Nissan Murano: Engine Mechanical :: Removal and Installation / Camshaft

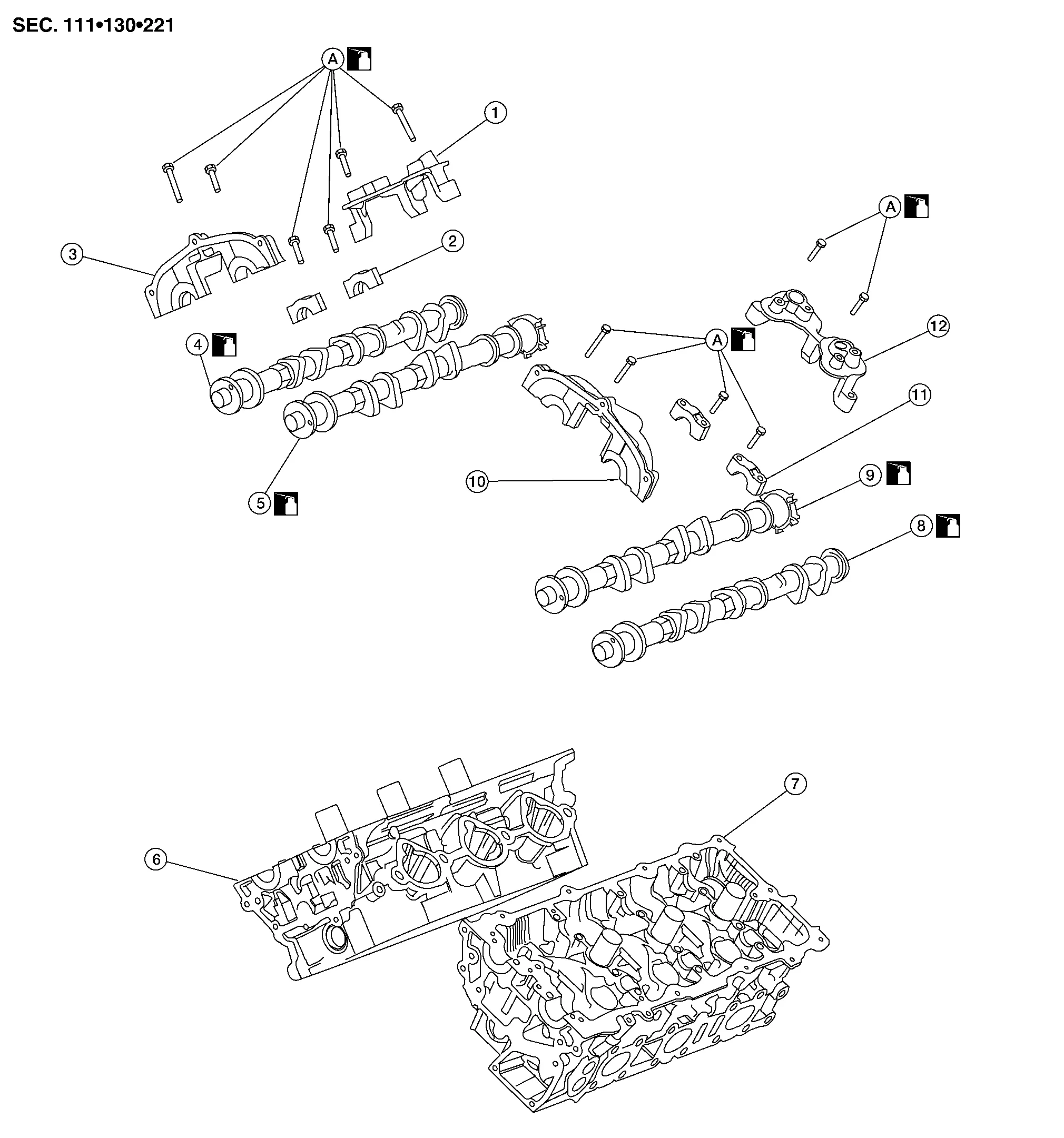

| 1. | Camshaft position sensor bracket (bank 1) | 2. | Camshaft brackets | 3. | No. 1 camshaft bracket (bank 1) |

| 4. | Camshaft (EXH) (bank 1) | 5. | Camshaft (INT) (bank 1) | 6. | Cylinder head (bank 1) |

| 7. | Cylinder head (bank 2) | 8. | Camshaft (EXH) (bank 2) | 9. | Camshaft (INT) (bank 2) |

| 10. | No. 1 camshaft bracket (bank 2) | 11. | Camshaft brackets | 12. | Camshaft position sensor bracket (bank 2) |

| A. | Refer to Removal and Installation. |

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

REMOVAL

Remove the timing chains. Refer to Removal and Installation.

Remove camshaft position sensor brackets (RH shown LH similar).

