Nissan Murano: Precaution / Handling Precautions for Plastics

Nissan Murano (Z52) 2015-2024 Service Manual / Body Exterior, Doors, Roof & Vehicle Security / Body Repair :: Repair Information / Precaution / Handling Precautions for Plastics

| Abbreviation | Material name | Heat resisting temperature °C (°F) |

Resistance to gasoline and solvents | Other cautions |

|---|---|---|---|---|

| PE | Polyethylene | 60 (140) | Gasoline and most solvents are harmless if applied for a very short time (wipe out quickly). | Flammable |

| EPM | Ethylene Propylene Copolymer | 80 (176) | ↑ | Flammable |

| EPDM | Ethylene Propylene Diene Copolymer | 80 (176) | ↑ | Flammable |

| PVC | Poly Vinyl Chloride | 80 (176) | ↑ | Poisonous gas is emitted when burned. |

| TPO | Thermoplastic Olefine | 80 (176) | ↑ | Flammable |

| TPR | Thermoplastic Rubber | 80 (176) | ↑ | Flammable |

| PP | Polypropylene | 90 (194) | ↑ | Flammable, avoid battery acid. |

| PS | Polystyrene | 80 (176) | Avoid solvents. | Flammable |

| ABS | Acrylonitrile Butadiene Styrene | 80 (176) | Avoid gasoline and solvents. | — |

| AES | Acrylonitrile Ethylene Styrene | 80 (176) | ↑ | — |

| AAS | Acrylonitrile Acrylic Styrene | 85 (185) | ↑ | — |

| PMMA | Poly Methyl Methacrylate | 85 (185) | ↑ | — |

| EVAC | Ethylene Vinyl Acetate | 90 (194) | ↑ | — |

| PUR | Polyurethane | 90 (194) | ↑ | — |

| UP | Unsaturated Polyester | 90 (194) | ↑ | Flammable |

| ASA | Acrylonitrile Styrene Acrylate | 100 (212) | ↑ | Flammable |

| PPE | Poly Phenylene Ether | 110 (230) | ↑ | — |

| TPU | Thermoplastic Urethane | 110 (230) | ↑ | — |

| PBT + PC | Poly Butylene Terephthalate + Polycarbonate | 120 (248) | ↑ | Flammable |

| PC | Polycarbonate | 120 (248) | ↑ | — |

| POM | Poly Oxymethylene | 120 (248) | ↑ | Avoid battery acid. |

| PA | Polyamide | 140 (284) | ↑ | Avoid immersing in water. |

| PBT | Poly Butylene Terephthalate | 140 (284) | ↑ | — |

| PAR | Polyarylate | 180 (356) | ↑ | — |

| PET | Polyethylene Terephthalate | 180 (356) | ↑ | — |

| PEI | Polyetherimide | 200 (392) | ↑ | — |

CAUTION:

-

When repairing and painting a portion of the body adjacent to plastic parts, consider their characteristics (influence of heat and solvent) and remove them if necessary or take suitable measures to protect them.

-

Plastic parts should be repaired and painted using methods suiting the materials, characteristics.

