Nissan Murano: Repairing Procedures and Precautions / Repair Procedure for Pulling

In general, no single bend or twist is produced in a collision. Body deformation results from a combination of bending and twisting and other types of damage.

Repair should start where the damage is most deeply propagated.

If concentrating only on apparent damage while overlooking the propagation of impact to the whole body, it is impossible to obtain correct body alignment.

Repair work should basically be performed in this order of damage.

CAUTION:

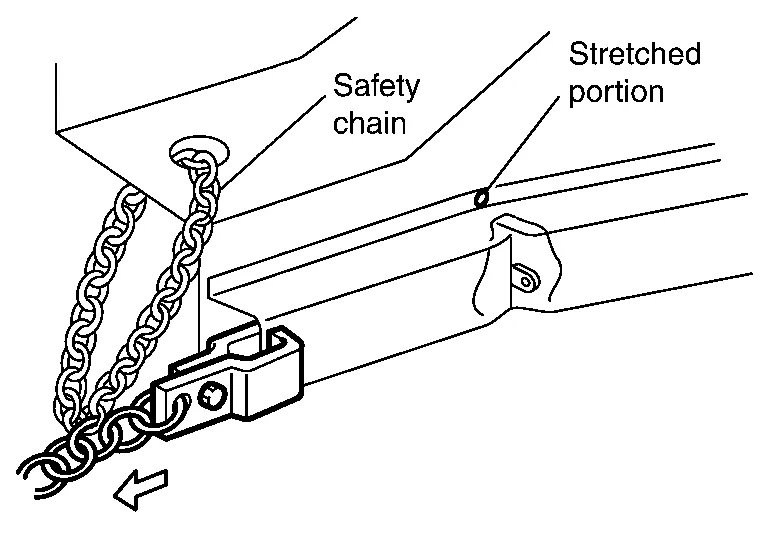

Illustration shows a badly damaged side member for clarity. Badly damaged or kinked side rails must always be replaced.

(1) STRETCHING SHRUNK PORTIONS

-

The repair of a bent closed cross-sectional structure, such as a side member, is done by clamping the surface of the bent-in side and pulling. The pulling direction should be such that force is applied in the direction of an imaginary straight line extending through the original position of the part.

-

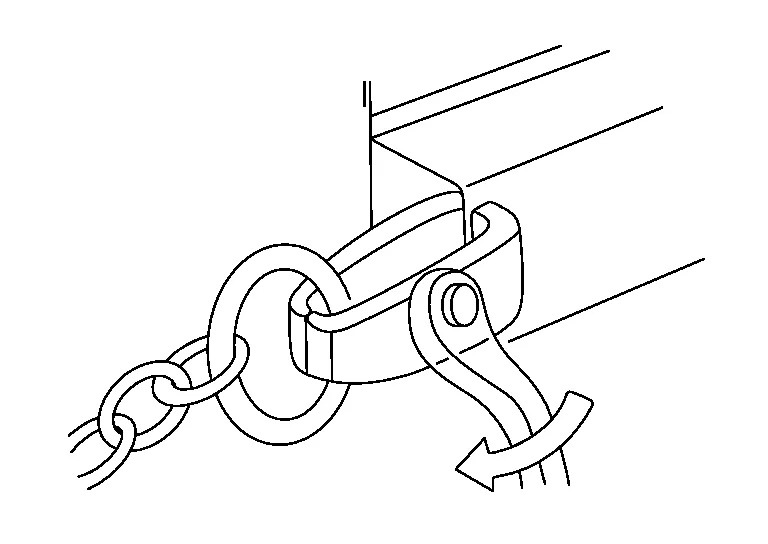

Sometimes a load of approximately 5,000 kg (11,025 lb) is applied during repair work. Accordingly, the clamp must be tightened securely. Be sure to use safety chain.

(2) GRADUAL PULL

-

Pull step by step.

The damaged portion may be work hardened.

Pulling all at once may cause cracking.