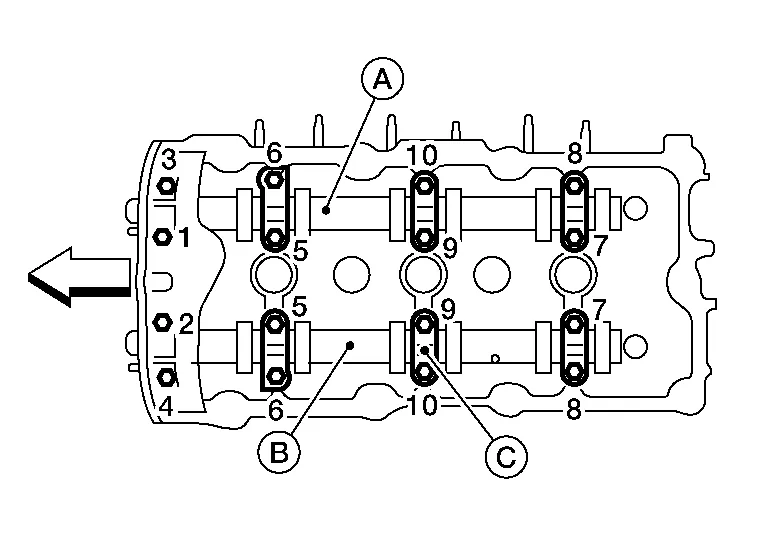

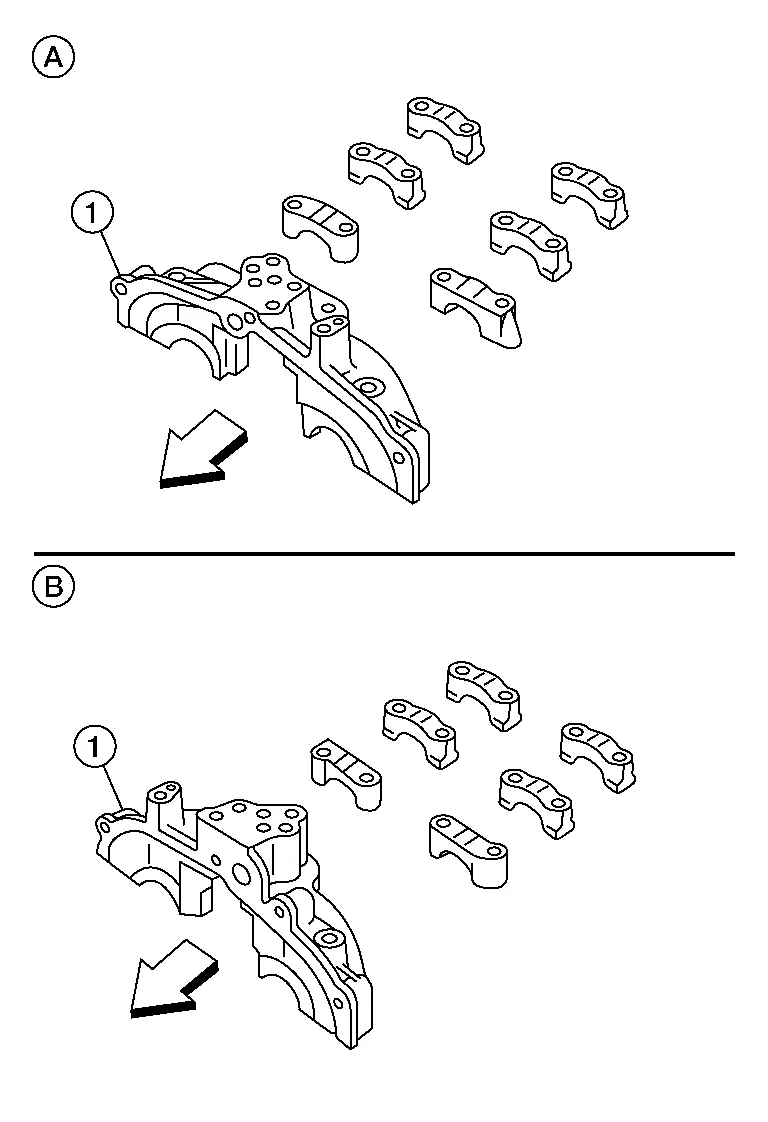

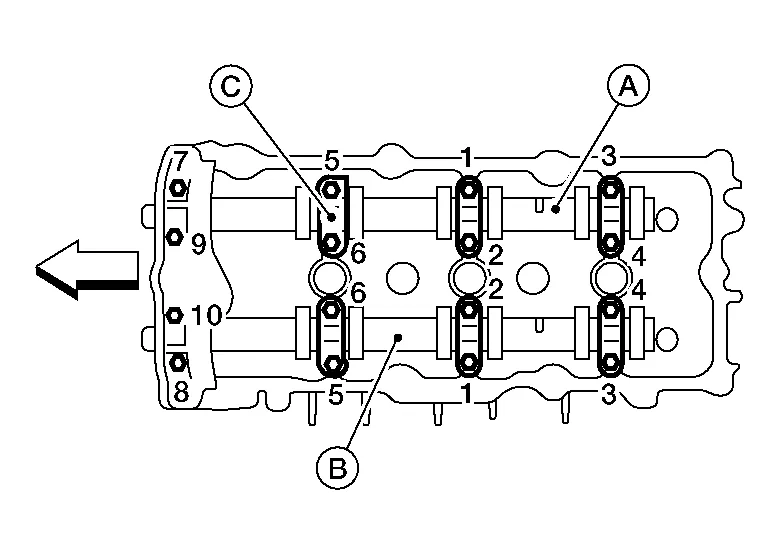

Remove the intake and exhaust camshaft brackets (bank 1) (C) and the camshafts (bank 1) (A/B).

-

Mark the camshafts (bank 1) (A/B), camshaft brackets (bank 1) (C), and bolts so they are placed in the same position and direction for installation.

-

Equally loosen the camshaft bracket bolts in several steps in the numerical order as shown.

|

:Engine front |

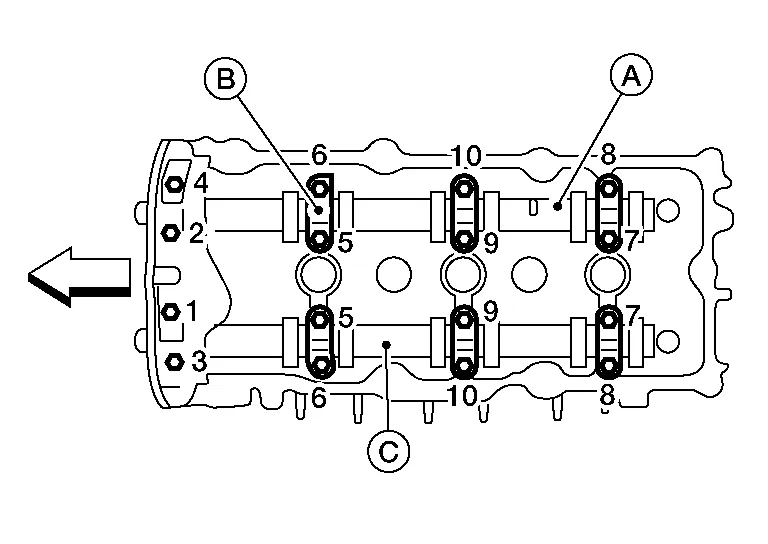

Remove the intake and exhaust camshaft brackets (bank 2) (B) and the camshafts (bank 2) (A/C).

-

Mark the camshafts (bank 2) (A/C), camshaft brackets (bank 2) (B), and bolts so they are placed in the same position and direction for installation.

-

Equally loosen the camshaft bracket bolts in several steps in the numerical order as shown.

|

:Engine front |

Remove valve lifters (if necessary).

NOTE:

NOTE:

Identify installation positions to ensure proper installation.

