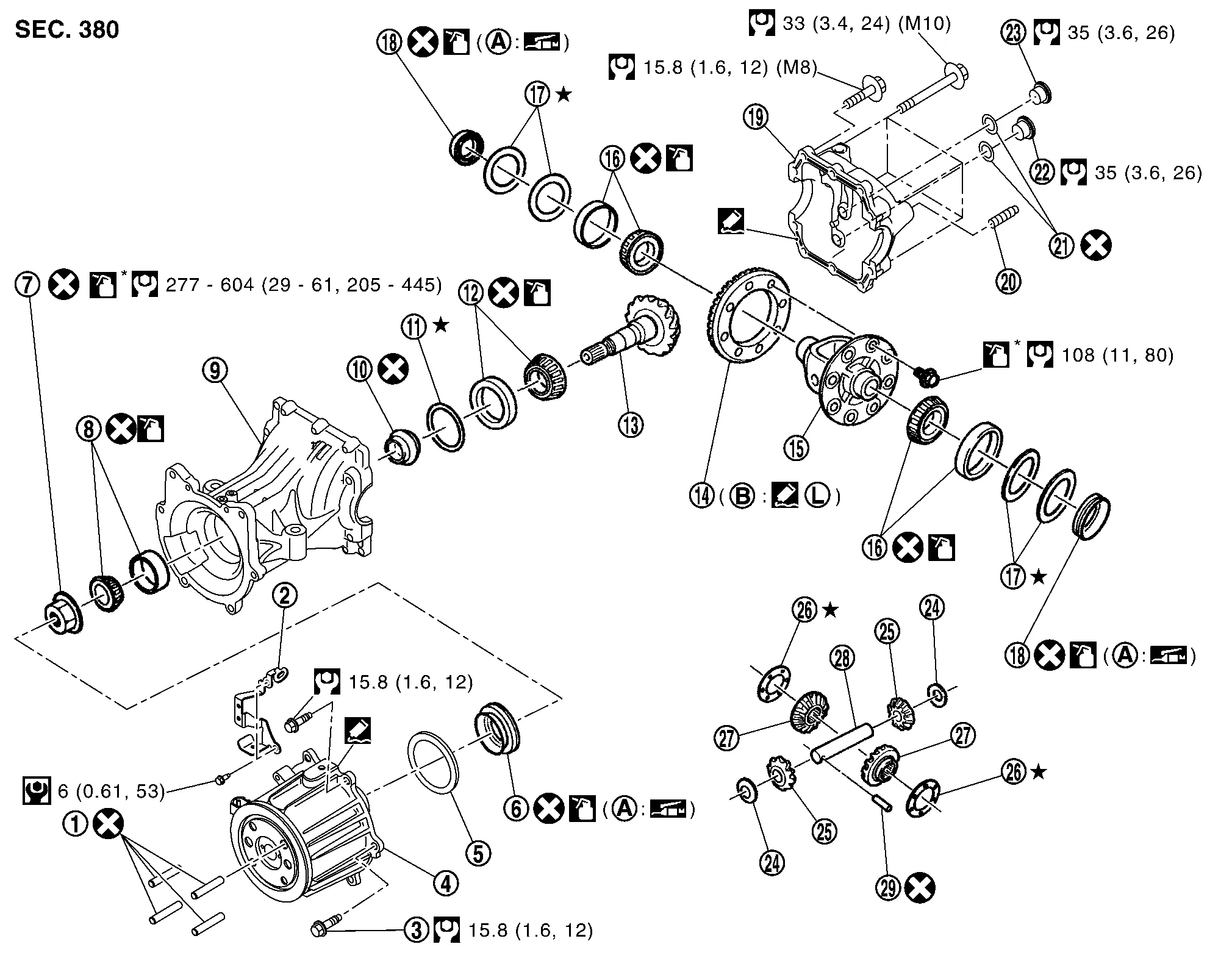

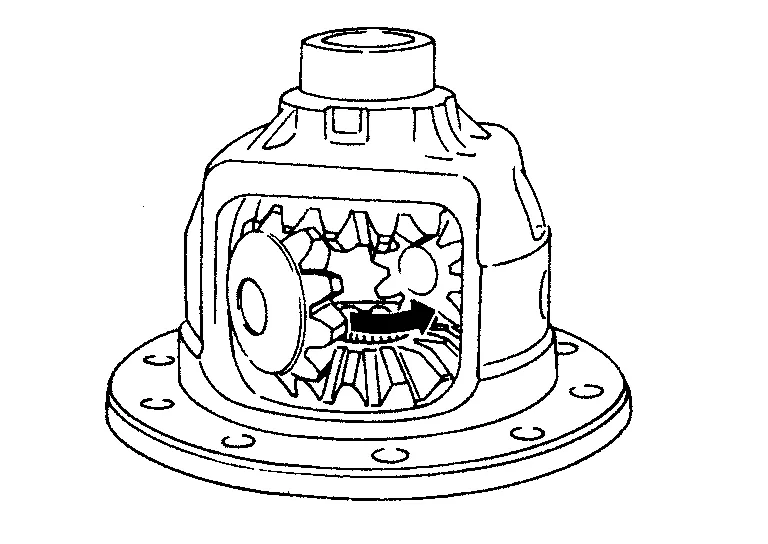

Nissan Murano: Unit Disassembly and Assembly / Differential Assembly

|

Stud bolt |  |

Connector bracket |  |

Reamer bolt |

|

Electric controlled coupling assembly |  |

Wave spring |  |

Drive pinion oil seal |

|

Drive pinion lock nut |  |

Pinion front bearing |  |

Gear carrier |

|

Collapsible spacer |  |

Drive pinion adjusting shim |  |

Pinion rear bearing |

|

Drive pinion |  |

Drive gear |  |

Differential case |

|

Side bearing |  |

Side bearing adjusting shim |  |

Side oil seal |

|

Rear cover |  |

Stud bolt |  |

Gasket |

|

Drain plug |  |

Filler plug |  |

Pinion mate thrust washer |

|

Pinion mate gear |  |

Side gear thrust washer |  |

Side gear |

|

Pinion mate shaft |  |

Lock pin | ||

|

Oil seal lip |  |

Screw hole | ||

: N·m (kg-m, in-lb) : N·m (kg-m, in-lb) |

|||||

: N·m (kg-m, ft-lb) : N·m (kg-m, ft-lb) |

|||||

: Always replace after every disassembly. : Always replace after every disassembly. |

|||||

: Select with proper thickness. : Select with proper thickness. |

|||||

: Apply gear oil. : Apply gear oil. |

|||||

*: Apply anti-corrosion oil. *: Apply anti-corrosion oil. |

|||||

: Apply multi purpose grease. : Apply multi purpose grease. |

|||||

: Apply Genuine Silicone RTV or equivalent. Refer to Recommended Chemical Products and Sealants. : Apply Genuine Silicone RTV or equivalent. Refer to Recommended Chemical Products and Sealants. |

|||||

: Apply Genuine High Strength Thread Locking Sealant or equivalent. Refer to Recommended Chemical Products and Sealants. : Apply Genuine High Strength Thread Locking Sealant or equivalent. Refer to Recommended Chemical Products and Sealants. |

|||||

DISASSEMBLY

Remove drain plug, filler plug and gaskets.

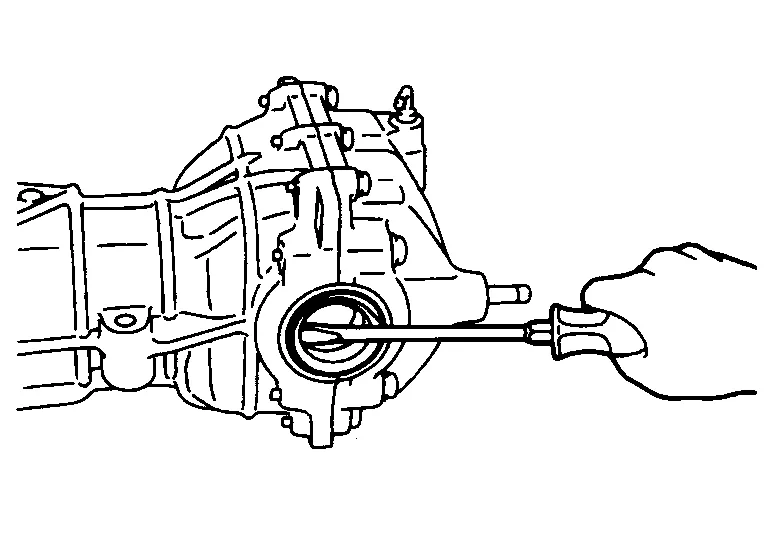

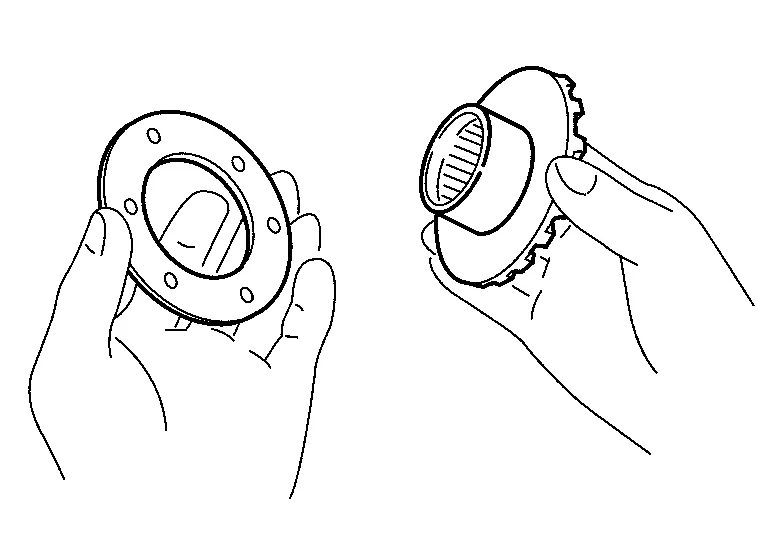

Remove the side oil seal, using oil seal remover (commercial service tool).