-

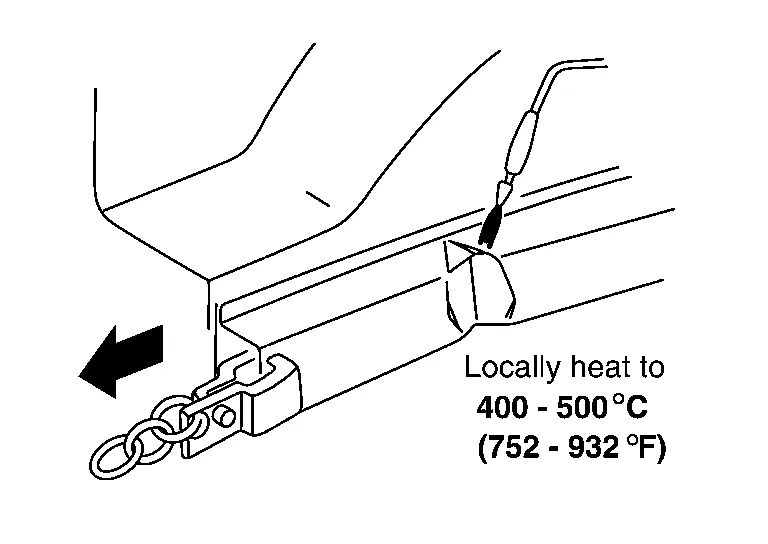

Reduce the hardness of the work-hardened portion.

Locally heat the panel to 400°C - 500°C (752°C - 932°F) to the extent that the panel is not colored. Do not heat above 700°C (1,292°F), or strength will be reduced. Do not raise to a temperature of more than 550°C (1,020°F) for HSS parts.

(3) CONSIDER SPRING-BACK

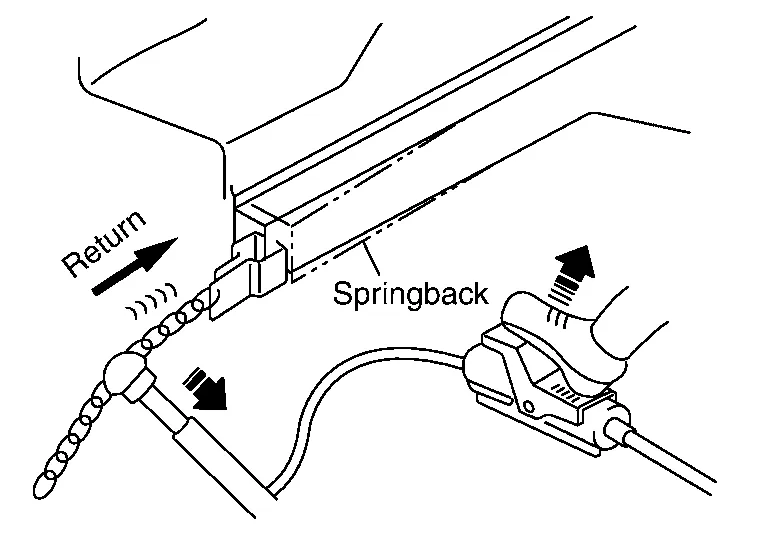

When pulling force is applied to a panel, spring-back is generated by the residual stress.

-

Proper amount of pull

Pull 2 mm - 3 mm (0.08 in - 0.12 in) more than the required dimension. Adjust the amount of pull corresponding to the spring-back.