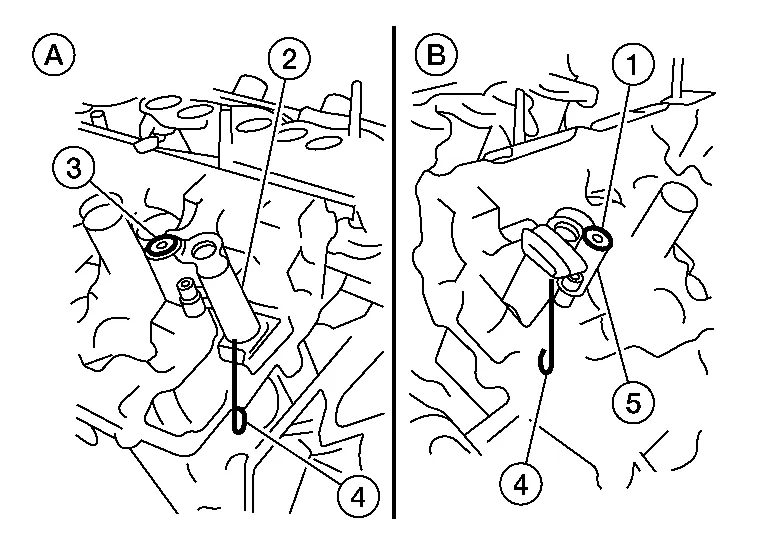

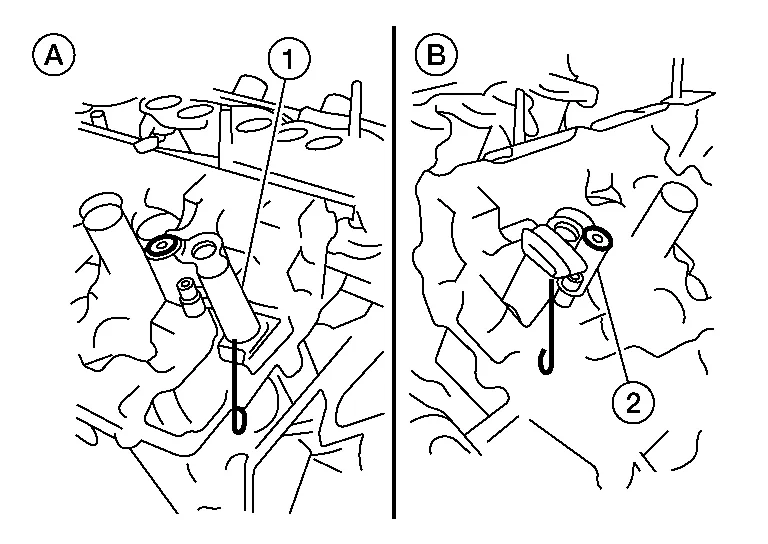

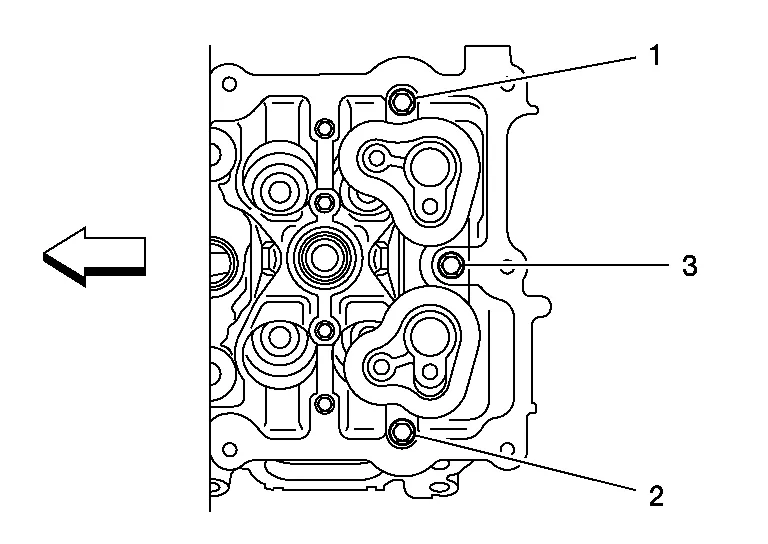

Remove secondary timing chain tensioner (2/5) from bank 1/bank 2 (A/B).

-

Remove secondary tensioner (2/5) with its stopper pin (4) attached.

NOTE:

NOTE:

-

Stopper pin (4) was attached when secondary timing chain (2/5) was removed.

-

Do not reuse O-rings (1/3).

