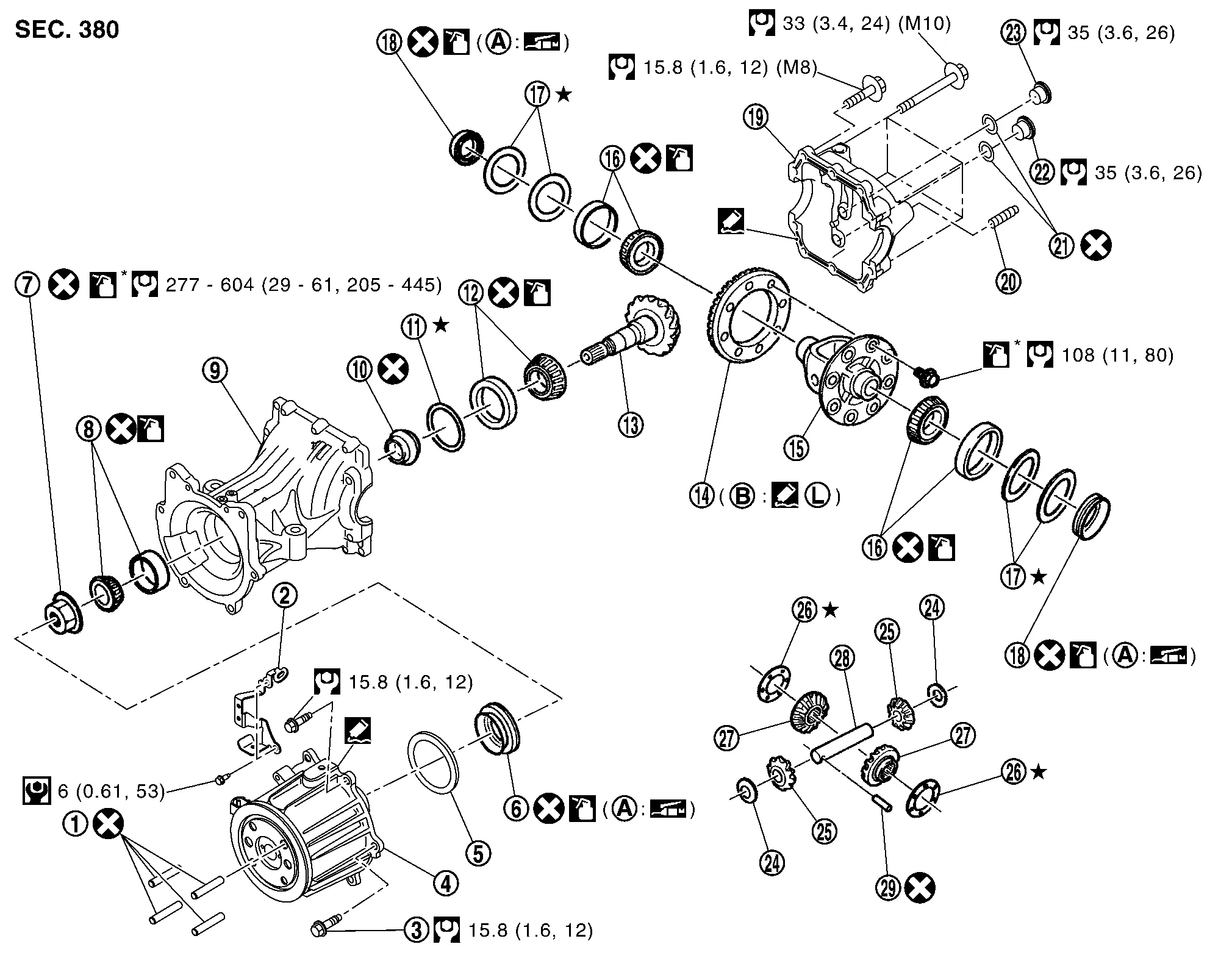

Nissan Murano: Unit Disassembly and Assembly / Electric Controlled Coupling

|

Stud bolt |  |

Connector bracket |  |

Reamer bolt |

|

Electric controlled coupling assembly |  |

Wave spring |  |

Drive pinion oil seal |

|

Drive pinion lock nut |  |

Pinion front bearing |  |

Gear carrier |

|

Collapsible spacer |  |

Drive pinion adjusting shim |  |

Pinion rear bearing |

|

Drive pinion |  |

Drive gear |  |

Differential case |

|

Side bearing |  |

Side bearing adjusting shim |  |

Side oil seal |

|

Rear cover |  |

Stud bolt |  |

Gasket |

|

Drain plug |  |

Filler plug |  |

Pinion mate thrust washer |

|

Pinion mate gear |  |

Side gear thrust washer |  |

Side gear |

|

Pinion mate shaft |  |

Lock pin | ||

|

Oil seal lip |  |

Screw hole | ||

: N·m (kg-m, in-lb) : N·m (kg-m, in-lb) |

|||||

: N·m (kg-m, ft-lb) : N·m (kg-m, ft-lb) |

|||||

: Always replace after every disassembly. : Always replace after every disassembly. |

|||||