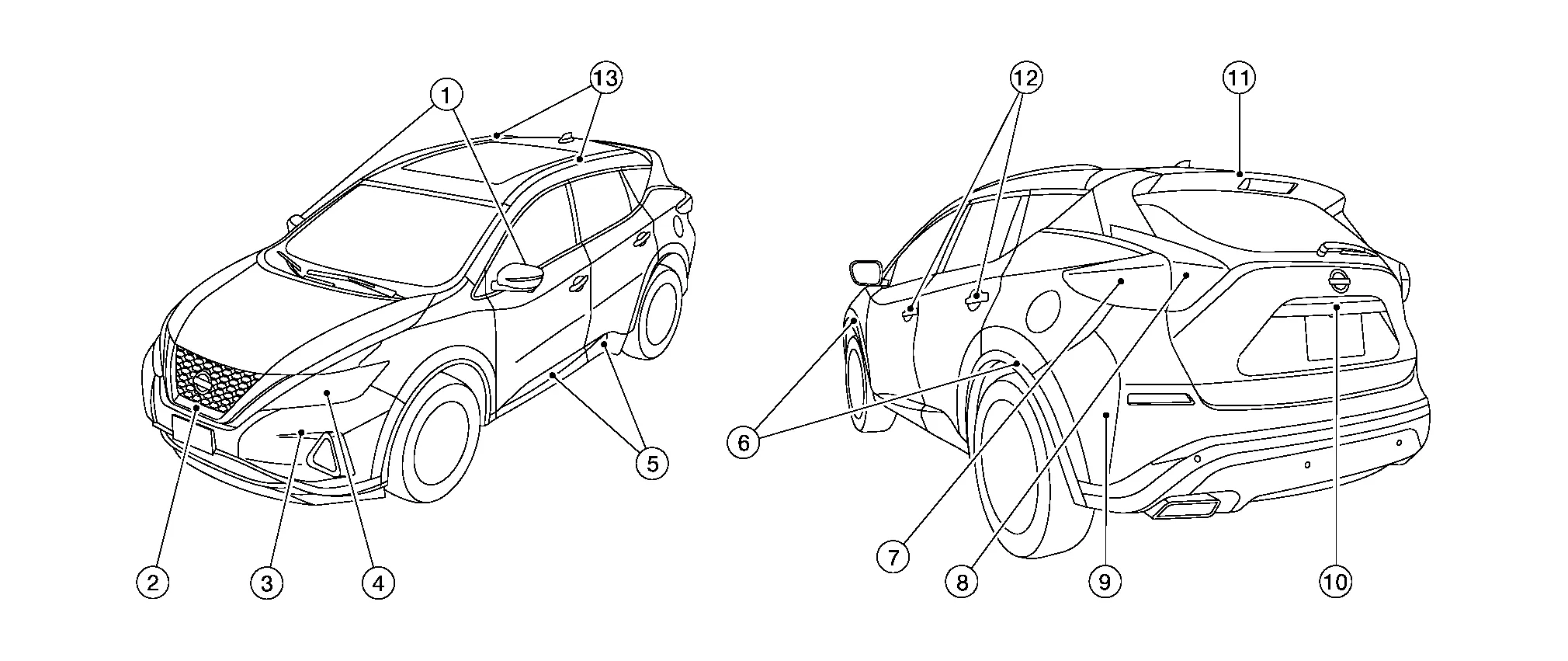

LOCATION OF PLASTIC PARTS

| Item | Component | Abbreviation | Material | |

|---|---|---|---|---|

| 1. | Door mirror | Base | ABS | Acrylonitrile Butadiene Styrene |

| Housing | ABS | Acrylonitrile Butadiene Styrene | ||

| 2. | Front grille | ABS | Acrylonitrile Butadiene Styrene | |

| 3. | Front bumper fascia | PP | Polypropylene | |

| 4. | Front combination lamp | Lens | PC | Polycarbonate |

| Housing | PP | Polypropylene | ||

| 5. | Door outside lower moldings | Molding | PP | Polypropylene |

| Chrome | ABS | Acrylonitrile Butadiene Styrene | ||

| 6. | Over fenders | PP | Polypropylene | |

| 7. | Rear combination lamp (body side) | Lens | PMMA | Poly Methyl Methacrylate |

| Housing | ASA | Acrylonitrile Styrene Acrylate | ||

| 8. | Rear combination lamp (back door side) | Lens | PMMA | Poly Methyl Methacrylate |

| Housing | PC | Polycarbonate | ||

| 9. | Rear bumper fascia | PP | Polypropylene | |

| 10. | Back door outer finisher | ASA | Acrylonitrile Styrene Acrylate | |

| 11. | Rear spoiler | ABS + PC | Acrylonitrile Butadiene Styrene + Polycarbonate | |

| 12. | Door outside handle | Grip | PC | Polycarbonate |

| Escutcheon | ABS | Acrylonitrile Butadiene Styrene | ||

| 13. | Roof rack (if equipped) | ABA + PC | Acrylonitrile Styrene Acrylatee + Polycarbonate | |

