Nissan Murano: Dtc/circuit Diagnosis / P0441 Evap Control System

DTC DETECTION LOGIC

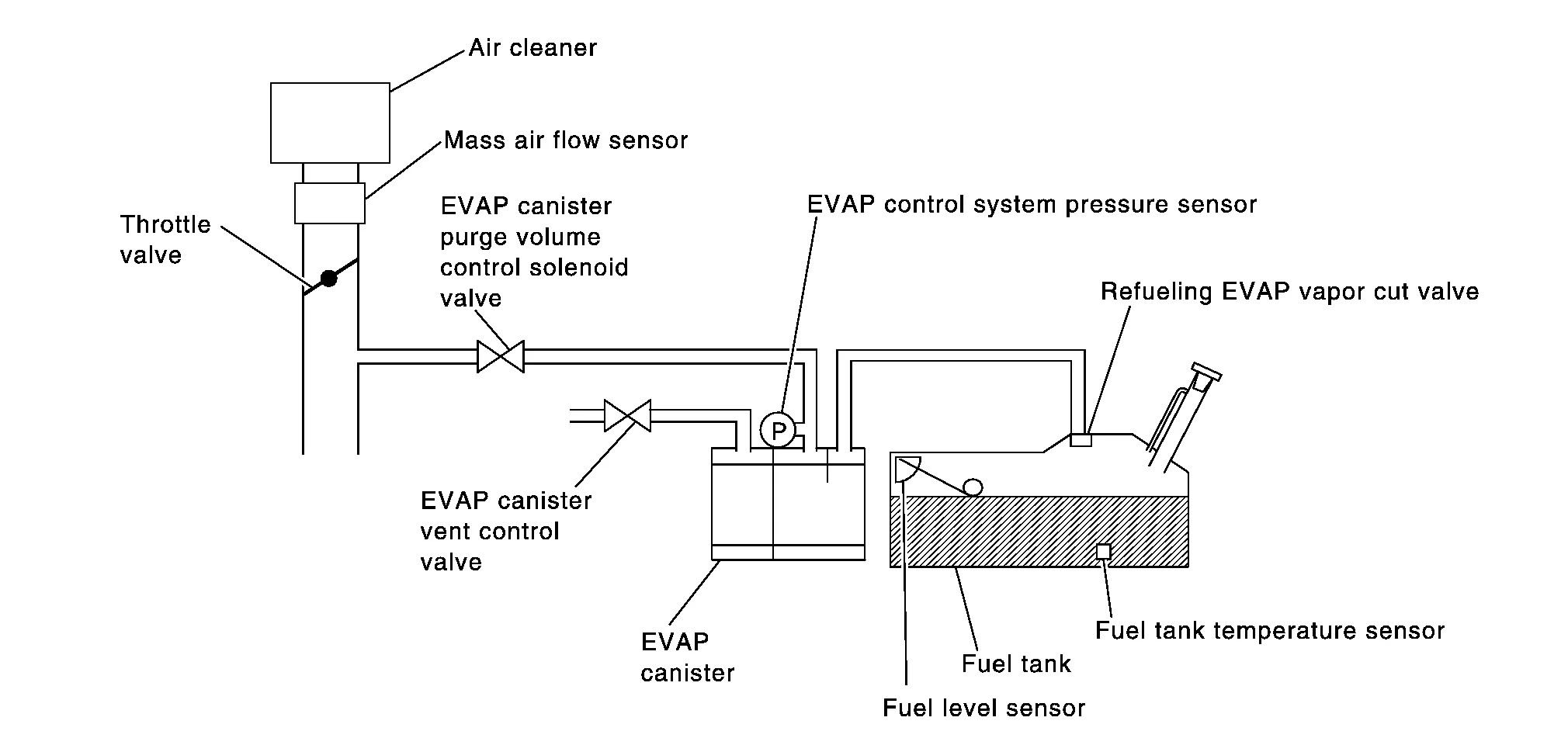

In this evaporative emission (EVAP) control system, purge flow occurs during non-closed throttle conditions. Purge volume is related to air intake volume. Under normal purge conditions (non-closed throttle), the EVAP canister purge volume control solenoid valve is open to admit purge flow. Purge flow exposes the EVAP control system pressure sensor to intake manifold vacuum.

