Nissan Murano: Aluminum Repair / Sheet Metal Work (aluminum)

Repairing aluminum alloy panels is basically the same as repairing steel panels. Special considerations for repairing aluminum alloy are listed below.

Aluminum alloy panels are softer than steel plates. It is important to select the proper type and grade of sanding disc. Also, care must be taken not to overgrind the surface.

Because aluminum powder is light and tends to float in the air, eyes and respiratory parts of the body must be fully protected during grinding work.

| Tool | Coarse | Application |

|---|---|---|

| Disc sander | Approx. #120 |

|

| Double action sander | Approx. #120 - #180 |

|

Elongation of aluminum alloy during hammering will be greater than with steel plates. Therefore, a wooden or plastic hammer should be used with a softer blow to prevent stretching and work hardening of panels. Observe the following in case body filler is applied after hammering.

Apply wash primer and let it dry for 1 hour at 20°C (68°F) before applying body filler.

Use putty that can be used for aluminum panels. Do not perform forced drying because the coefficient of linear expansion is twice as much as that of sheet steel.

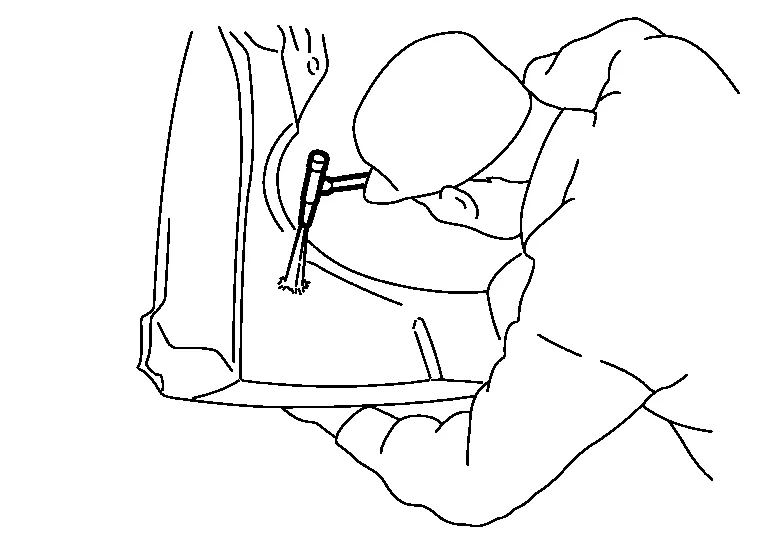

While hammering work is being performed during the rough repair stage, the area needs to be heated. First, cover your hand with a glove (cloth material), and then place hand on the reverse side of the panel near the repair area. Apply heat to the entire repair area using a gas burner (oxy-acetylene gas welder) until your covered hand feels heat.

WARNING:

The panel may crack when hammered without sufficient heat being applied.

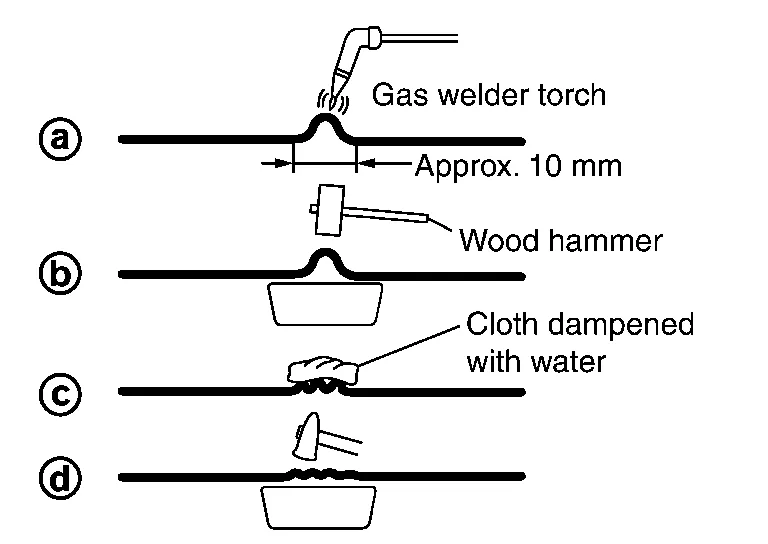

(1) FLAME SHRINKING

-

The area should be heated to approximately 250°C.

Aluminum alloy panels do not turn red when heated like steel plates. Prior to heating up the panel you are trying to repair, first practice with a scrap piece to get a good idea of how much heat is needed. This way the number of passes with the gas burner needed to achieve the correct temperature can be determined.

