Nissan Murano: Unit Disassembly and Assembly / Ring Gear Shaft

|

Oil seal |  |

Transfer cover |  |

Filler plug |

|

Gasket |  |

Drain plug |  |

Oil seal |

|

O-ring |  |

Ring gear bearing adjusting shim (transfer cover side) |  |

Ring gear bearing (transfer cover side) |

|

Drive shaft oil seal |  |

Ring gear shaft |  |

Ring gear bearing (transfer case side) |

|

Ring gear bearing adjusting shim (transfer case side) |  |

Ring gear |  |

Baffle plate |

|

Transfer case |  |

Plug |  |

O-ring |

|

Oil seal |  |

Dowel pin |  |

Drive pinion |

|

Drive pinion adjusting shim |  |

O-ring |  |

Pinion bearing assembly |

|

Oil seal |  |

Dust cover |  |

Companion flange |

|

Pinion lock nut | ||||

|

Oil seal lip |  |

Comply with the assembly procedure when tightening. Refer to Disassembly and Assembly. | ||

: N·m (kg-m, in-lb) : N·m (kg-m, in-lb) |

|||||

: N·m (kg-m, ft-lb) : N·m (kg-m, ft-lb) |

|||||

: Always replace after every disassembly. : Always replace after every disassembly. |

|||||

: Apply gear oil. : Apply gear oil. |

|||||

*: Apply anti-corrosive oil. *: Apply anti-corrosive oil. |

|||||

: Apply multi-purpose grease. : Apply multi-purpose grease. |

|||||

: Select with proper thickness. : Select with proper thickness. |

|||||

DISASSEMBLY

Remove transfer cover assembly. Refer to Disassembly and Assembly.

Remove ring gear bearing outer race (transfer cover side) and ring gear bearing adjusting shim (transfer cover side) from the transfer cover. Refer to Disassembly and Assembly.

Remove ring gear shaft assembly from the transfer case.

Remove ring gear bearing outer race (transfer case side) and ring gear bearing adjusting shim (transfer case side) from the transfer case. Refer to Disassembly and Assembly.

