Nissan Murano: Compressor / Magnet Clutch

REMOVAL

Remove the compressor. Refer to Removal and Installation.

Remove the center bolt by holding the clutch disc steady using a suitable tool.

Remove the clutch disc and shim.

CAUTION:

Retain all the shims for installation.

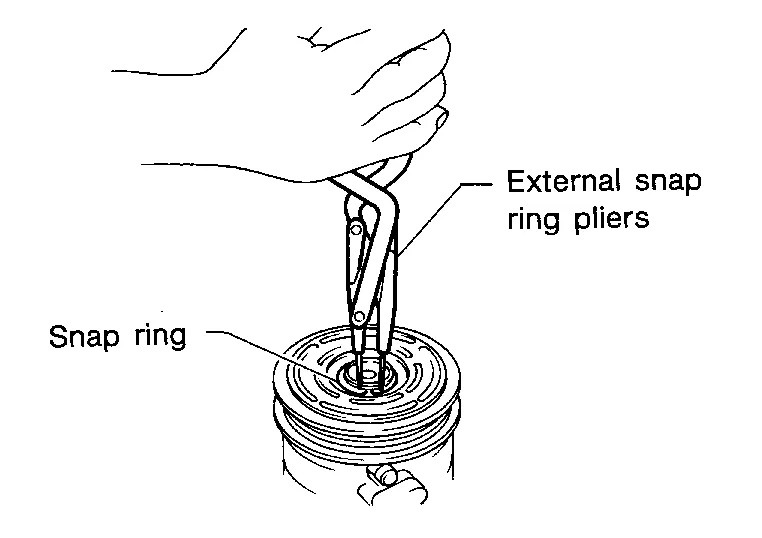

Remove the snap ring using a suitable tool as shown.

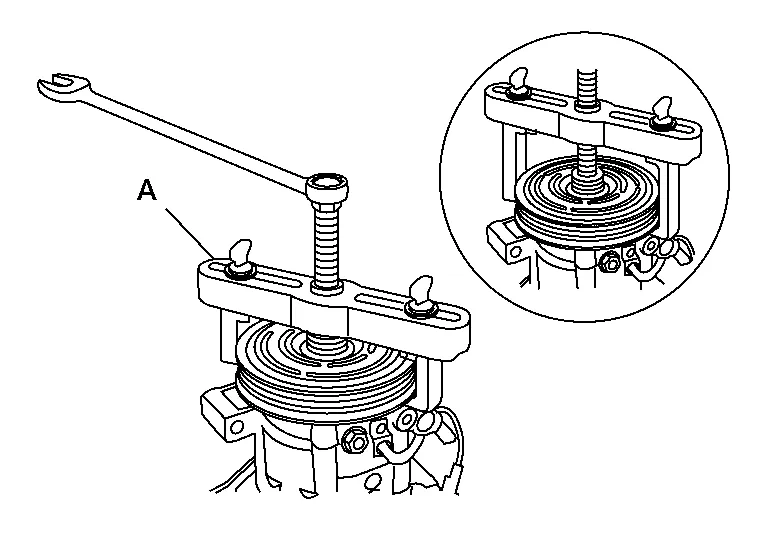

Remove the pulley assembly using a suitable tool (A) as shown.

CAUTION:

To prevent deformation of the pulley groove, the puller claws should be hooked under (not into) the pulley groove.