CAUTION:

Do not damage gear carrier and rear cover.

Remove rear cover mounting bolts.

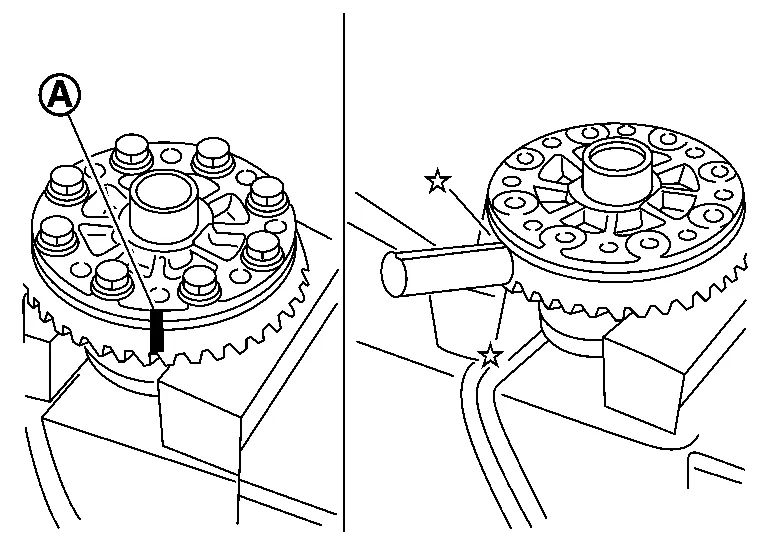

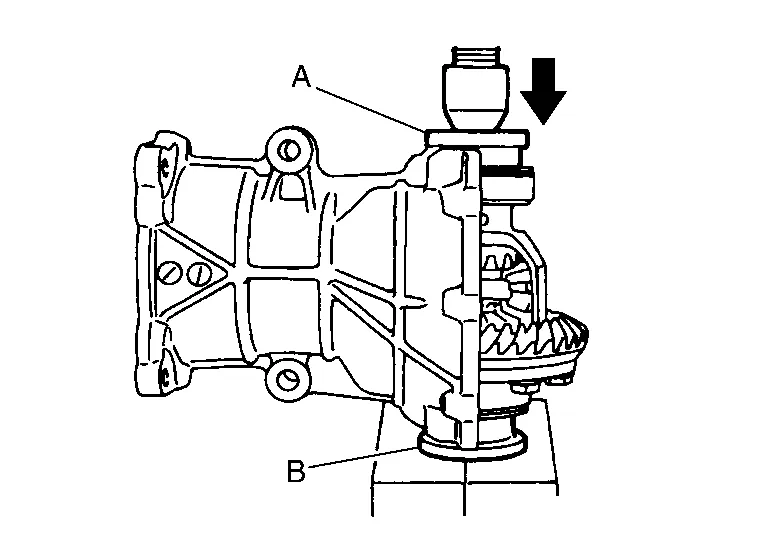

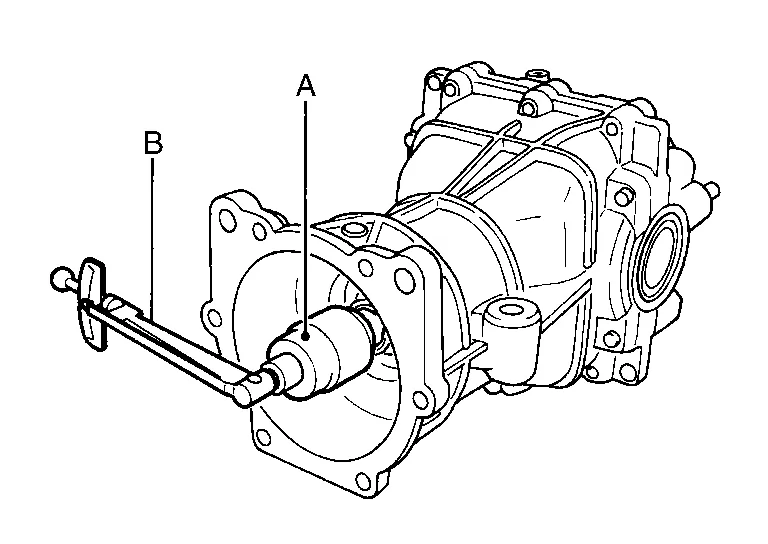

Set drifts (A and B) to the right and left side bearing adjusting shims individually. Press differential assembly with side bearing to remove gear carrier assembly and rear cover assembly.

| A | : Drift [SST: KV40100610 (J-26089)] |

| B | : Drift [SST: KV40100610 (J-26089)] |

CAUTION:

The pressure shall be as low as possible to remove gear carrier assembly and rear cover assembly. The maximum pressure shall be 10 kN (1 ton, 1.0 Imp ton).

NOTE:

NOTE:

Differential assembly, side bearings, and adjusting washers are compressed and integrated in gear carrier and rear cover.

Remove stud bolt from rear cover.

NOTE:

NOTE:

It is not necessary to remove stud bolt except when it is replaced.

Remove side bearing adjusting shims and side bearing outer races.

CAUTION:

Mark the side bearing adjusting shims so that the original mounting positions (right/left) can be identified later.

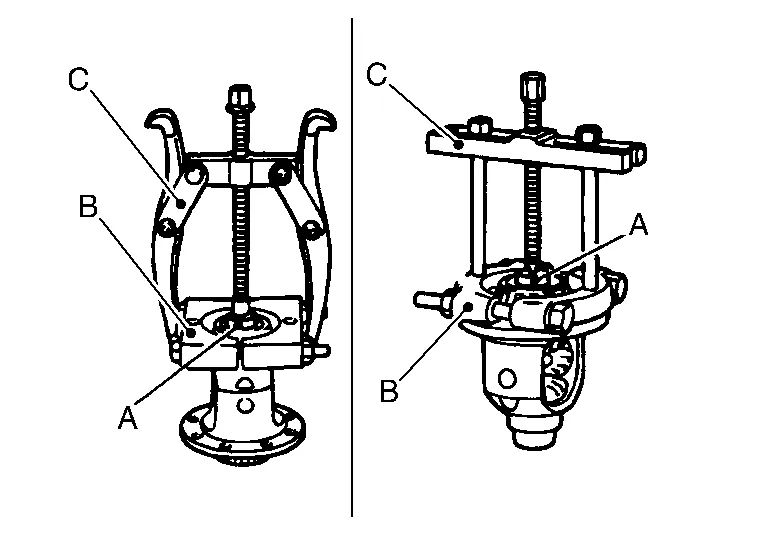

Remove side bearing inner races, using adaptor (A), separator (B) and puller (C).

| A | : Adaptor [SST: ST33052000 ( — )] |

| B | : Separator (commercial service tool) |

| C | : Puller (commercial service tool) |

CAUTION:

-

To prevent damage to the side bearing and drive gear, place copper plates between these parts and vise.

-

It is not necessary to remove side bearing inner race except when it is replaced.

For proper reinstallation, paint matching marks  on one differential assembly and drive gear.

on one differential assembly and drive gear.

CAUTION:

For matching marks, use paint. do not damage differential assembly and drive gear.

Remove drive gear mounting bolts and then remove drive gear from differential assembly.