Under normal conditions (non-closed throttle), sensor output voltage indicates if pressure drop and purge flow are adequate. If not, a malfunction is determined.

EVAP control system does not operate properly, EVAP control system has a leakage between intake manifold and EVAP control system pressure sensor.

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | |

| P0441 |

EVAP PURG FLOW/MON (Evaporative emission system incorrect purge flow) |

Diagnosis condition | — |

| Signal (terminal) | — | ||

| Threshold | EVAP control system does not operate properly, EVAP control system has a leakage between intake manifold and EVAP control system pressure sensor | ||

| Diagnosis delay time | — | ||

POSSIBLE CAUSE

-

EVAP canister purge volume control solenoid valve stuck closed

-

EVAP control system pressure sensor and the circuit

-

Loose, disconnected or improper connection of rubber tube

-

Blocked rubber tube

-

Cracked EVAP canister

-

EVAP canister purge volume control solenoid valve circuit

-

Accelerator pedal position sensor

-

Blocked purge port

-

EVAP canister vent control valve

FAIL-SAFE

Not applicable

CHECK DTC PRIORITY

If DTC P0441 is displayed with other DTC such as P2122, P2123, P2127, P2128 or P2138, first perform trouble diagnosis for other DTC.

Is applicable DTC detected?

YES>>Perform diagnosis of applicable. Refer to DTC Index.

NO>>GO TO 2.

INSPECTION START

Will CONSULT be used?

Will CONSULT be used?

YES>>GO TO 3.

NO>>GO TO 7.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Always perform test at a temperature of 5°C (41°F) or more.

>>

GO TO 4.

PERFORM DTC CONFIRMATION PROCEDURE-I

With CONSULT

With CONSULT

-

Start engine and warm it up to normal operating temperature.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Start engine and let it idle for at least 70 seconds.

-

Select “PURG FLOW P0441” of “EVAPORATIVE SYSTEM” in “DTC WORK SUPPORT” mode with CONSULT.

-

Touch “START”.

Is “COMPLETED” displayed on CONSULT screen?

YES>>GO TO 6.

NO>>GO TO 5.

PERFORM DTC CONFIRMATION PROCEDURE-II

When the following conditions are met, “TESTING” will be displayed on the CONSULT screen. Maintain the conditions continuously until “TESTING” changes to “COMPLETED”. (It will take at least 35 seconds.)

| Selector lever | Suitable position |

| VHCL SPEED SE | 32 - 120 km/h (20 - 75 mph) |

| ENG SPEED | 500 - 3,000 rpm |

| B/FUEL SCHDL | 1.25 - 9.0 msec |

| COOLANT TEMP/S | More than 0°C (32°F) |

CAUTION:

Always drive Nissan Murano vehicle at a safe speed.

If “TESTING” does not change for a long time, retry from step 2.

Is “COMPLETED” displayed on CONSULT screen?

YES>>GO TO 6.

NO>>Perform DTC CONFIRMATION PROCEDURE again. GO TO 3.

PERFORM DTC CONFIRMATION PROCEDURE-III

Touch “SELF-DIAG RESULTS”.

Which is displayed on CONSULT screen?

OK-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

OK-2>>Confirmation after repair: INSPECTION END

NG>>Proceed to Diagnosis Procedure.

PERFORM COMPONENT FUNCTION CHECK

Without CONSULT

Without CONSULT

-

Lift up drive wheels.

-

Start engine (VDC switch OFF) and warm it up to normal operating temperature.

-

Turn ignition switch OFF, wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF, wait at least 10 seconds.

-

Start engine and wait at least 70 seconds.

-

Set voltmeter probes to ECM harness connector terminals under the following conditions.

ECM Connector + – Terminal E32 121 148 -

Check EVAP control system pressure sensor value at idle speed and note it.

-

Establish and maintain the following conditions for at least 1 minute.