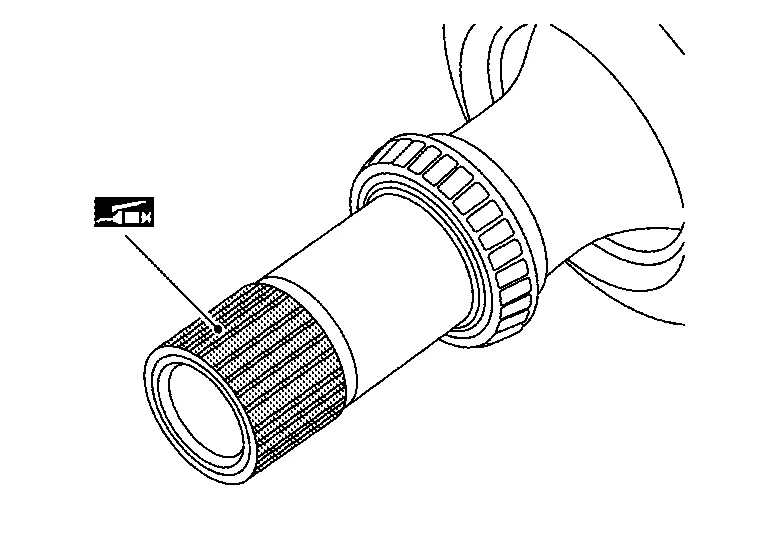

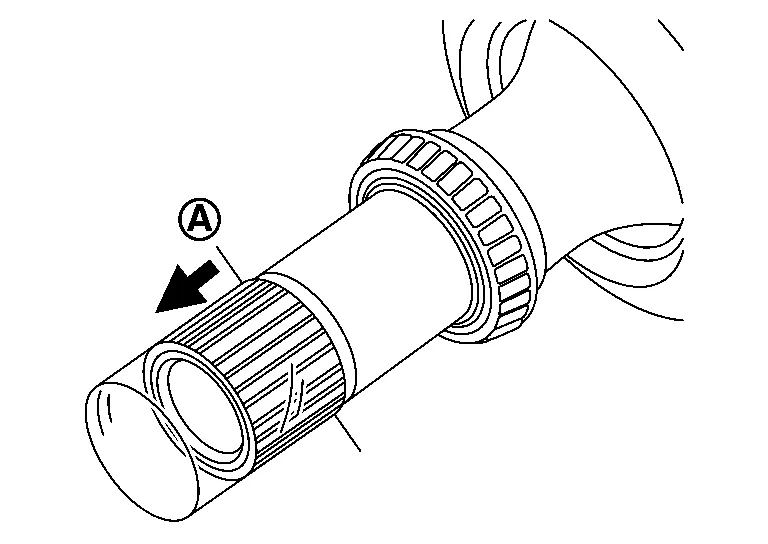

Remove ring gear bearing inner race (transfer cover side) from ring gear shaft with drift (A) (commercial service tool) and bearing separator (commercial service tool).

Remove ring gear bearing inner race (transfer case side) from ring gear shaft with Tool (A) and puller (commercial service tool).

| Tool number | : ST33061000 (J-8107–2) |

Remove the ring gear mounting bolts.

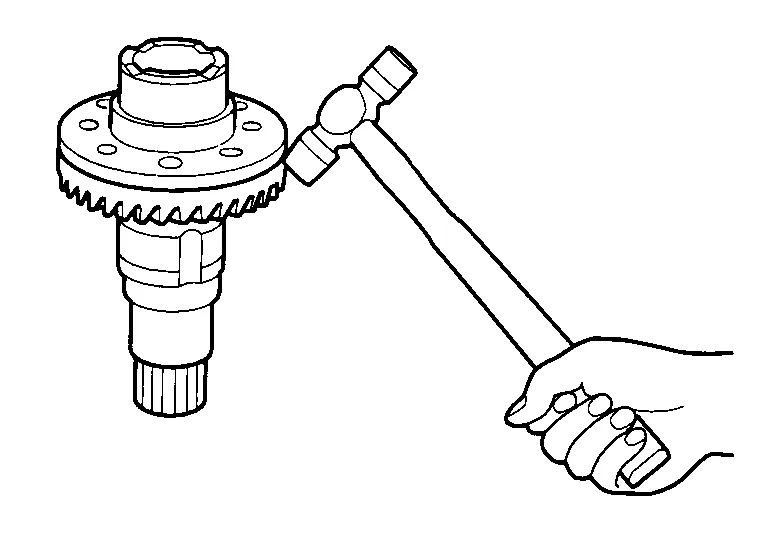

Lightly tap ring gear with a plastic hammer to remove ring gear from the ring gear shaft.

Remove drive shaft oil seal from the ring gear shaft using Tool (A).

| Tool number | : KV381054S0 (J-34286) |

Perform inspection after disassembly. Refer to Inspection.

ASSEMBLY

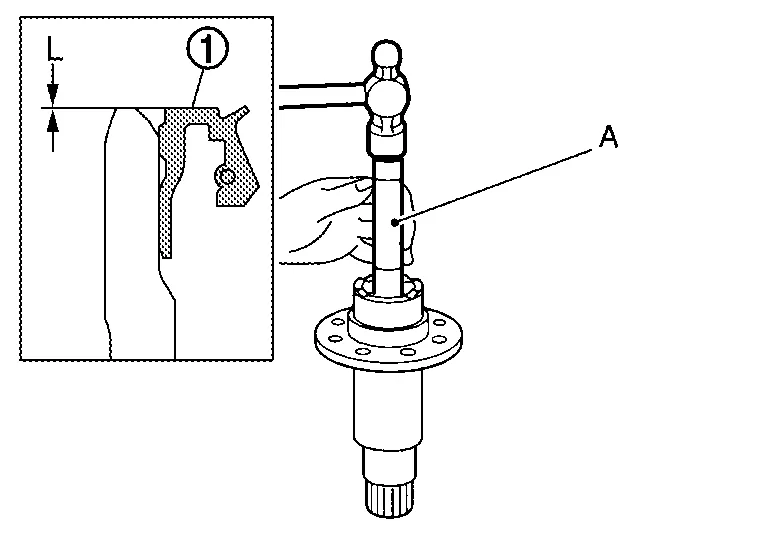

Using drift (A) (commercial service tool), install drive shaft oil seal  within the dimension (L) shown as follows.

within the dimension (L) shown as follows.

| L | : 2.0 +0.6/−0 mm (0.079 +0.024/−0 in) |

CAUTION:

-

Do not reuse the oil seal.

