Nissan Murano: Structure and Operation / Transaxle

|

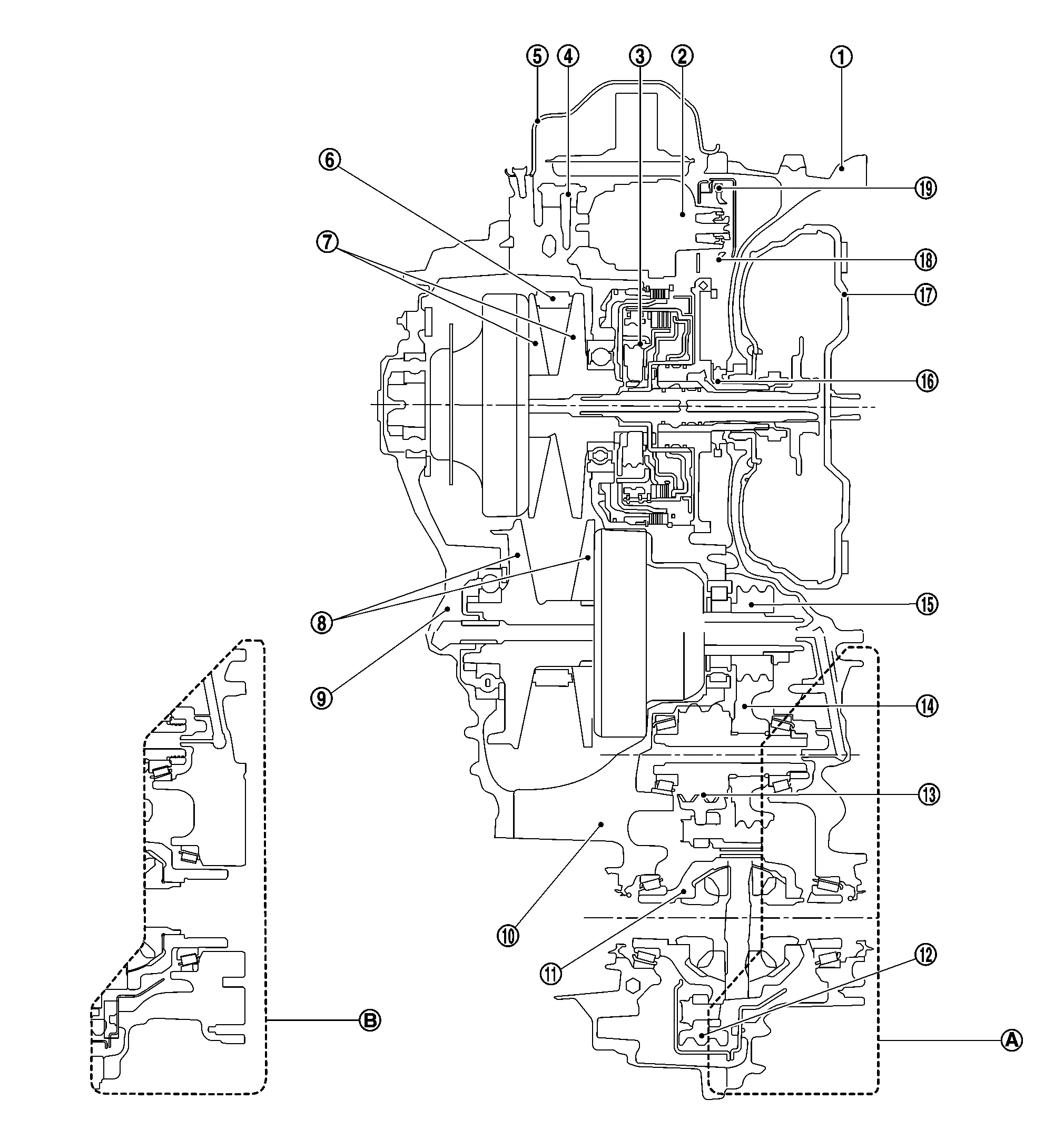

Converter housing |  |

Oil pump |  |

Planetary gear |

|

Control valve |  |

Oil pan |  |

Chain belt |

|

Planetary pulley |  |

Secondary pulley |  |

Side cover |

|

Transaxle case |  |

Differential case |  |

Final gear |

|

Reduction gear |  |

Idler gear |  |

Output gear |

|

Drive sprocket |  |

Torque converter |  |

Driven sprocket |

|

Oil pump chain | ||||

|

FWD models |  |

AWD models |

TORQUE CONVERTER (WITH LOCK-UP FUNCTION)

In the same way as a conventional A/T, the torque converter is a system that increases the engine torque and transmits the torque to the transaxle. A symmetrical 3-element, 1-stage, 2-phase type is used here.