INSTALLATION

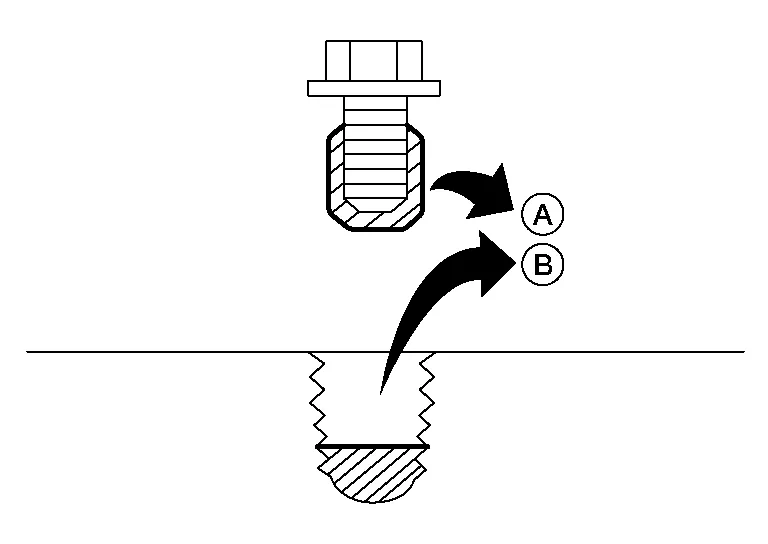

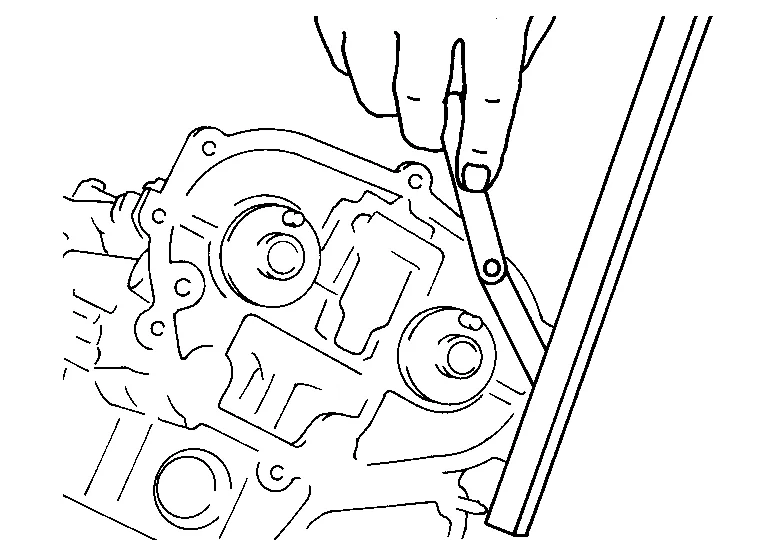

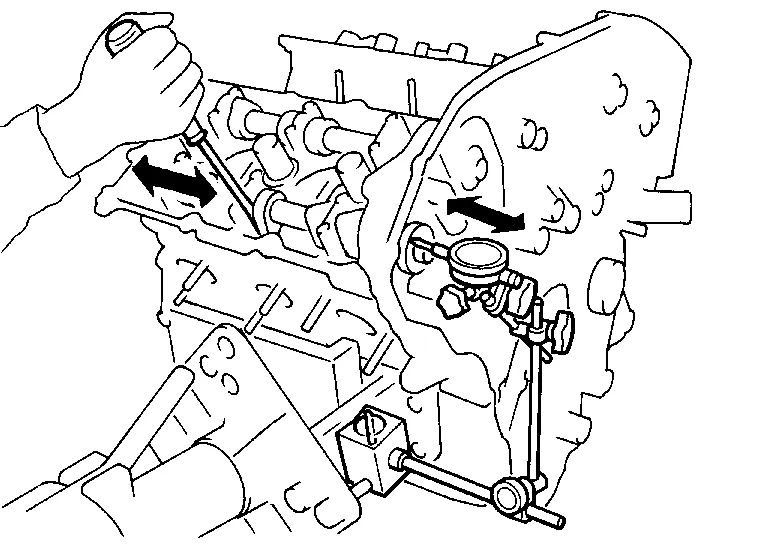

Before installation, remove any old Silicone RTV Sealant (A) from component mating surfaces using a suitable tool.

-

Remove the old Silicone RTV Sealant (A) from the bolt holes (B) and threads.

-

Do not scratch or damage the mating surfaces.

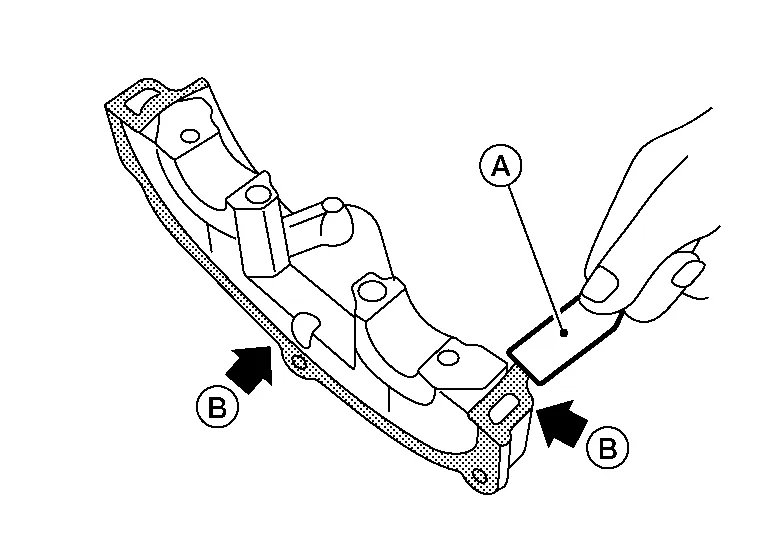

Before installing the front cam bracket, remove the old Silicone RTV Sealant (B) from the mating surface using a suitable tool (A).

-

Do not scratch or damage the mating surface.

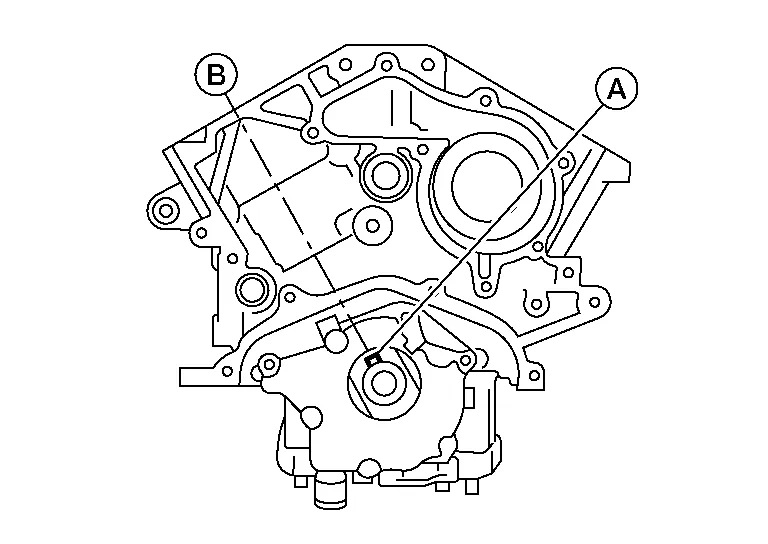

Turn the crankshaft until No. 1 piston is set at TDC on the compression stroke.

-

The crankshaft key (A) should line up with the right bank cylinder center line (B) as shown.

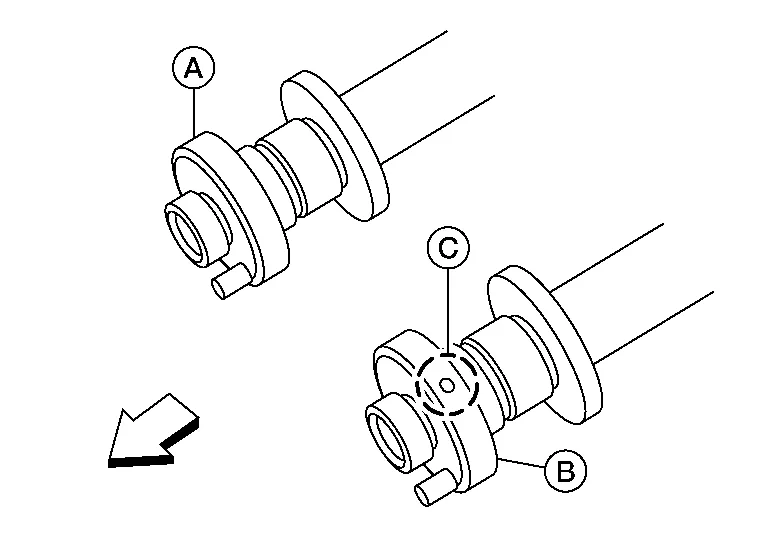

Install camshaft chain tensioners (1/2) at bank 1 (A) and bank 2 (B). Refer to Exploded View.