: Select with proper thickness. : Select with proper thickness. |

|||||

: Apply gear oil. : Apply gear oil. |

|||||

*: Apply anti-corrosion oil. *: Apply anti-corrosion oil. |

|||||

: Apply multi purpose grease. : Apply multi purpose grease. |

|||||

: Apply Genuine Silicone RTV or equivalent. Refer to Recommended Chemical Products and Sealants. : Apply Genuine Silicone RTV or equivalent. Refer to Recommended Chemical Products and Sealants. |

|||||

: Apply Genuine High Strength Thread Locking Sealant or equivalent. Refer to Recommended Chemical Products and Sealants. : Apply Genuine High Strength Thread Locking Sealant or equivalent. Refer to Recommended Chemical Products and Sealants. |

|||||

NOTE:

NOTE:

-

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

-

Before replacing electric controlled coupling due to vibration and/or noise when making low speed turns, refer to TSB to assist in proper diagnosis.

DISASSEMBLY

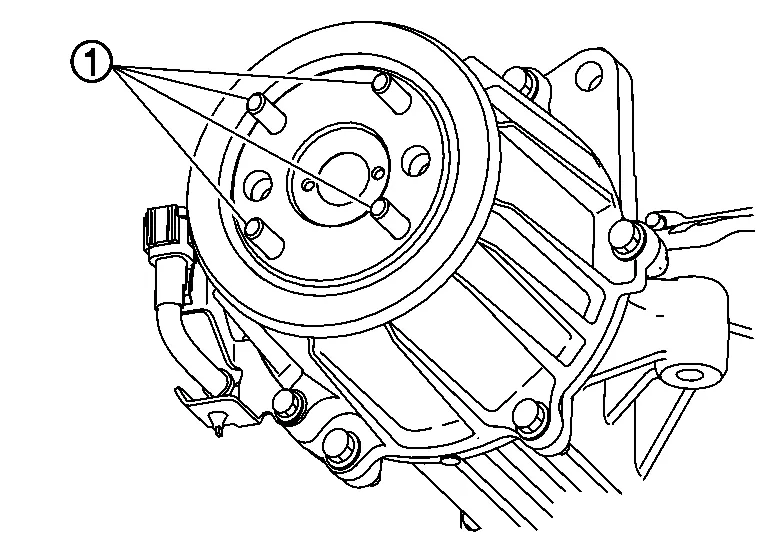

Remove stud bolts  .

.