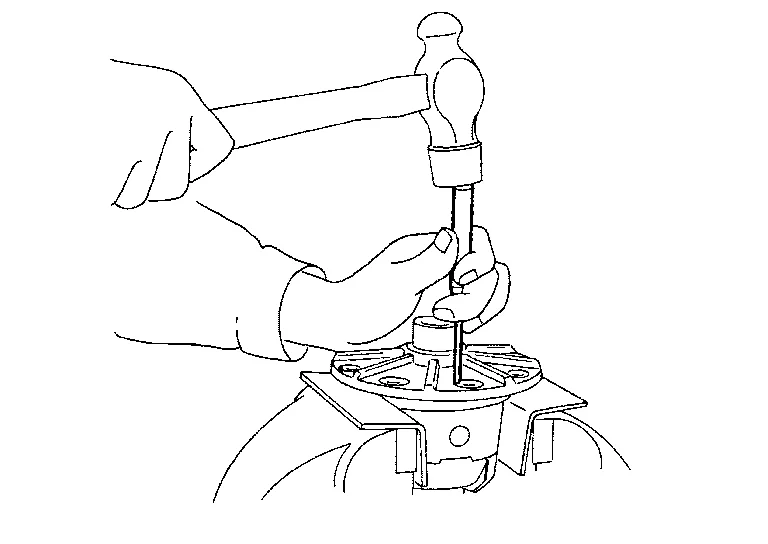

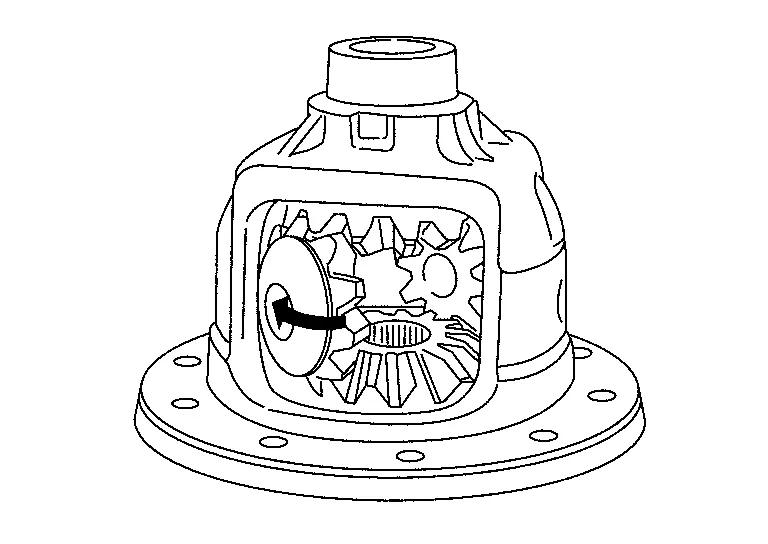

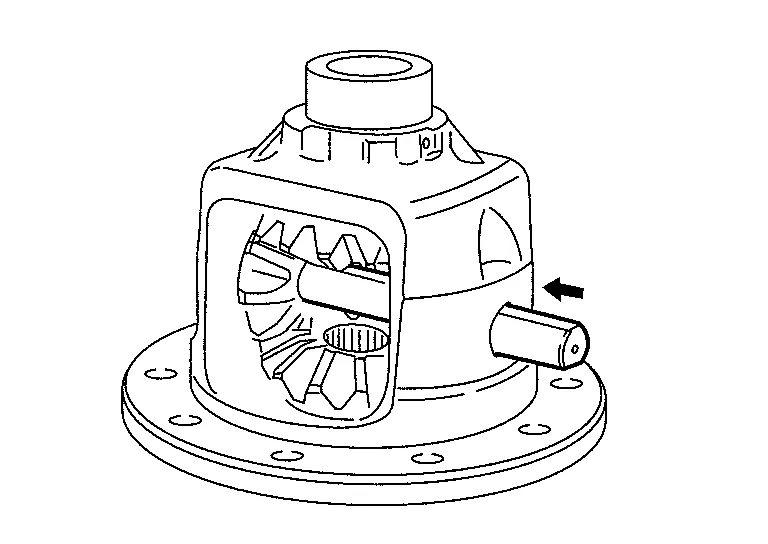

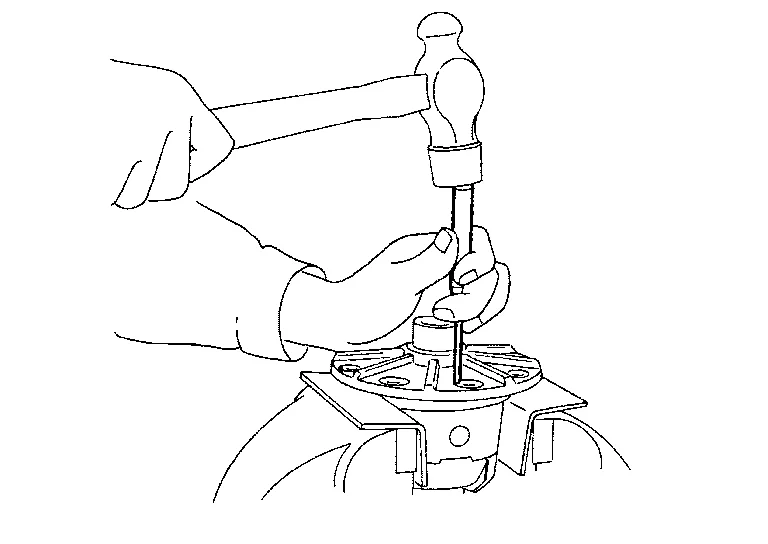

Remove lock pin of pinion mate shaft, using the pin punch (commercial service tool).

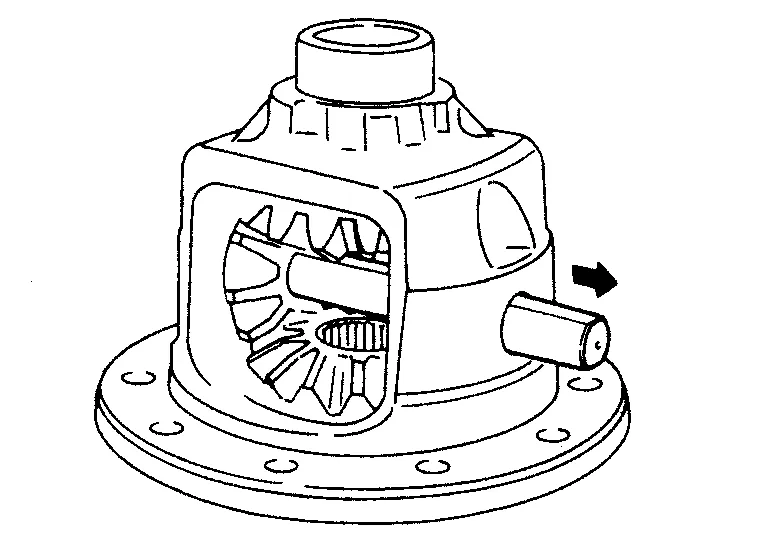

Remove pinion mate shaft.