OIL PUMP

Utilizes a vane-type oil pump that is driven by the engine through the oil pump drive chain in order to increase efficiency of pump discharge volume in low-speed zone and optimize pump discharge volume in high-speed zone. Discharged oil from oil pump is transmitted to control valve. It is used as the oil of primary and secondary pulley operation, the oil of clutch operation, and the lubricant for each part.

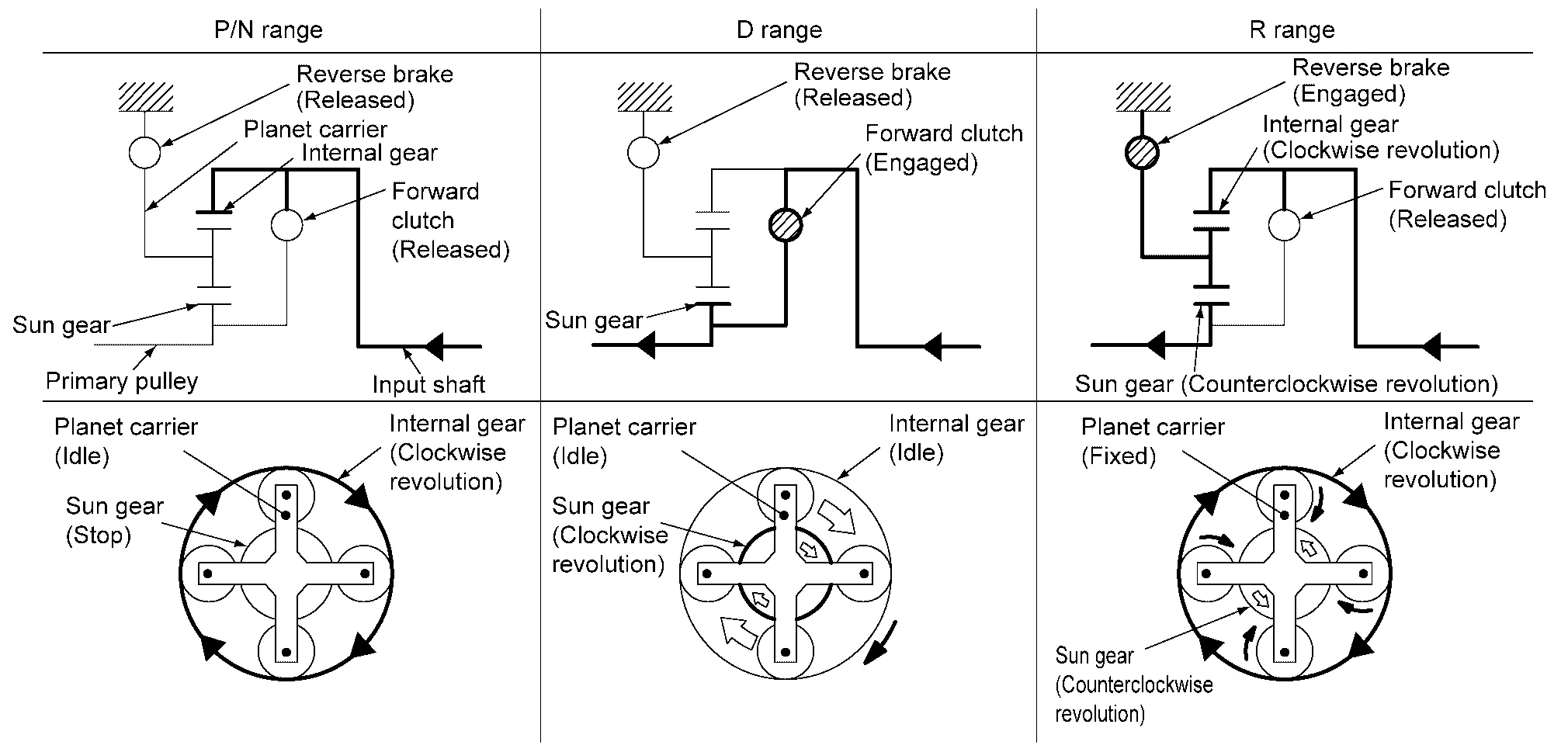

PLANETARY GEAR

-

A planetary gear type of forward/reverse selector mechanism is installed between the torque converter and primary pulley.

