Nissan Murano: Precaution / Repairing High Strength Steel

High strength steel is used for body panels in order to reduce vehicle weight.

Accordingly, precautions in repairing automotive bodies made of high strength steel are described below:

| Tensile strength | Major applicable parts |

|---|---|

| 370 - 590 MPa |

|

| 780 - 1350 MPa |

|

Read the following precautions when repairing HSS:

-

Additional points to consider:

-

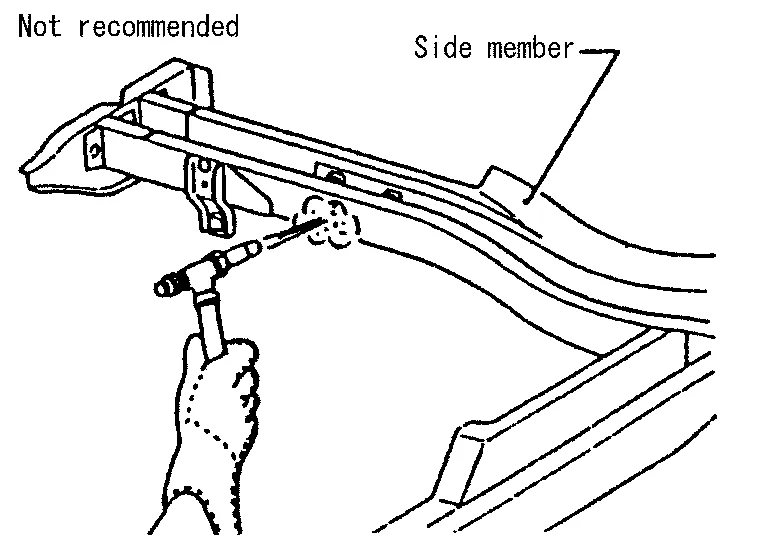

The repair of reinforcements (such as side members) by heating is not recommended since it may weaken the component. When heating is unavoidable, do not heat HSS parts above 550°C (1,022°F).

Verify heating temperature with a thermometer.

(Crayon-type and other similar type thermometers are appropriate.)

-

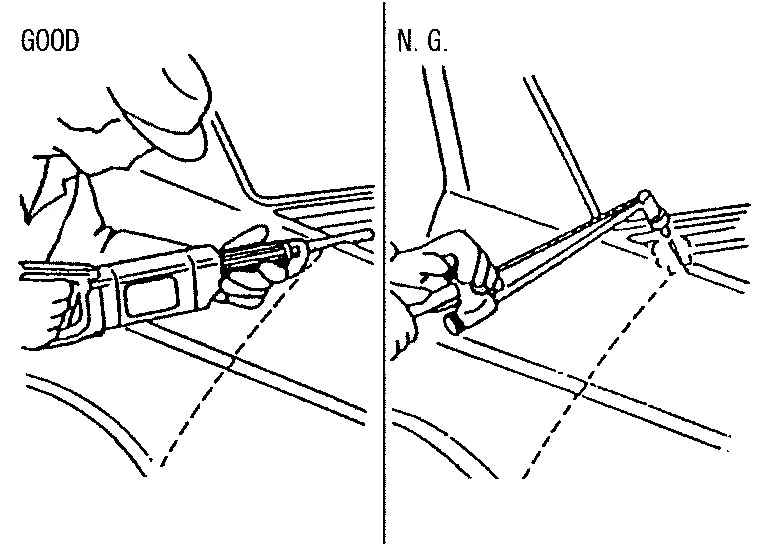

When straightening body panels, use caution in pulling any HSS panel. Because HSS is very strong, pulling may cause deformation in adjacent portions of the body. In this case, increase the number of measuring points and carefully pull the HSS panel.

-

When cutting HSS panels, avoid gas (torch) cutting if possible. Instead, use a saw to avoid weakening surrounding areas due to heat. If gas (torch) cutting is unavoidable, allow a minimum margin of 50 mm (1.97 in).

