Nissan Murano: Removal and Installation / Electric Controlled Coupling

|

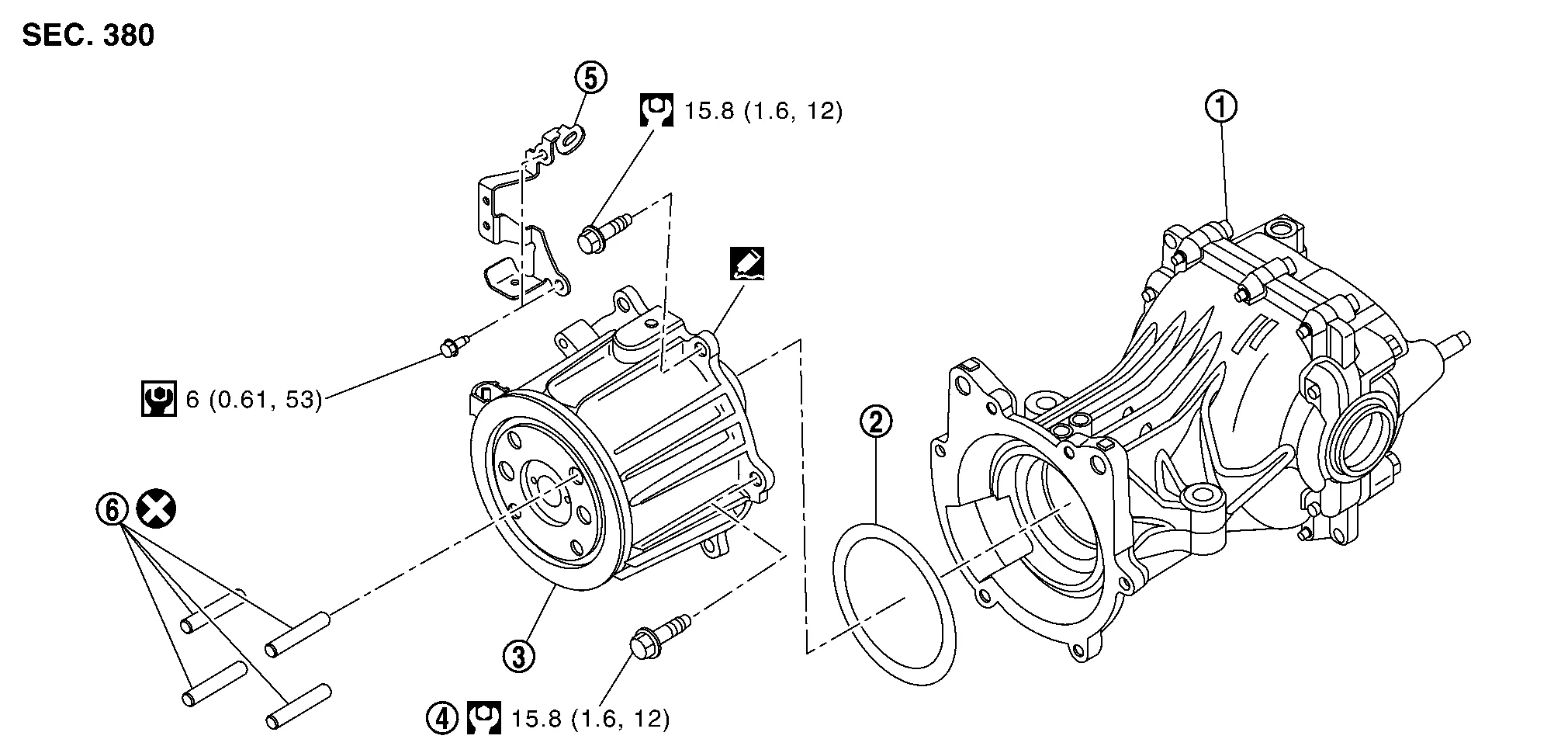

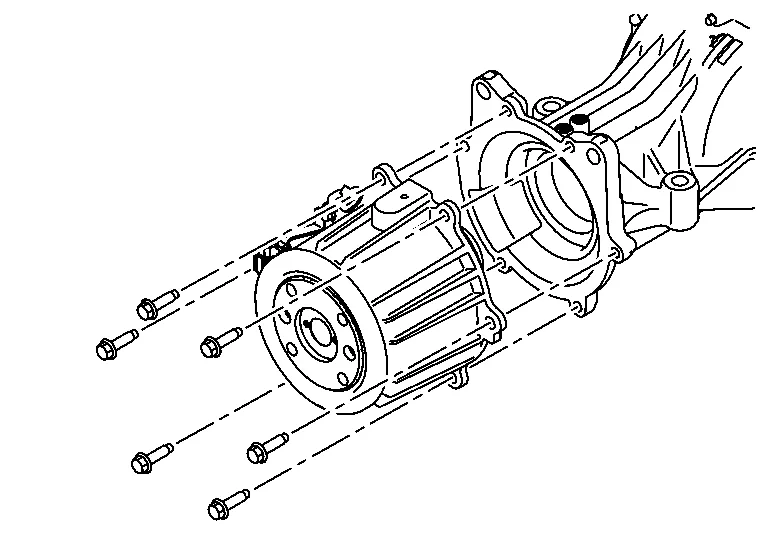

Rear final drive assembly |  |

Wave spring |  |

Electric controlled coupling assembly |

|

Reamer bolt |  |

Connector bracket |  |

Stud bolt |

: N·m (kg-m, in-lb) : N·m (kg-m, in-lb) |

|||||

: N·m (kg-m, ft-lb) : N·m (kg-m, ft-lb) |

|||||

: Always replace after every disassembly. : Always replace after every disassembly. |

|||||