-

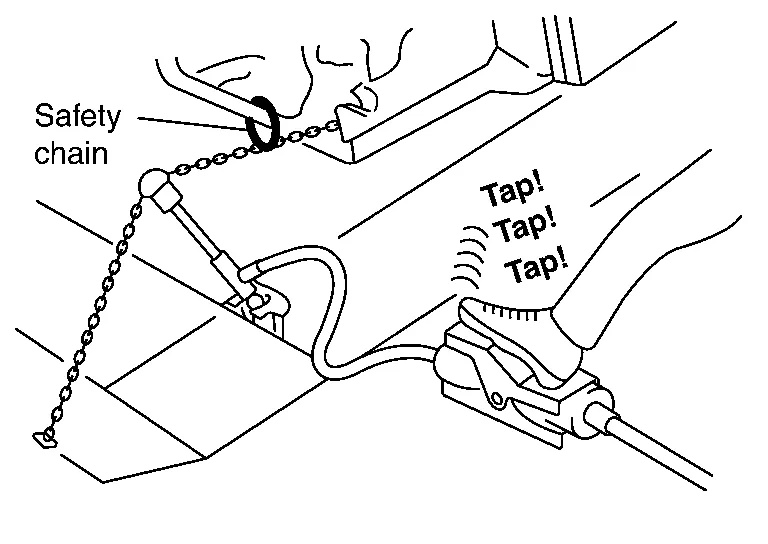

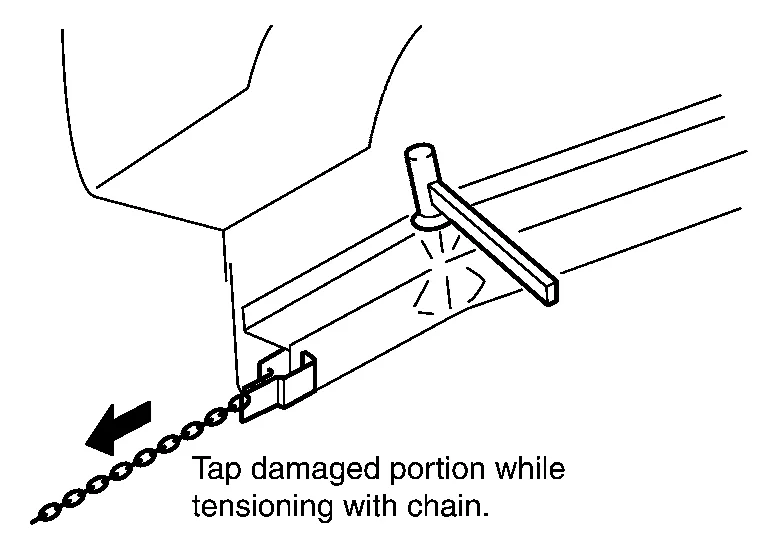

Use of hammer

Residual stress caused by kinetic energy of the collision can be removed by hammering.

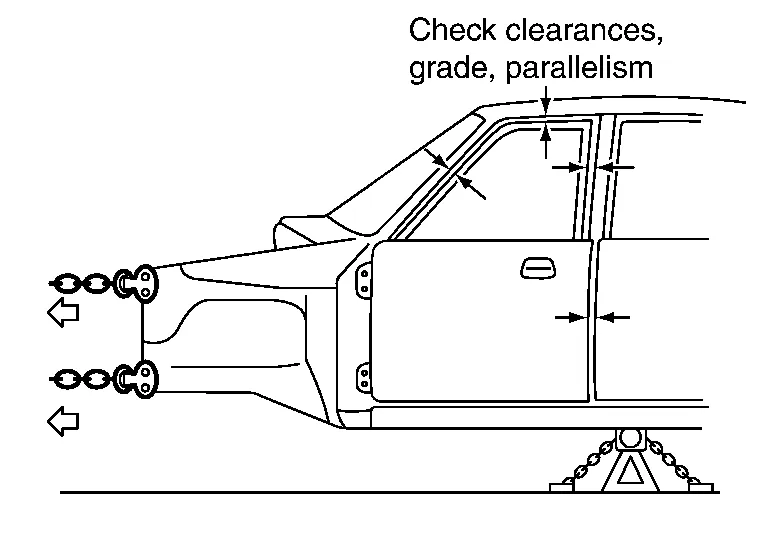

(4) DETERMINING PROPER AMOUNT OF PULL BY OBSERVING DOOR FIT

The proper amount of pull can be determined by observing the clearance at the door or trunk lid.