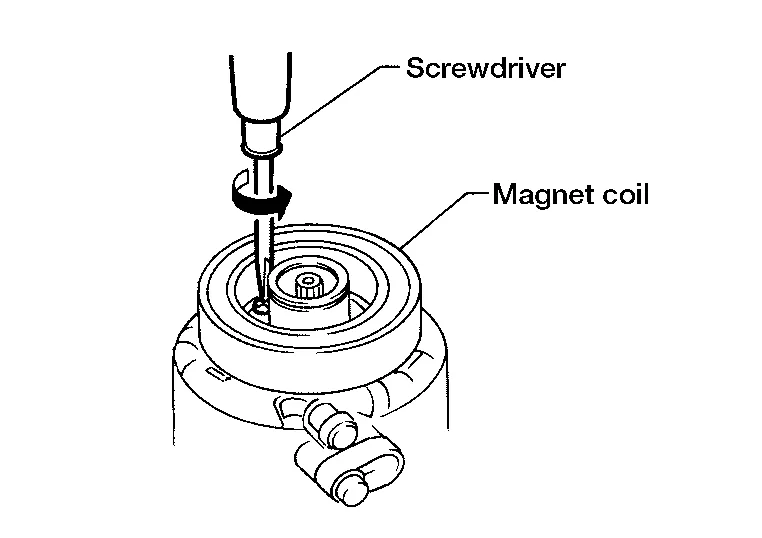

Disconnect the harness connector from the magnet coil.

Remove the three magnet coil screws using a suitable tool as shown then remove the magnet coil.

INSPECTION AFTER REMOVAL

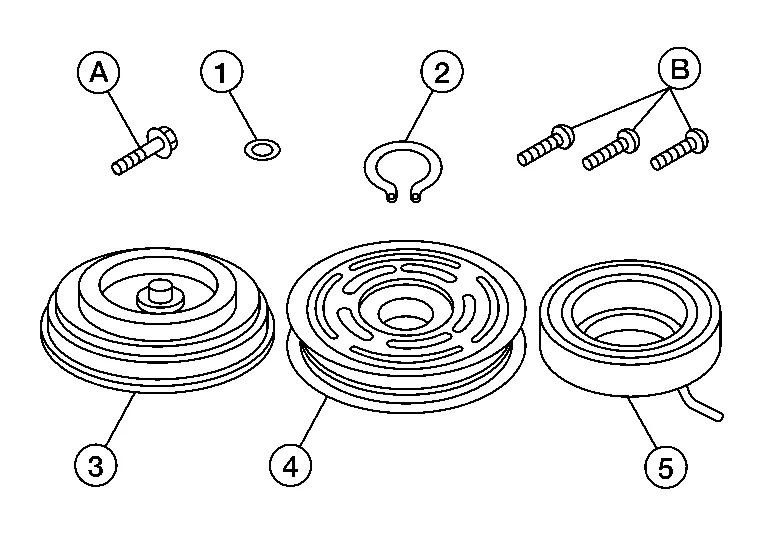

-

(1): Shim

-

(2): Snap ring

-

(3): Clutch disc

-

(4): Pulley

-

(5): Magnet coil

-

(A): Center bolt

-

(B): Magnet coil screws

Clutch Disc

If the contact surface shows signs of damage due to excessive heat, replace as necessary.

Pulley

Check the appearance of the pulley assembly. If the contact surface of the pulley shows signs of excessive grooving, replace as necessary. The contact surfaces of the pulley assembly should be cleaned with a suitable solvent before installation.

Magnet Coil

Check the magnet coil for a loose connection or cracked insulation. Replace as necessary.