: Apply Genuine Silicone RTV or equivalent. Refer to Recommended Chemical Products and Sealants. : Apply Genuine Silicone RTV or equivalent. Refer to Recommended Chemical Products and Sealants. |

|||||

NOTE:

NOTE:

-

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

-

Before replacing electric controlled coupling due to vibration and/or noise when making low speed turns, refer to TSB to assist in proper diagnosis.

REMOVAL

Drain gear oil. Refer to Draining.

Remove propeller shaft from rear final drive assembly. Refer to Removal and Installation.

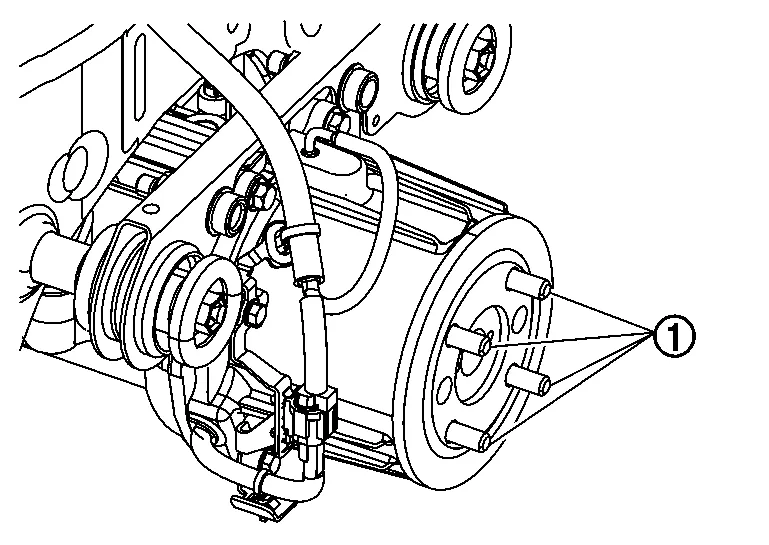

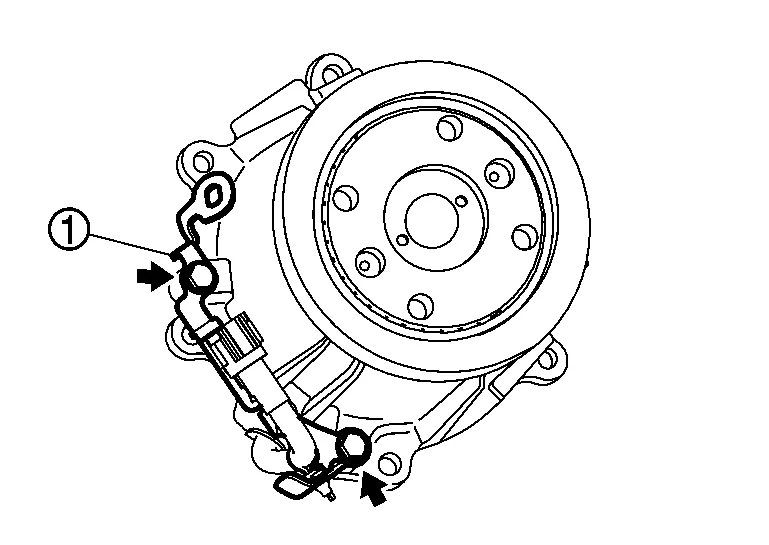

Remove stud bolts (1).