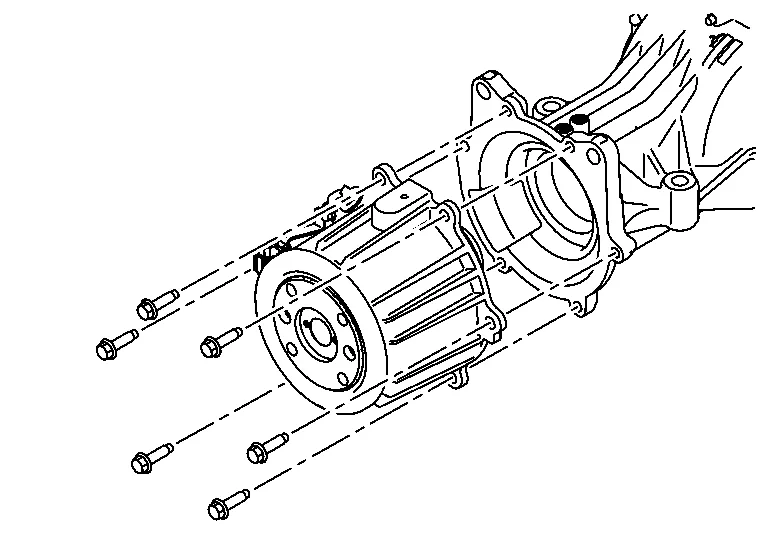

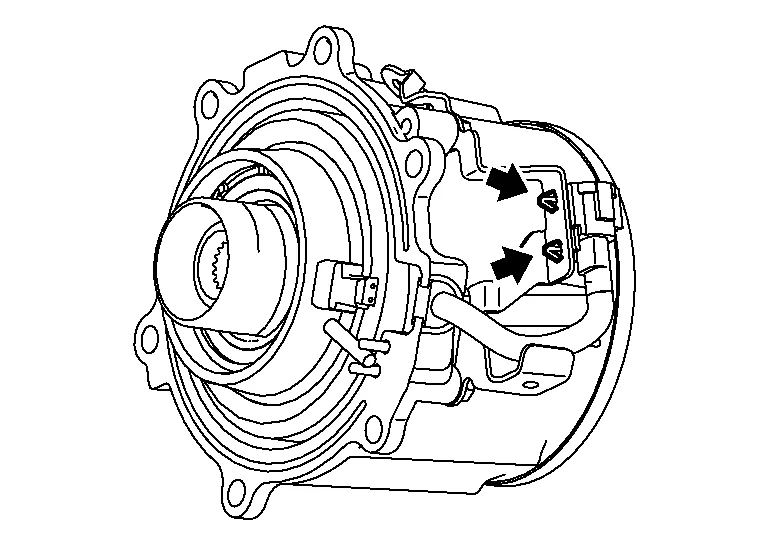

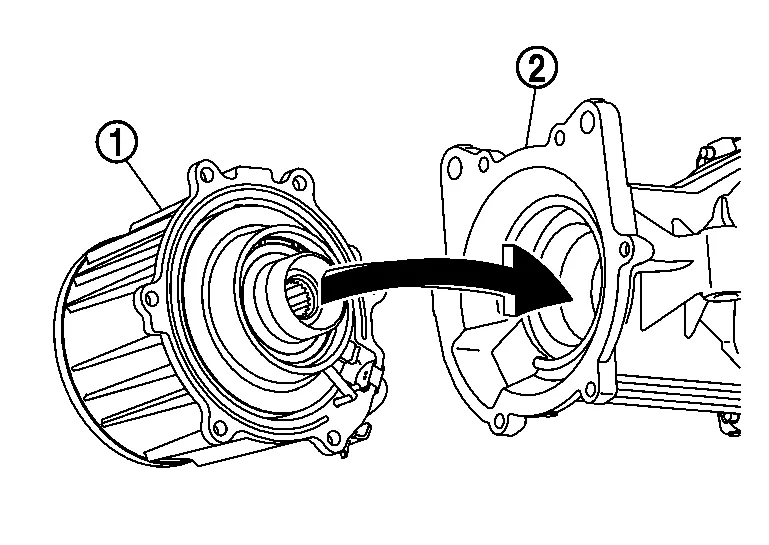

Remove electric controlled coupling assembly from final drive assembly.

Remove wave spring.

Remove drive pinion oil seal from the inside of gear carrier. Refer to Disassembly and Assembly.

CAUTION:

When removing electric controlled coupling, replace drive pinion oil seal.