CAUTION:

Do not reuse O-rings.

Install valve lifters, if removed.

NOTE:

NOTE:

Install them in original positions.

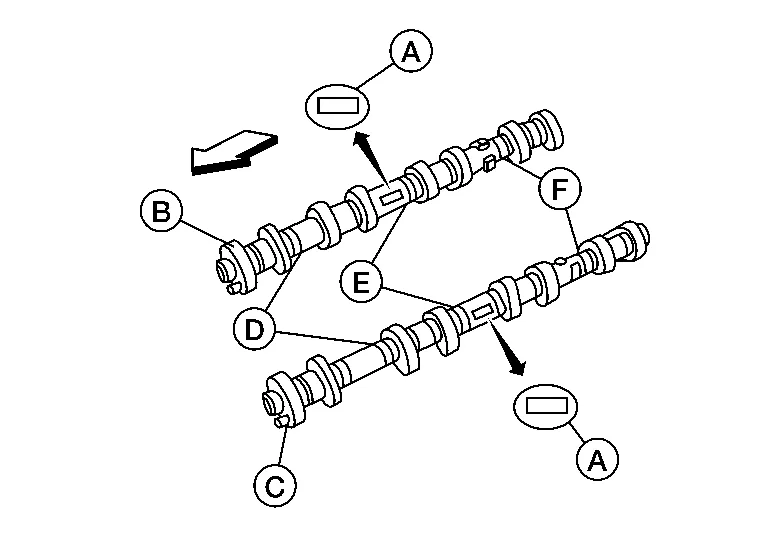

Install exhaust camshaft (A) and intake camshaft (B) and camshaft brackets.

-

Intake camshaft has a drill mark (C) on camshaft sprocket mounting flange.

-

Follow your identification marks made during removal, or follow the identification marks that are present on the new camshafts components for proper placement and direction of the components.

:Engine front Bank INT/EXH ID mark (A) Drill mark Paint marks M1 (E) M2 (F) M3 (D) 1 (B) INT 1A Yes Purple No Light blue EXH 1C No No Brown Light blue 2 (C) INT 1B Yes Purple No Light blue EXH 1D No No Brown Light blue -

Position the camshaft dowel pins (A) as shown.

(1) :Crankshaft key

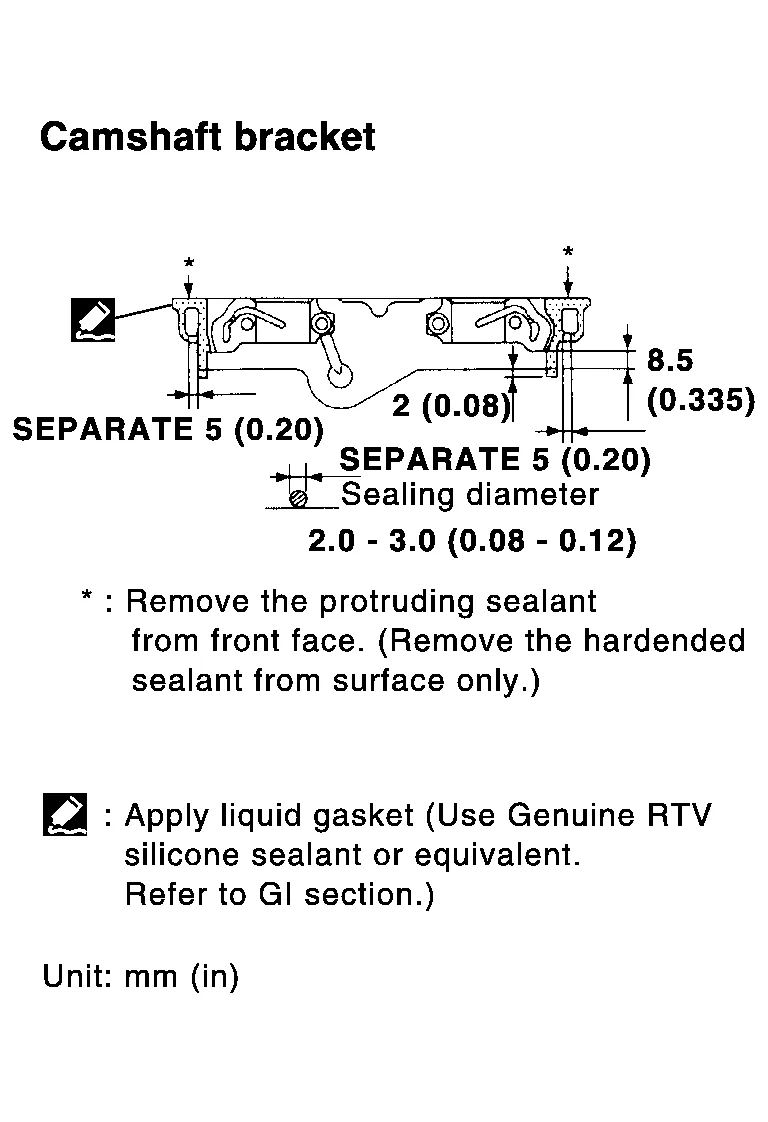

Apply sealant to mating surface of camshaft brackets (1) of bank 1 (A) and bank 2 (B) cylinder heads.

-

Use Genuine Silicone RTV Sealant, or equivalent. Refer to Recommended Chemical Products and Sealants.

-

Before installation, wipe off any protruding sealant from front face of camshaft bracket. Refer to Precaution for Liquid Gasket.