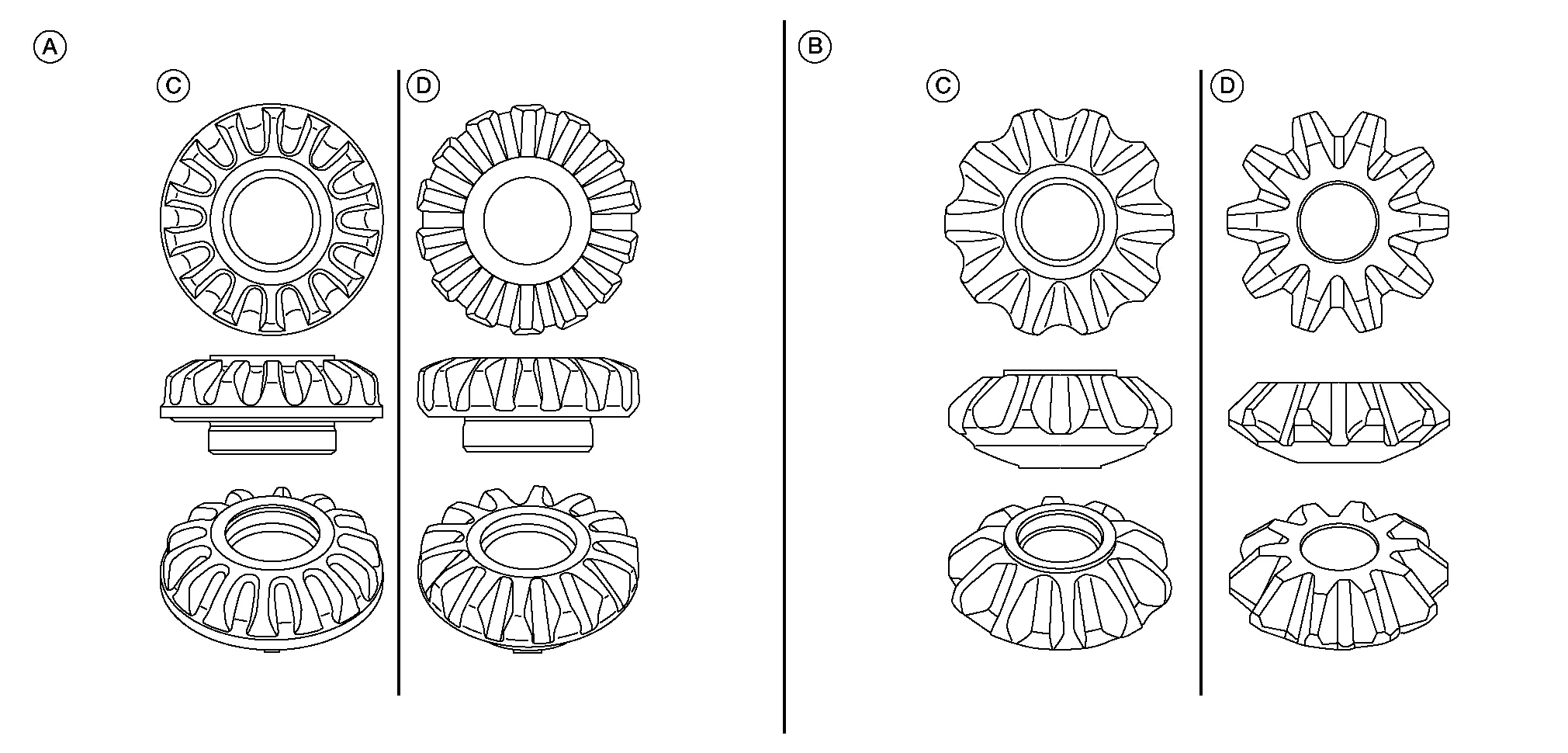

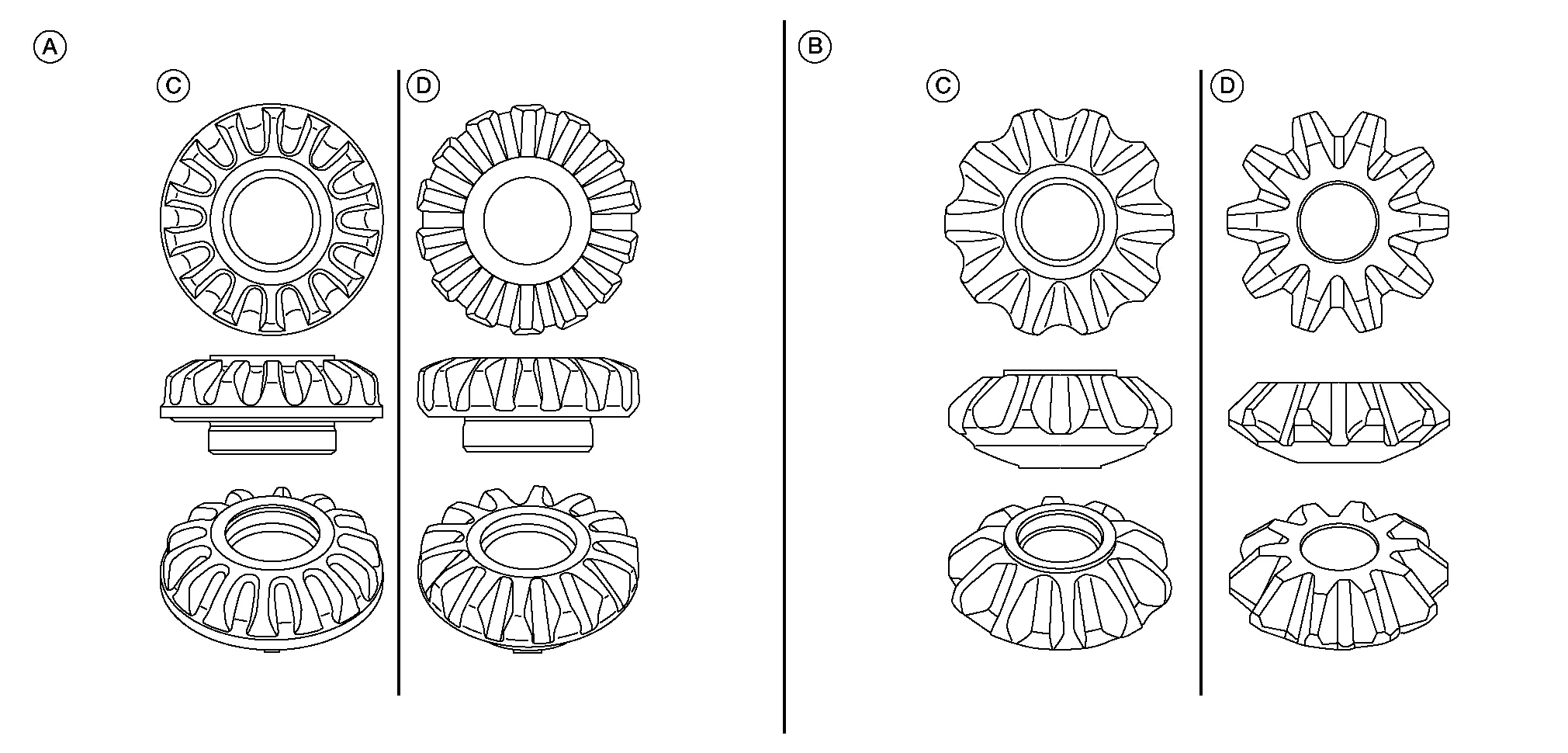

Remove pinion mate gears, pinion mate thrust washers, side gears, side gear thrust washers from differential case.

CAUTION:

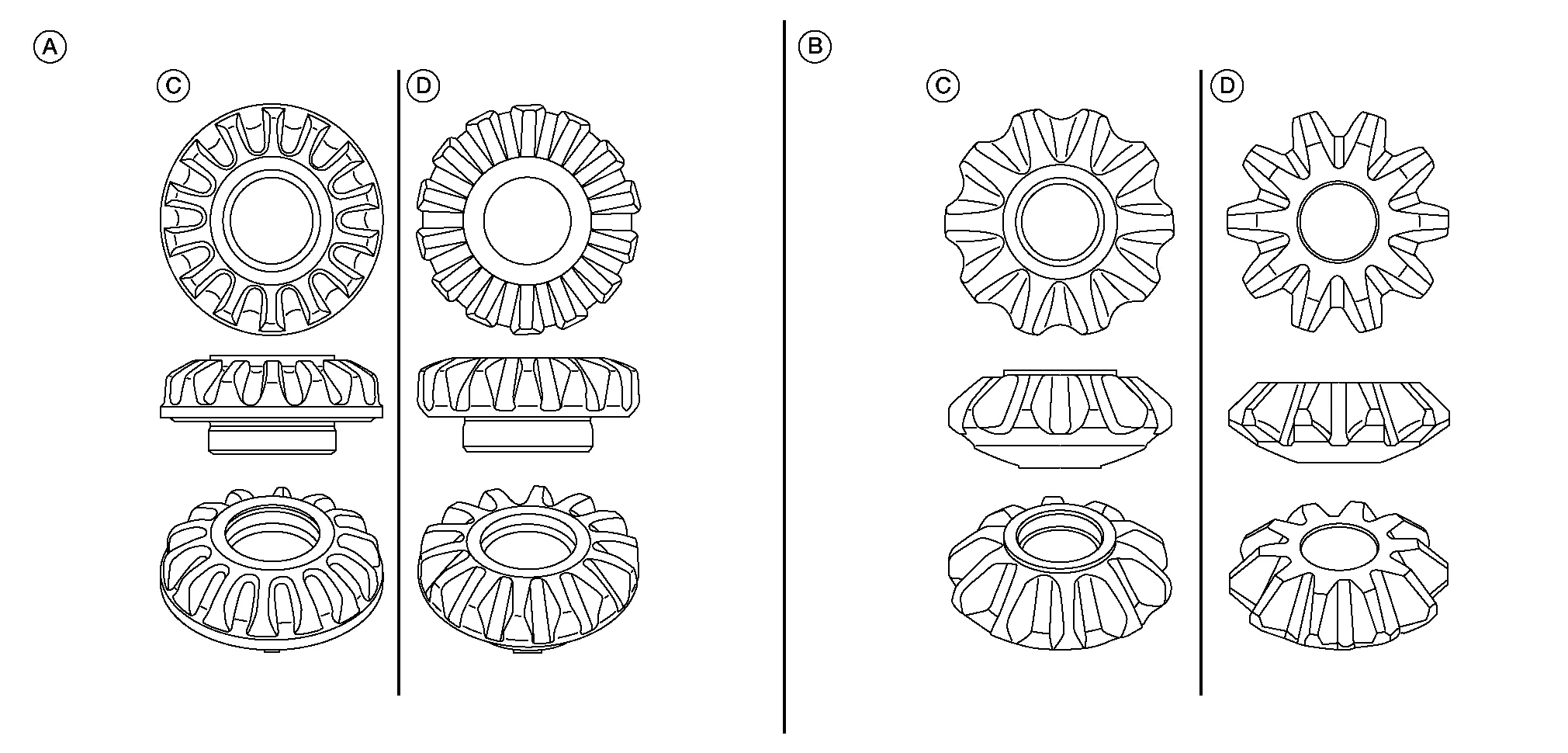

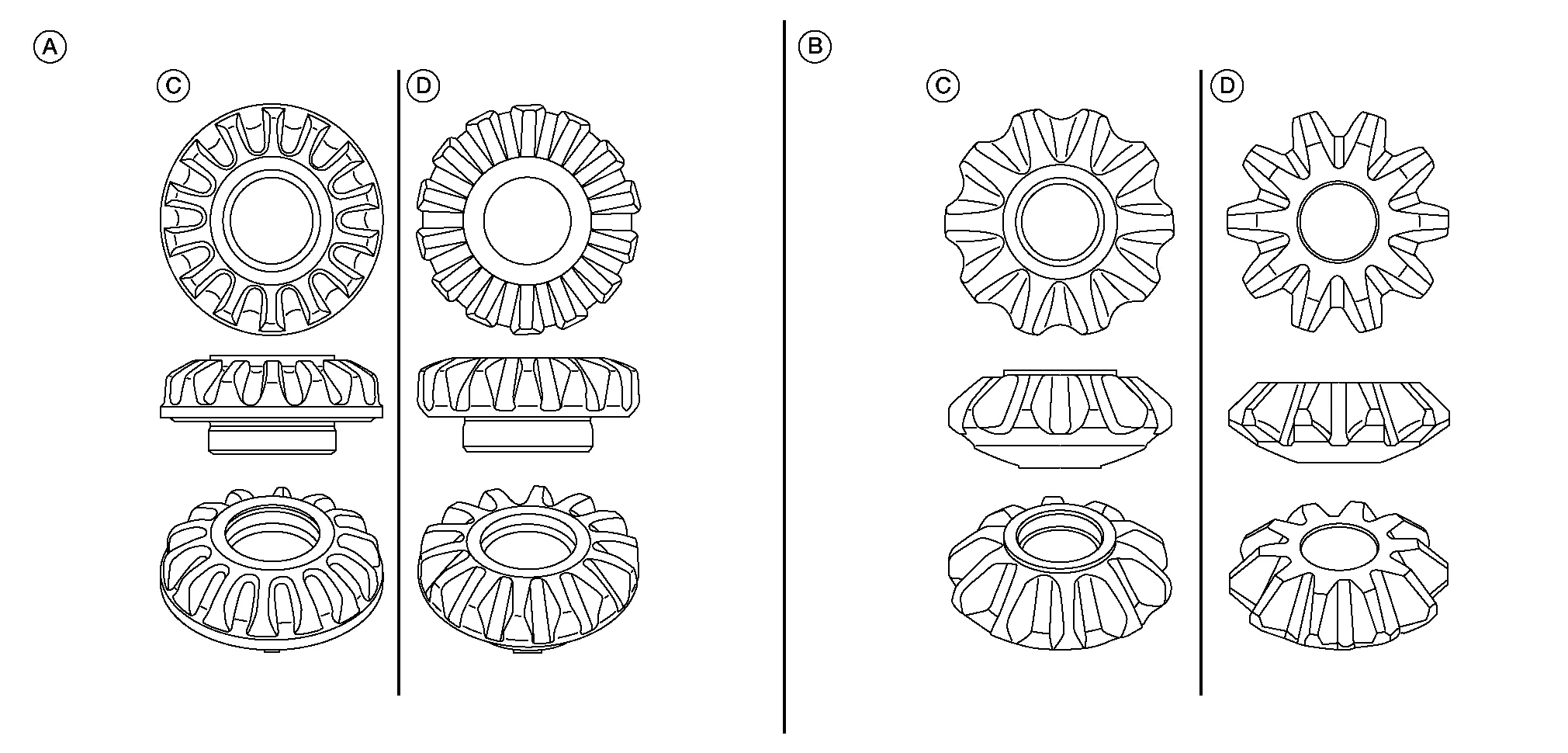

If replacing the side gears (A) or pinion mate gears (B), always replace as a set. Do not mix machined gears (D) with forged gears (C) or damage could result.

