Nissan Murano: Repairing Procedures and Precautions / Repair of Rust and Corrosion

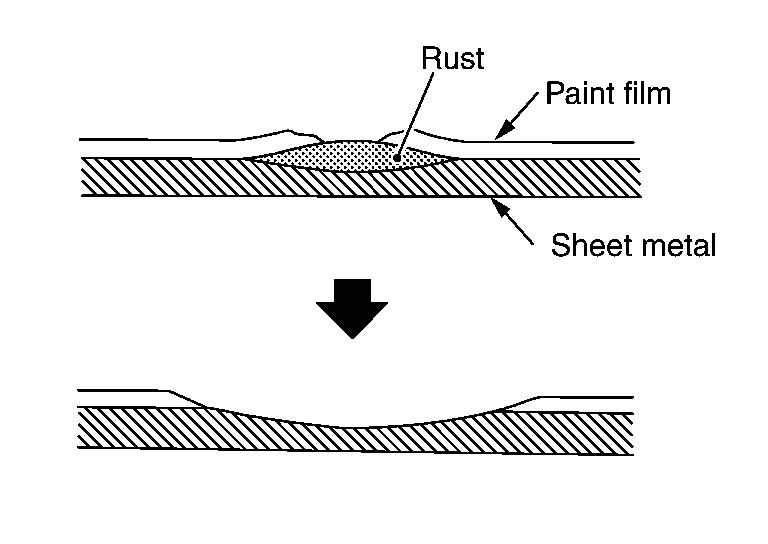

Rust on sheet metal is the result of the chemical reaction of steel to oxygen in the air, which is called oxidation. This rust, if left untreated, will increase and finally corrode and damage the sheet metal. If the Nissan Murano vehicle is used for a long time under severe environmental conditions, rust or corrosion may form on body surfaces. When repairing rust and corrosion, it is necessary to keep rust from spreading from the repaired portion.

Grind the rusted portion with an air sander or the like.

Rust may be more extensive than it appears from the outside. Therefore, it is necessary to grind the area around rusted portion. Repair the ground out portion using body filler.

(1) FILLING WITH FIBERGLASS

(a) Grind off the corroded portion of the panel with an air sander. If corrosion is severe, cut off the affected portion with a chisel or tinman's shears. Remove the paint from the surrounding areas.

(b) Hollow the area surrounding the repair hole by tapping with a hammer and bending the panel.

(c) Cut a piece of fiberglass cloth. The cloth should be large enough to overlap the repair hole.

Apply fiberglass putty to the cloth using a spatula until the mesh is filled. Prepare the fiberglass putty by mixing 100 parts of base with 2 to 3 parts of hardener.

(d) Apply a thin coat of fiberglass putty to the panel where the piece of fiberglass cloth is to be attached.

Apply putty also to the edge and back of the repair hole.

(e) Apply the piece of fiberglass cloth to the surrounding portion and the back of the repair hole.

This is necessary to prevent rust.

(f) Apply the piece of fiberglass cloth prepared in step (c) above to the repair hole. Press the periphery of the cloth to the panel for better adhesion. If the repair hole is large and the cloth sags in the center, support the cloth with tape applied behind the panel.

(g) Apply the fiberglass putty to the piece of fiberglass cloth. The fiberglass putty surface should be below the surrounding panel surface. If the area to be repaired is deep, use two or more piece of fiberglass cloth. In such a case, avoid thick application of fiberglass putty. Thick fiberglass putty will crack after drying.

(h) Dry the fiberglass putty, and grind the surface with an air sander. Then trim the entire panel using body filler.

When force drying fiberglass putty, allow the putty to sit for approximately 20 minutes. Then heat at a temperature below 60°C (140°F). Rapid heating which causes the putty to change color must be avoided, as it will lead to cracked putty. Fiberglass putty forms blowholes easily. Body filler must be used to finish the surface of fiberglass putty.

(2) PATCHING

(a) Remove the corroded portion of the panel.

Remove paint from the panel around the repair hole.

Make a flange by bending the surrounding panel with pliers and hammer, then apply anti-corrosive treatment (Metallic solution).

(b) Using tinman's shears, cut a patch large enough to overlap the repair hole. Apply the anti-corrosive treatment to the portion to be welded. Use of stainless steel is recommended to avoid rusting. If the repair hole is large, use a panel having the same thickness as the original panel to retain the original strength.

(c) Weld the patch to the repair hole. If stainless steel is used, use the MAG welding or spot welding method.

NOTE:

NOTE:

When welding the patch by MAG welding, use the plug welding method.

(d) Apply the body filler to the repaired portion of the panel.

(e) Apply the anti-corrosive treatment to the back of the panel. If accessible from behind, apply a sealer to the panel-to-patch mating section.

(f) If inaccessible from behind, apply an anti-corrosive wax from an inner panel opening or the like. It is also important to apply the anti-corrosive treatment to other portions in addition to the repaired portion.

Use of Body Filler (putty) and Grinding

Use of Body Filler (putty) and Grinding

Use of Body Filler (Putty) and Grinding

Panel irregularities may be corrected with a hammer and dolly. However, exact restoration of the original shape with these tools takes a long time...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Engine Lubrication System :: Preparation. Preparation

Special Service Tools The actual shape of the tools may differ from those illustrated here. Tool number (TechMate No.) Tool name Description KV10111100 (J-37228) Seal cutter Removing oil pan (lower) etc. Commercial Service Tools (TechMate No...

Nissan Murano (Z52) 2015-2024 Service Manual: Open Function

Diagnosis Procedure Back door auto closure function does not operate when back door opening operations are performed.CHECK BACK DOOR OPENER SWITCH Check back door opener switch. Refer to Component Function Check. Is the inspection result normal? YES>> GO TO 2...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Power Steering Fluid (PSF)

- Indicator lights

- All-Wheel Drive (AWD) (if so equipped)

- New on site

- Most important about car

Luggage hooks

When securing items using luggage hooks located on the back of the seat or side finisher do not apply a load over more than 6.5 lbs. (29 N) to a single hook.

The luggage hooks that are located on the floor should have loads less than 110 lbs. (490 N) to a single hook.