:Engine front -

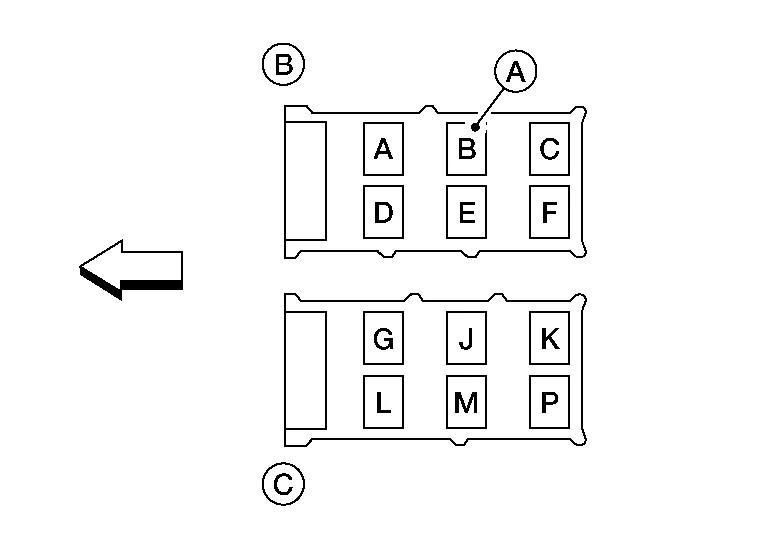

Install bank 1 (B) and bank 2 (C) camshaft brackets in their original positions and direction. Align the stamp marks (A) as shown.

-

If checking and adjusting any part of valve assembly or camshaft, check valve clearance according to the reference data. Refer to Valve Clearance.

:Engine front Valve clearance (cold) Intake : 0.26 - 0.34 mm (0.010 - 0.013 in) Valve clearance (cold) Exhaust : 0.29 - 0.37 mm (0.011 - 0.015 in)

-

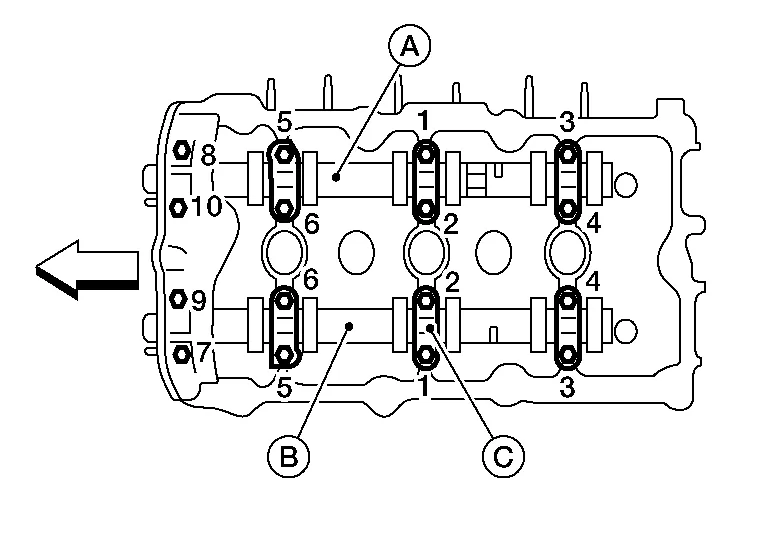

Locate the camshaft (EXH) (bank 1) (A) and camshaft (INT) (bank 1) (B). Tighten the camshaft brackets (C) in the three steps, in numerical order as shown.

-

Locate the camshaft (EXH) (bank 2) (B) and camshaft (INT) (bank 2) (A). Tighten the camshaft brackets (C) in the three steps, in numerical order as shown.

| 1 | 1.96 N·m (0.20 kg-m, 17 in-lb) | Tighten No. 7 - 10, then tighten 1 - 6 in numerical order as shown. |

| 2 | 5.88 N·m (0.60 kg-m, 52 in-lb) | Tighten No. 1 - 10 in numerical order as shown. |

| 3 | 10.41 N·m (1.1 kg-m, 8 ft-lb) | Tighten No. 1 - 10 in numerical order as shown. |

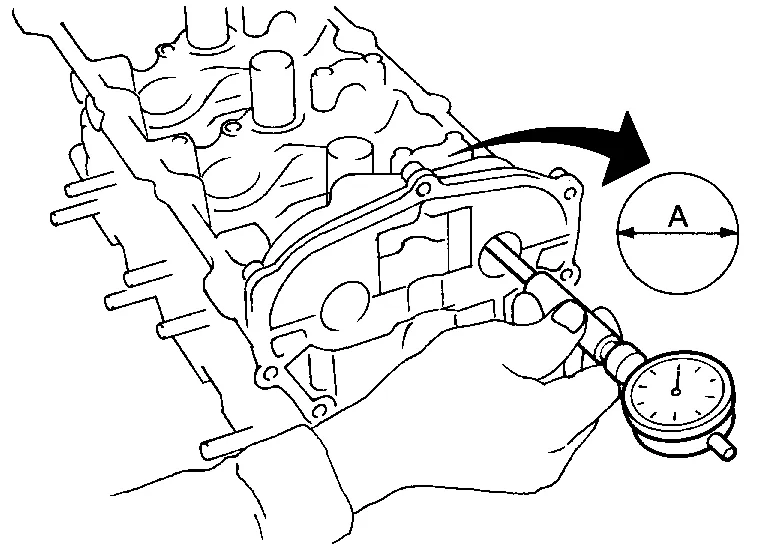

Measure difference in levels between front end faces of No. 1 camshaft bracket and cylinder head.

| Standard | : – 0.14 (– 0.0055 in) |

-

If measurement is outside the specified range, reinstall camshaft and camshaft bracket.

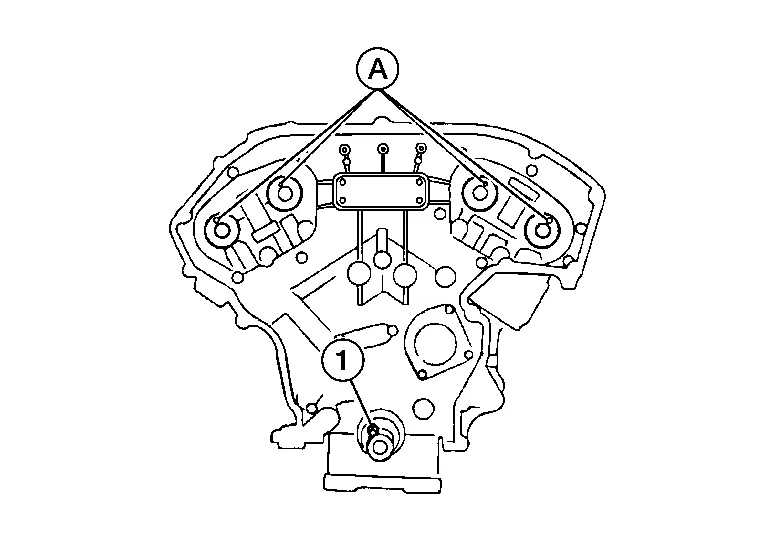

Install camshaft position sensor bracket [(PHASE (RH and LH bank)] and tighten to specified torque in sequence shown.

| Bolts 1-3 | : 10.4 N·m |

|

: Engine front |

Install the timing chains. Refer to Removal and Installation.

