Nissan Murano: Removal and Installation / Corrosion Protection

To provide improved corrosion prevention, the following anti-corrosive measures have been implemented in NISSAN production plants. When repairing or replacing body panels, it is necessary to use the same anti-corrosive measures.

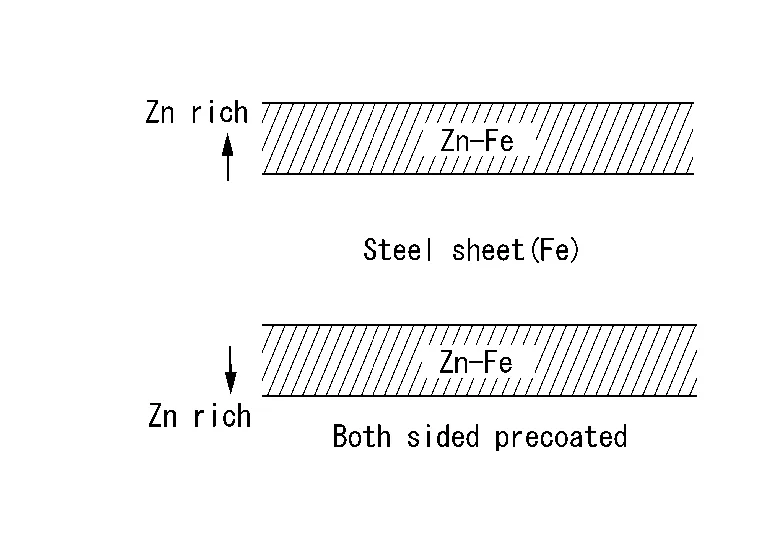

Anti-Corrosive Precoated Steel (Galvannealed Steel)

To improve repairability and corrosion resistance, a new type of anti-corrosive precoated steel sheet has been adopted, replacing conventional zinc-coated steel sheet.

Galvannealed steel is electroplated and heated to form zinc-iron alloy, which provides excellent and long term corrosion resistance with cationic electrodeposition primer.

NISSAN Genuine Service Parts are fabricated from galvannealed steel. Therefore, it is recommended that GENUINE NISSAN PARTS or equivalent be used for panel replacement to maintain the anti-corrosive performance built into the Nissan Murano vehicle at the factory.

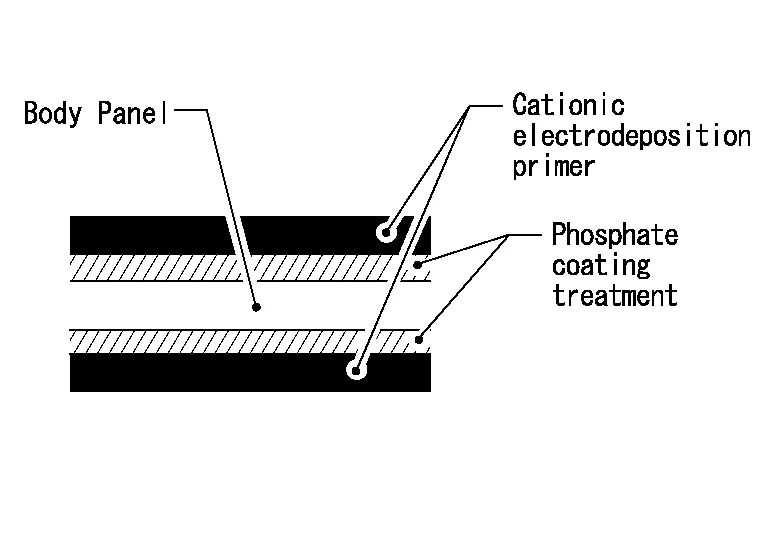

Phosphate Coating Treatment and Cationic Electrodeposition Primer

A phosphate coating treatment and a cationic electrodeposition primer, which provide excellent corrosion protection, are employed on all body components.

CAUTION:

Confine paint removal during welding operations to an absolute minimum.

NISSAN Genuine Service Parts are also treated in the same manner. Therefore, it is recommended that GENUINE NISSAN PARTS or equivalent be used for panel replacement to maintain anti-corrosive performance built into the Nissan Murano vehicle at the factory.

