Nissan Murano: Dtc/circuit Diagnosis / P1217 Engine Over Temperature

DTC DETECTION LOGIC

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is indicated.

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P1217 |

ENG OVER TEMP [Engine over temperature (Overheat)] |

1 | Diagnosis condition | — |

| Signal (terminal) | — | |||

| Threshold | Cooling fan does not operate properly (Overheat) | |||

| Diagnosis delay time | — | |||

| 2 | Diagnosis condition | — | ||

| Signal (terminal) | — | |||

| Threshold | Cooling fan system does not operate properly (Overheat) | |||

| Diagnosis delay time | — | |||

| 3 | