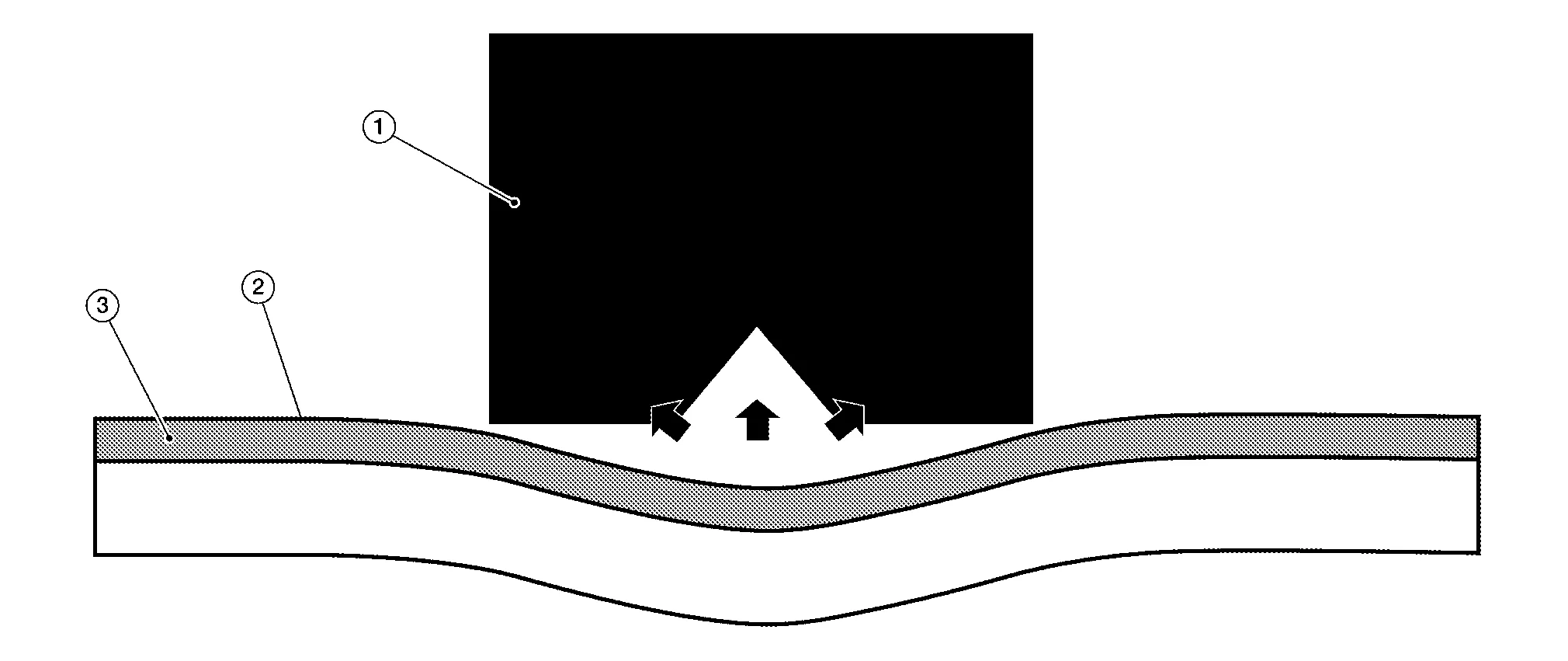

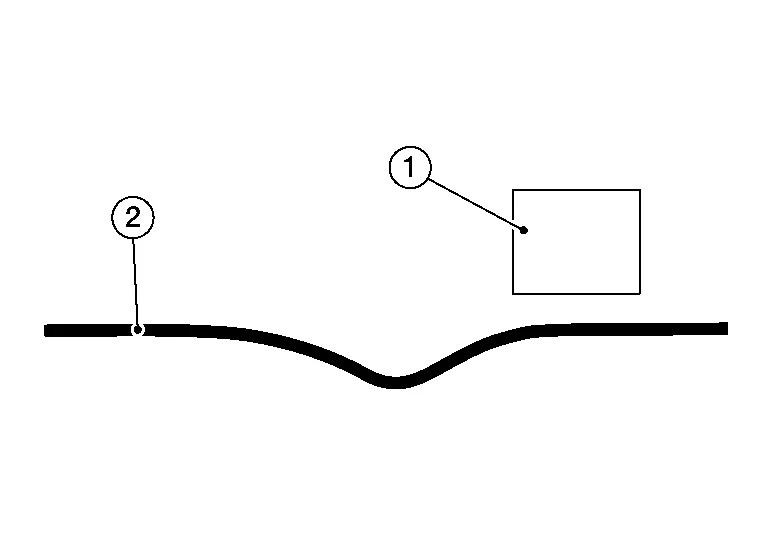

Hotbox dent removal

The dent removal with induction heating works on the basis of surface heating of the sheet metal (1). By using a certain frequency the surface (2) of the sheet metal gets activated so that the top surface of the sheet metal is heated and thus expands. The other key working function is the vibrating impulse in the tool which helps the process.

| A | 0.7mm (0.028 in) |

This effect makes it ideal for the rising of soft damages.

| 1 | :Hotbox |

| 2 | :Sheet metal |

| 3 | :Surface |

-

There are four applications

-

Soft dents

-

Dent reduction of larger or sharper dents

-

Area work or cleaning up an area that has been repaired by the dent removal tools or glue system.

-

Shrinking or stiffening of metal

-

-

The use of each applications

Soft dents or elastic dents can be repaired as long as the metal is not stretched and or that the main stress on the metal is not larger than the pulling force of the Hotbox effect.

With dents which have a plastic deformation or dents which are larger or where the center is stretched, the energy part (plastic deformation) of the dent cant be removed, as long as the main stress on the metal is not larger than the pulling force of the Hotbox.

After a dent has been repaired by the dent tools or the glue system, it often happens that the general area is still low and might have some waves in it. Then this area can be easily brought up by the Hotbox.

If by large dents the damage was that large that the mechanical strength of the material has been weakened, then the Hotbox can be used to shrink this area, best done by applying the tool to the center and then heating it to the maximum and then to cool off with cold air or water. This is best done more than 3 times to get the stiffness into the metal.

The setting of the unit as far as the power is concerned is always 100% with the Hotbox. With the T-Hotbox the power setting is always 100% if the time functions is being used.

-

The Applications

-

Application (Small soft dents)

Don’t press the heat pen (1) on the metal (2). Just hold it on top and as the metal comes up pull up the tool head.

-

Application (Large soft dents)

1 :Hotbox 2 :Sheet metal Start on the side with a short impulse. Depending on the size of the damage it might be necessary to start far away from the center of the dent as shown. The impulse should sound like a beebeep (2 Beeps). This is about .1 sec pressing the red button on the hotbox (1). Always use the light and look on the surface to see what the metal (2) is doing.

If the metal is going down, go further away. Also check if there might be a brace behind it, or maybe the damage might be too large.

1 :Hotbox Then move closer to the dent, and again a short impulse (bee-beep). It is important to do an impulse on the edge or almost going down into the center of the dent.

1 :Hotbox 2 :Sheet metal Then once the metal has come up, bring up the center by heating for at least .6 sec. The metal should be over-pulled. Also the raising of the metal can be done by short impulses, always raise the tool to see what the metal is doing. This will take some practice.

-

Shrinking the Sheet Metal

Shrinking the Sheet Metal

Shrinking The Sheet Metal

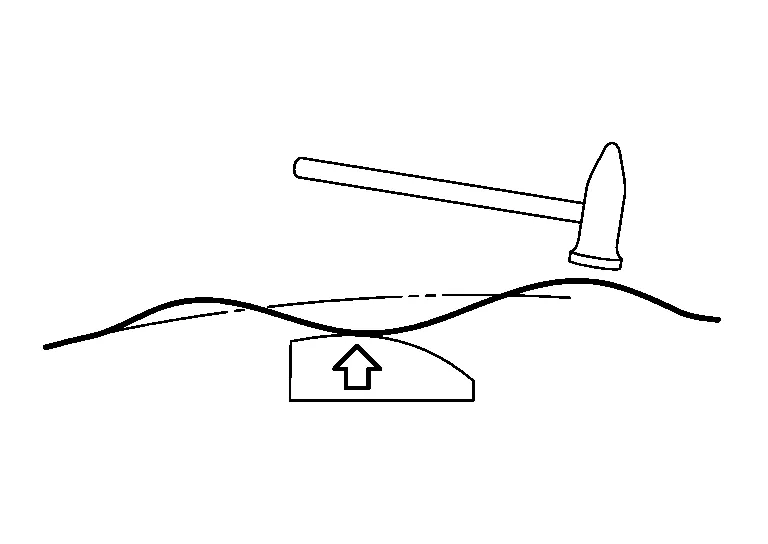

Plastic deformation may cause reduced panel thickness and the panel may stretch. Even when it is repaired using a hammer and dolly, the panel tends to bulge, losing its original shape...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Diagnostic Can Communication Circuit

Diagnosis Procedure CONNECTOR INSPECTION Turn the ignition switch OFF. Disconnect the battery cable from the negative terminal. Check the following terminals and connectors for damage, bend and loose connection (unit side and connector side). Data link connector 3CH CAN gateway Is the inspection result normal? YES>> GO TO 2...

Nissan Murano (Z52) 2015-2024 Owners Manual: Maintenance requirements

Some day-to-day and regular maintenance is essential to maintain your vehicle good mechanical condition, as well as its emissions and engine performance. It is the owner’s responsibility to make sure that the scheduled maintenance, as well as general maintenance, is performed...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Jacking up vehicle and removing the damaged tire

- System malfunction

- Indicator lights

- New on site

- Most important about car

Autolight system

The autolight system allows the headlights to turn on and off automatically. The autolight system can:

Turn on the headlights, front parking, tail, license plate and instrument panel lights automatically when it is dark. Turn off all the lights (except daylight running lights) when it is light. Keep all the lights on for a period of time after you place the ignition switch in the OFF position and all doors are closed.