INSTALLATION

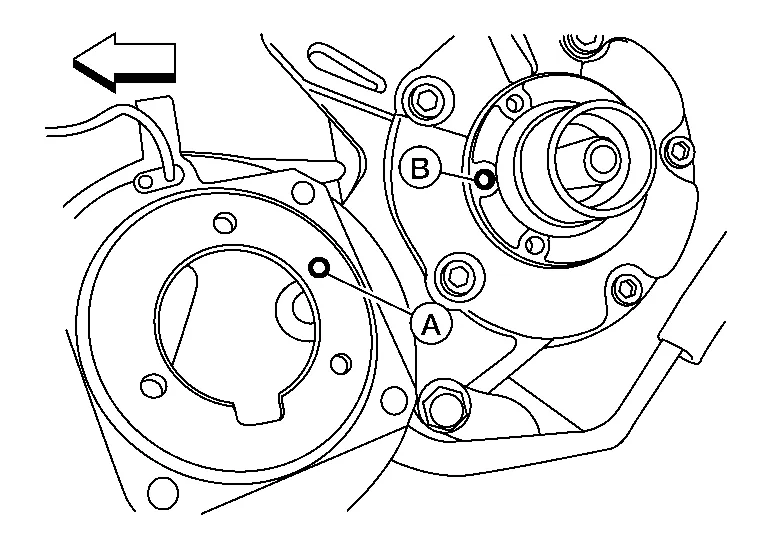

Install the magnet coil by aligning the magnet coil pin (A) with the hole (B) in the compressor front head as shown then install the magnet coil screws.

-

: Nissan Murano Vehicle rear

: Nissan Murano Vehicle rear

CAUTION:

-

Be sure to align the magnet coil pin with the hole in the compressor front head.

Connect the magnet coil harness to the compressor body.

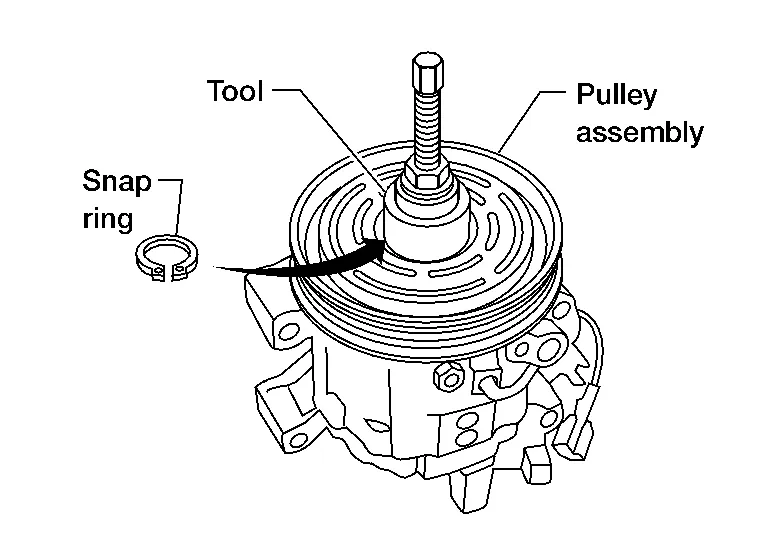

Install the pulley assembly using Tool and a wrench as shown then install the snap ring using a suitable tool.

| Tool number | : — (J-38873-A) |

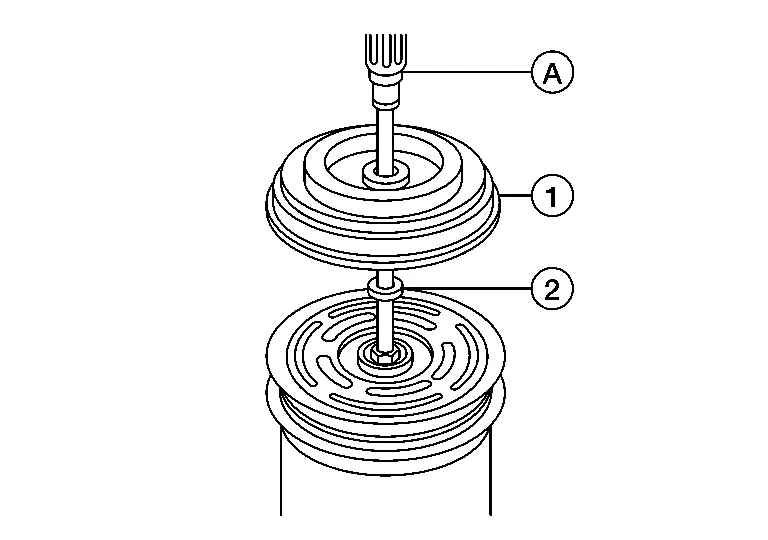

Install the clutch disc (1) on the drive shaft together with all of the original shim(s) (2) using a suitable tool (A).

Install the center bolt using a suitable tool.