-

The power from the torque converter is input via the input shaft, operating a wet multi-plate clutch by means of hydraulic pressure to switch between forward and reverse driving.

Operation of Planetary gear

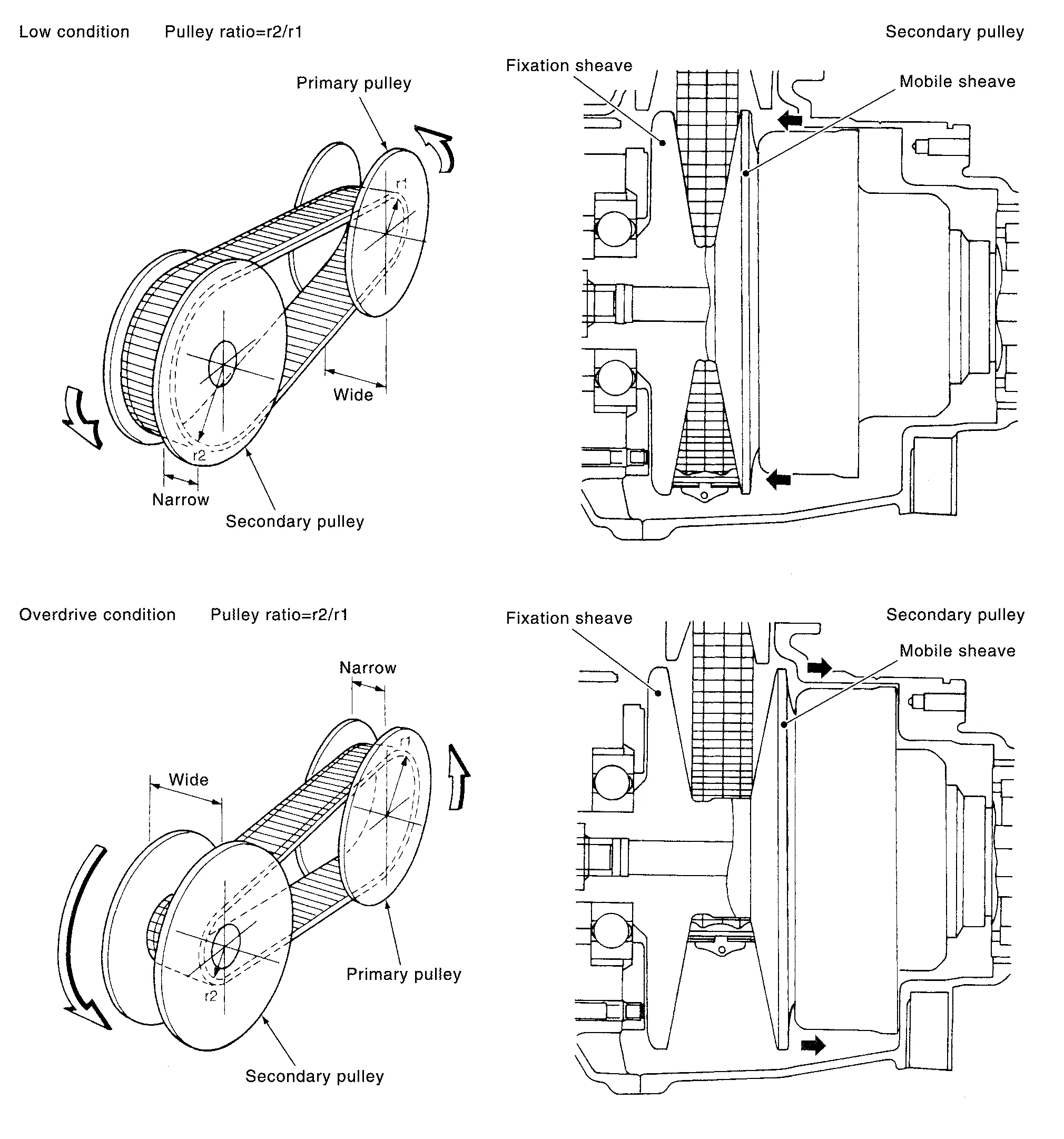

It is composed of a pair of pulleys (the groove width is changed freely in the axial direction) and the chain belt .The groove width changes according to wrapping radius of chain belt and pulley from low status to overdrive status continuously with non-step. It is controlled with the oil pressures of primary pulley and secondary pulley.

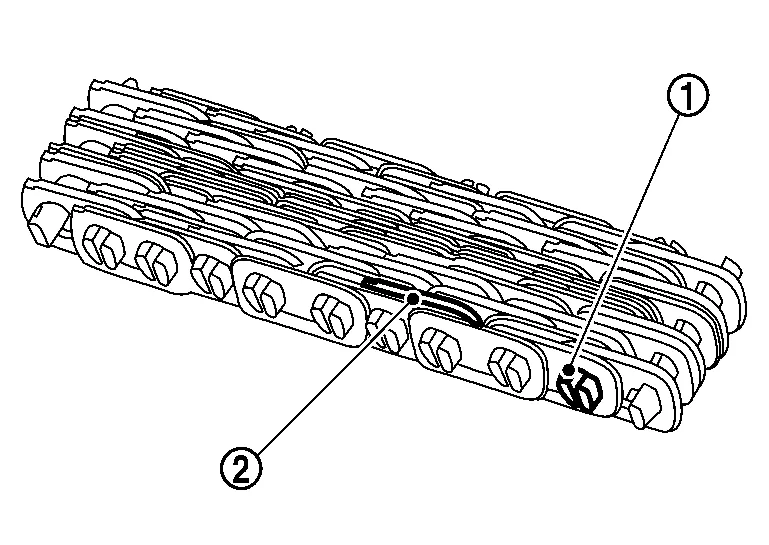

Chain belt

The chain belt consists of approximately 150 locker pins  and 1,000 link plates

and 1,000 link plates  . Chains are rotated by locker pins sandwiched by pulleys. This produces tension difference in chains among pulleys. Accordingly, the power is transferred by the tension.

. Chains are rotated by locker pins sandwiched by pulleys. This produces tension difference in chains among pulleys. Accordingly, the power is transferred by the tension.

Pulley

The primary pulley (input shaft side) and the secondary pulley (output shaft side) have the shaft with slope (fixed cone surface), movable sheave (movable cone surface that can move in the axial direction) and oil pressure chamber at the back of the movable sheave.

The movable sheave slides on the shaft to change the groove width of the pulley. Input signals of engine load (accelerator pedal opening), primary pulley speed and secondary pulley speed change the operation pressures of the primary pulley and the secondary pulley, and controls the pulley groove width.