INSPECTION AFTER REMOVAL

Camshaft Visual Check

Check camshaft for scratches, seizure and wear. Replace if necessary.

Camshaft Runout

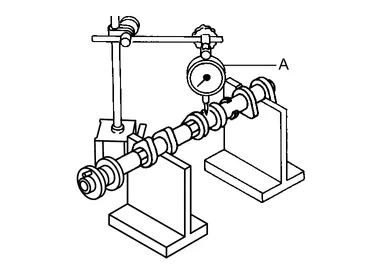

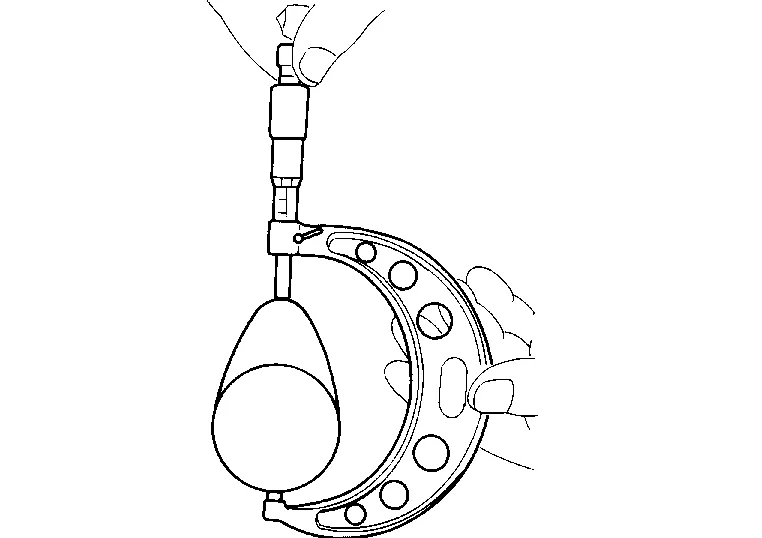

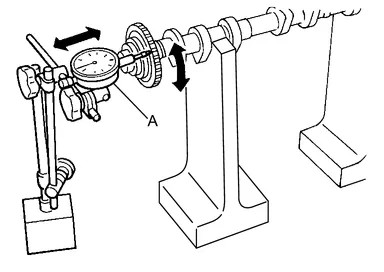

Put V-block on precise flat bed and support No. 2 and No. 4 journal of camshaft as shown.

Set dial gauges vertically to No. 3 journal as shown.

Turn camshaft in one direction slowly by hand, measure the camshaft runout on the dial gauges.

-

Runout is the largest indicator reading after one full revolution. Refer to Camshaft.

If actual runout exceeds the limit, replace the camshaft.

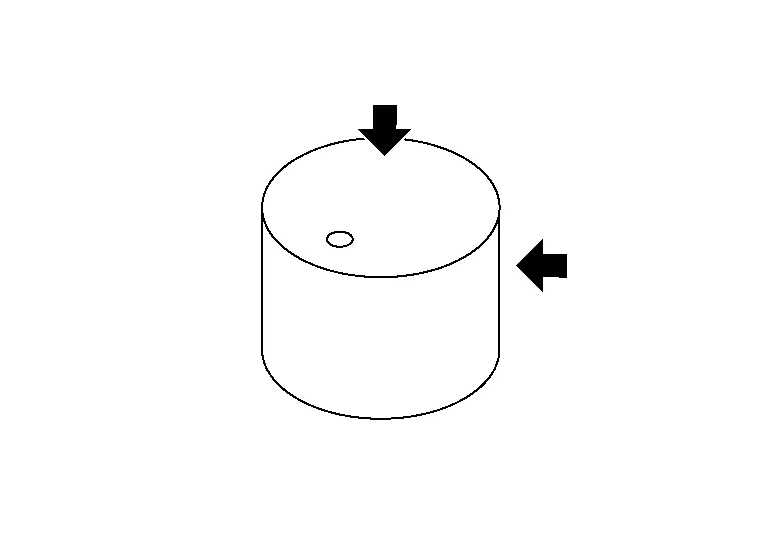

Camshaft Cam Lobe Height

Measure camshaft cam lobe height as shown. Refer to Camshaft.

If wear has reduced the lobe height below specifications, replace the camshaft.