Install the compressor. Refer to Removal and Installation.

INSPECTION AFTER INSTALLATION

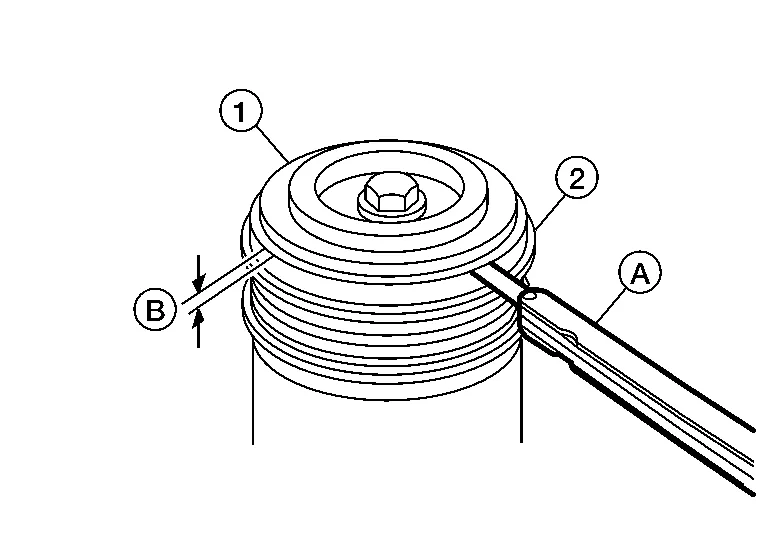

Check the clearance (B) all the way around between the clutch disc (1) and pulley (2) using a suitable tool (A) as shown.

| Clutch disc-to-pulley clearance (B) | : Refer to Compressor. |

If the specified clearance (B) is not obtained, replace the adjusting shims and recheck the clearance (B) as shown.

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engaging and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

Compressor

Compressor

Removal and Installation

REMOVALDischarge the refrigerant. Refer to Recycle Refrigerant.

Partially remove the front edge of the front fender protector (RH)...

Cooler Pipe and Hose

Cooler Pipe and Hose

Exploded View

1.

Heating and cooling unit assembly

2.

Internal heat exchanger

3.

High-pressure pipe

4.

Condenser

5.

Compressor

6...

Other information:

Nissan Murano (Z52) 2015-2024 Owners Manual: Engine oil and oil filter recommendations

Selecting the correct oil It is essential to choose the correct grade, quality and viscosity engine oil to ensure satisfactory engine life and performance. For additional information, refer to “Recommended fluids/lubricants and capacities” in this section...

Nissan Murano (Z52) 2015-2024 Service Manual: B1360 Combination Meter

DTC Description DTC DETECTION LOGIC DTC No. CONSULT screen terms (Trouble diagnosis content) DTC detection condition B1360–02 Combination meter (Combination meter connection error) Diagnosis condition When ignition switch is ON. Signal (terminal) — Threshold — Diagnosis delay time — POSSIBLE CAUSE AV communication circuit is open Combination meter FAIL-SAFESteering switch is inoperative DTC Confirmation Procedure PERFORM DTC CONFIRMATION PROCEDURE CONSULT Ignition switch ON...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Intelligent Forward Collision Warning (I-FCW)

- Checking engine oil level

- All-Wheel Drive (AWD) (if so equipped)

- New on site

- Most important about car

LATCH (Lower Anchors and Tethers for CHildren) system

LATCH system lower anchor locations - bench seat

Your vehicle is equipped with special anchor points that are used with LATCH system compatible child restraints. This system may also be referred to as the ISOFIX or ISOFIX compatible system. With this system, you do not have to use a vehicle seat belt to secure the child restraint unless the combined weight of the child and child restraint exceeds 65 lbs. (29.5 kg). If the combined weight of the child and child restraint is greater than 65 lbs. (29.5 kg), use the vehicle’s seat belt (not the lower anchors) to install the child restraint. Be sure to follow the child restraint manufacturer’s instructions for installation.