CAUTION:

After removing propeller shaft, replace stud bolt.

NOTE:

NOTE:

When replacing electric controlled coupling assembly, stud bolts are not required to be removed.

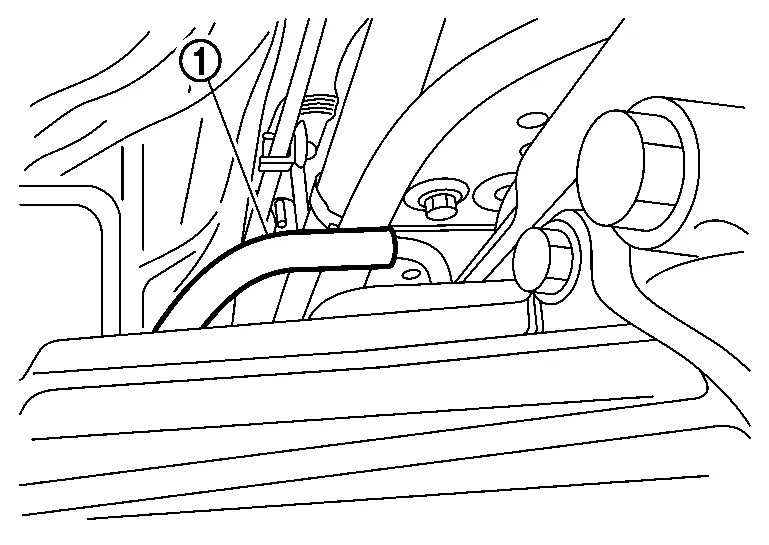

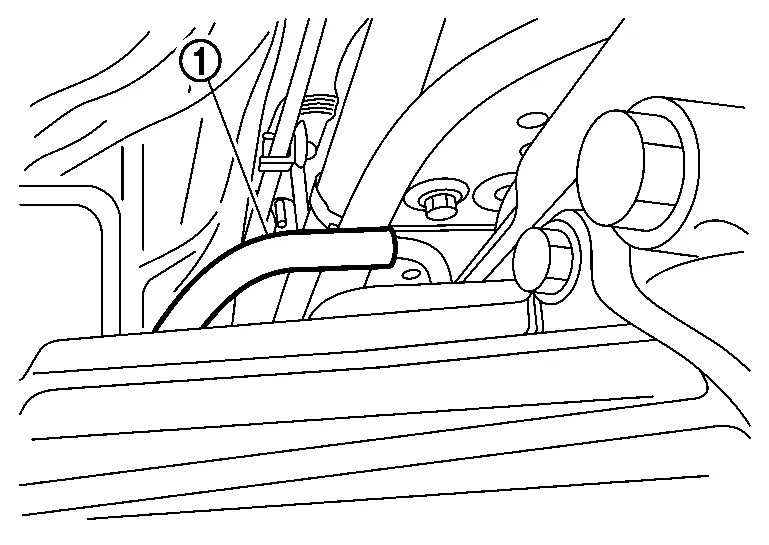

Disconnect AWD solenoid harness connector (1).

Remove air breather hose (1) from electric controlled coupling assembly. Refer to Removal and Installation.

Remove electric controlled coupling assembly from final drive assembly.

Remove wave spring.

Remove drive pinion oil seal from the inside of gear carrier. Refer to Removal and Installation.

CAUTION:

When removing electric controlled coupling, replace drive pinion oil seal.

Remove connector bracket (1) from electric controlled coupling.

|

bolt |

Remove connector clip to disconnect connector bracket from AWD solenoid harness connector.

|

Clip |

INSTALLATION

Install connector bracket to electric controlled coupling.

-

For tightening torque, refer to Exploded View.

Lock AWD solenoid harness with connector clip.

Install drive pinion oil seal to the inside of gear carrier. Refer to Removal and Installation.

CAUTION:

When removing electric controlled coupling, replace drive pinion oil seal.