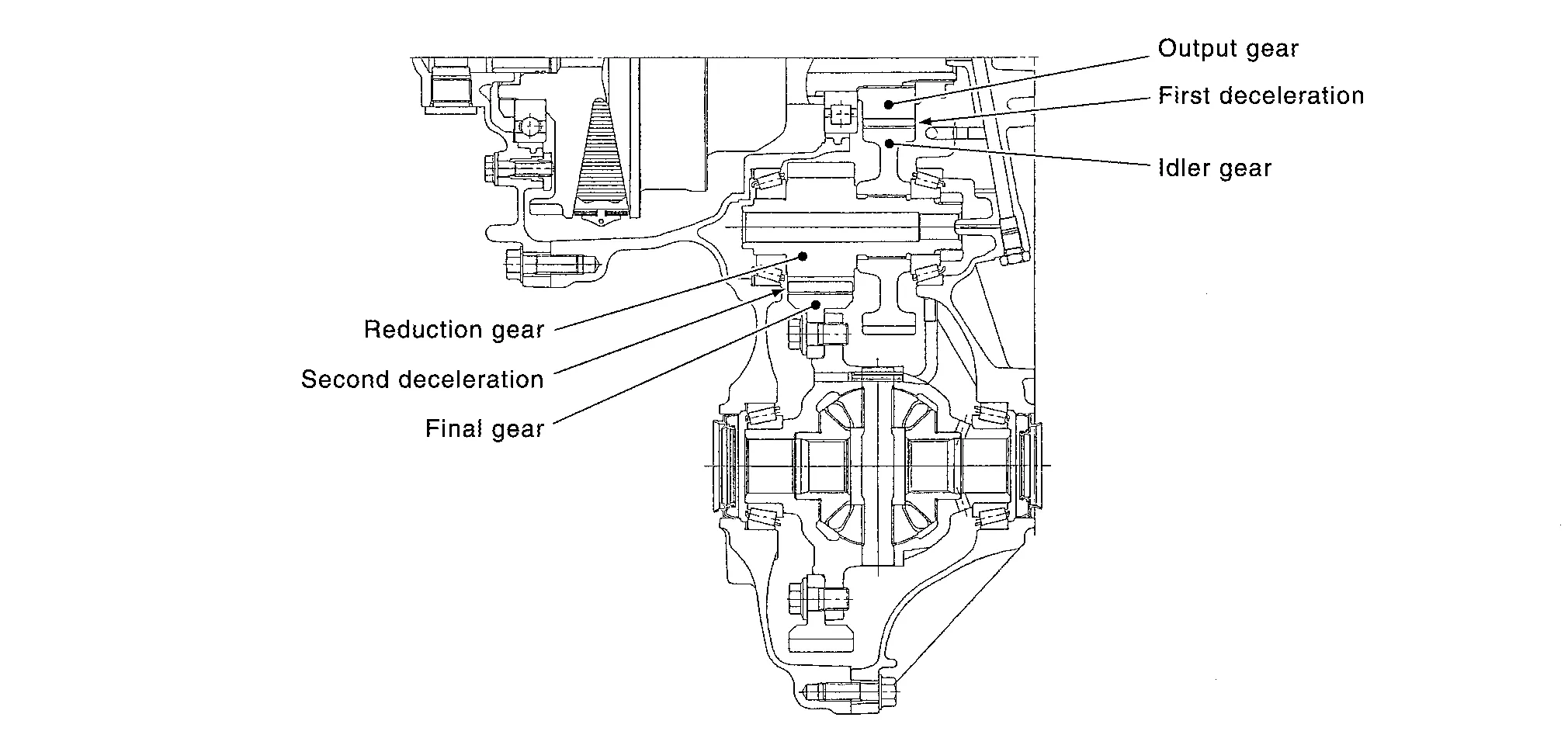

FINAL DRIVE AND DIFFERENTIAL

The deceleration gears are composed of 2 stages: primary deceleration (output gear, idler gear pair) and secondary deceleration (reduction gear, final gear pair). All of these gears are helical gears.

The lubrication oil is the same as the CVT fluid which lubricates the entire transaxle.

×: Engaged or applied.

| Selector lever position | Parking mechanism | Forward clutch | Reverse brake | Primary pulley | Secondary pulley | Chain belt | Final drive |