-

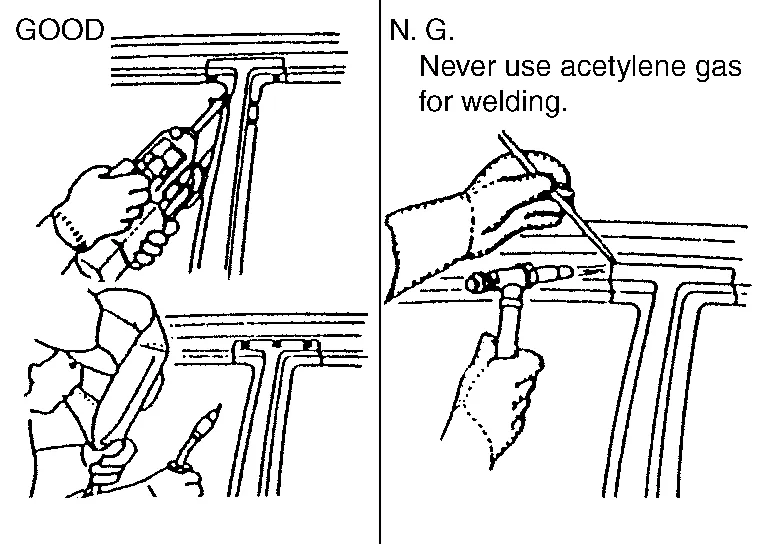

When welding HSS panels, use spot welding whenever possible in order to minimize weakening surrounding areas due to heat.

If spot welding is impossible, use MAG welding. Do not use gas (torch) for welding because it is inferior in welding strength.

-

The spot weld on HSS panels is harder than that of an ordinary steel panel.

Therefore, when cutting spot welds on a HSS panel, use a low speed high torque drill (1,000 to 1,200 rpm) to increase drill bit durability and facilitate the operation.

-

-

Precautions in spot welding HSS

This work should be performed under standard working conditions. Always note the following when spot welding HSS:

-

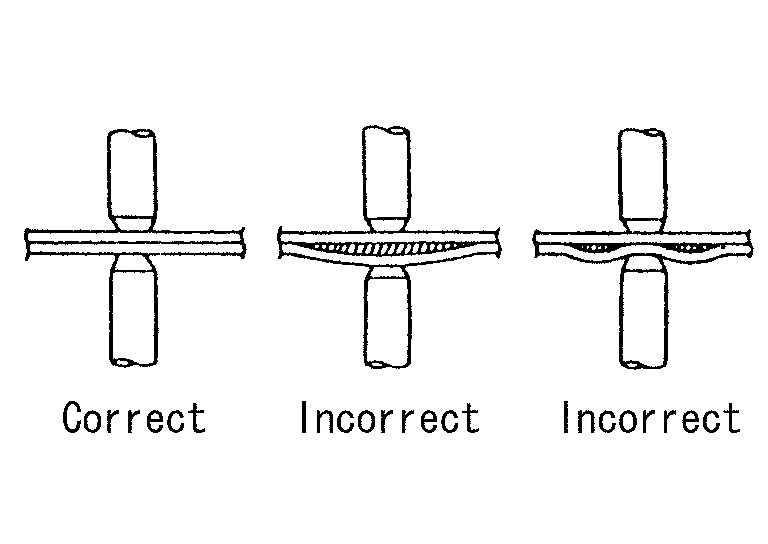

The electrode tip diameter must be sized properly according to the metal thickness.

-

The panel surfaces must fit flush to each other, leaving no gaps.

-

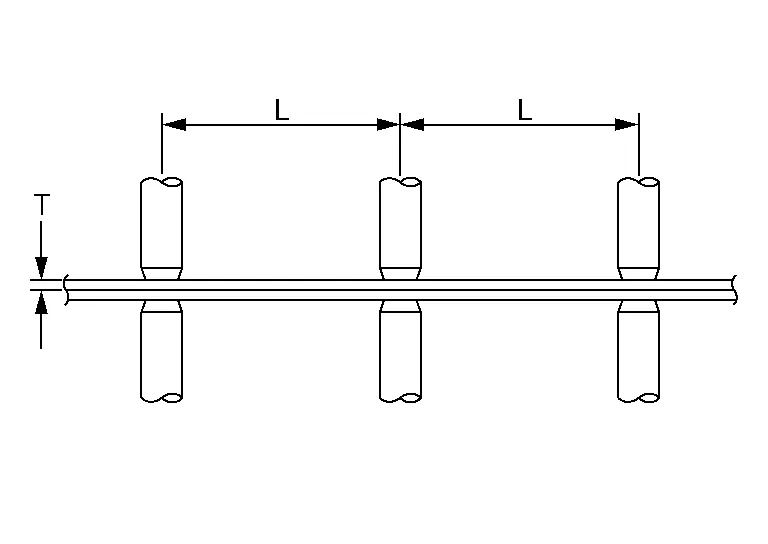

Follow the specifications for the proper welding pitch.

