Nissan Murano: Dtc/circuit Diagnosis / P0137 Ho2s2

DTC DETECTION LOGIC

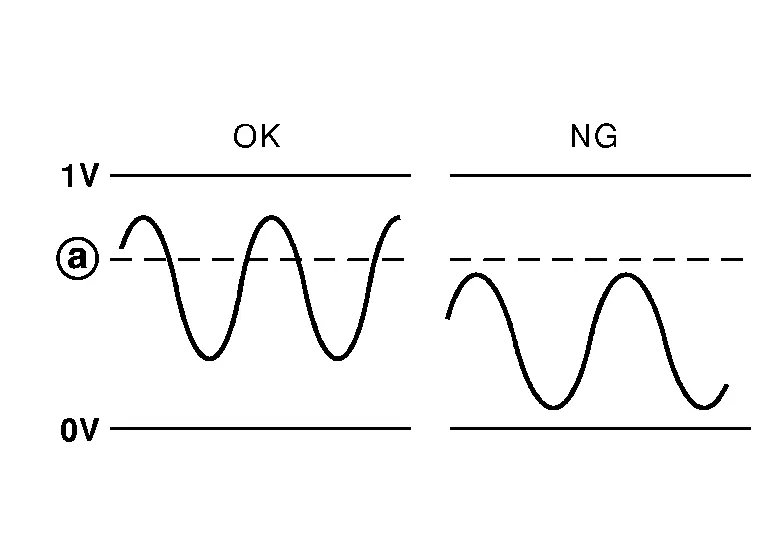

The heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/F) sensor 1. The oxygen storage capacity of the three way catalyst (manifold) causes the longer switching time. To judge the malfunctions of heated oxygen sensor 2, ECM monitors whether the maximum voltage of the sensor is sufficiently high during various driving conditions such as fuel-cut.

|

: 0.72 V |

The maximum voltage from the sensor does not reach the specified voltage.

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P0137 |

HO2S2 (B1) (O2 sensor circuit low voltage bank 1 sensor 2) |

A | Diagnosis condition | — |

| Signal (terminal) | Voltage signal transmitted from heated oxygen sensor 2 to ECM | |||

| Threshold | The maximum voltage from the sensor does not reach the specified voltage | |||

| Diagnosis delay time | — | |||

| B | Diagnosis condition | — | ||

| Signal (terminal) | — | |||

| Threshold | ECM detects the heated oxygen sensor 2 heater circuit is short to ground. | |||

| Diagnosis delay time | — | |||

POSSIBLE CAUSE

P0137

-

Harness or connectors (The sensor circuit is open or shorted)

-

Heated oxygen sensor 2

-

Fuel pressure

-

Fuel injector

-

Intake air leakage

FAIL-SAFE

Not applicable

INSPECTION START

Will CONSULT be used?

Will CONSULT be used?

YES>>GO TO 2.

NO>>GO TO 5.

PRECONDITIONING

If DTC confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

For better results, perform “DTC WORK SUPPORT” at a temperature of 0 to 30°C (32 to 86°F).

>>

GO TO 3.

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT.

-

Start engine and warm it up to the normal operating temperature.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

-

Let engine idle for 1 minute.

-

Check that “COOLANT TEMP/S” indicates more than 70°C (158°F).

If not, warm up engine and go to next step when “COOLANT TEMP/S” indication reaches 70°C (158°F).

-

Open engine hood.

-

Select “HO2S2 (B1) P1147” (for DTC P0137) of “HO2S2” in “DTC WORK SUPPORT” mode with CONSULT.

-

Follow the instruction of CONSULT display.

NOTE:

NOTE:

It will take at most 10 minutes until “COMPLETED” is displayed.

-

Touch “SELF-DIAG RESULTS”.

Which is displayed on CONSULT screen?

OK-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

OK-2>>Confirmation after repair: INSPECTION END

NG>>Proceed to Diagnosis Procedure.

CAN NOT BE DIAGNOSED>>GO TO 4.

PERFORM DTC CONFIRMATION PROCEDURE AGAIN

-

Turn ignition switch OFF and leave the Nissan Murano vehicle in a cool place (soak the vehicle).

-

Perform DTC confirmation procedure again.

>>

GO TO 3.

PERFORM COMPONENT FUNCTION CHECK-I

Without CONSULT

Without CONSULT

-

Start engine and warm it up to the normal operating temperature.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

-

Let engine idle for 1 minute.

-

Check the voltage between ECM harness connector terminals under the following conditions.