Perform inspection after disassembly. Refer to Inspection.

ASSEMBLY

Install side gear thrust washers with the same thickness as the ones installed prior to disassembly or reinstall the old ones on the side gears.

Install side gears and side gear thrust washers into differential case.

CAUTION:

If replacing the side gears (A) or pinion mate gears (B), always replace as a set. Do not mix machined gears (D) with forged gears (C) or damage could result.

Align 2 pinion mate gears in diagonally opposite positions, then rotate and install them into differential case after installing thrust washer to pinion mate gear.

CAUTION:

If replacing the side gears (A) or pinion mate gears (B), always replace as a set. Do not mix machined gears (D) with forged gears (C) or damage could result.

Align the lock pin holes on differential case with pinion mate shaft, and install pinion mate shaft.

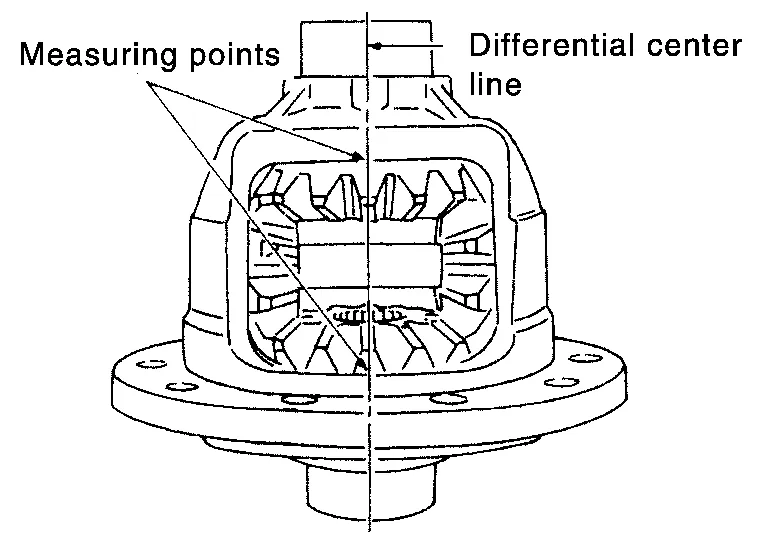

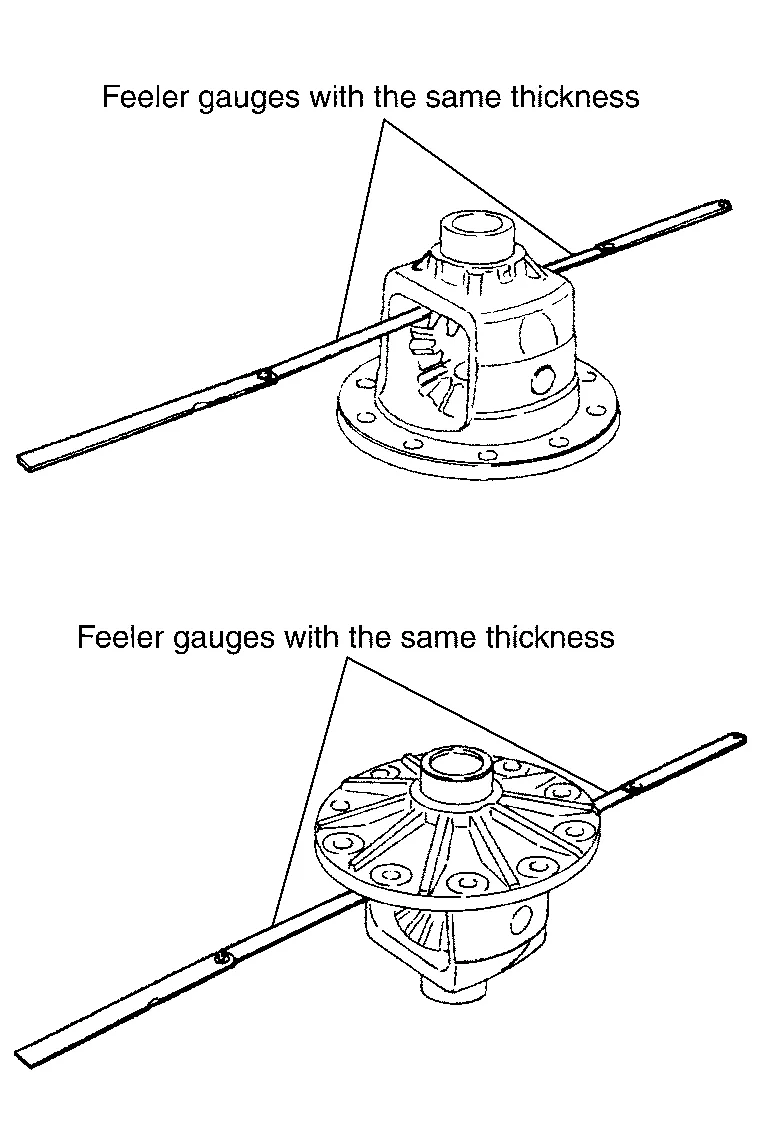

Measure side gear end play. If necessary, select the appropriate side gear thrust washers.Place differential assembly straight up so that side gear to be measured comes upward.

| Side gear back clearance | : Refer to Differential Side Gear Clearance. |

CAUTION:

To prevent side gear from tilting, insert feeler gauges with the same thickness from both sides.

-

If the back clearance is outside the specification, use a thicker/thinner side gear thrust washer to adjust. For selecting thrust washer, refer to the latest parts information.

When the back clearance is large : Use a thicker thrust washer. When the back clearance is small : Use a thinner thrust washer. CAUTION:

Select a side gear thrust washer for right and left individually.

Drive a lock pin into pinion mate shaft, using the pin punch (commercial service tool).

CAUTION:

Do not reuse lock pin.

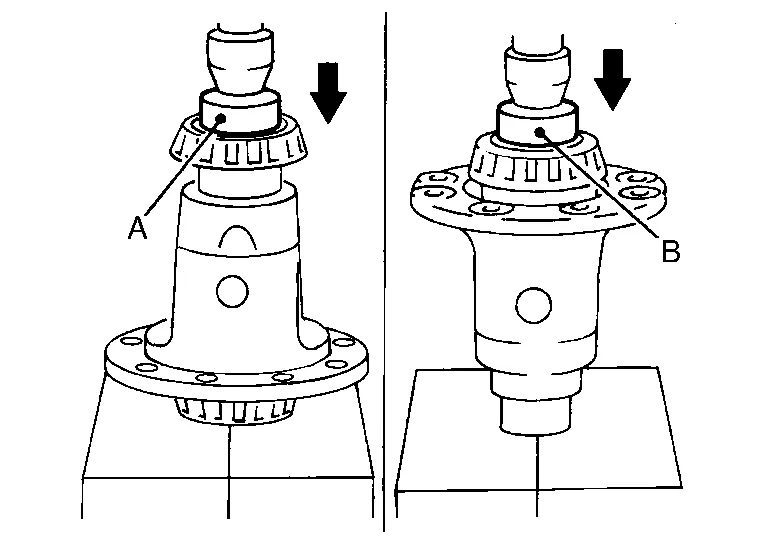

Press side bearing inner races to differential assembly, using the drifts (A and B).

| A | : Drift [SST: KV40105020 ( — )] |

| B | : Drift [SST: KV40105020 ( — )] |

CAUTION:

-

Do not reuse side bearing inner race.

-

Apply gear oil to side bearing.

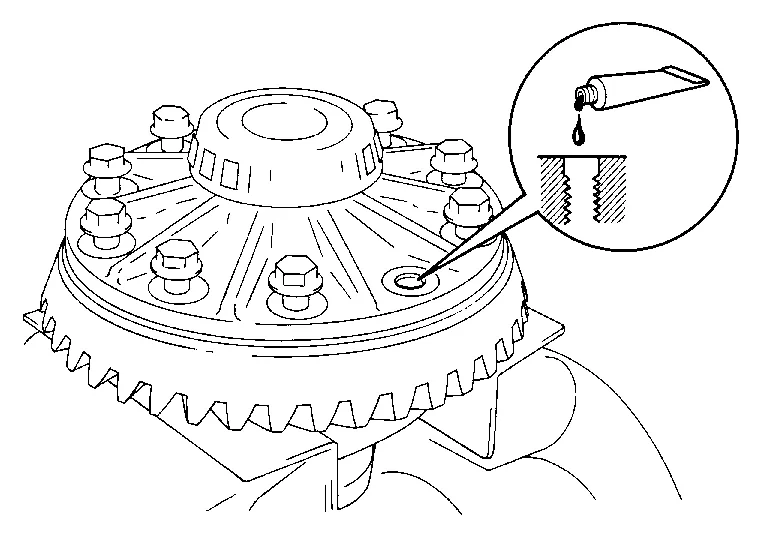

Apply thread locking sealant into the thread hole of drive gear.

-

For applying thread locking sealant, refer to Exploded View.

CAUTION:

Clean and degrees drive gear back and threaded holes sufficiently.

Install the drive gear to differential assembly.

CAUTION:

Align the matching mark of differential assembly and drive gear.

Tighten the bolts in a crisscross fashion to the specified torque.

-

For tightening torque, refer to Exploded View.

CAUTION:

Apply anti-corrosion oil to the thread and seat of mounting bolts.

Assemble side bearing outer races to inner races.

CAUTION:

-

Do not reuse side bearing outer race.

-

Apply gear oil to side bearing.

Install new side bearing adjusting shims (2 pieces for one side) with the same thickness as the ones installed prior to disassembly or re-install the old ones, on side bearing outer race of differential assembly.

If side bearing adjusting shims have been already selected, use them.

