Nissan Murano: Heater & Air Conditioning System :: Periodic Maintenance / Oil

MAINTENANCE OF OIL LEVEL

The compressor oil is circulating in the system together with the refrigerant. It is necessary to fill compressor with oil when replacing A/C system parts or when a large amount of refrigerant leaks are detected. It is important to always maintain oil level within the specified level or the following conditions may occur:

-

Insufficient oil amount: Stuck compressor

-

Excessive oil amount: Insufficient cooling (caused by insufficient heat exchange)

| Oil Type | : "Oil". |

If a compressor is malfunctioning (internal noise, insufficient cooling), check the compressor oil.

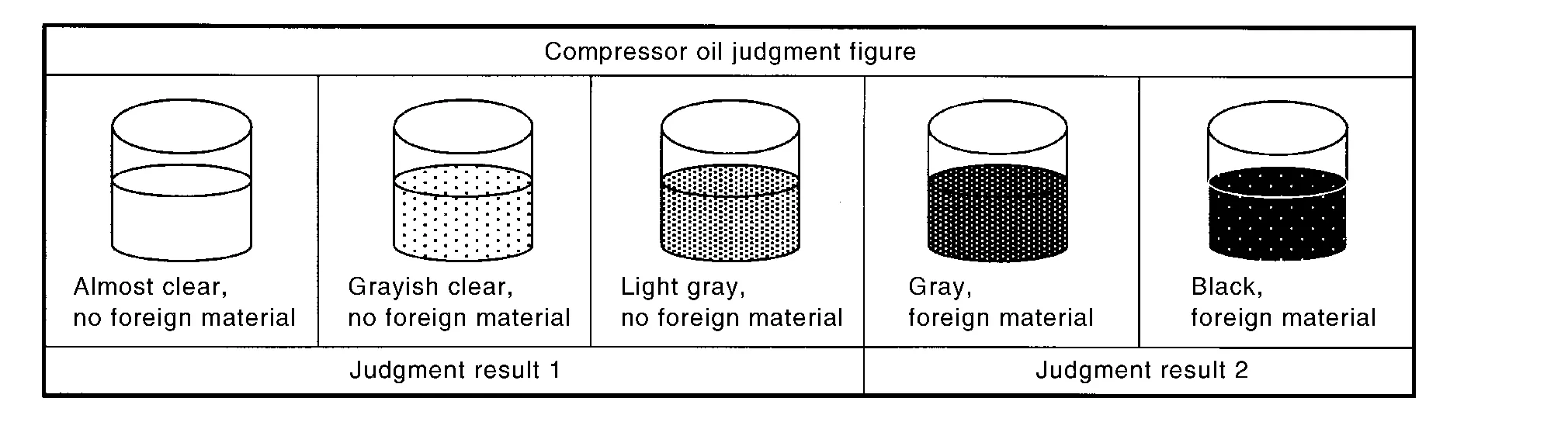

COMPRESSOR OIL JUDGMENT

-

Remove the compressor. Refer to Removal and Installation.

-

Sample compressor oil and judge according to the figure below.

Judgment result 1>>

Replace compressor only.

Judgment result 2>>Replace compressor and condenser (includes liquid tank).

CAUTION:

If a large amount of refrigerant or oil leaks are detected, do not perform oil return operation.

Start the engine and set to the following conditions:

-

Engine speed: Idling to 1,200 rpm

-

A/C switch: ON

-

Fan (blower) speed: Maximum speed set

-

Intake door position: Recirculation

-

Temperature setting: Full cold

Perform oil return operation for approximately 10 minutes.

Stop the engine.

Oil return operation is complete.

Fill with oil to the amount that is calculated according to the following conditions.

Example: Oil amount to be added when replacing evaporator [m (US fl oz, Imp fl oz)] = 75 (2.5, 2.6) + α

(US fl oz, Imp fl oz)] = 75 (2.5, 2.6) + α

| Conditions |

Oil amount to be added to A/C system m (US fl oz, Imp fl oz) (US fl oz, Imp fl oz) | |

|---|---|---|

| Replace evaporator | 75 (2.5, 2.6) | |

| Replace condenser (includes liquid tank) | 80 (2.7, 2.8) | |

| Refrigerant leak is detected | Large amount leak | 30 (1.0, 1.1) |

| Small amount leak | — | |

| Oil amount that is recycled together with refrigerant during recycle operation | α | |