(5) PULLING UPPER PORTIONS FROM UNDERBODY CLAMP

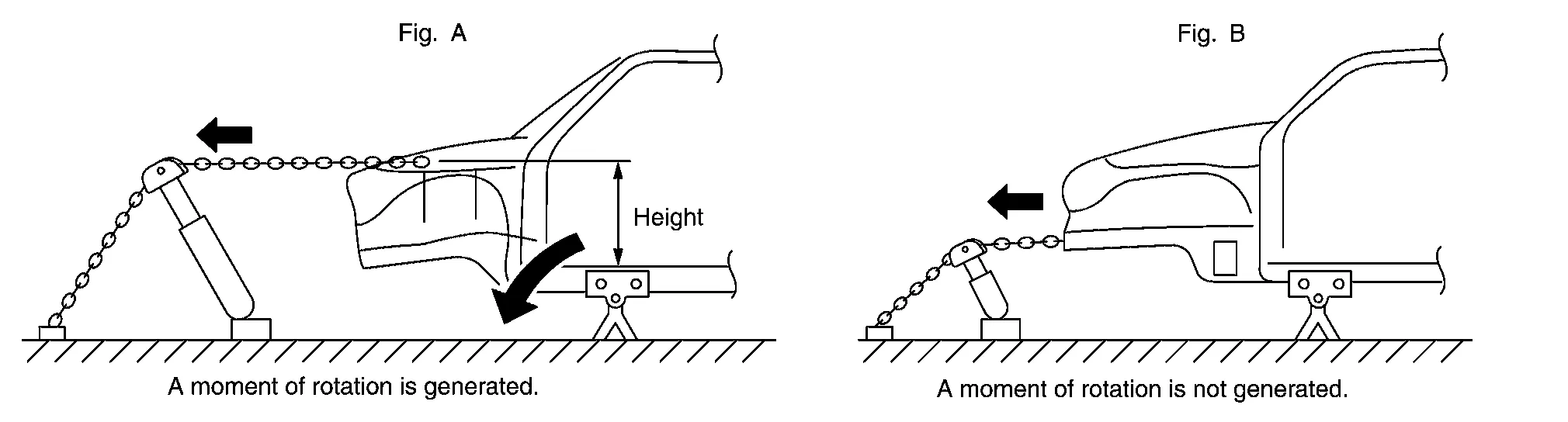

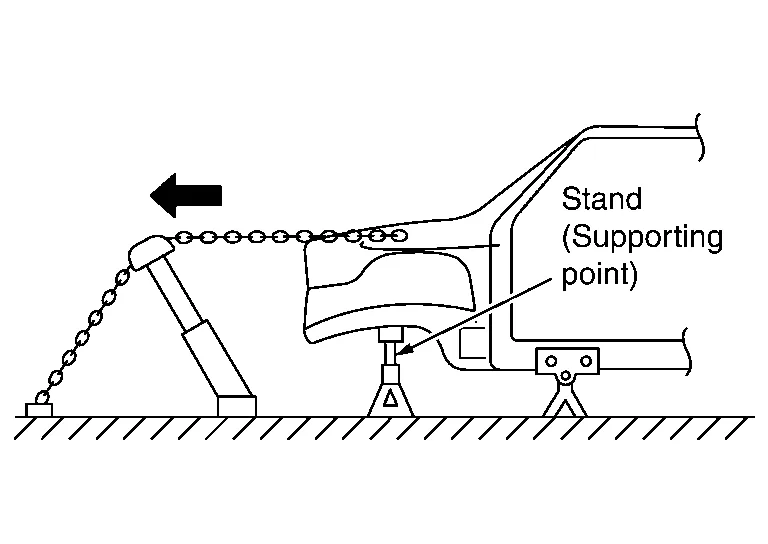

Note that if there is distance between the pulling point and the underbody clamp, as indicated by (A) in the figure, a moment of rotation is produced.

This may cause secondary damage to the clamped portion.

Provide a supporting point under the side member to prevent generation of this moment of rotation.