Camshaft Journal Clearance

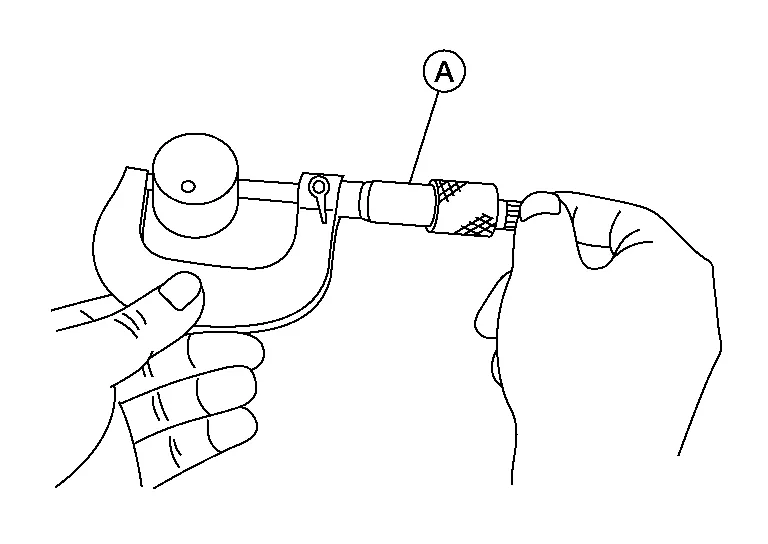

Outer Diameter of Camshaft Journal

-

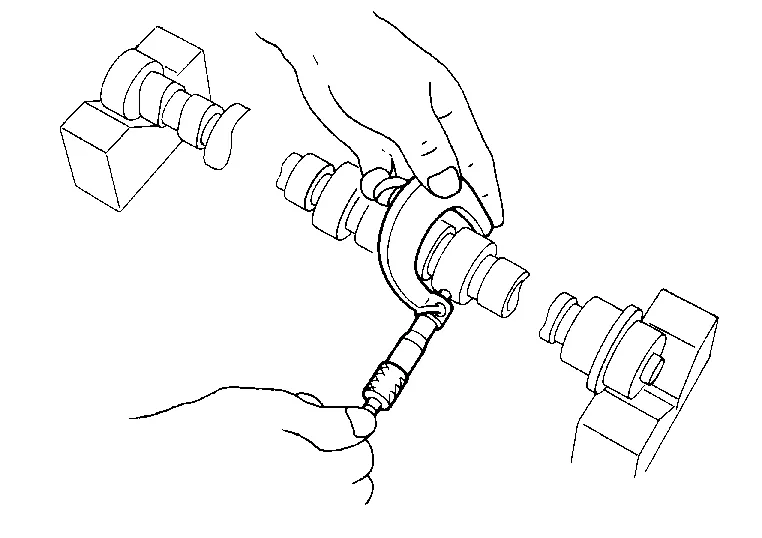

Measure outer diameter of camshaft journal as shown. Refer to Camshaft.

Inner Diameter of Camshaft Bracket

-

Tighten camshaft bracket bolt with specified torque.

-

Using inside micrometer, measure inner diameter (A) of camshaft bearing. Refer to Camshaft.

Calculation of Camshaft Journal Clearance

(Journal clearance) = (inner diameter of camshaft bracket) – (outer diameter of camshaft journal). Refer to Camshaft.

When out of the specified range, replace either or both camshaft and cylinder head.

NOTE:

NOTE:

Inner diameter of camshaft bracket is manufactured together with cylinder head. Replace the whole cylinder head assembly.

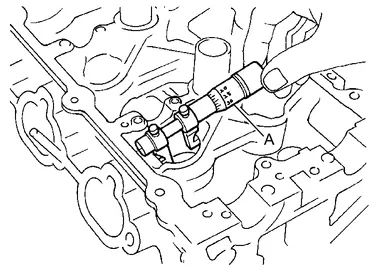

Camshaft End Play

Install the camshaft in the cylinder head.

Install dial gauge in thrust direction on front end of camshaft. Measure end play when camshaft is moved forward/backward (in direction to axis) as shown. Refer to Camshaft.

-

If out of the specified range, replace with new camshaft and measure again.

-

If out of the specified range again, replace with new cylinder head.

Camshaft Sprocket Runout

Put V-block on precise flat bed and support No. 2 and No. 4 journal of camshaft as shown.

Install camshaft sprocket on camshaft.

Measure camshaft sprocket runout. Refer to Camshaft.

If sprocket runout exceeds the limit, replace camshaft sprocket.

Valve Lifter

-

Check if the surface of the valve lifter has any excessive wear or cracks, replace as necessary.

Valve Lifter Clearance

Outer Diameter of Valve Lifter

-

Measure the outer diameter of the valve lifter with a suitable tool (A). Refer to Camshaft.

-

If out of the specified range, replace the valve lifter.

Valve Lifter Bore Diameter

-

Using inside micrometer, measure diameter of valve lifter bore of cylinder head. Refer to Camshaft.

-

If out of the specified range, replace the cylinder head assembly.

Calculation of Valve Lifter Clearance

-

(Valve lifter clearance) = (hole diameter for valve lifter) – (outer diameter of valve lifter) Refer to Camshaft.

-

If out of specified range, replace either or both valve lifter and cylinder head assembly.

INSPECTION OF CAMSHAFT SPROCKET (INT) OIL GROOVE

WARNING:

Check when engine is cold so as to prevent burns from any splashing engine oil.

CAUTION:

Perform this inspection only when DTC P0011 is detected in self-diagnostic results of CONSULT and it is directed according to inspection procedure of EC section. Refer to Diagnosis Procedure.

Check engine oil level. Refer to Inspection.

Perform the following procedure so as to prevent the engine from being unintentionally started while checking.Release fuel pressure. Refer to Work Procedure. Disconnect ignition coil and injector harness connectors, if practical.

Remove intake valve timing control solenoid valve.

Crank engine, and then make sure that engine oil comes out from intake valve timing control solenoid valve cover oil hole. End cranking after checking.

WARNING:

Be careful not to touch rotating parts (drive belts, idler pulley, and crankshaft pulley, etc.).

CAUTION:

-

Engine oil may squirt from intake valve timing control solenoid valve installation hole during cranking. Use a shop cloth to prevent engine oil from splashing on worker, engine components and Nissan Murano vehicle.

-

Do not allow engine oil to get on rubber components such as drive belts or engine mount insulators. Immediately wipe off any splashed engine oil.

Clean oil groove between oil strainer and intake valve timing control solenoid valve if engine oil does not come out from intake valve timing control solenoid valve cover oil hole.

Remove components between intake valve timing control solenoid valve and camshaft sprocket (INT), and then check each oil groove for clogging.

-

Clean oil groove if necessary.

After inspection, installation of the remaining components is in the reverse order of removal.

Rear Timing Chain Case

Rear Timing Chain Case

Exploded View

1.

O-ring

2.

Blind plug (if equipped)

3.

Rear timing chain case

4.

Cylinder block

5.

O-ring

6.

O-ring

A.

Refer to Removal and Installation...

Oil Seal

Oil Seal

Removal and Installation of Valve Oil Seal

REMOVALTurn crankshaft until the cylinder requiring new oil seals is at TDC. This will prevent valve from dropping into cylinder...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Front Suspension :: Precaution. Precautions

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER" The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of collisions...

Nissan Murano (Z52) 2015-2024 Service Manual: Roof :: Precaution. Precautions

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER" The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of collisions...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Checking engine oil level

- High Beam Assist (if so equipped)

- Warning lights

- New on site

- Most important about car

Vehicle security system

Your vehicle has two types of security systems:

Vehicle security system NISSAN Vehicle Immobilizer SystemThe vehicle security system provides visual and audible alarm signals if someone opens the doors, liftgate or the hood when the system is armed. It is not, however, a motion detection type system that activates when a vehicle is moved or when a vibration occurs.