Nissan Murano: Engine Mechanical :: Removal and Installation / Oil Seal

REMOVAL

Turn crankshaft until the cylinder requiring new oil seals is at TDC. This will prevent valve from dropping into cylinder.

CAUTION:

When rotating crankshaft, be careful to avoid scarring the front cover with the timing chain.

Remove camshaft relating to valve oil seal to be removed. Refer to Removal and Installation.

Remove valve lifters.

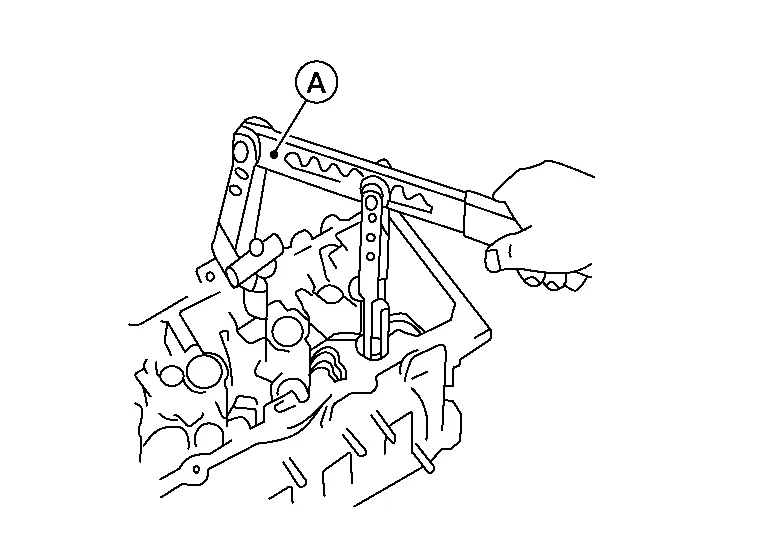

Remove valve collet, valve spring retainer and valve spring using suitable tool (A).

CAUTION:

Be careful not to damage valve lifter bore.

-

Compress valve spring using suitable tool, attachment and adapter. Remove valve collet with magnet hand.

Remove valve oil seal using suitable tool (A).

INSTALLATION

Apply new engine oil to new valve oil seal joint surface and seal lip.

Press in valve oil seal to height (H) using suitable tool (A).

NOTE:

NOTE:

Dimension (H): height measured before valve spring seat installation.

| Intake and exhaust (H) | : 14.3 - 14.9 mm (0.563 - 0.587 in) |

Installation of the remaining components is in the reverse order of removal.

REMOVAL

Remove drive belt. Refer to Removal and Installation.

Lock the drive plate using Tool.

| Tool number | : — (J-50288) |

CAUTION:

Do not damage the ring gear teeth or the signal plate teeth behind the ring gear when setting the Tool.

Remove the crankshaft pulley as follows:Loosen crankshaft pulley and locate bolt seating surface at 10 mm (0.39 in) from its original position. Position a pulley puller at recess hole of crankshaft pulley to remove crankshaft pulley.

CAUTION:

Do not use a puller claw on the outer diameter of the crankshaft pulley.

Remove front oil seal from front cover using a suitable tool.

CAUTION:

Be careful not to damage front cover or crankshaft.

INSTALLATION

Apply new engine oil to oil seal lip (C) and dust seal (D) and install.

-

Install new oil seal towards the engine inside (B) as shown.

CAUTION:

-

Press fit straight and avoid causing burrs to engine inside (C) or engine outside (A) or tilting the oil seal.

-

Do not reuse front oil seal.

-

Press-fit oil seal until it becomes flush with the timing chain case end face, using Tool (A).

Tool number (A) : — (J-37066) -

Make sure the garter spring in the oil seal is in position and seal lip is not inverted.

Install crankshaft pulley and tighten the bolt in two steps.

-

Lubricate thread and seat surface of the bolt with new engine oil.

-

For the second step angle tighten using Tool.

