Nissan Murano: Body Welding and Precautions / Outline of Welding

-

No restrictions on the shape of joint

-

Reduction in weight compared to using of bolts or rivets

-

Great strength

-

Airtight and watertight

-

High working efficiency

-

Some welding processes require higher welding skills.

-

The welded parts can be separated only by breaking the weld. (Except when brazing)

The occupational safety regulations include provisions on preventative measures for avoiding damage and accidents. As the occupational safety regulations are country- specific, this document only lists general information on occupational health and safety for working with steel.

The general, non-material-specific protection and hygiene measures in the workshop must always be observed.

Protective equipment

The following table provides an overview of the general personal protective equipment for material processing:

| Protective equipment | MAG welding | Spot welding | Sanding / Grinding & Cutting |

| Protective shoes | X | X | X |

| Work clothing | X | X | X |

| Safety goggles | X | X | |

| Welding gloves | X | ||

| General protection gloves | X | X | |

| General apron | |||

| Latex gloves | |||

| Fine dust mask | X | ||

| Breathing protection with filter* | |||

| Ear defenders | X | ||

| Welding apron, clothing suitable for welding | X | X | |

| Welding shield, welding mask | X |

*only if there is insufficient ventilation

The up-to-date guidelines and notes in the workshop information system ISTA must always be observed. In addition to the general protective equipment, country-specific provisions must also be complied with where applicable.

Working area

A safe and high-quality working environment requires cleanliness and order. When processing steel components, workers must always not only ensure that they themselves are safe, but also that other work bays and employees are not put at risk.

| Protective equipment | MAG welding | Spot Welding | Sanding / Grinding & Cutting | Bonding |

| Partition walls, protective curtains | X | X | X | |

| Welding emission extraction | X |

A fire extinguisher must always be close to hand during work with a raised level of fire risk for example MAG welding.

The up-to-date guidelines and notes in the workshop information system ISTA must always be observed. In addition to the general protective measures for the working area, country- specific provisions must also be complied with where applicable.

Tools

The general and country-specific safety regulations for work with tools for processing metal must be complied with.

The general safety regulations are:

-

Do not clean tools with compressed air.

-

Do not use abrasives that have already been used for processing aluminum.

-

Always separate tools for steel processing and aluminum processing.

Environment

The proper disposal and recycling of materials are described in the environmental protection law. The laws serve to protect natural resources and preserve the environment. Environmental protection laws are regulated on a market-specific basis.

Recycling

Scrap metals from vehicles are largely recyclable. The steel is added to the steel production process.

To separate the various materials in the body shell, the body shell is compressed into a bundle and shredded. The shredded material is separated into ferrous metals, non- ferrous metals and other materials. This is done with the sink-float method using their different weights.