-

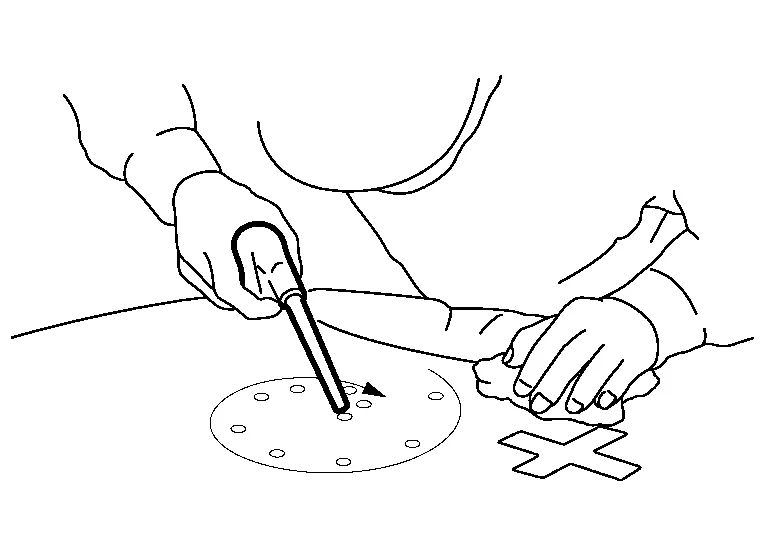

A thermometry pen may be applied to the repair area before heat application. Apply the thermometry pen to the heated part. Check if the thermometry pen is melted to judge if the temperature on the heated area is within the range of the specified temperature. When measuring temperature, use two thermometry pens of different specified temperatures. This allows the top and bottom of the temperature range to be judged accurately.

(Example: Tempilstik or equivalent)

-

The heat conduction efficiency of aluminum alloy panel is approximately twice that of steel plate, which allows heat to be absorbed and released at a faster rate. Hammering [(b) in the figure] and rapid cooling work [(c) in the figure] must be performed while the area is still hot.

-

Don't use a shrinking hammer because it causes a crack.

(2) SHRINKING BY ELECTRIC WELDING

Shrinking with an electric welder is easier than with a gas burner, however this method leaves spark marks, scratches, carbon deposits, and oxide film on the panel surface.

For this reason, as an undercoating preparation, the panel surface must be cleaned using silicon off and a stainless steel wire brush.

When spark marks and scratches are large, the impurities are first completely removed using a wire brush, and then wash primer and putty are applied.

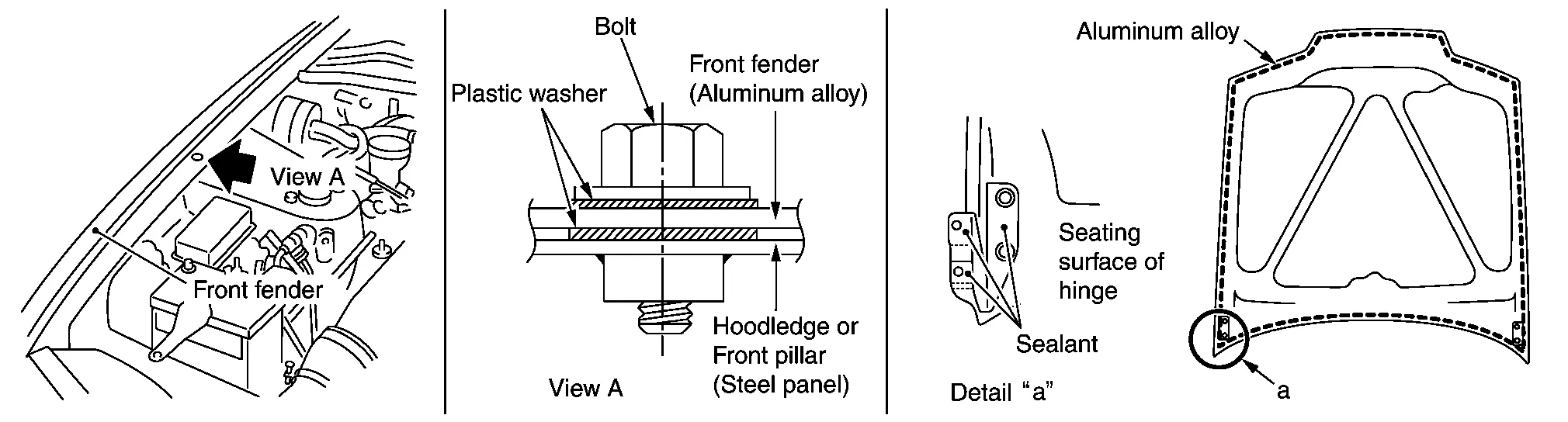

When installing parts, insulating materials such as resin washers (bolts at front fender) and anti-corrosion sealant (hood hinges) are inserted between the aluminum alloy panel and steel plates to prevent contact corrosion which occurs where different metals touch.

Welding (aluminum)

Welding (aluminum)

Welding (Aluminum)

To repair a crack or a hole in a steel plate, welding is usually used. Either oxygen and acetylene gas welding, arc welding, or brazing is commonly used...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Av Control Unit

Values on the Diagnosis Tool NOTE: The following table includes information (items) inapplicable to this Nissan Murano vehicle. For information (items) applicable to this vehicle, refer to CONSULT display items. Monitor Item Condition Value/Status Sunload sensor — Off — On Parking brake Parking brake not applied...

Nissan Murano (Z52) 2015-2024 Service Manual: Door Does Not Lock/unlock with Intelligent Key (one Key)

Diagnosis Procedure All doors do not lock/unlock using Intelligent Key button. (One Intelligent Key has the symptom, other keys operate normally.)NOTE: Before starting diagnosis check that vehicle condition is as shown in “Conditions of Nissan Murano vehicle”, and check each symptom...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Vehicle Dynamic Control (VDC) OFF switch

- Rear bench seat adjustment

- Jacking up vehicle and removing the damaged tire

- New on site

- Most important about car

Front manual seat adjustment (if so equipped)

Your vehicle seats can be adjusted manually. For additional information about adjusting the seats, refer to the steps outlined in this section.

Forward and backward