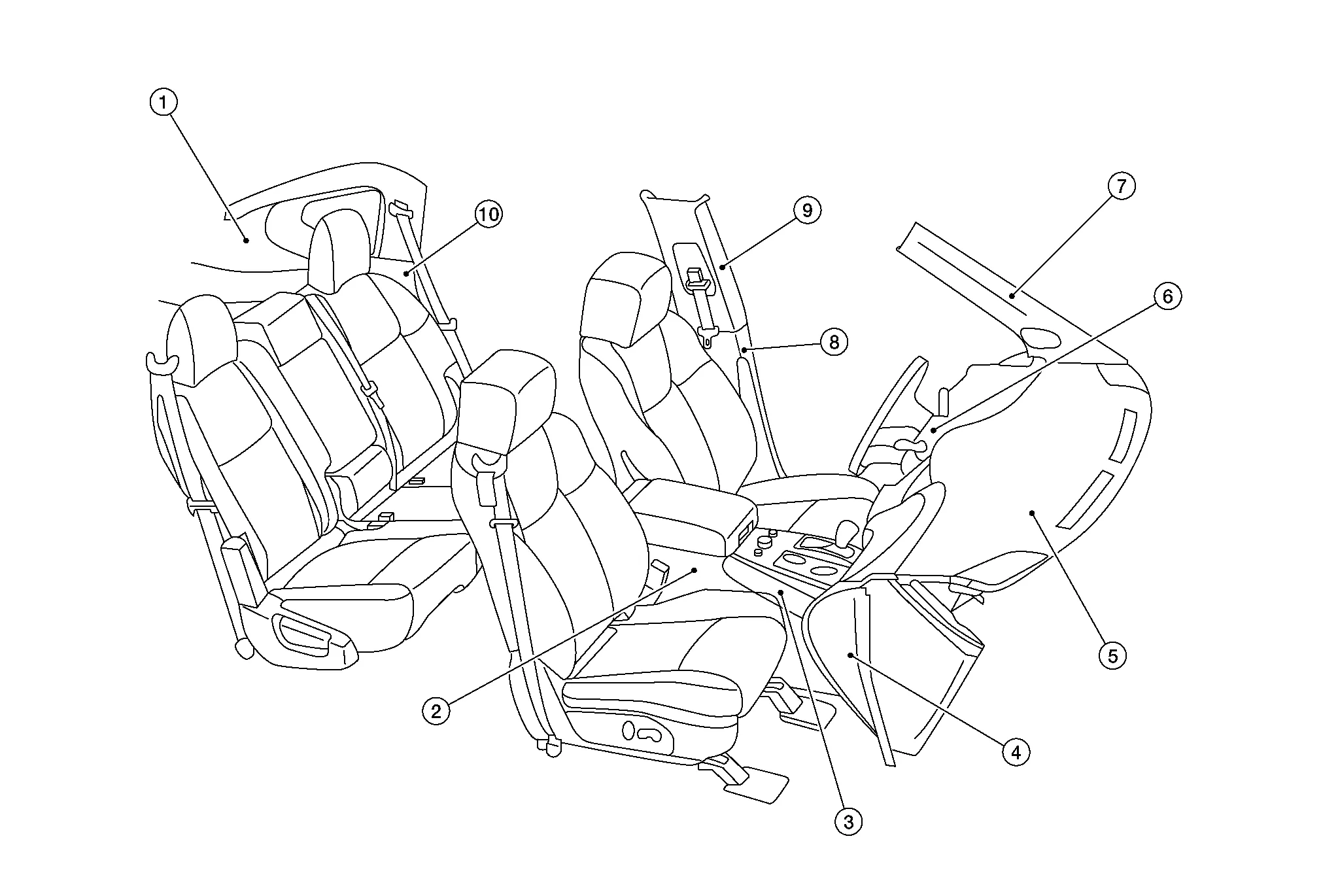

| Item | Component | Abbreviation | Material | |

|---|---|---|---|---|

| 1. | Luggage side upper finisher | PP | Polypropylene | |

| 2. | Center console assembly | Base | PP + EPM |

Polypropylene + Ethylene Propylene (Diene) copolymer |

| 3. | Shift selector side finisher | Base | ABS + PC | Acrylonitrile Butadiene Styrene + Polycarbonate |

| Skin | PVC | Poly Vinyl Chloride | ||

| 4. | Instrument panel side finisher | PP + EPM |

Polypropylene + Ethylene Propylene (Diene) copolymer |

|

| 5. | Instrument panel | Skin | TPO | Thermoplastic Olefine |

| Pad | PUR | Polyurethane | ||

| Core | PP | Polypropylene | ||

| 6. | Steering column covers | PPC | Polypropylene Composite | |

| 7. | Front pillar finisher | PP | Polypropylene | |

| 8. | Center pillar lower finisher | PP | Polypropylene | |

| 9. | Center pillar upper finisher | PP | Polypropylene | |

| 10. | Luggage side lower finisher | PP | Polypropylene | |

Precautions

Precautions

Precautions for Body Repair

WARNING:

The repair information in this section is intended for trained body repair technicians who have attained a high level of skill and experience (e...

Repairing High Strength Steel

Repairing High Strength Steel

High Strength Steel (HSS)

High strength steel is used for body panels in order to reduce vehicle weight.Accordingly, precautions in repairing automotive bodies made of high strength steel are described below: Tensile strength Major applicable parts

370 - 590 MPa

Lower front and rear hoodledge

Upper hoodledge

Side dash

Roof bow No...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Unit Removal and Installation. Transfer Assembly

Exploded View Transfer assembly Transfer gusset Rear gusset : Nissan Murano Vehicle front : N·m (kg-m, ft-lb) Removal and Installation NOTE: When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling...

Nissan Murano (Z52) 2015-2024 Owners Manual: Chassis and body maintenance

Brake lines and cables: Visually inspect for proper installation. Check for chafing, cracks, deterioration, and signs of leaking. Replace any deteriorated or damaged parts immediately. Brake pads and rotors: Check for wear, deterioration and fluid leaks...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Memory storage function (key-link)

- Shift lock release

- Power Steering Fluid (PSF)

- New on site

- Most important about car

Luggage hooks

When securing items using luggage hooks located on the back of the seat or side finisher do not apply a load over more than 6.5 lbs. (29 N) to a single hook.

The luggage hooks that are located on the floor should have loads less than 110 lbs. (490 N) to a single hook.

Copyright © 2026 www.nimurano.com