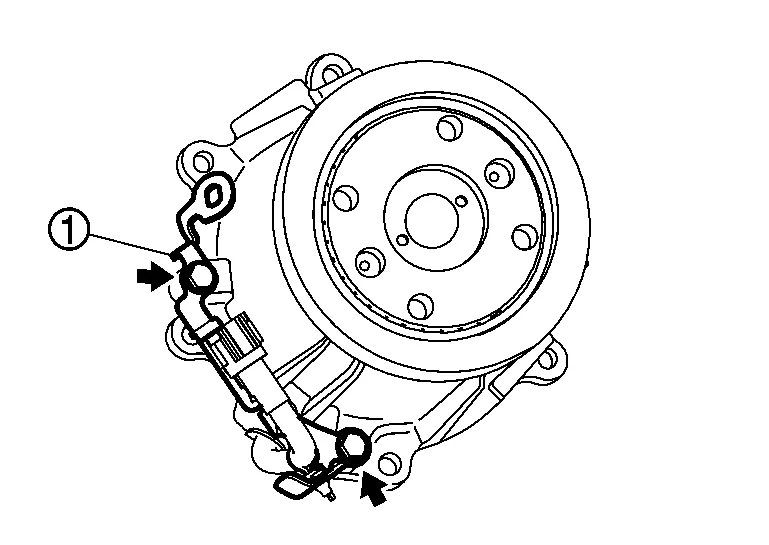

Remove connector bracket  from electric controlled coupling.

from electric controlled coupling.

Separate connector clip from connector bracket.

ASSEMBLY

Install connector bracket to electric controlled coupling.

-

For tightening torque, refer to Exploded View.

Join AWD solenoid harness with connector clip.

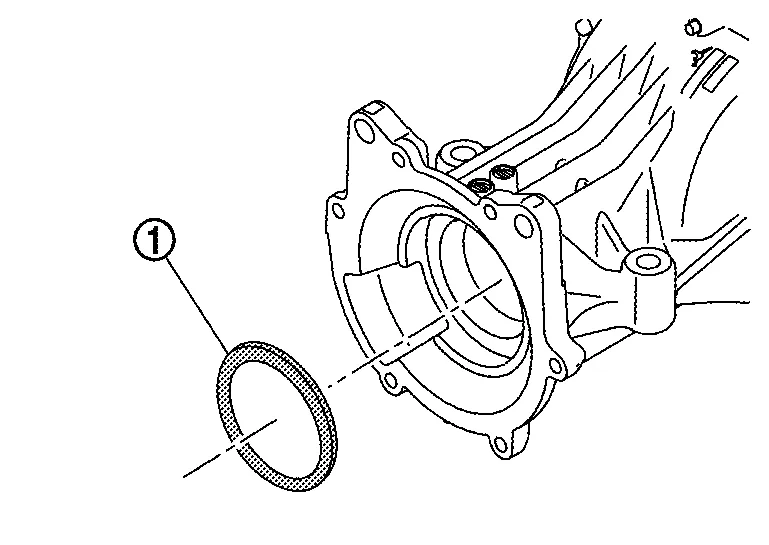

Install drive pinion oil seal to the inside of gear carrier. Refer to Disassembly and Assembly.

CAUTION:

When removing electric controlled coupling, replace drive pinion oil seal.

Install wave spring  to the inside of gear carrier.

to the inside of gear carrier.