-

When installing, Do not incline oil seal.

-

Apply multi-purpose grease onto oil seal lips, and gear oil onto the circumference of the oil seal.

Select ring gear bearing adjusting shim (transfer case side) and ring gear bearing adjusting shim (transfer cover side). Refer to Adjustment.

Assemble the selected ring gear bearing adjusting shim (transfer case side) and ring gear bearing outer race (transfer case side) to transfer case. Refer to Disassembly and Assembly.

CAUTION:

-

Do not reuse ring gear bearing.

-

Apply gear oil to the ring gear bearing.

Assemble the selected ring gear bearing adjusting shim (transfer cover side) and ring gear bearing outer race (transfer cover side) to transfer cover. Refer to Disassembly and Assembly.

CAUTION:

-

Do not reuse ring gear bearing.

-

Apply gear oil to the ring gear bearing.

Install the ring gear to ring gear shaft, and tighten mounting bolts to the specified torque.

Install ring gear bearing inner race (transfer cover side) with drift (A) (commercial service tool).

CAUTION:

-

Do not reuse ring gear bearing.

-

Apply gear oil to the ring gear bearing.

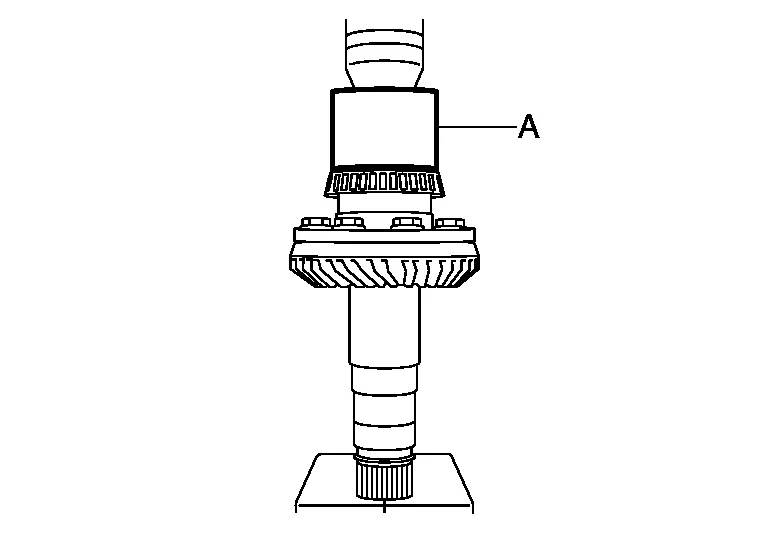

Install the ring gear bearing inner race (transfer case side) to ring gear shaft with drift (A) (commercial service tool).

CAUTION:

-

Do not reuse ring gear bearing.

-

Apply gear oil to the ring gear bearing.

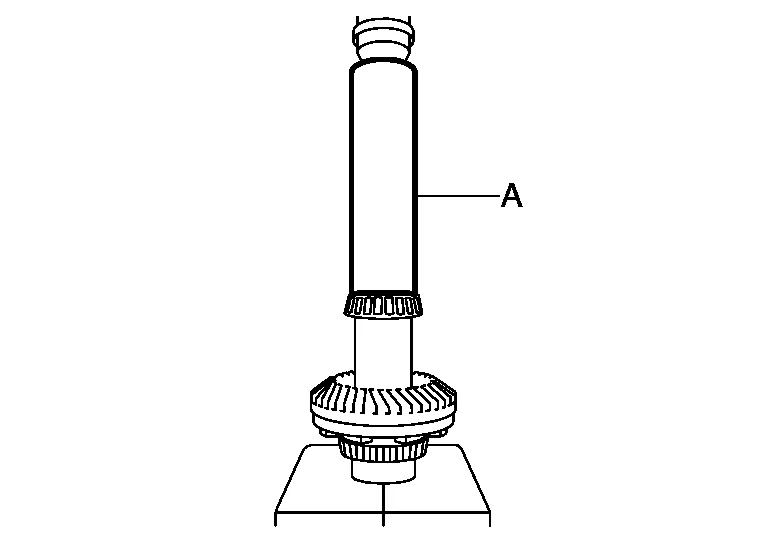

Install the ring gear shaft assembly to the transfer case.

CAUTION:

Protect transfer case oil seals beforehand from being damaged by the spline of ring gear shaft below method following.