ECM Condition Voltage Connector + – Terminal F78 41 35 Revving up to 4,000 rpm under no load at least 10 times The voltage should be above 0.72 V at least once during this procedure.

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 6.

PERFORM COMPONENT FUNCTION CHECK-II

Check the voltage between ECM harness connector terminals under the following conditions.

| ECM | Condition | Voltage | ||

|---|---|---|---|---|

| Connector | + | – | ||

| Terminal | ||||

| F78 | 41 | 35 | Keeping engine at idle for 10 minutes | The voltage should be above 0.72 V at least once during this procedure. |

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 7.

PERFORM COMPONENT FUNCTION CHECK-III

Check the voltage between ECM harness connector terminals under the following conditions.

| ECM | Condition | Voltage | ||

|---|---|---|---|---|

| Connector | + | – | ||

| Terminal | ||||

| F78 | 41 | 35 | Coasting from 80 km/h (50 MPH) with selector lever in the D position | The voltage should be above 0.72 V at least once during this procedure. |

Is the inspection result normal?

YES>>To check malfunction symptom before repair: Refer to Intermittent Incident.

YES>>Confirmation after repair: INSPECTION END

NO>>Proceed to Diagnosis Procedure.

CLEAR MIXTURE RATIO SELF-LEARNING VALUE

-

Clear the mixture ratio self-learning value. Refer to Description.

-

Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0171 detected? Is it difficult to start engine?

YES>>Perform trouble diagnosis for DTC P0171. Refer to DTC Description.

NO>>GO TO 2.

CHECK HO2S2 GROUND CIRCUIT

-

Turn ignition switch OFF.

-

Disconnect heated oxygen sensor 2 harness connector.

-

Disconnect ECM harness connector.

-

Check the continuity between heated oxygen sensor 2 (HO2S2) harness connector and ECM harness connector.

HO2S2 ECM Continuity Bank Connector Terminal Connector Terminal 1 F62 4 F78 35 Existed -

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair open circuit, short to ground or short to power in harness or connectors.

CHECK HO2S2 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

-

Check the continuity between HO2S2 harness connector and ECM harness connector.

HO2S2 ECM Continuity Bank Connector Terminal Connector Terminal 1 F62 3 F78 41 Existed -

Check the continuity between HO2S2 harness connector and ground, or ECM harness connector and ground.

HO2S2 Ground Continuity Bank Connector Terminal 1 F62 3 Ground Not existed ECM Ground Continuity Connector Terminal F78 41 Ground Not existed -

Also check harness for short to power.

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair open circuit, short to ground or short to power in harness or connectors.

CHECK HEATED OXYGEN SENSOR 2

Check heated oxygen sensor 2. Refer to Component Inspection.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace malfunctioning heated oxygen sensor 2. Refer to Removal and Installation (bank 1).

INSPECTION START

Will CONSULT be used?

Will CONSULT be used?

YES>>GO TO 2.

NO>>GO TO 3.

CHECK HEATED OXYGEN SENSOR 2

With CONSULT

With CONSULT

-

Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT.

-

Start engine and warm it up to the normal operating temperature.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

-

Let engine idle for 1 minute.