Air conditioner switch ON Head lamp switch ON Rear window defogger switch ON Engine speed Approx. 3,000 rpm Gear position Any position other than P, N or R -

Verify that EVAP control system pressure sensor value stays 0.1 V less than the value at idle speed (measured at step 6) for at least 1 second.

Is the inspection result normal?

YES>>To check malfunction symptom before repair: Refer to Intermittent Incident.

YES>>Confirmation after repair: INSPECTION END

NO>>Proceed to Diagnosis Procedure.

CHECK DTC PRIORITY

If DTC P0441 is displayed with other DTC such as P2122, P2123, P2127, P2128 or P2138, first perform trouble diagnosis for other DTC.

Is applicable DTC detected?

YES>>Perform diagnosis of applicable. Refer to DTC Index.

NO>>GO TO 2.

CHECK EVAP CANISTER

-

Turn ignition switch OFF.

-

Check EVAP canister for cracks.

Is the inspection result normal?

YES>>With CONSULT: GO TO 3.

YES>>Without CONSULT: GO TO 4.

NO>>Replace EVAP canister. Refer to Removal and Installation.

CHECK PURGE FLOW

With CONSULT

With CONSULT

-

Disconnect vacuum hose connected to EVAP canister purge volume control solenoid valve at EVAP service port and install vacuum gauge. For the location of EVAP service port, refer to System Description.

-

Start engine and let it idle.

-

Select “PURG VOL C/V” in “ACTIVE TEST” mode with CONSULT.

-

Touch “Qd” and “Qu” on CONSULT screen to adjust “PURG VOL C/V” opening and check vacuum existence.

PURG VOL C/V Vacuum 100% Existed 0% Not existed

Is the inspection result normal?

YES>>GO TO 8.

NO>>GO TO 5.

CHECK PURGE FLOW

Without CONSULT

Without CONSULT

-

Start engine and warm it up to normal operating temperature.

-

Stop engine.

-

Disconnect vacuum hose connected to EVAP canister purge volume control solenoid valve at EVAP service port and install vacuum gauge. For the location of EVAP service port, refer to System Description.

-

Start engine and let it idle.

Do not depress accelerator pedal even slightly.

-

Check vacuum gauge indication before 60 seconds pass after starting engine.

Vacuum should not exist. -

Rev engine up to 2,000 rpm after 100 seconds pass after starting engine.

Vacuum should exist.

Is the inspection result normal?

YES>>GO TO 8.

NO>>GO TO 5.

CHECK EVAP PURGE LINE

-

Turn ignition switch OFF.

-

Check EVAP purge line for improper connection or disconnection.

Refer to System Description.

Is the inspection result normal?

YES>>GO TO 6.

NO>>Repair EVAP purge line.

CHECK EVAP PURGE HOSE AND PURGE PORT

-

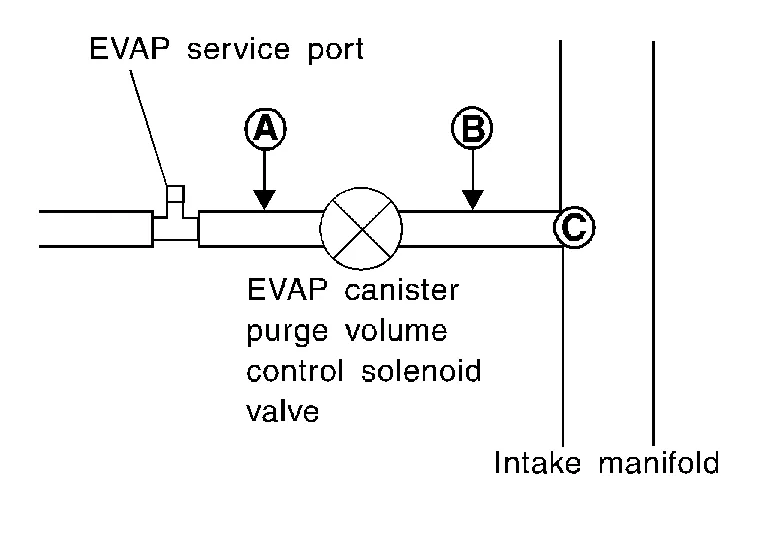

Disconnect purge hoses connected to EVAP service port A and EVAP canister purge volume control solenoid valve B.