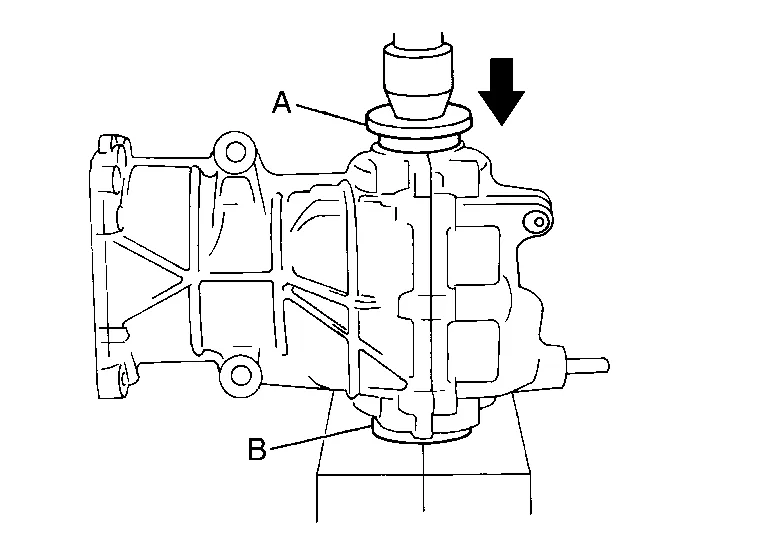

Set the drifts (A and B) to the right and left side bearing adjusting shims individually. Compress differential assembly and side bearing to gear carrier assembly to install differential assembly.

| A | : Drift [KV40100610 (J-26089)] |

| B | : Drift [KV40100610 (J-26089)] |

CAUTION:

-

The drift shall be placed on the center of the adjusting shims.

-

The pressure shall be as low as possible to install differential assembly into gear carrier assembly. The maximum pressure shall be 10 kN (1 ton, 1.1 US ton, 1.0 Imp ton).

-

If the adjusting shims are installed by tapping, the gear carrier may be damaged. Avoid tapping.

Install dummy cover set, check and adjust drive gear runout, tooth contact, backlash, and total preload torque. Refer to Adjustment.

Remove dummy cover set.

Install stud bolt to rear cover.

CAUTION:

Screw the stud bolt until the thread becomes invisible by applying a torque of 20 N·m (2.0 kg-m, 15 ft-lb) or less.

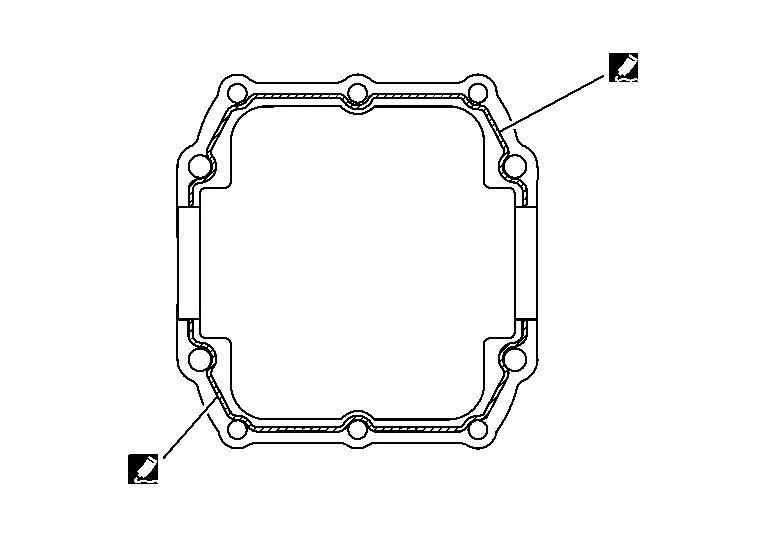

Apply liquid gasket to mating surface of rear cover.

-

For applying liquid gasket, refer to Exploded View.

CAUTION:

-

Remove old gasket adhering to the mounting surfaces. Also remove any moisture, oil, or foreign material adhering to the mounting surfaces.

-

The width of sealant bead is approximately 3 mm (0.12 in). Apply sealant evenly.

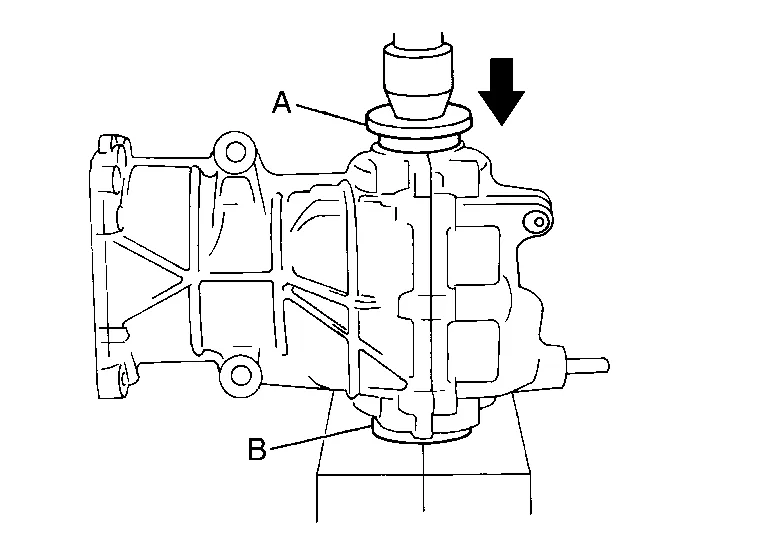

Set the drifts (A and B) to the right and left side bearing adjusting shims individually. Compress differential assembly and side bearing to install rear cover.

| A | : Drift [SST: KV40100610 (J-26089)] |

| B | : Drift [SST: KV40100610 (J-26089)] |

CAUTION:

-

The drift shall be placed on the center of the adjusting shims.

-

The pressure shall be as low as possible to install differential assembly into gear carrier assembly. The maximum pressure shall be 10 kN (1 ton, 1.1 US ton, 1.0 Imp ton).

-

If the adjusting shims are installed by tapping, the gear carrier may be damaged. Avoid tapping.

Tighten rear cover mounting bolts to the specified torque.

-

For tightening torque, refer to Exploded View.

Using the drift (A) [SST: KV38100200 (J-26233)], drive side oil seals until it becomes flush with the gear carrier end.

CAUTION:

-

Do not reuse oil seal.

-

When installing, do not incline oil seal.

-

Apply multi-purpose grease onto oil seal lips, and gear oil onto the circumference of oil seal.

Check total preload torque. Refer to Adjustment.

TOTAL PRELOAD TORQUE

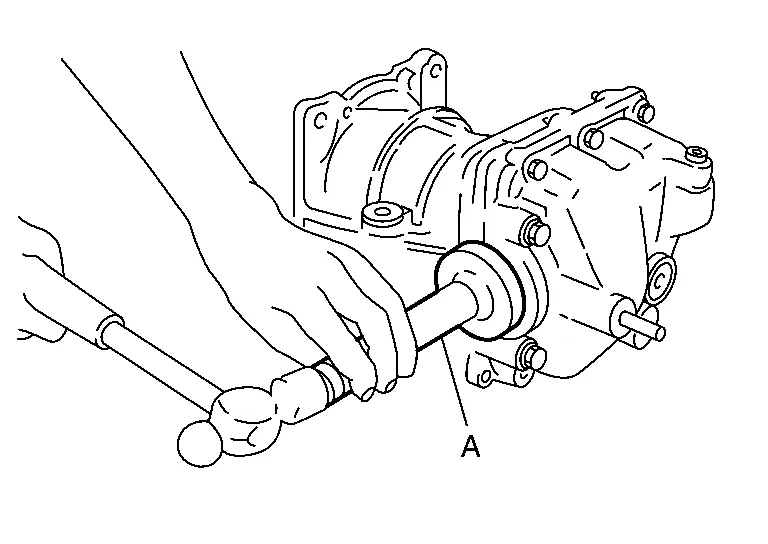

Remove electric controlled coupling assembly. Refer to Disassembly and Assembly.

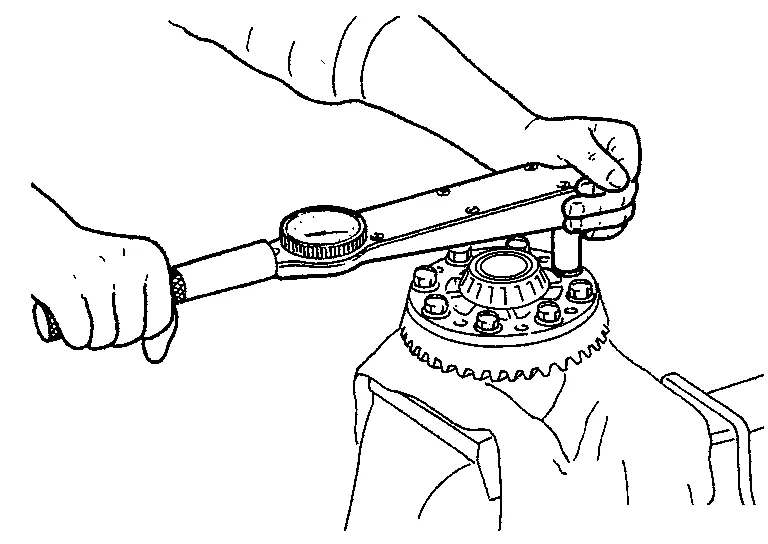

Rotate drive pinion back and forth 2 to 3 times to check for unusual noise and rotation malfunction.

Rotate drive pinion at least 20 times to check for smooth operation of the bearing.

