Nissan Murano: Unit Disassembly and Assembly / Transfer Cover

|

Oil seal |  |

Transfer cover |  |

Filler plug |

|

Gasket |  |

Drain plug |  |

Oil seal |

|

O-ring |  |

Ring gear bearing adjusting shim (transfer cover side) |  |

Ring gear bearing (transfer cover side) |

|

Drive shaft oil seal |  |

Ring gear shaft |  |

Ring gear bearing (transfer case side) |

|

Ring gear bearing adjusting shim (transfer case side) |  |

Ring gear |  |

Baffle plate |

|

Transfer case |  |

Plug |  |

O-ring |

|

Oil seal |  |

Dowel pin |  |

Drive pinion |

|

Drive pinion adjusting shim |  |

O-ring |  |

Pinion bearing assembly |

|

Oil seal |  |

Dust cover |  |

Companion flange |

|

Pinion lock nut | ||||

|

Oil seal lip |  |

Comply with the assembly procedure when tightening. Refer to Disassembly and Assembly. | ||

: N·m (kg-m, in-lb) : N·m (kg-m, in-lb) |

|||||

: N·m (kg-m, ft-lb) : N·m (kg-m, ft-lb) |

|||||

: Always replace after every disassembly. : Always replace after every disassembly. |

|||||

: Apply gear oil. : Apply gear oil. |

|||||

*: Apply anti-corrosive oil. *: Apply anti-corrosive oil. |

|||||

: Apply multi-purpose grease. : Apply multi-purpose grease. |

|||||

: Select with proper thickness. : Select with proper thickness. |

|||||

DISASSEMBLY

Remove transfer cover mounting bolts ( ).

).

Lightly tap transfer cover  with a plastic hammer to remove transfer cover.

with a plastic hammer to remove transfer cover.

Remove O-ring from transfer cover.

CAUTION:

-

Do not use a tool.

-

Do not damage transfer cover.

-

Do not reuse O—ring.

Lightly tap the metal part of oil seals  with punch from back side of transfer cover to remove oil seals.

with punch from back side of transfer cover to remove oil seals.

CAUTION:

-

When removing, Do not damage the transfer cover by scooping it out with a tool.

-

Do not reuse oil seal.

Remove the ring gear bearing adjusting shim (transfer cover side)  and ring gear bearing outer race (transfer cover side)

and ring gear bearing outer race (transfer cover side)  using drift (commercial service tool).

using drift (commercial service tool).

Remove drain plug and gasket.

Remove filler plug and gasket.

Perform inspection after disassembly. Refer to Inspection.

ASSEMBLY

Select the ring gear bearing adjusting shim (transfer cover side). Refer to Adjustment.

Install the selected ring gear bearing adjusting shim (transfer cover side)  and ring gear bearing outer race (transfer cover side)

and ring gear bearing outer race (transfer cover side)  using drift (commercial service tool).

using drift (commercial service tool).

CAUTION:

-

Do not reuse ring gear bearing.

-

Apply gear oil to the ring gear bearing.

Install gasket onto drain plug and install them to transfer cover.

CAUTION:

Do not reuse gasket.

Install the transfer cover to the transfer case, and apply anti-corrosive oil onto thread and seats on the mounting bolts. Then tighten mounting bolts to the specified torque.

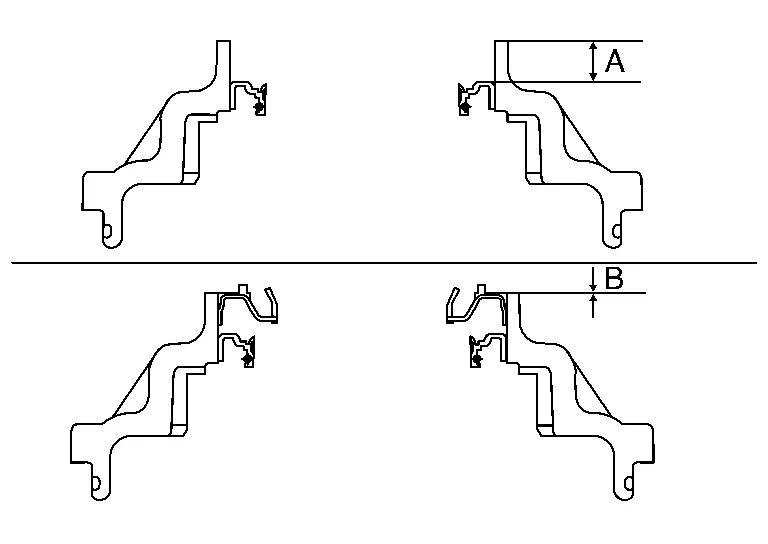

| A | : M10 bolt |

| B | : M8 bolt |

NOTE:

NOTE:

At this timing, O-ring installing to transfer cover is not necessary. Install O-ring after tooth contact is checked.

Check backlash, tooth contact, total preload and companion flange runout. Refer to Adjustment.

CAUTION:

Measure the total preload without oil seals of transfer cover and transfer case.

Remove transfer cover to install O-ring.

Apply multi-purpose grease lightly and evenly onto an O-ring, and install it to the transfer cover.

CAUTION:

-

Do not reuse O-ring.

-

When installing O-ring, Do not use a tool.

-

Do not damage O-ring.

Install the transfer cover to the transfer case, and apply anti-corrosive oil onto thread and seats on the mounting bolts. Then tighten mounting bolts to the specified torque.

| A | : M10 bolt |

| B | : M8 bolt |

Using drift (commercial service tool), drive the transfer cover oil seals.

| A | : 10.3 +0.6/-0 mm (0.406 +0.024/-0 in) |

| B | : 0 +0.6/-0 mm (0 +0.024/-0 in) |

CAUTION:

-

When checking the total preload torque, measure it without the oil seal, then install the oil seal.

-

Do not reuse the oil seal.

-

When installing, Do not incline oil seal.

-

Apply multi-purpose grease onto oil seal lips, and gear oil onto the circumference of the oil seal.

Install gasket onto filler plug and install them to transfer cover.

CAUTION:

-

Do not reuse gasket.

-

Install filler plug after oil is filled.

INSPECTION AFTER DISASSEMBLY

Check items below. If necessary, replace them with new ones.

transfer cover

Check the bearing mounting surface for wear, cracks and damages.

Check the bearing mounting surface for wear, cracks, and damages.

Replace mounting surface parts as necessary.

Ring Gear Shaft

Ring Gear Shaft

Exploded View

Oil seal

Transfer cover

Filler plug

Gasket

Drain plug

Oil seal

O-ring

Ring gear bearing adjusting shim (transfer cover side)

Ring gear bearing (transfer cover side)

Drive shaft oil seal

Ring gear shaft

Ring gear bearing (transfer case side)

Ring gear bearing adjusting shim (transfer case side)

Ring gear

Baffle plate

Transfer case

Plug

O-ring

Oil seal

Dowel pin

Drive pinion

Drive pinion adjusting shim

O-ring

Pinion bearing assembly

Oil seal

Dust cover

Companion flange

Pinion lock nut

Oil seal lip

Comply with the assembly procedure when tightening...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Body Side Welt

Removal and Installation - Front Door Welt REMOVALRemove center pillar upper finisher. Refer to Removal and Installation. Remove front body side welt.INSTALLATIONInstallation is in the reverse order of removal. Removal and Installation - Rear Door Welt REMOVALRemove center pillar upper finisher...

Nissan Murano (Z52) 2015-2024 Service Manual: Sonar System :: Ecu Diagnosis Information. Sonar Control Unit

Values on the Diagnosis Tool NOTE: The following table includes information (items) inapplicable to this Nissan Murano vehicle. For information (items) applicable to this vehicle, refer to CONSULT display items. Monitor Item Condition Value/Status Nissan Murano Vehicle SPEED While driving, equivalent to speedometer reading mph, km/h SONAR C/U POWER SUPPLY Key ON...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Jacking up vehicle and removing the damaged tire

- High Beam Assist (if so equipped)

- Checking engine oil level

- New on site

- Most important about car

Luggage hooks

When securing items using luggage hooks located on the back of the seat or side finisher do not apply a load over more than 6.5 lbs. (29 N) to a single hook.

The luggage hooks that are located on the floor should have loads less than 110 lbs. (490 N) to a single hook.