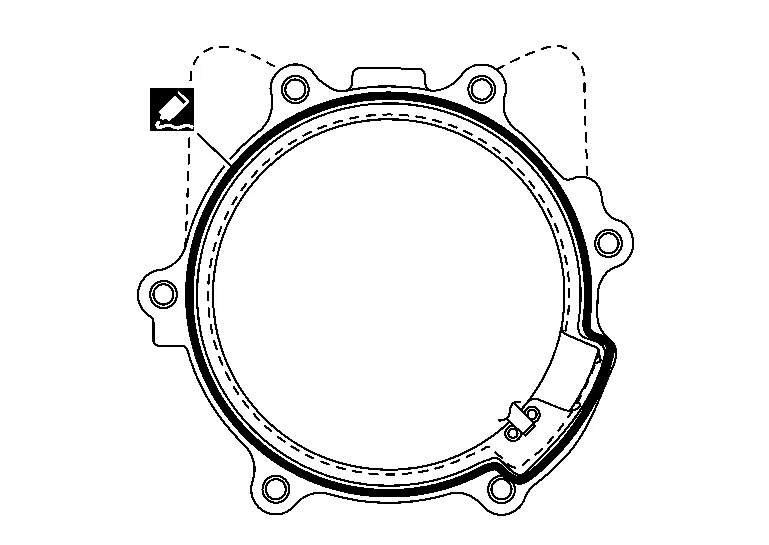

Apply liquid gasket to mating surface of electric controlled coupling assembly.

-

For applying liquid gasket, refer to Exploded View.

CAUTION:

-

Remove old gasket adhering to the mounting surfaces. Also remove any moisture, oil, or foreign material adhering to the mounting surfaces.

-

The width of sealant bead is approximately 3 mm (0.12 in). Apply sealant evenly.

Match electric controlled coupling assembly  to spline of drive pinion, then install it to final drive assembly

to spline of drive pinion, then install it to final drive assembly  .

.

CAUTION:

Be careful not to damage drive pinion oil seal.

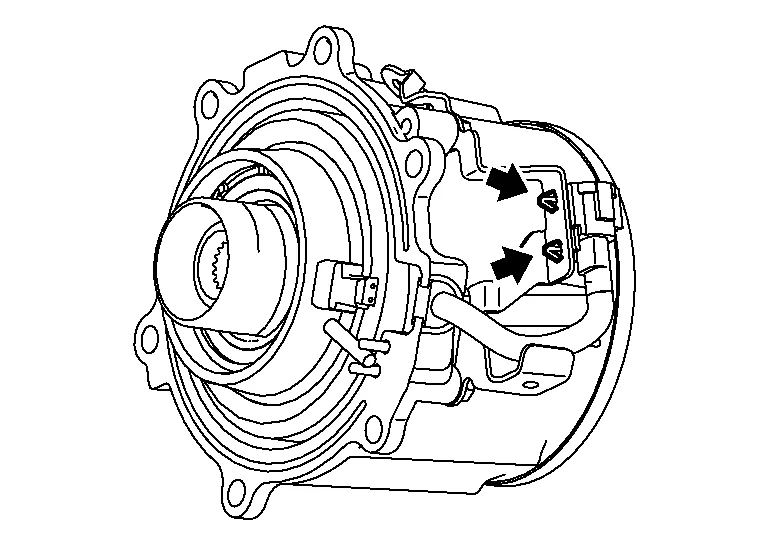

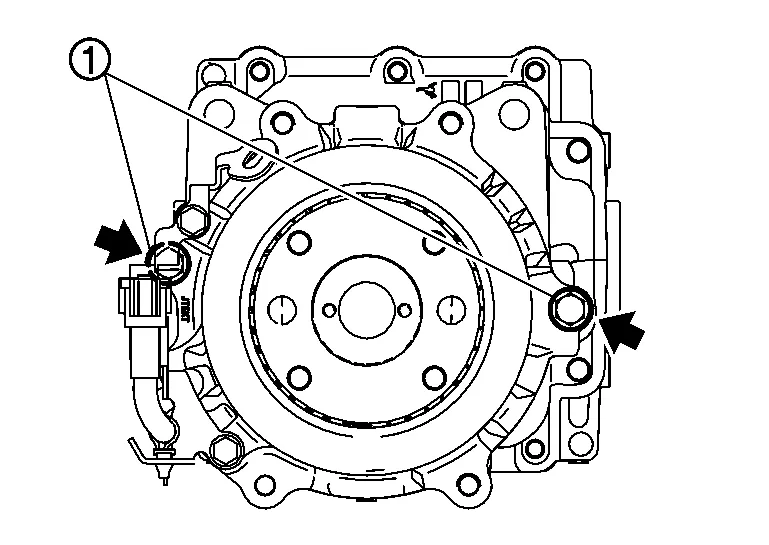

Temporarily tighten reamer bolts  to the positions shown in the figure.

to the positions shown in the figure.