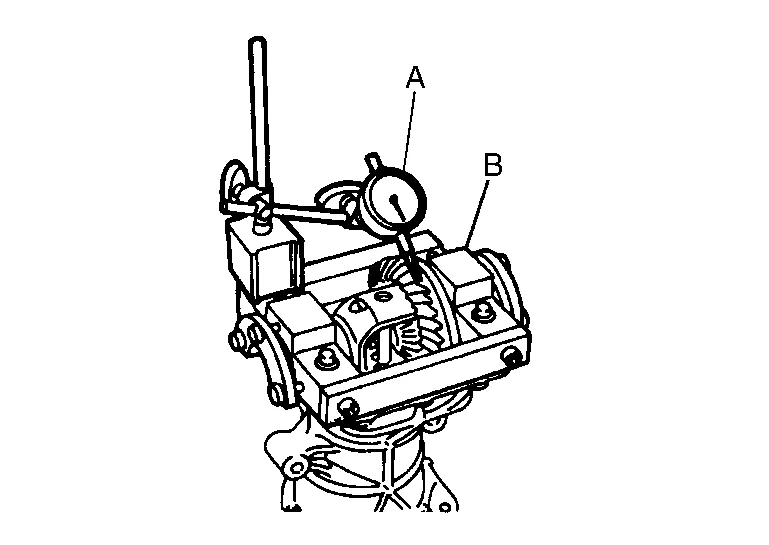

Fit drive pinion socket onto drive pinion spline. Measure the total preload, using the preload gauge and drive pinion socket.

| A | : Drive pinion socket [SST: KV38109500 ( — )] |

| B | : Preload gauge [SST: ST3127S000 (J-25765-A)] |

| Total preload torque | : Refer to Preload Torque. |

NOTE:

NOTE:

Total preload torque = Pinion bearing torque + Side bearing torque

-

If measured value is out of the specification, disassemble it to check and adjust each part. Adjust the pinion bearing preload and side bearing preload.

Adjust the pinion bearing preload first, then adjust the side bearing preload.

When the preload torque is large On pinion bearings: Replace the collapsible spacer. On side bearings: Use thinner side bearing adjusting shims. For selecting adjusting shim, refer to the latest parts information. When the preload is small On pinion bearings: Tighten the drive pinion nut. On side bearings: Use thicker side bearing adjusting shims. For selecting adjusting shim, refer to the latest parts information.

DRIVE GEAR RUNOUT

Remove rear cover. Refer to Disassembly and Assembly.

Following the procedure below, install a dummy cover set [SST: KV381086S1 ( — )] to gear carrier.Set dummy cover shims [SST: KV38108630 ( — )] to the right and left side bearing adjusting shims. Temporarily tighten dummy cover [SST: KV38108610 ( — )] to gear carrier. Position dummy cover spacers [SST: KV38108621 ( — )] to dummy cover [SST: KV38108610 ( — )]. Tighten rear cover mounting bolts to the specified torque. Refer to Exploded View. Tighten dummy cover spacer mounting bolts evenly to the specified torque.

|

: 5.9 N·m (0.6 kg-m, 52 in-lb) |

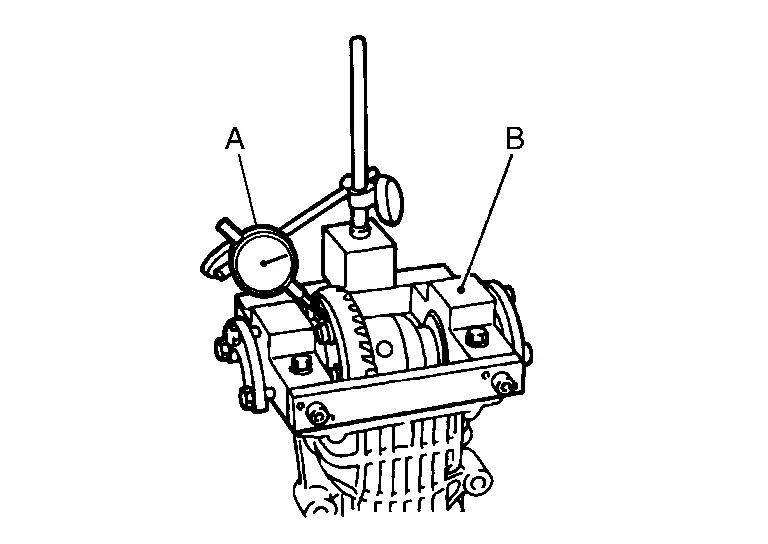

Fit a dial indicator (A) to the drive gear back face.

| B | : Dummy cover set [SST: KV381086S1 ( — )] |

Rotate the drive gear to measure runout.

| Drive gear back face runout | : Refer to Drive Gear Runout. |

-

If the runout is outside of the repair limit, check drive gear assembly condition; foreign material may be caught between drive gear and differential case, or differential case or drive gear may be deformed, etc.

CAUTION:

Replace drive gear and drive pinion as a set.

TOOTH CONTACT

Remove rear cover. Refer to Disassembly and Assembly.

Following the procedure below, install a dummy cover set [SST: KV381086S1 ( — )] to gear carrier.Set dummy cover shims [SST: KV38108630 ( — )] to the right and left side bearing adjusting shims. Temporarily tighten dummy cover [SST: KV38108610 ( — )] to gear carrier. Position dummy cover spacers [SST: KV38108621 ( — )] to dummy cover [SST: KV38108610 ( — )]. Tighten rear cover mounting bolts to the specified torque. Refer to Exploded View. Tighten dummy cover spacer mounting bolts evenly to the specified torque.

|

: 5.9 N·m (0.6 kg-m, 52 in-lb) |

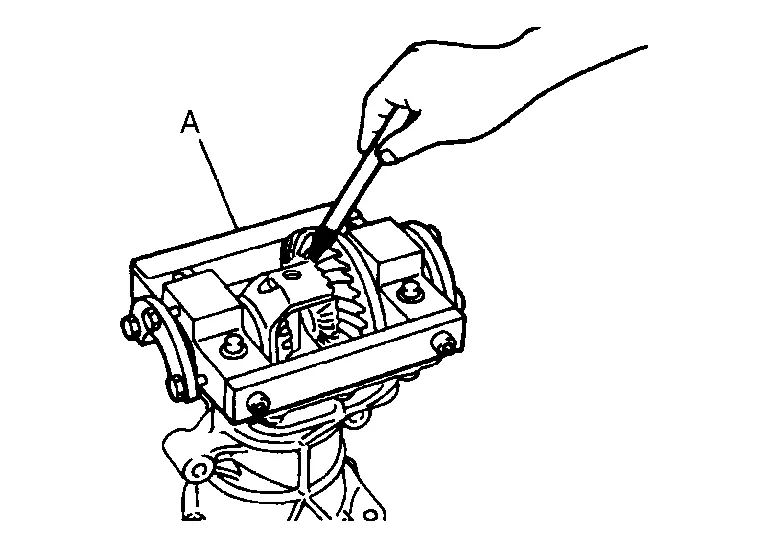

Apply red lead or equivalent to drive gear.

| A | : Dummy cover set [SST: KV381086S1 ( — )] |

CAUTION:

Apply red lead or equivalent to both the faces of 3 to 4 gears at 4 locations evenly spaced on drive gear.

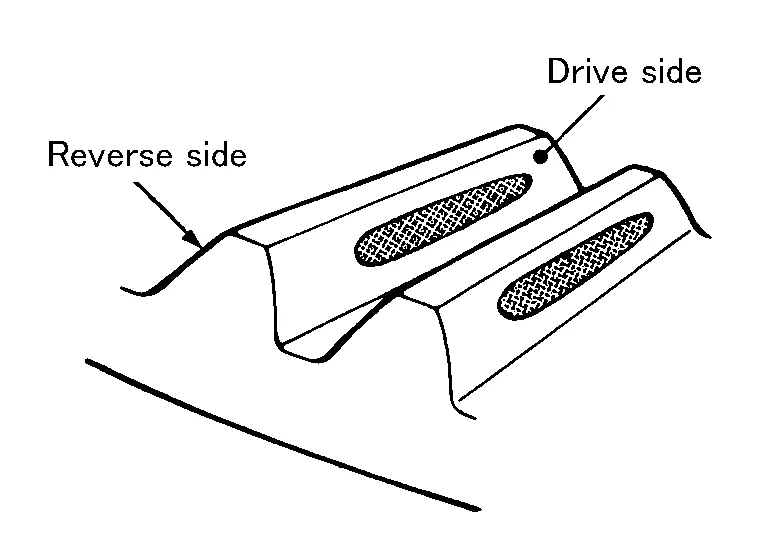

Rotate drive gear back and forth several times, check drive pinion gear to drive gear tooth contact.

CAUTION:

Check tooth contact on drive side and reverse side.