(6) ADDITIONAL ANCHORING

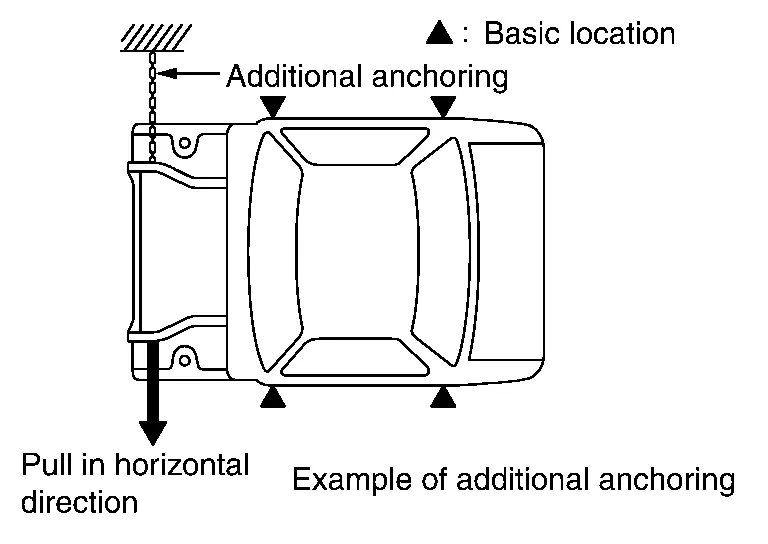

Pulling work must be performed with care taken not to damage the anchoring points or undamaged area of the body. If area not targeted for repair is affected by the excessive pulling force or the direction of pulling, additional anchoring points need to be provided to protect undamaged areas. Side sills are strong enough against longitudinal force, however, they are easily damaged by downward or lateral force. For this reason, additional anchoring should be provided by supporting side members with the port power, or attaching a clamp and chain.

(7) PURPOSE OF BODY ALIGNMENT

This operation is necessary to obtain correct alignment of parts to be used again. Therefore, the damage caused by propagated impact is recovered by pulling out the first input point.

Repair Techniques Using Body Straightening Equipment

Repair Techniques Using Body Straightening Equipment

Steps and Process

Each step and process should be described in detail. See below the steps:Details

Repair preparation

Repair method confirmation

Check the contents of the repair sheet and the work procedure...

Replacement of Panel

Replacement of Panel

Replacement of Panel

Panel replacement work includes replacement of the front fenders and hood which are installed by bolts, and replacement of rear fenders and the roof which are welded...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: B2409 Half Latch Sw

DTC Description DTC DETECTION LOGIC DTC No. CONSULT screen items (Trouble diagnosis content) DTC detecting condition B2409–71 HALF LATCH SW (Half latch switch) Diagnosis condition All times Signal (terminal) Half latch switch signal (automatic back door control module connector terminal: 7) Threshold When all of the following conditions are satisfied Back door: half latch or open Half latch switch: ON → OFF Diagnosis delay time – POSSIBLE CAUSE Entry of foreign materials to back door lock assembly Back door mechanism Half latch switch Harness or connectors (half latch switch circuit is open or shorted) Automatic back door control module FAIL-SAFEInhibit automatic back door system auto open/close function DTC Confirmation Procedure PERFORM DTC CONFIRMATION PROCEDURE CONSULT Ignition switch ON...

Nissan Murano (Z52) 2015-2024 Service Manual: Cooling Fan

Exploded View 1. Radiator core support 2. Fan 3. Fan motor 4. Fan shroud and motor assembly 5. Isolator (lower) 6. Grommet Front Removal and Installation WARNING: Do not remove the radiator cap when the engine is hot...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Checking engine oil level

- Power Steering Fluid (PSF)

- Intelligent Forward Collision Warning (I-FCW)

- New on site

- Most important about car

LATCH (Lower Anchors and Tethers for CHildren) system

LATCH system lower anchor locations - bench seat

Your vehicle is equipped with special anchor points that are used with LATCH system compatible child restraints. This system may also be referred to as the ISOFIX or ISOFIX compatible system. With this system, you do not have to use a vehicle seat belt to secure the child restraint unless the combined weight of the child and child restraint exceeds 65 lbs. (29.5 kg). If the combined weight of the child and child restraint is greater than 65 lbs. (29.5 kg), use the vehicle’s seat belt (not the lower anchors) to install the child restraint. Be sure to follow the child restraint manufacturer’s instructions for installation.