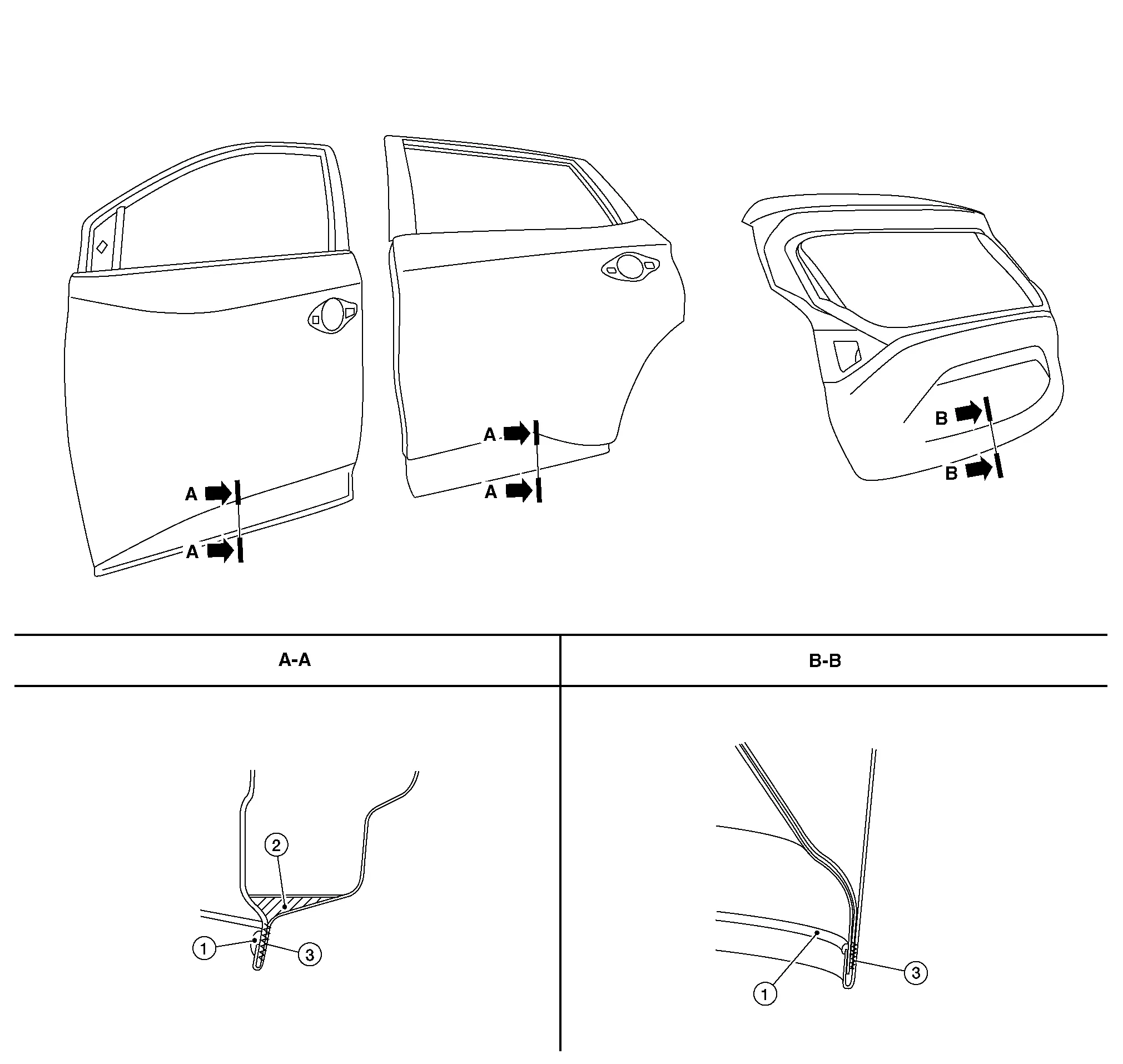

To improve corrosion resistance, anti-corrosive wax is applied inside the body sill and inside other closed sections. Accordingly, when replacing these parts, be sure to apply anti-corrosive wax to the appropriate areas of the new parts. Select an excellent anti-corrosive wax which will penetrate after application and has a long shelf life.