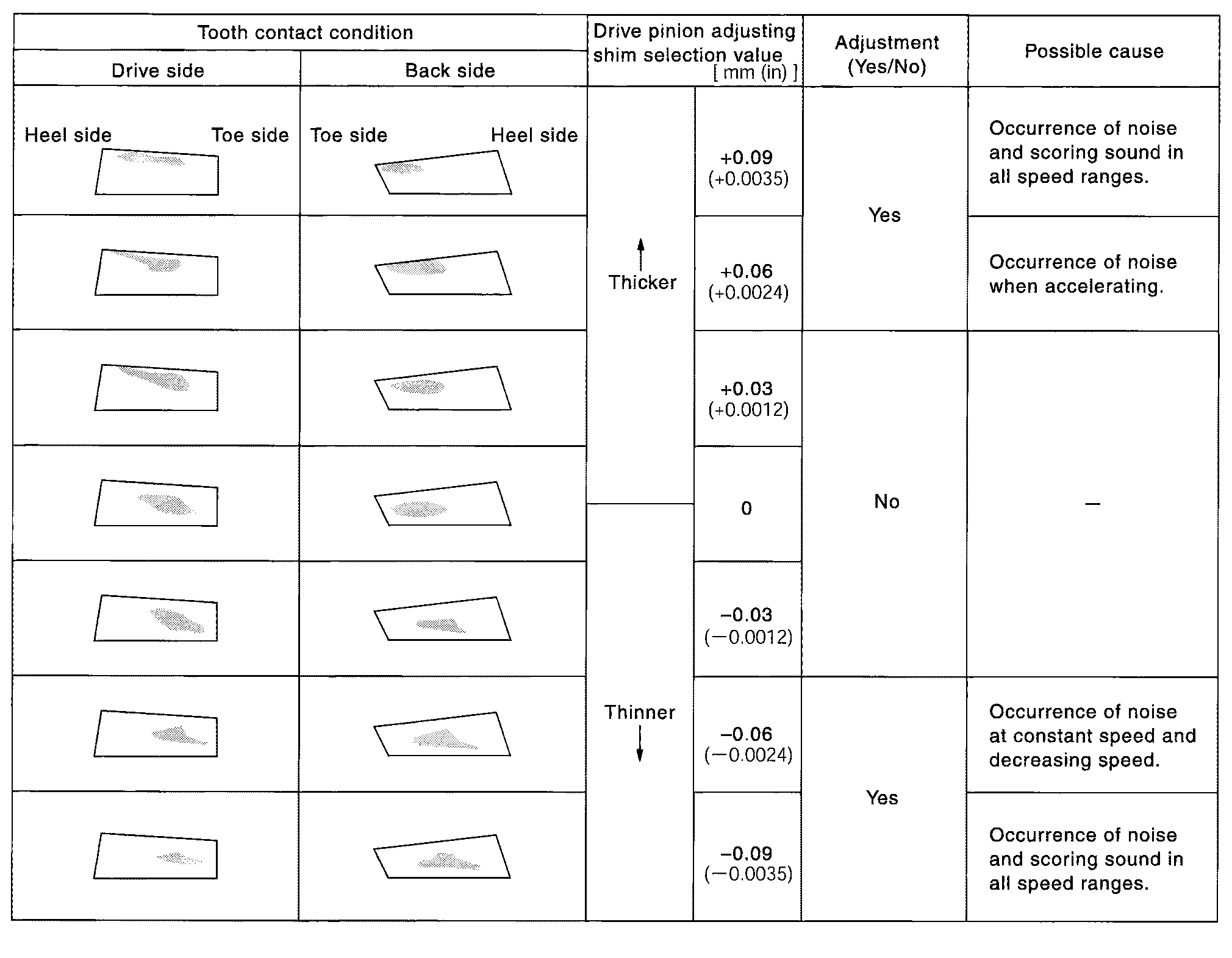

Tooth Contact Judgment Guide

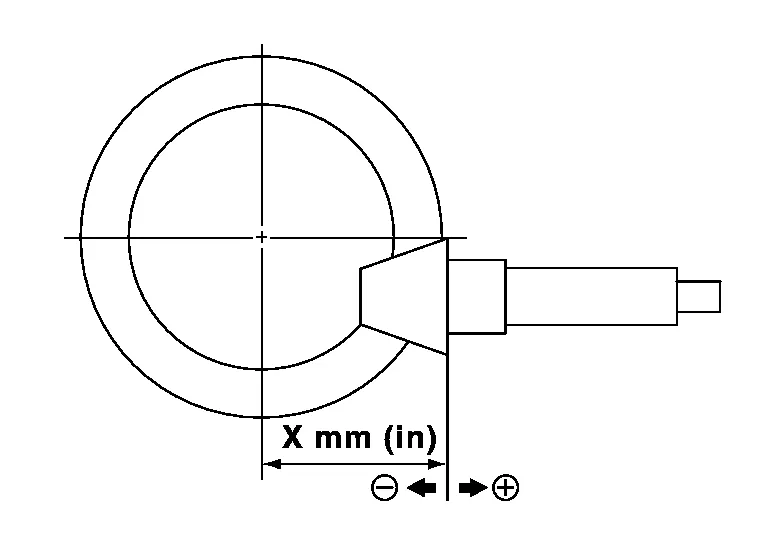

If tooth contact is improperly adjusted, follow the procedure below to adjust the pinion height (dimension X).

-

If the tooth contact is near the face (face contact), or near the heel (heel contact), thicken drive pinion gear adjusting shim to move drive pinion closer to drive gear.

For selecting adjusting shim, refer to the latest parts information.

-

If the tooth contact is near the flank (flank contact), or near the toe (toe contact), thin drive pinion gear adjusting shim to move drive pinion farther from drive gear.

For selecting adjusting shim, refer to the latest parts information.

BACKLASH

Remove rear cover. Refer to Disassembly and Assembly.

Following the procedure below, install a dummy cover set [SST: KV381086S1 ( — )] to gear carrier.Set dummy cover shims [SST: KV38108630 ( — )] to the right and left side bearing adjusting shims. Temporarily tighten dummy cover [SST: KV38108610 ( — )] to gear carrier. Position dummy cover spacers [SST: KV38108621 ( — )] to dummy cover [SST: KV38108610 ( — )]. Tighten rear cover mounting bolts to the specified torque. Refer to Exploded View. Tighten dummy cover spacer mounting bolts evenly to the specified torque.

|

: 5.9 N·m (0.6 kg-m, 52 in-lb) |

Fit a dial indicator (A) to the drive gear face to measure the backlash.

| B | : Dummy cover set [SST: KV381086S1 ( — )] |

| Backlash | : Refer to Backlash. |

-

If the backlash is outside of the specified value, change the thickness of side bearing adjusting shims.

| When the backlash is large: | |

| Make drive gear back adjusting shims thicker, and drive gear front adjusting shims thinner. For selecting adjusting shim, refer to the latest parts information. | |

| When the backlash is small: | |

| Make drive gear back adjusting shims thinner, and drive gear front adjusting shims thicker. For selecting adjusting shim, refer to the latest parts information. | |

INSPECTION AFTER DISASSEMBLY

Drive Gear and Drive Pinion

Clean up the disassembled parts.

If the gear teeth never mesh or line-up correctly, determine the cause and adjust or replace as necessary.

If the gears are worn, cracked, damaged, pitted or chipped (by friction) noticeably, replace with new drive gear and drive pinion as a set.

Bearing

-

Clean up the disassembled parts.

-

If any chipped (by friction), pitted, worn, rusted or scratched marks, or unusual noise from the bearing is observed, replace as a bearing assembly (as a new set).

Oil Seal

-

Whenever disassembled, replace.

-

If wear, deterioration of adherence (sealing force lips), or damage is detected on the lips, replace them.

Differential Assembly

DIFFERENTIAL CASE

-

Clean up the disassembled parts.

-

If any wear or crack on the contact sides of the differential case is found, replace.

SIDE GEAR AND PINION MATE GEAR

CAUTION:

If replacing the side gears (A) or pinion mate gears (B), always replace as a set. Do not mix machined gears (D) with forged gears (C) or damage could result.

-

Clean up the disassembled parts.

-

If any cracks or damage on the surface of the tooth is found, replace.

-

If any worn or chipped mark on the contact sides of the thrust washer is found, replace.

SIDE GEAR THRUST WASHER AND PINION MATE THRUST WASHER

-

Clean up the disassembled parts.

-

If it is chipped (by friction), damaged, or unusually worn, replace.

Electric Controlled Coupling

Electric Controlled Coupling

Exploded View

Stud bolt

Connector bracket

Reamer bolt

Electric controlled coupling assembly

Wave spring

Drive pinion oil seal

Drive pinion lock nut

Pinion front bearing

Gear carrier

Collapsible spacer

Drive pinion adjusting shim

Pinion rear bearing

Drive pinion

Drive gear

Differential case

Side bearing

Side bearing adjusting shim

Side oil seal

Rear cover

Stud bolt

Gasket

Drain plug

Filler plug

Pinion mate thrust washer

Pinion mate gear

Side gear thrust washer

Side gear

Pinion mate shaft

Lock pin

Oil seal lip

Screw hole

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: Always replace after every disassembly...

Drive Pinion

Drive Pinion

Exploded View

Stud bolt

Connector bracket

Reamer bolt

Electric controlled coupling assembly

Wave spring

Drive pinion oil seal

Drive pinion lock nut

Pinion front bearing

Gear carrier

Collapsible spacer

Drive pinion adjusting shim

Pinion rear bearing

Drive pinion

Drive gear

Differential case

Side bearing

Side bearing adjusting shim

Side oil seal

Rear cover

Stud bolt

Gasket

Drain plug

Filler plug

Pinion mate thrust washer

Pinion mate gear

Side gear thrust washer

Side gear

Pinion mate shaft

Lock pin

Oil seal lip

Screw hole

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: Always replace after every disassembly...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: P0456 Evap Control System

DTC Description DTC DETECTION LOGICThis diagnosis detects leaks in the EVAP line between fuel tank and EVAP canister purge volume control solenoid valve, using the negative pressure caused by decrease of fuel temperature in the fuel tank after turning ignition switch OFF...

Nissan Murano (Z52) 2015-2024 Service Manual: Diagnosis System (lane Camera Unit)

CONSULT Function (LANE CAMERA UNIT) APPLICATION ITEMSCONSULT performs the following functions by communicating with the lane camera unit. Diagnosis mode Description Work support Performs the camera aiming. Self Diagnostic Result Displays the name of a malfunctioning system stored in the lane camera unit Data Monitor Displays lane camera unit input/output data in real time Ecu Identification Displays lane camera unit part number CAN Diag Support Monitor Displays a reception/transmission state of CAN communication Configuration The Nissan Murano vehicle specification that is written in lane camera unit can be displayed or stored The vehicle specification can be written when lane camera unit is replaced SELF DIAGNOSTIC RESULTRefer to DTC Index...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Indicator lights

- Power Steering Fluid (PSF)

- High Beam Assist (if so equipped)

- New on site

- Most important about car

Fuel gauge

The gauge indicates the approximate fuel level in the tank.

The gauge may move slightly during braking, turning, acceleration, or going up or down hills.

The gauge needle returns to 0 (Empty) after the ignition switch is placed in the OFF position.