Nissan Murano: Audio, Visual & Navigation System :: Telematics System / Precaution. Precautions

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of collisions.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” sections of this Service Manual.

WARNING:

Always observe the following items for preventing accidental activation:

-

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in the event of a collision that would result in air bag inflation, it is recommended that all maintenance and repair be performed by an authorized NISSAN/INFINITI dealer.

-

Improper repair, including incorrect removal and installation of the SRS, can lead to personal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag Module, see “SRS AIR BAG”.

-

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

Always observe the following items for preventing accidental activation:

-

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition/power switch ON or engine running, never use air or electric power tools or strike near the sensor(s) with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing serious injury.

-

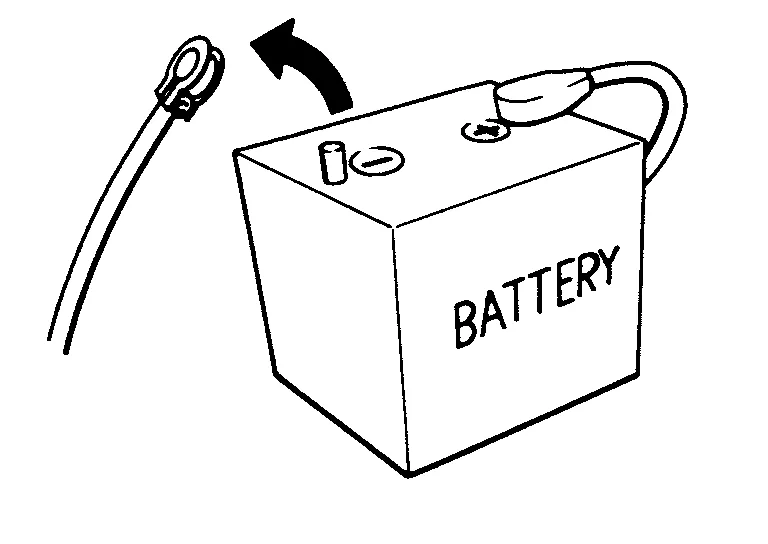

When using air or electric power tools or hammers, always switch the ignition/power switch OFF, disconnect the 12V battery or batteries, and wait at least 3 minutes before performing any service.

When disconnecting the battery terminal, pay attention to the following.

-

Always use a 12V battery as power source.

-

Never disconnect battery terminal while engine is running.

-

When removing the 12V battery terminal, turn OFF the ignition switch and wait at least 30 seconds.

-

For Nissan Murano vehicles with the engine listed below, remove the battery terminal after a lapse of the specified time:

BR08DE : 4 minutes V9X engine : 4 minutes D4D engine : 20 minutes YD25DDTi : 2 minutes HR09DET : 12 minutes YS23DDT : 4 minutes HRA2DDT : 12 minutes YS23DDTT : 4 minutes K9K engine : 4 minutes ZD30DDTi : 60 seconds M9R engine : 4 minutes ZD30DDTT : 60 seconds R9M engine : 4 minutes  NOTE:

NOTE:

ECU may be active for several tens of seconds after the ignition switch is turned OFF. If the battery terminal is removed before ECU stops, then a DTC detection error or ECU data corruption may occur.

-

After high-load driving, if the Nissan Murano vehicle is equipped with the V9X engine, turn the ignition switch OFF and wait for at least 15 minutes to remove the battery terminal.

NOTE:

NOTE:

-

Turbocharger cooling pump may operate in a few minutes after the ignition switch is turned OFF.

-

Example of high-load driving

-

Driving for 30 minutes or more at 140 km/h (86 MPH) or more.

-

Driving for 30 minutes or more on a steep slope.

-

-

-

For Nissan Murano vehicles with the 2-batteries, be sure to connect the main battery and the sub battery before turning ON the ignition switch.

NOTE:

NOTE:

If the ignition switch is turned ON with any one of the terminals of main battery and sub battery disconnected, then DTC may be detected.

-

After installing the 12V battery, always check "Self Diagnosis Result" of all ECUs and erase DTC.

NOTE:

NOTE:

The removal of 12V battery may cause a DTC detection error.

AV COMMUNICATION SYSTEM

-

Do not apply voltage of 7.0 V or higher to the measurement terminals.

-

Use the tester with its open terminal voltage being 7.0 V or less.

-

Be sure to turn ignition switch OFF and disconnect the battery cable from the negative terminal before checking the circuit.

AV COMMUNICATION SYSTEM

-

Solder the repaired parts, and wrap with tape. [Frays of twisted line must be within 110 mm (4.33 in).]

-

Do not perform bypass wire connections for the repair parts. (The spliced wire will become separated and the characteristics of twisted line will be lost.)

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Noise, Vibration and Harshness (nvh) Troubleshooting

NVH Troubleshooting Chart Use the chart below to find the cause of the symptom. If necessary, repair or replace these parts. Reference page Balancing Wheels Balancing Wheels Balancing Wheels Tire Air Pressure Balancing Wheels — — Tire Air Pressure NVH Troubleshooting Chart Symptom Table NVH Troubleshooting Chart or NVH Troubleshooting Chart NVH Troubleshooting Chart or NVH Troubleshooting Chart — — NVH Troubleshooting Chart or NVH Troubleshooting Chart ...

Nissan Murano (Z52) 2015-2024 Service Manual: Parking, License Plate and Tail Lamp System

System Description SYSTEM DIAGRAMSignal transmission function list Signal name Input Output Description Combination switch signal Combination switch (lighting and turn signal switch) BCM Transmits the combination switch signal to the BCM. Position light request signal BCM IPDM E/R (CAN) Combination meter (CAN) Transmits the position light request signal via CAN communication...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Intelligent Forward Collision Warning (I-FCW)

- Indicator lights

- High Beam Assist (if so equipped)

- New on site

- Most important about car

Luggage hooks

When securing items using luggage hooks located on the back of the seat or side finisher do not apply a load over more than 6.5 lbs. (29 N) to a single hook.

The luggage hooks that are located on the floor should have loads less than 110 lbs. (490 N) to a single hook.