Unit: mm (in)

Thickness (T) Minimum pitch (L) 0.6 (0.024)

0.8 (0.031)

1.0 (0.039)

1.2 (0.047)

1.6 (0.063)

1.8 (0.071)10 (0.39) or over

12 (0.47) or over

18 (0.71) or over

20 (0.79) or over

27 (1.06) or over

31 (1.22) or over

-

PROHIBITION OF CUT AND CONNECTION

Do not cut and join the lower lock pillar reinforcement (center pillar reinforcement inside frame parts) because its material is high strength steel plate (ultra high strength steel plate).

The center pillar reinforcement must be replaced if this part is damaged.

SPOT WELDING

Spot welding is limited to ultra high strength steel of (tensile strength: 980 MPa) according to the welding conditions listed below.

CAUTION:

-

If the below welding conditions cannot be met, then perform plug welding.

-

Never spot weld ultra high strength steel of tensile strength more than 980 MPa. For this type of ultra high strength steel, perform plug welding.

-

The below welding condition is applicable only to this Nissan Murano vehicle. Never apply these same conditions to other vehicles.

| Welder tip diameter | 6 MM | |

| Welding pressure (Gun force) | 4150 N | |

| Welding current | 7900 A | |

| Weld time* |

.24 sec (12 cyc: 50 Hz) .23 sec (14 cyc: 60 Hz) |

|

| Panel configuration | Combination of a plate of tensile strength of 980 MPa and that of tensile strength less than 980 MPa. (Up to 3 plates) | |

|

* Select weld time based on the frequency (Hz) of the electrical power supplied in your area. |

||

PLUG WELDING

To weld ultra high strength steel of tensile strength 980 MPa or more, perform plug welding observing the welding hole diameter described in the manual.

CAUTION:

-

To perform plug welding, use fuel mixture (Ar 80% + CO2 20%) for shielding gas of welder.

-

Never use carbon dioxide gas (CO2 100%) as shielding gas of welder. Using CO2 100% gas results in inadequate weld strength.

-

When welding hole diameter cannot be met, make multiple holes (smaller diameter) so that the sum of the holes areas equals the area of the original weld hole.

Handling Precautions for Plastics

Handling Precautions for Plastics

Precautions For Plastics

Abbreviation Material name Heat resisting temperature °C (°F)

Resistance to gasoline and

solvents Other cautions

PE

Polyethylene

60 (140)

Gasoline and most solvents are harmless if applied for a very short time (wipe out quickly)...

Preparation

Preparation

..

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: P0447 Evap Canister Vent Control Valve

DTC Description DTC DETECTION LOGICAn improper voltage signal is sent to ECM through EVAP canister vent control valve. DTC CONSULT screen terms (Trouble diagnosis content) DTC detection condition P0447 VENT CONTROL VALVE (Evaporative emission system vent control circuit open) Diagnosis condition Start engine and let it idle Signal (terminal) Voltage signal transmitted from EVAP canister vent control valve to ECM Threshold An improper voltage signal is sent to ECM through EVAP canister vent control valve Diagnosis delay time — POSSIBLE CAUSE Harness or connectors (The valve circuit is open or shorted...

Nissan Murano (Z52) 2015-2024 Service Manual: Precautions for Operation

Precautions for Operation In body repair, great importance is attached to quality, efficiency and cost. Consideration for workers' safety and health should, however, be deemed as the most important item. In reality, it is essential that measures be established to prevent accidents and to make the work environment safer and healthier...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Memory storage function (key-link)

- Shift lock release

- Intelligent Forward Collision Warning (I-FCW)

- New on site

- Most important about car

Fuel gauge

The gauge indicates the approximate fuel level in the tank.

The gauge may move slightly during braking, turning, acceleration, or going up or down hills.

The gauge needle returns to 0 (Empty) after the ignition switch is placed in the OFF position.