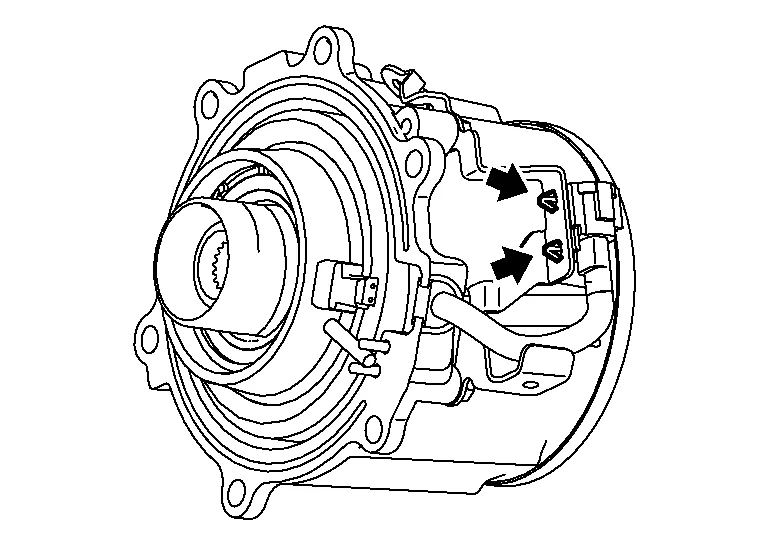

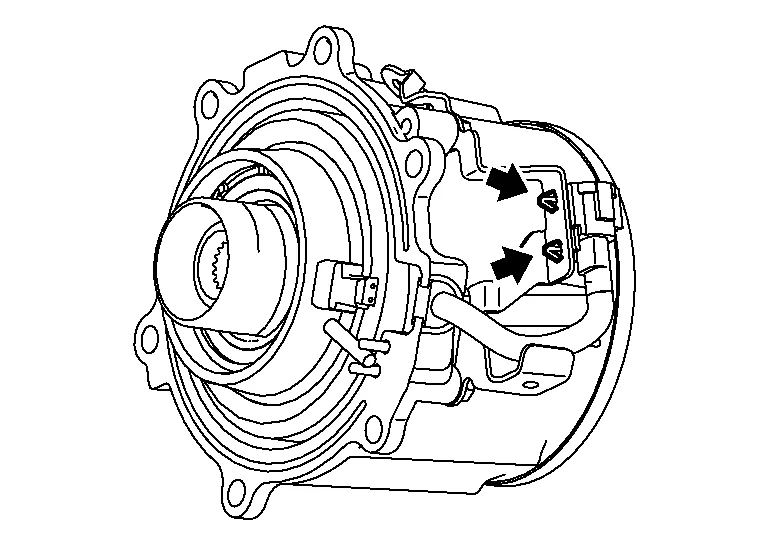

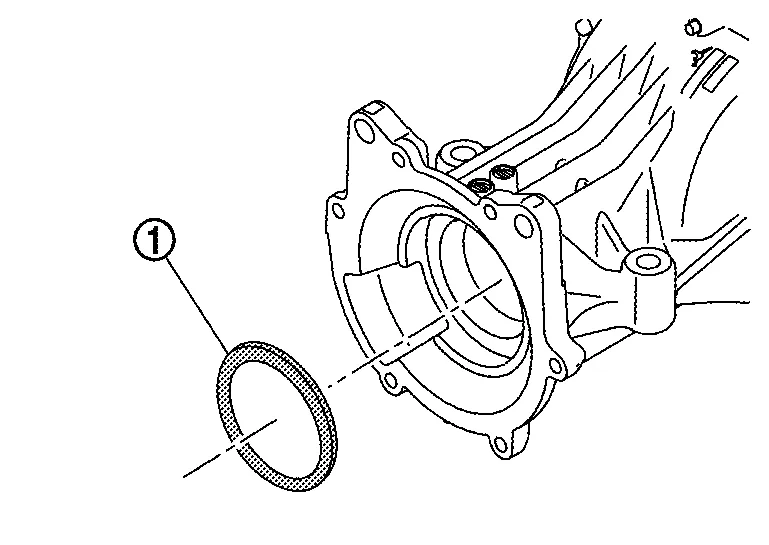

Install wave spring (1) to the inside of gear carrier.