|---|---|---|---|---|---|---|---|

| P | × | ||||||

| R | × | × | × | × | × | ||

| N | |||||||

| D | × | × | × | × | × |

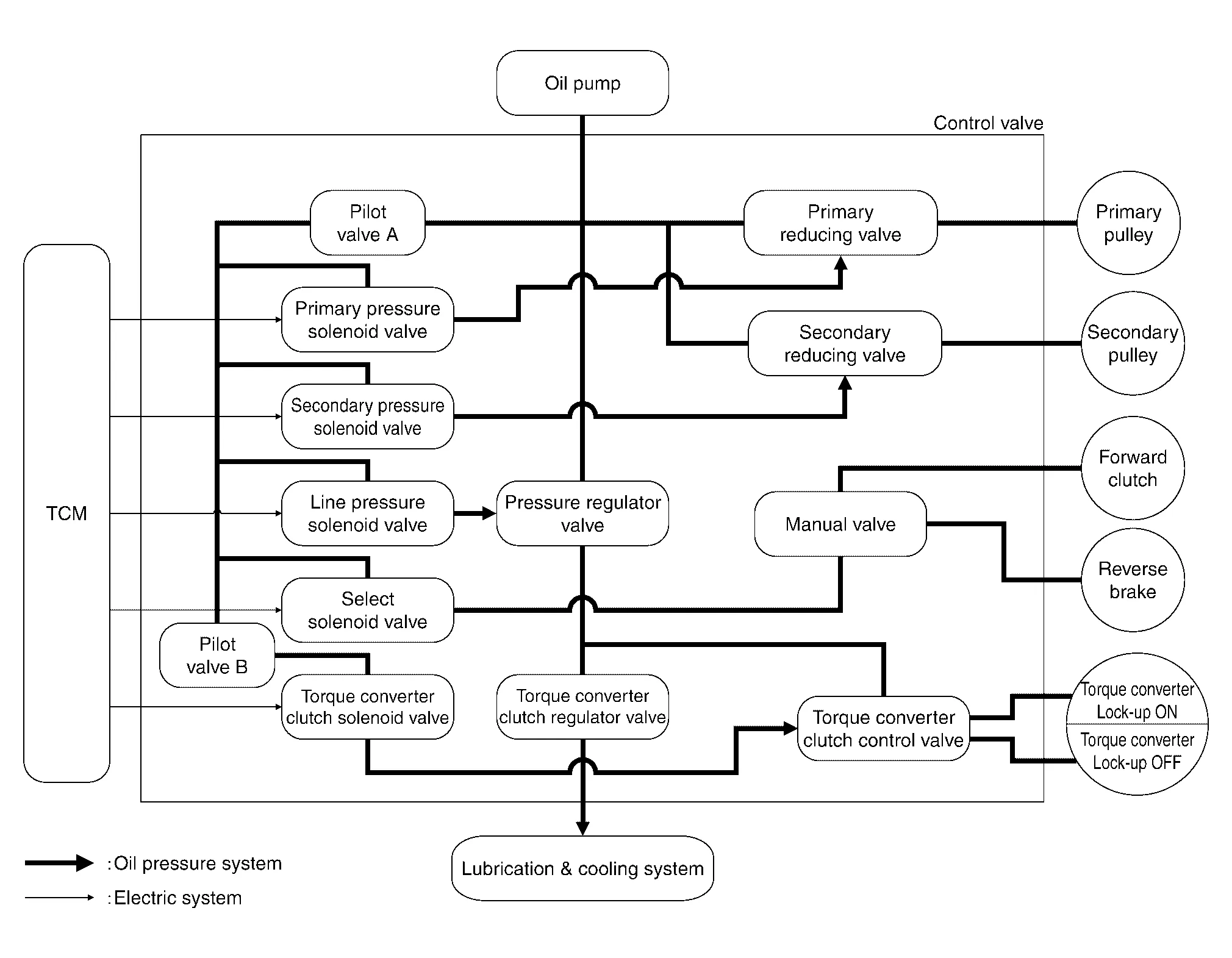

Oil pressure required for operation of the transaxle transmission mechanism is generated by oil pump, oil pressure control valve, solenoid valve, etc.

| Part name | Function |

|---|---|

| Torque converter | Increases engine torque and transmits it to the transaxle. |

| Oil pump | Utilizes a vane-type oil pump that is driven by the engine through the oil pump drive chain in order to increase efficiency of pump discharge volume in low-speed zone and optimize pump discharge volume in high-speed zone. Discharged oil from oil pump is transmitted to control valve. It is used as the oil of primary and secondary pulley operation, the oil of clutch operation, and the lubricant for each part. |

| Forward clutch | The forward clutch is wet and multiple plate type clutch that consists of clutch drum, piston, drive plate, and driven plate. It is a clutch to move the Nissan Murano vehicle forward by activating piston hydraulically, engaging plates, and directly connecting sun gear and input shaft. |

| Reverse brake | The reverse brake is a wet multiple-plate type brake that consists of transaxle case, piston, drive plate, and driven plate. It is a brake to move the Nissan Murano vehicle in reverse by activating piston hydraulically, engaging plates, and fixing planetary gear. |

| Internal gear | The internal gear is directly connected to forward clutch drum. It is a gear that moves the outer edge of pinion planet of planet carrier. It transmits power to move the Nissan Murano vehicle in reverse when the planet carrier is fixed. |