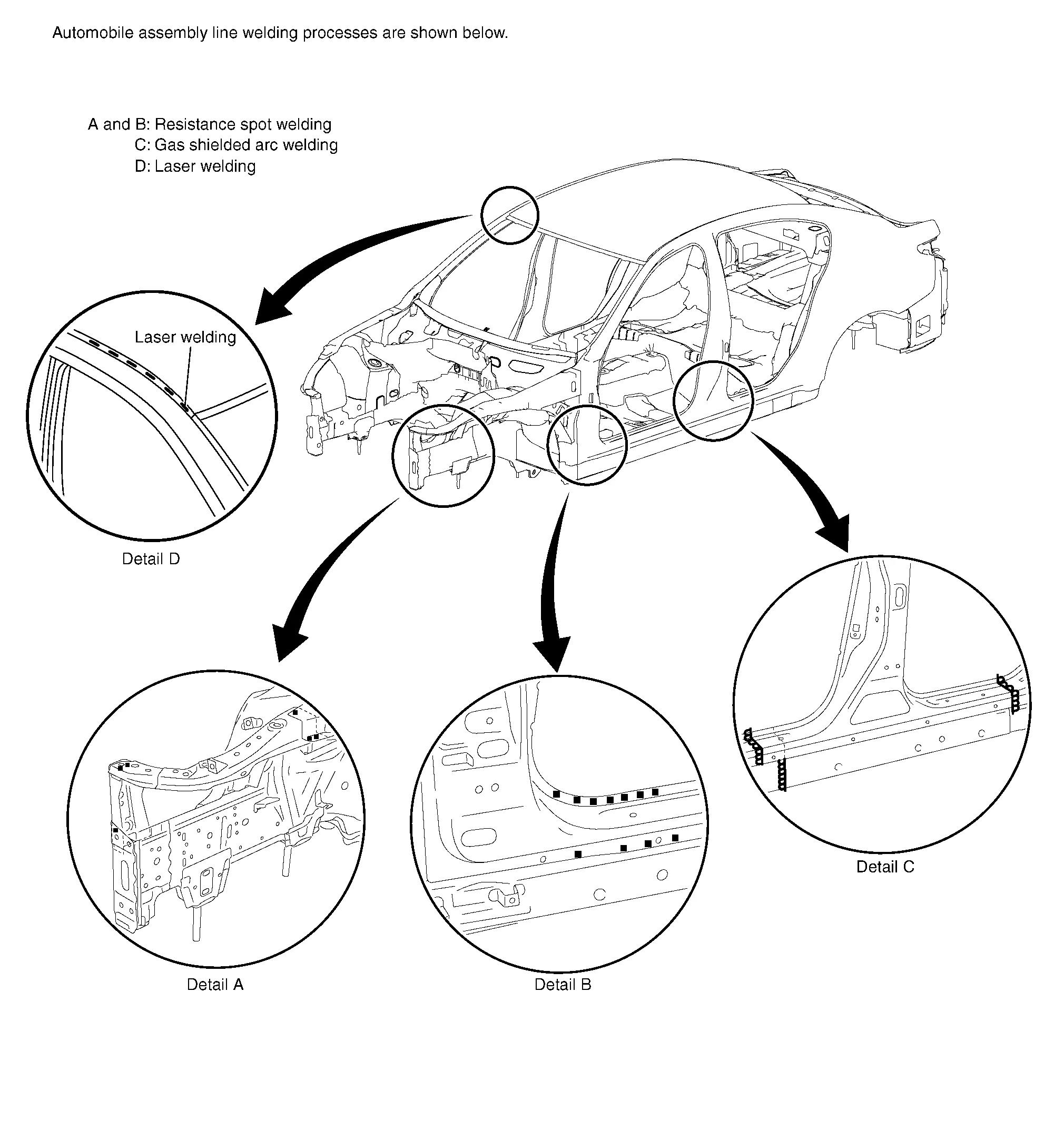

The automobile body is fabricated by welding 0.6 mm - 1.4 mm (0.024 in - 0.055 in) thick sheet steel. Spot welding is most suitable in terms of cost, quality and working efficiency. On the automobile production line, spot welding is widely used, except for some special areas which cannot use this procedure. Today, spot welding is mostly performed by robots.

In addition to spot welding MAG brazing are also used.

Soldering is not used in the automobile production line.

Automobile assembly line welding processes are shown below.

Electric Resistance Spot Welding

Electric Resistance Spot Welding

Principles of Spot Welding

Resistance spot welding is a kind of electric resistance welding. It is classified as pressure welding. Two or three sheets of metal are overlapped and pressed, and current is passed through the mating surfaces...

Other information:

Nissan Murano (Z52) 2015-2024 Owners Manual: Vehicle-to-vehicle distance control mode operation

The vehicle-to-vehicle distance control mode is designed to maintain a selected distance from the vehicle in front of you and can reduce the speed to match a slower vehicle ahead. The system will decelerate the vehicle as necessary and if the vehicle ahead comes to a stop, the vehicle decelerates to a standstill...

Nissan Murano (Z52) 2015-2024 Service Manual: Electric Resistance Spot Welding

Principles of Spot Welding Resistance spot welding is a kind of electric resistance welding. It is classified as pressure welding. Two or three sheets of metal are overlapped and pressed, and current is passed through the mating surfaces. As the current flows, the metals melt due to Joule heat at the mating surfaces and are joined by the pressure...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Intelligent Forward Collision Warning (I-FCW)

- Checking engine oil level

- High Beam Assist (if so equipped)

- New on site

- Most important about car

Front manual seat adjustment (if so equipped)

Your vehicle seats can be adjusted manually. For additional information about adjusting the seats, refer to the steps outlined in this section.

Forward and backward