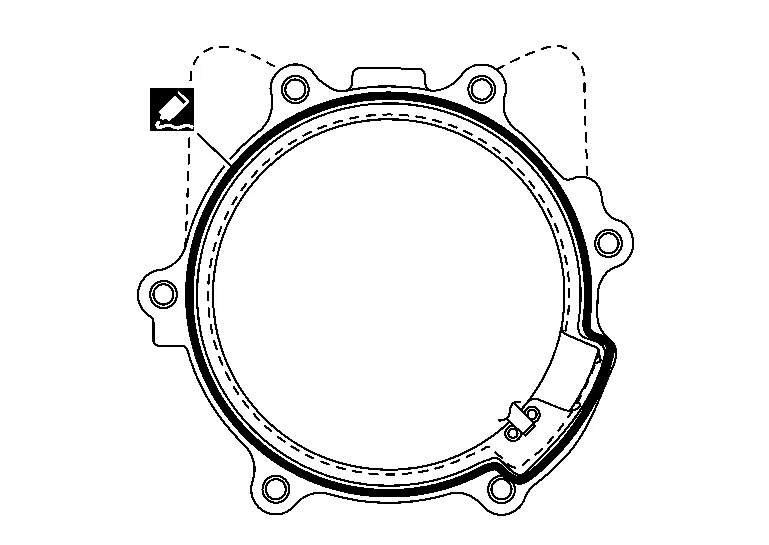

Apply liquid gasket to mating surface of electric controlled coupling assembly.

-

For applying liquid gasket, refer to Exploded View.

CAUTION:

-

Remove old gasket adhering to the mounting surfaces. Also remove any moisture, oil, or foreign material adhering to the mounting surfaces.

-

The width of sealant bead is approximately 3 mm (0.12 in). Apply sealant evenly.

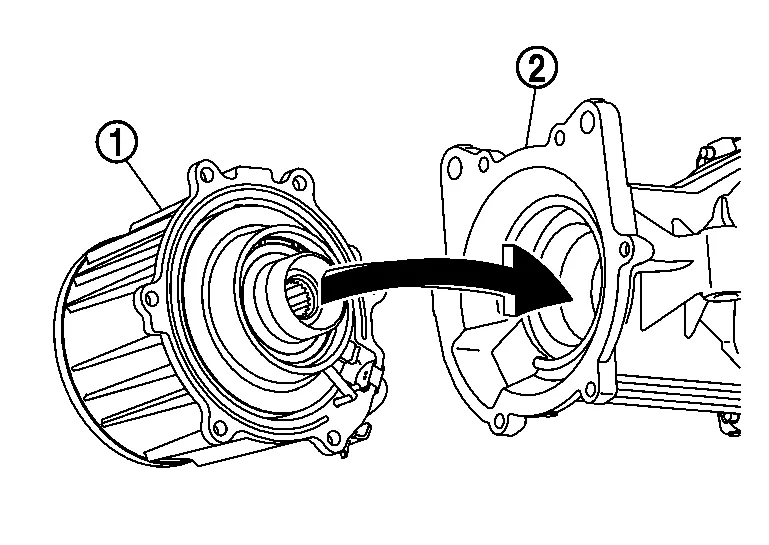

Join electric controlled coupling assembly (1) to spline of drive pinion, then install it to final drive assembly (2).

CAUTION:

Be careful not to damage drive pinion oil seal.