| Planet carrier | Composed of a carrier, pinion planet, and pinion shaft. This gear fixes and releases the planet carrier in order to switch between forward and reverse driving. |

| Sun gear | Sun gear is a set part with planet carrier and internal gear. It transmits transmitted force to primary fixed sheave. It rotates in forward or reverse direction according to activation of either forward clutch or reverse brake. |

| Input shaft | The input shaft is directly connected to forward clutch drum and transmits traction force from torque converter. In shaft center, there are holes for hydraulic distribution to primary pulley and hydraulic distribution for lockup ON/OFF. |

| Primary pulley | It is composed of a pair of pulleys (the groove width is changed freely in the axial direction) and the chain belt. The groove width changes according to wrapping radius of steel belt and pulley from low status to overdrive status continuously with non-step. It is controlled with the oil pressures of primary pulley and secondary pulley. |

| Secondary pulley | |

| Chain belt | |

| Manual shaft | When the manual shaft is in the P position, the parking rod that is linked to the manual shaft rotates the parking pole. When the parking pole rotates, it engages with the parking gear, fixing the parking gear. As a result, the secondary pulley that is integrated with the parking gear is fixed. |

| Parking rod | |

| Parking pawl | |

| Parking gear | |

| Output gear | The deceleration gears are composed of 2 stages: primary deceleration (output gear, idler gear pair) and secondary deceleration (reduction gear, final gear pair). All of these gears are helical gears. |

| Idler gear | |

| Reduction gear | |

| Differential | |

| Torque converter regulator valve | Adjusts the feed pressure to the torque converter to the optimum pressure corresponding to the driving condition. |

| Pressure regulator valve | Adjusts the discharge pressure from the oil pump to the optimum pressure (line pressure) corresponding to the driving condition. |

| Torque converter clutch control valve | Adjusts the torque converter engage and disengage pressures. |

| Manual valve | Distributes the clutch operation pressure to each circuit according to the selector lever position. |

| Secondary reducing valve | Reduces line pressure and adjusts secondary pressure. |

| Primary reducing valve | Reduces line pressure and adjusts primary pressure. |

| Pilot valve A |

Reduces line pressure and adjusts pilot pressure to the solenoid valves listed below.

|

| Pilot valve B | Reduces pilot pressure and adjusts pilot pressure to the torque converter clutch solenoid valve. |

Fluid Cooler Fluid Warmer System

Fluid Cooler Fluid Warmer System

System Description

CVT FLUID COOLER SCHEMATICCOMPONENT DESCRIPTIONCVT Oil Warmer

The CVT oil warmer (1) is installed on the front part of transaxle assembly...

Other information:

Nissan Murano (Z52) 2015-2024 Owners Manual: Hazard warning flasher switch

Push the switch on to warn other drivers when you must stop or park under emergency conditions. All turn signal lights flash. WARNING If stopping for an emergency, be sure to move the vehicle well off the road. Do not use the hazardwarning flashers while moving on the highway unless unusual circumstances force you to drive so slowly that your vehicle might become a hazard to other traffic...

Nissan Murano (Z52) 2015-2024 Service Manual: Optical Sensor

Exploded View 1. Optical sensor 2. Defroster grille A. Harness connector Pawl Removal and Installation REMOVALUsing a suitable tool, release pawls and remove optical sensor (2) from defroster grille (1). : Pawl Disconnect harness connector (A) from optical sensor...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Turning the AEB system on/off

- GAS STATION INFORMATION

- Tire rotation

- New on site

- Most important about car

LATCH (Lower Anchors and Tethers for CHildren) system

LATCH system lower anchor locations - bench seat

Your vehicle is equipped with special anchor points that are used with LATCH system compatible child restraints. This system may also be referred to as the ISOFIX or ISOFIX compatible system. With this system, you do not have to use a vehicle seat belt to secure the child restraint unless the combined weight of the child and child restraint exceeds 65 lbs. (29.5 kg). If the combined weight of the child and child restraint is greater than 65 lbs. (29.5 kg), use the vehicle’s seat belt (not the lower anchors) to install the child restraint. Be sure to follow the child restraint manufacturer’s instructions for installation.