Tighten reamer bolts and electric controlled coupling assembly mounting bolts to the specified torque.

-

For tightening torque, refer to Exploded View.

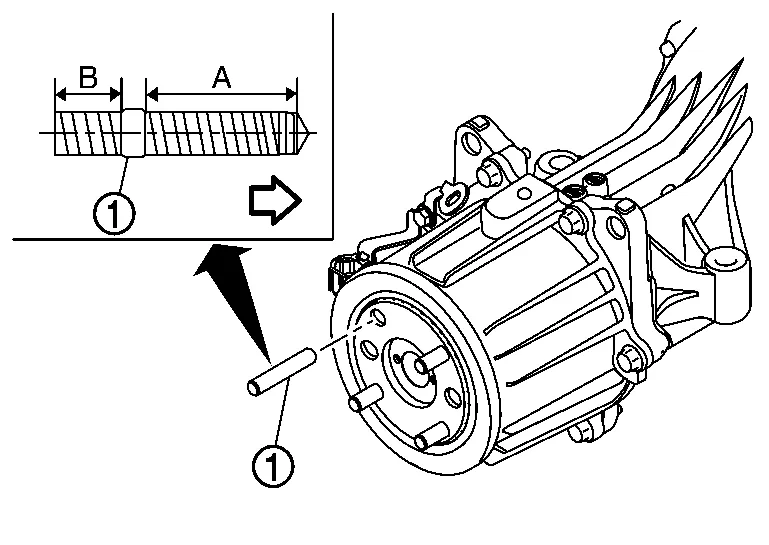

Install stud bolts  .

.

|

: Electric controlled coupling side |

| Thread length | |

| A | : Long |

| B | : Short |

CAUTION:

-

Do not reuse stud bolt.

-

Screw long thread side of stud bolt to electric controlled coupling.

-

Screw the stud bolt until the stop by applying a torque of 15 N·m (1.5 kg-m, 11 ft-lb) ±20%.

-

After installing stud bolt, the length of the protrusion from electric controlled coupling must be 19.8 mm (0.780 in) ±1.4 mm (0.055 in).

Differential Assembly

Differential Assembly

Exploded View

Stud bolt

Connector bracket

Reamer bolt

Electric controlled coupling assembly

Wave spring

Drive pinion oil seal

Drive pinion lock nut

Pinion front bearing

Gear carrier

Collapsible spacer

Drive pinion adjusting shim

Pinion rear bearing

Drive pinion

Drive gear

Differential case

Side bearing

Side bearing adjusting shim

Side oil seal

Rear cover

Stud bolt

Gasket

Drain plug

Filler plug

Pinion mate thrust washer

Pinion mate gear

Side gear thrust washer

Side gear

Pinion mate shaft

Lock pin

Oil seal lip

Screw hole

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: Always replace after every disassembly...

Other information:

Nissan Murano (Z52) 2015-2024 Owners Manual: TPMS with Easy-Fill Tire Alert

When adding air to an under-inflated tire, the TPMS with Easy-Fill Tire Alert provides visual and audible signals outside the vehicle to help you inflate the tires to the recommended COLD tire pressure. Vehicle set-up Park the vehicle in a safe and level place...

Nissan Murano (Z52) 2015-2024 Service Manual: C1160 Incomplete Decel G Sensor Calibration

DTC Description DTC DETECTION LOGIC DTC No. CONSULT screen item (Trouble diagnosis content) DTC detected condition C1160 DECEL G SEN SET (Decel G sensor set) Diagnosis condition When ignition switch ON. Signal (terminal) — Threshold When calibration of yaw rate/side/decel G sensor is not complete...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Intelligent Forward Collision Warning (I-FCW)

- Warning lights

- Rear bench seat adjustment

- New on site

- Most important about car

Luggage hooks

When securing items using luggage hooks located on the back of the seat or side finisher do not apply a load over more than 6.5 lbs. (29 N) to a single hook.

The luggage hooks that are located on the floor should have loads less than 110 lbs. (490 N) to a single hook.