| 1. | Body caulk | 2. | Anti-corrosive wax | 3. | Panel adhesive |

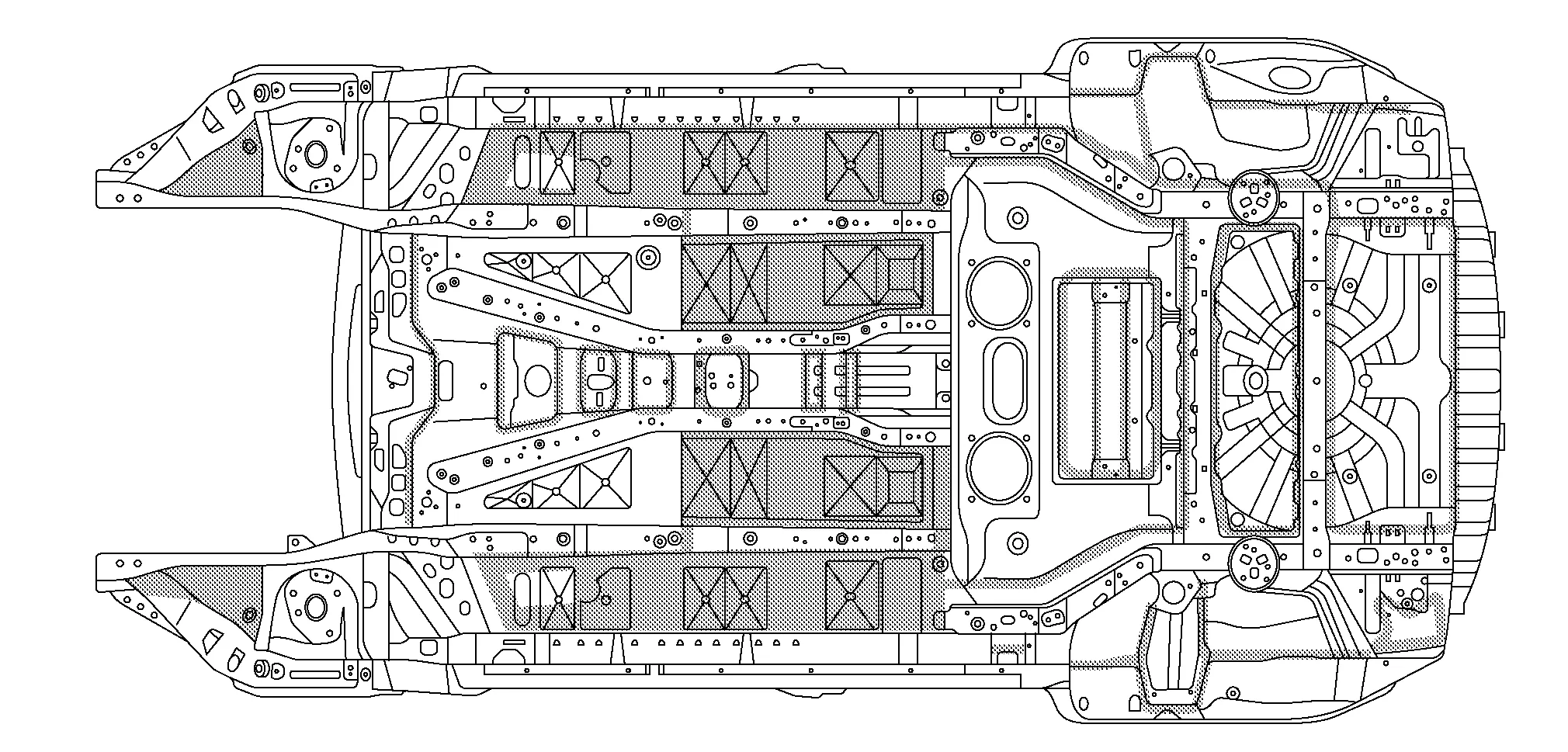

The underside of the floor and wheelhouse are undercoated to prevent rust, vibration, noise and stone chipping. Therefore, when such a panel is replaced or repaired, apply undercoating to that part. Use an undercoating which is rust preventive, soundproof, vibration-proof, shock-resistant, adhesive, and durable.

Precautions in Undercoating

Do not apply undercoating unless specified. Avoid areas such as the areas above the muffler and three-way catalyst which are subjected to heat

Do not undercoat the exhaust pipe or other parts which become hot.

Do not undercoat rotating parts.

Apply cavity wax after applying undercoating.

After putting seal on the Nissan Murano vehicle, put undercoating on it.

| Undercoated areas are shaded. |

Body Sealing

Body Sealing

Description

The following figure shows the areas which are sealed at the factory. Sealant which has been applied to these areas should be smooth and free from cuts or gaps...

Other information:

Nissan Murano (Z52) 2015-2024 Owners Manual: MOD system limitations

WARNING Listed below are the system limitations for MOD. Failure to operate the vehicle in accordance with these system limitations could result in serious injury or death. Do not use the MOD system when towing a trailer. The system may not function properly...

Nissan Murano (Z52) 2015-2024 Owners Manual: Rear Automatic Braking (RAB) (if so equipped)

WARNING Failure to follow the warnings and instructions for proper use of the RAB system could result in serious injury or death. The RAB system is a supplemental aid to the driver. It is not a replacement for proper driving procedures. Always use the side and rear mirrors and turn and look in the direction you willmove before and while backing up...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Memory storage function (key-link)

- How to enable/disable the LDW system

- Fuel recommendation

- New on site

- Most important about car

LATCH (Lower Anchors and Tethers for CHildren) system

LATCH system lower anchor locations - bench seat

Your vehicle is equipped with special anchor points that are used with LATCH system compatible child restraints. This system may also be referred to as the ISOFIX or ISOFIX compatible system. With this system, you do not have to use a vehicle seat belt to secure the child restraint unless the combined weight of the child and child restraint exceeds 65 lbs. (29.5 kg). If the combined weight of the child and child restraint is greater than 65 lbs. (29.5 kg), use the vehicle’s seat belt (not the lower anchors) to install the child restraint. Be sure to follow the child restraint manufacturer’s instructions for installation.