CAUTION:

-

Do not damage the front oil seal when inserting crankshaft pulley.

-

Use only brass or plastic hammer if tapping on the crankshaft pulley.

-

Do not hammer on pulley grooves.

| Step 1 | : 44.1 N·m (4.5 kg-m, 33 ft-lb) |

| Step 2 | : 90°(+0°/-6°) degrees clockwise |

| Tool number | : KV10112100 (BT-8653-A) |

Remove the Tool to unlock the drive plate.

| Tool number | : — (J-50288) |

CAUTION:

Do not damage the ring gear teeth, or the signal plate teeth behind the ring gear, when removing the Tool.

Installation of the remaining components is in the reverse order of removal.

REMOVAL

Remove the upper oil pan. Refer to Removal and Installation (Upper Oil Pan).

Remove drive plate. Refer to Exploded View.

Remove rear oil seal retainer using Tool (A).

| Tool Number (A) | : KV10111100 (J-37228) |

CAUTION:

-

Be careful not to damage mating surface.

-

If rear oil retainer is removed, replace it with a new one

NOTE:

NOTE:

Rear oil seal and retainer form a single part and are replaced as an assembly.

INSTALLATION

Remove old liquid gasket material from mating surface of cylinder block and oil pan using a suitable scraper.

Install the rear oil seal using Tool (A).

CAUTION:

Do not reuse rear oil seal.

| Tool number (A) | : — (J-47128) |

Use Genuine Silicone RTV Sealant or equivalent. Refer to Recommended Chemical Products and Sealants.

CAUTION:

-

Installation should be done within 5 minutes after applying liquid gasket.

-

Do not fill the engine with oil for at least 30 minutes after the components are installed to allow the liquid gasket to cure.

| Rear oil seal retainer bolts | : 8.8 N·m (0.9 kg-m, 78 in-lb) |

Installation of the remaining components is in the reverse order of removal.

CAUTION:

-

When replacing an engine or transmission you must make sure the dowels are installed correctly during reassembly.

-

Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of drivetrain components.

Camshaft

Camshaft

Exploded View

1.

Camshaft position sensor bracket (bank 1)

2.

Camshaft brackets

3.

No. 1 camshaft bracket (bank 1)

4.

Camshaft (EXH) (bank 1)

5...

Cylinder Head

Cylinder Head

Exploded View

1.

Cylinder head bolt

2.

Cylinder head

3.

Cylinder head gasket

4.

Engine block

A.

Refer to Removal and Installation.

Removal and Installation

REMOVALRemove the engine from the vehicle...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: P0966 Pressure Control Solenoid B

DTC Description DTC DETECTION LOGIC DTC CONSULT screen terms (Trouble diagnosis content) DTC detection condition P0966 PC SOLENOID B (Pressure Control Solenoid B Control Circuit Low) Diagnosis condition TCM power supply voltage: More than 11 V Signal — Threshold TCM judges that solenoid valve circuit is shorted to ground Diagnosis delay time Maintained for 1 second POSSIBLE CAUSE Harness or connector (Primary pressure solenoid valve circuit shorted to ground) Primary pressure solenoid valve FAIL-SAFE Selector shock is large Start is slow Acceleration is slow Lock-up is not performed DTC Confirmation Procedure PREPARATION BEFORE WORK If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test...

Nissan Murano (Z52) 2015-2024 Service Manual: P0841 Transmission Fluid Pressure Sen/sw a

DTC Description DTC DETECTION LOGIC DTC CONSULT screen terms (Trouble diagnosis content) DTC detection condition P0841 FLUID PRESS SEN/SW A (Transmission Fluid Pressure Sensor/Switch “A” Circuit Range/Performance) Diagnosis condition When all of the following conditions are satisfied: TCM power supply voltage: More than 11 V DTC other than the applicable DTC is not detected...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Passenger compartment

- Power Steering Fluid (PSF)

- GAS STATION INFORMATION

- New on site

- Most important about car