Apply multi-purpose grease to spline part indicated in the figure.

: limit line)

: limit line)

CAUTION:

Do not wrap sliding surfaces on oil seal.

Install transfer cover to check and adjust each part. Refer to Disassembly and Assembly.

NOTE:

NOTE:

At this timing, O-ring installing to transfer cover is not necessary. Install O-ring after backlash and tooth contact are checked.

Check backlash, tooth contact, total preload and companion flange runout. Refer to Adjustment.

CAUTION:

Measure the total preload without oil seals of transfer cover and transfer case.

Reinstall transfer cover for installing O-ring. Refer to Disassembly and Assembly.

After installing transfer case oil seals, remove wrapped vinyl from the spline of ring gear shaft.

INSPECTION AFTER DISASSEMBLY

Check items below. If necessary, replace them with new ones.

Gear and Shaft

Check gear face and shaft for wear, cracks, damage, and seizure.

CAUTION:

If malfunction is detected on the ring gear or drive pinion, replace the ring gear and drive pinion as a set.

Bearing

Check for seizure, peeling, wear, corrosion, sticking, unusual noise, roughness in hand turning, and other damage.

CAUTION:

When replacing the bearing, always replace the inner race and outer race as a pair.

Shim

Check for seizure, damage, and unusual wear.

Replace defective parts as necessary.

Transfer Cover

Transfer Cover

Exploded View

Oil seal

Transfer cover

Filler plug

Gasket

Drain plug

Oil seal

O-ring

Ring gear bearing adjusting shim (transfer cover side)

Ring gear bearing (transfer cover side)

Drive shaft oil seal

Ring gear shaft

Ring gear bearing (transfer case side)

Ring gear bearing adjusting shim (transfer case side)

Ring gear

Baffle plate

Transfer case

Plug

O-ring

Oil seal

Dowel pin

Drive pinion

Drive pinion adjusting shim

O-ring

Pinion bearing assembly

Oil seal

Dust cover

Companion flange

Pinion lock nut

Oil seal lip

Comply with the assembly procedure when tightening...

Drive Pinion

Drive Pinion

Exploded View

Oil seal

Transfer cover

Filler plug

Gasket

Drain plug

Oil seal

O-ring

Ring gear bearing adjusting shim (transfer cover side)

Ring gear bearing (transfer cover side)

Drive shaft oil seal

Ring gear shaft

Ring gear bearing (transfer case side)

Ring gear bearing adjusting shim (transfer case side)

Ring gear

Baffle plate

Transfer case

Plug

O-ring

Oil seal

Dowel pin

Drive pinion

Drive pinion adjusting shim

O-ring

Pinion bearing assembly

Oil seal

Dust cover

Companion flange

Pinion lock nut

Oil seal lip

Comply with the assembly procedure when tightening...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: P1800 Vias Control Solenoid Valve 1

DTC Description DTC DETECTION LOGICAn excessively low or high voltage signal is sent to ECM through the VIAS control solenoid valve 1. DTC CONSULT screen terms (Trouble diagnosis content) DTC detection condition P1800 VIAS S/V CIRC-B1 (VIAS solenoid valve circuit bank 1) Diagnosis condition Start engine and let it idle Signal (terminal) VIAS control solenoid valve 1 signal Threshold An excessively low or high voltage signal is sent to ECM Diagnosis delay time — POSSIBLE CAUSE Harness or connectors (Input speed sensor circuit is open or shorted) VIAS control solenoid valve 1 FAIL-SAFENot applicable DTC Confirmation Procedure CONDITIONING If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test...

Nissan Murano (Z52) 2015-2024 Service Manual: C1b0a-16 Power Supply Circuit2

DTC Description DTC DETECTION LOGIC DTC No. CONSULT screen terms (Trouble diagnosis content) DTC detection condition C1B0A-16 POWER SUPPLY CIRCUIT2 (Power supply circuit) Diagnosis condition When ignition switch is ON. Signal (terminal) - Threshold Lane camera unit ignition voltage is less than 10...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- High Beam Assist (if so equipped)

- Shift lock release

- Passenger compartment

- New on site

- Most important about car

Fuel gauge

The gauge indicates the approximate fuel level in the tank.

The gauge may move slightly during braking, turning, acceleration, or going up or down hills.

The gauge needle returns to 0 (Empty) after the ignition switch is placed in the OFF position.