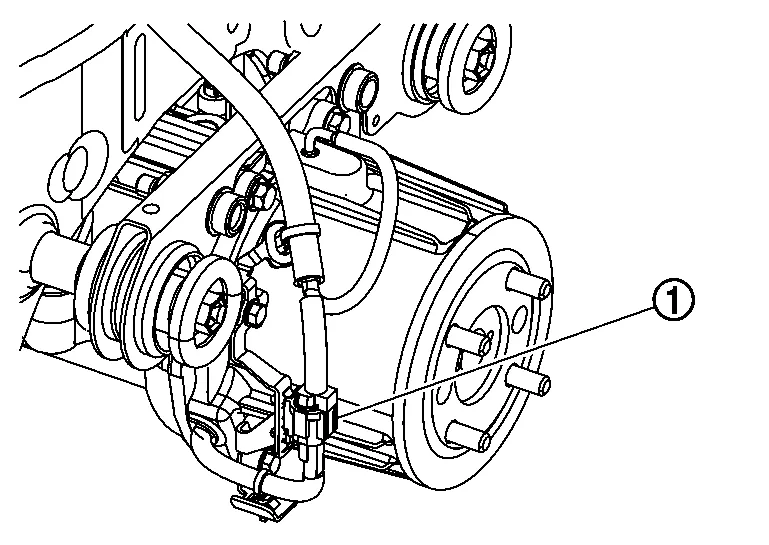

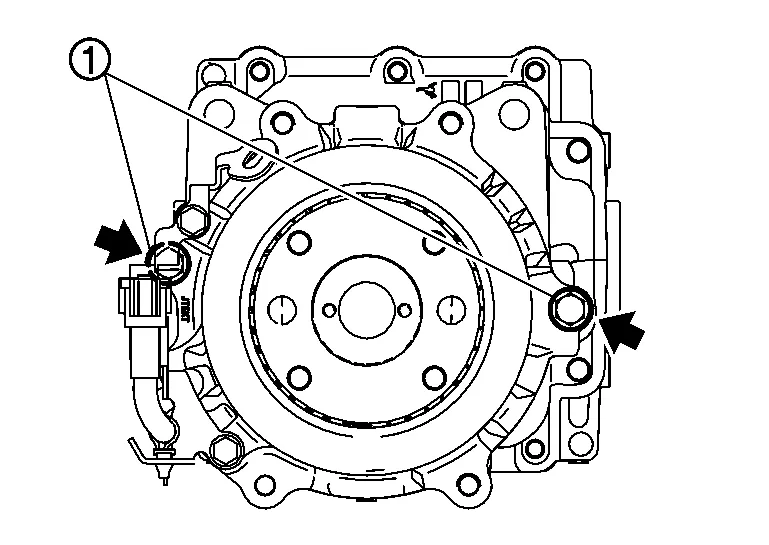

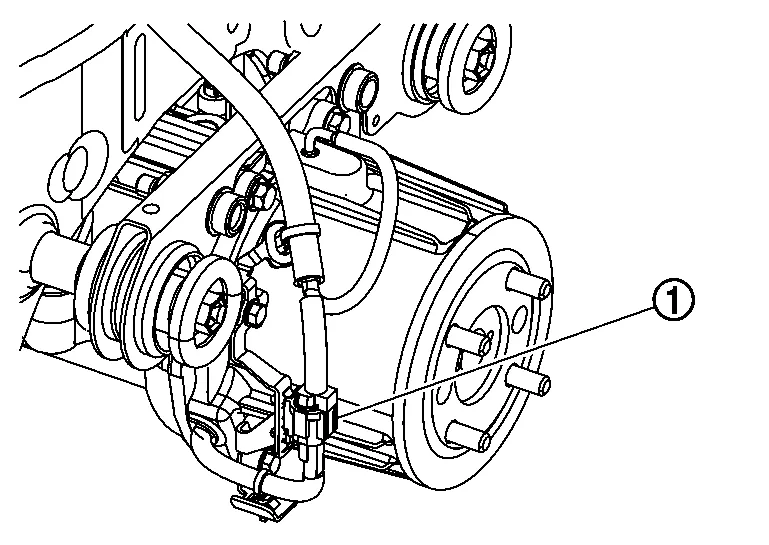

Temporarily tighten reamer bolts (1) to the positions shown in the figure.

Tighten reamer bolts and electric controlled coupling assembly mounting bolts to the specified torque.

-

For tightening torque, refer to Exploded View.

Install air breather hose (1) to electric controlled coupling assembly. Refer to Removal and Installation.

Connect AWD solenoid harness connector (1).

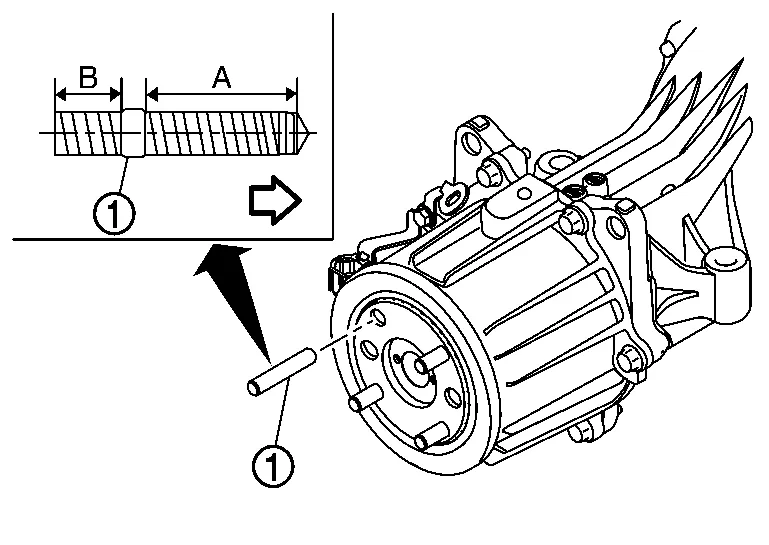

Install stud bolts (1).

|

: Electric controlled coupling side |

| Thread length | |

| A | : Long |

| B | : Short |

CAUTION:

-

Do not reuse stud bolt.