-

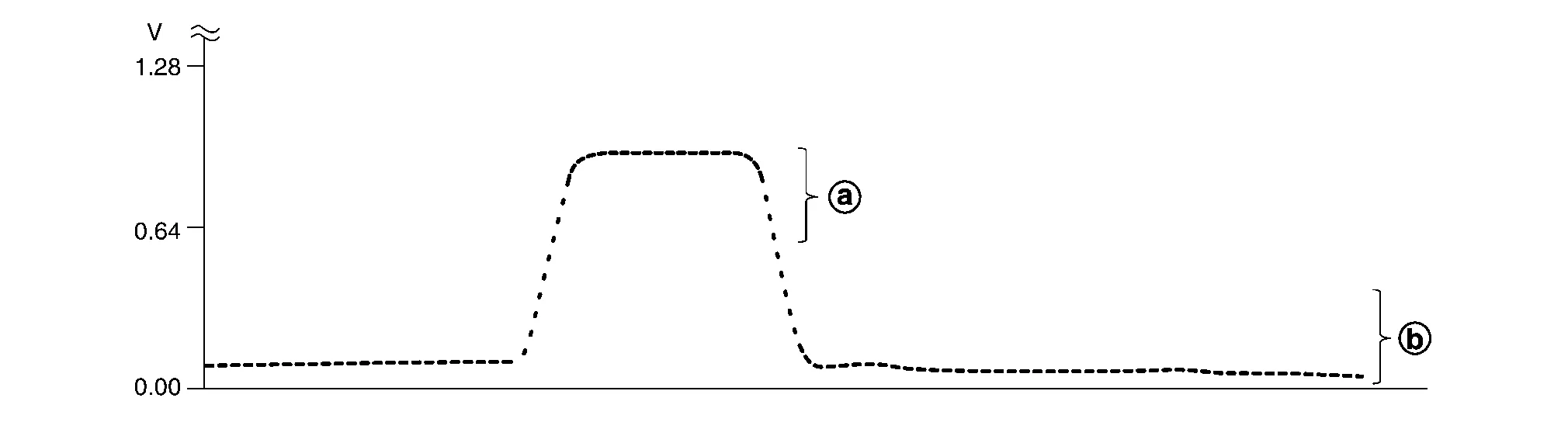

Select “FUEL INJECTION” in “ACTIVE TEST” mode, and select “HO2S2 (B1)/(B2)” as the monitor item with CONSULT.

-

Check “HO2S2 (B1)/(B2)” at idle speed when adjusting “FUEL INJECTION” to ± 25%.

: The voltage should be above 0.72 V at least on time.

: The voltage should be below 0.27 V at least on time. “HO2S2 (B1)/(B2)” should be above 0.72 V at least once when the “FUEL INJECTION” is + 25%.

“HO2S2 (B1)/(B2)” should be below 0.27 V at least once when the “FUEL INJECTION” is − 25%.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace malfunctioning heated oxygen sensor 2. Refer to Removal and Installation (bank 1).

CHECK HEATED OXYGEN SENSOR 2-I

Without CONSULT

Without CONSULT

-

Start engine and warm it up to the normal operating temperature.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

-

Let engine idle for 1 minute.

-

Check the voltage between ECM harness connector terminals under the following conditions.

ECM Condition Voltage Connector + – Terminal F78 41 35 Revving up to 4,000 rpm under no load at least 10 times The voltage should be above 0.72 V at least once during this procedure.

The voltage should be below 0.27 V at least once during this procedure.

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 4.

CHECK HEATED OXYGEN SENSOR 2-II

Check the voltage between ECM harness connector terminals under the following conditions.

| ECM | Condition | Voltage | ||

|---|---|---|---|---|

| Connector | + | – | ||

| Terminal | ||||

| F78 | 41 | 35 | Keeping engine at idle for 10 minutes |

The voltage should be above 0.72 V at least once during this procedure. The voltage should be below 0.27 V at least once during this procedure. |

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 5.

CHECK HEATED OXYGEN SENSOR 2-III

Check the voltage between ECM harness connector terminals under the following conditions.

| ECM | Condition | Voltage | ||

|---|---|---|---|---|

| Connector | + | – | ||

| Terminal | ||||

| F78 | 41 | 35 | Coasting from 80 km/h (50 MPH) with selector lever in the D position |

The voltage should be above 0.72 V at least once during this procedure. The voltage should be below 0.27 V at least once during this procedure. |

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace malfunctioning heated oxygen sensor 2. Refer to Removal and Installation (bank 1).

P0136 Ho2s2

P0136 Ho2s2

DTC Description

DTC DETECTION LOGICThe heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/F) sensor 1...

P0139 Ho2s2

P0139 Ho2s2

DTC Description

DTC DETECTION LOGICThe heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/F) sensor 1...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Component Parts. Srs Air Bag Control System

Component Parts Location A. Left side of roof line (view with headliner removed) B. Right of rear passenger seat (view with rear wheel house finisher removed) C. Base of passenger seat lap belt (view with center pillar garnish removed) D...

Nissan Murano (Z52) 2015-2024 Service Manual: Power Supply, Ground & Circuit Elements :: Preparation. Preparation

Special Service Tools The actual shape of the tools may differ from those illustrated here. Tool number (TechMate No.) Tool name Description 165-GR8-1200KIT ( — ) Midtronics Battery Charger and Tester Tests batteries, starting and charging systems and charges batteries...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Passenger compartment

- Rear bench seat adjustment

- Fuel recommendation

- New on site

- Most important about car

Luggage hooks

When securing items using luggage hooks located on the back of the seat or side finisher do not apply a load over more than 6.5 lbs. (29 N) to a single hook.

The luggage hooks that are located on the floor should have loads less than 110 lbs. (490 N) to a single hook.