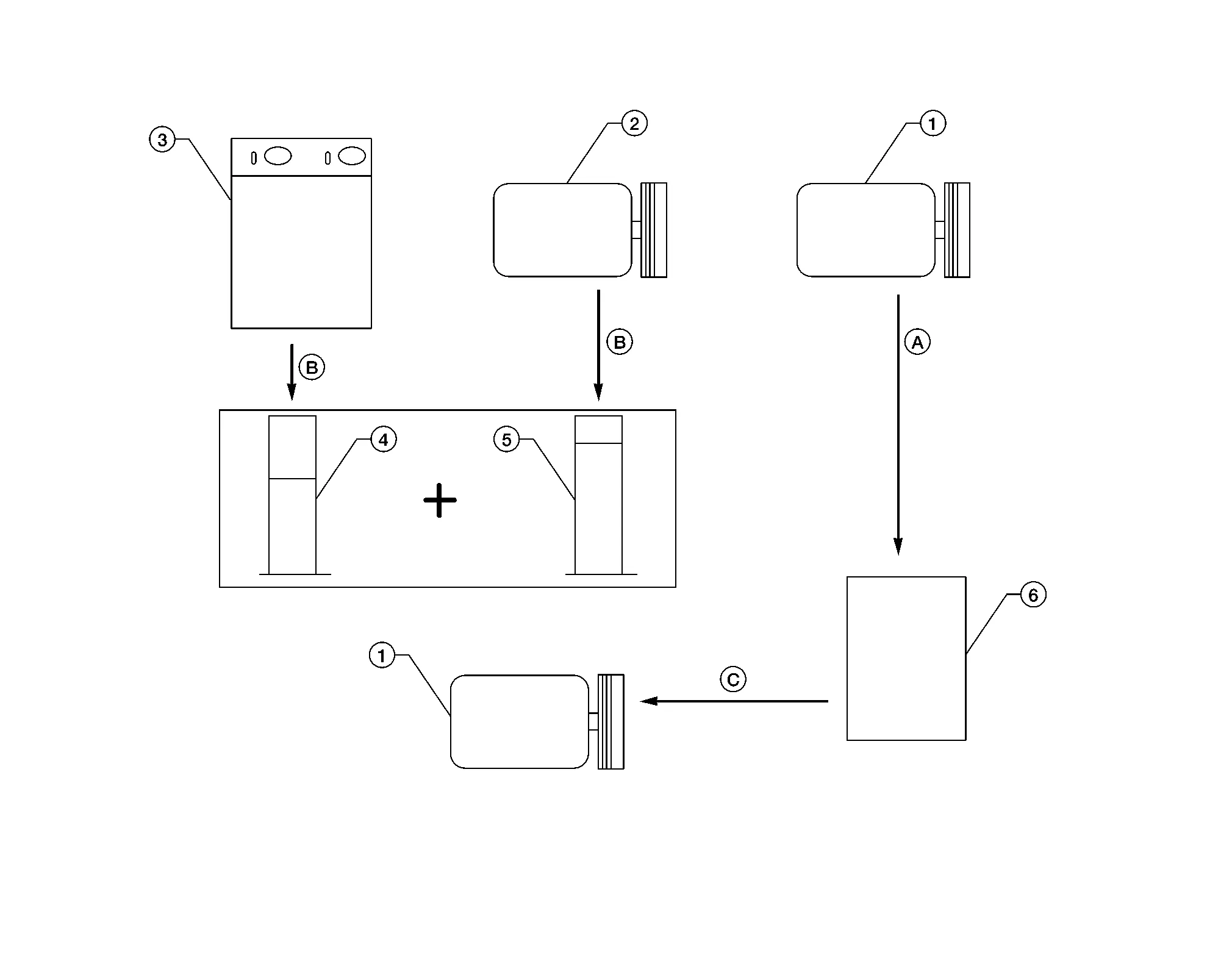

| 1. | New compressor | 2. | Old compressor | 3. | Recovery/recycling equipment |

| 4. | Measuring cup X | 5. | Measuring cup Y | 6. | New oil |

| A. | Drain oil from the new compressor into clean container | B. | Record amount of oil recovered | C. | Install new oil equal to recorded amounts in measuring cups X and Y |

Before connecting recovery/recycling/recharging equipment to vehicle, check recovery/recycling/recharging equipment gauges. No refrigerant pressure should be displayed. If NG, recover refrigerant from equipment lines.

Connect recovery/recycling/recharging equipment to Nissan Murano vehicle. Confirm refrigerant purity in supply tank using recovery/recycling/recharging equipment and refrigerant identifier. If NG, refer to Precautions For Refrigerant System Service.

Confirm refrigerant purity in Nissan Murano vehicle A/C system using recovery/recycling equipment and refrigerant identifier. If NG, refer to Precautions For Refrigerant System Service.

Discharge refrigerant into the refrigerant recovery/recycling equipment. Measure oil discharged into the recovery/recycling/recharging equipment.

Drain the oil from the old (removed) compressor into a graduated container and recover the amount of oil drained.

Drain the oil from the new compressor into a separate, clean container.

Measure the amount of new oil installed equal to amount drained from old compressor. Add this oil to new compressor through the suction port opening.

Measure the amount of new oil equal to the amount recovered during discharging. Add this oil to new compressor through the suction port opening.

Refrigerant

Refrigerant

Description

CONNECTION OF SERVICE TOOLS AND EQUIPMENT 1.

Shut-off valve

2.

A/C service valve

3.

Recovery/recycling/recharging equipment

4...

Performance Test

Performance Test

Inspection

INSPECTION PROCEDURE

Connect recovery/recycling/recharging equipment (for HFO-1234yf) or manifold gauge.

Start the engine, and set to the following conditions...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Meter, Warning Lamp & Indicator :: Basic Inspection. Diagnosis and Repair Work Flow

Work flow OVERALL SEQUENCE Reference 1: On Board Diagnosis Function. Reference 2: DTC Index. Reference 3: Diagnosis Procedure. Reference 4: Component Inspection. Reference 5: Diagnosis Procedure. DETAILED FLOWOBTAIN INFORMATION ABOUT SYMPTOM Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred...

Nissan Murano (Z52) 2015-2024 Service Manual: Steering Gear and Linkage

Exploded View 1. Outer socket 2. Inner socket lock nut 3. Small boot clamp 4. Boot 5. Large boot clamp 6. Inner socket 7. Spacer 8. Rack bar (not serviceable) 9. Bracket 10. Steering gear Disassembly and Assembly DISASSEMBLYRemove inner socket lock nut (A) and outer socket (1)...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- How to enable/disable the LDW system

- Indicator lights

- Turning the AEB system on/off

- New on site

- Most important about car

Fuel gauge

The gauge indicates the approximate fuel level in the tank.

The gauge may move slightly during braking, turning, acceleration, or going up or down hills.

The gauge needle returns to 0 (Empty) after the ignition switch is placed in the OFF position.