-

After removing propeller shaft, replace stud bolt.

-

Screw long thread side of stud bolt to electric controlled coupling.

-

Screw the stud bolt until the stop by applying a torque of 15 N·m (1.5 kg-m, 11 ft-lb) ±20%.

-

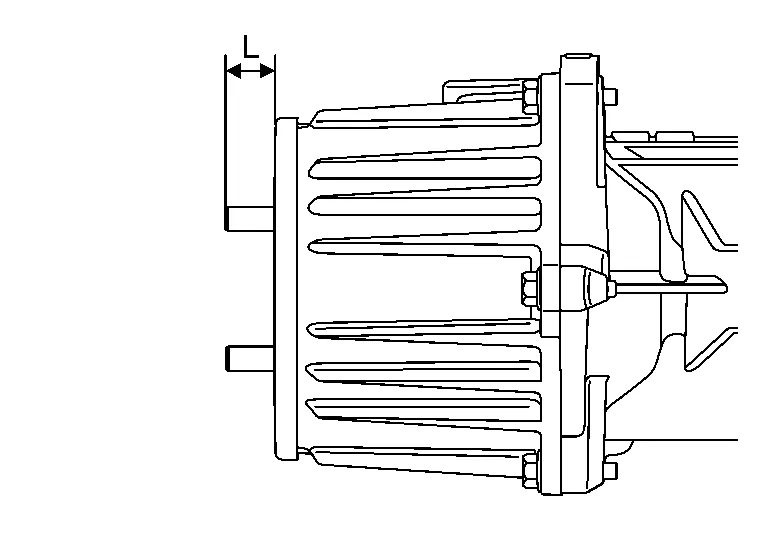

After installing stud bolt, the length of the protrusion from electric controlled coupling must be as described below.

Length (L) : 19.8 mm (0.780 in) ±1.4 mm (0.055 in)

NOTE:

NOTE:

When replacing electric controlled coupling assembly, stud bolts are not required to be installed.

Install propeller shaft. Refer to Removal and Installation.

Refill gear oil to the final drive. Refer to Refilling.

Perform inspection and adjustment after installation. Refer to Inspection and Adjustment.

INSPECTION AFTER INSTALLATION

Check final drive for leaks.

Check oil level. Refer to Inspection.

ADJUSTMENT AFTER INSTALLATION

When replaced electric controlled coupling, perform writing unit characteristics. Refer to Description.

Side Oil Seal

Side Oil Seal

Exploded View

Rear final drive assembly

Side oil seal

Oil seal lip

: Always replace after every disassembly...

Air Breather

Air Breather

Exploded View

1.

Rear final drive breather

2.

Breather connector (resin)

3.

Air breather hose

4.

Breather connector (metal)

5.

Rear final drive assembly

: Always replace after every disassembly...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Instrument Panel :: Preparation. Preparation

Special Service Tool The actual shape of the tools may differ from those illustrated here. Tool number (TechMate No.) Tool name Description — (J-39570) Chassis Ear Locating the noise — (J-50397) Squeak and Rattle Kit Repairing the cause of noise — (J-46534) Trim Tool Set Removing trim components Commercial Service Tools (TechMate No...

Nissan Murano (Z52) 2015-2024 Service Manual: Battery Saver Output/power Supply Circuit

Component Function Check CHECK INTERIOR ROOM LAMP POWER SUPPLY FUNCTION CONSULT Ignition switch ON. Turn each interior room lamp ON. Personal lamp 2nd row LH Personal lamp 2nd row RH Front room/map lamp assembly Luggage room lamp Vanity lamp LH Vanity lamp RH Select “BATTERY SAVER” in “Active Test” mode of “BCM(BATTERY SAVER)”...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- All-Wheel Drive (AWD) (if so equipped)

- Turning the AEB system on/off

- Intelligent Forward Collision Warning (I-FCW)

- New on site

- Most important about car