-

Blow air into each hose and EVAP purge port C.

-

Check that air flows freely.

Is the inspection result normal?

YES>>With CONSULT: GO TO 7.

YES>>Without CONSULT: GO TO 8.

NO>>Repair or clean hoses and/or purge port.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT

With CONSULT

-

Start engine.

-

Perform “PURG VOL C/V” in “ACTIVE TEST” mode with CONSULT. Check that engine speed varies according to the valve opening.

Does engine speed vary according to the valve opening?

YES>>GO TO 9.

NO>>GO TO 8.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Check EVAP canister purge volume control solenoid valve. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 9.

NO>>Replace EVAP canister purge volume control solenoid valve. Refer to Component Parts Location.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

-

Disconnect EVAP control system pressure sensor harness connector.

-

Check that water is not inside connectors.

Is the inspection result normal?

YES>>GO TO 10.

NO>>Replace EVAP control system pressure sensor. Refer to Removal and Installation.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR FUNCTION

Check EVAP control system pressure sensor function. Refer to DTC Description for DTC P0452, DTC Description for DTC P0453.

Is the inspection result normal?

YES>>GO TO 11.

NO>>Replace EVAP control system pressure sensor. Refer to Removal and Installation.

CHECK RUBBER TUBE FOR CLOGGING

-

Disconnect rubber tube connected to EVAP canister vent control valve.

-

Check the rubber tube for clogging.

Is the inspection result normal?

YES>>GO TO 12.

NO>>Clean the rubber tube using an air blower.

CHECK EVAP CANISTER VENT CONTROL VALVE

Check EVAP canister vent control valve. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 13.

NO>>Replace EVAP canister vent control valve. Refer to Removal and Installation.

CHECK EVAP PURGE LINE

Inspect EVAP purge line (pipe and rubber tube). Check for evidence of leakage.

Refer to System Description.

Is the inspection result normal?

YES>>GO TO 14.

NO>>Repair EVAP purge line.

CLEAN EVAP PURGE LINE

Clean EVAP purge line (pipe and rubber tube) using air blower.

>>

INSPECTION END

P0420 Three Way Catalyst Function

P0420 Three Way Catalyst Function

DTC Description

DTC DETECTION LOGICThe ECM monitors the switching frequency ratio of air fuel ratio (A/F) sensor 1 and heated oxygen sensor 2.A three way catalyst (manifold) with high oxygen storage capacity will indicate a low switching frequency of heated oxygen sensor 2...

P0443 Evap Canister Purge Volume Control Solenoid Valve

P0443 Evap Canister Purge Volume Control Solenoid Valve

DTC Description

DTC DETECTION LOGIC

The canister purge flow is detected during the vehicle is stopped while the engine is running, even when EVAP canister purge volume control solenoid valve is completely closed...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: C1160 Incomplete Decel G Sensor Calibration

DTC Description DTC DETECTION LOGIC DTC No. CONSULT screen item (Trouble diagnosis content) DTC detected condition C1160 DECEL G SEN SET (Decel G sensor set) Diagnosis condition When ignition switch ON. Signal (terminal) — Threshold When calibration of yaw rate/side/decel G sensor is not complete...

Nissan Murano (Z52) 2015-2024 Service Manual: Daytime Running Light Relay Circuit

Component Function Check CHECK DAYTIME RUNNING LIGHT OPERATION CONSULT Select “EXTERNAL LAMPS” in “Active Test” mode of “IPDM E/R”. While operating the test items, check daytime running light operation. TAIL : Daytime running light ON Off : Daytime running light Off Is the inspection result normal? YES>> Daytime running light relay circuit is normal...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Power Steering Fluid (PSF)

- Shift lock release

- How to enable/disable the LDW system

- New on site

- Most important about car

Luggage hooks

When securing items using luggage hooks located on the back of the seat or side finisher do not apply a load over more than 6.5 lbs. (29 N) to a single hook.

The luggage hooks that are located on the floor should have loads less than 110 lbs. (490 N) to a single hook.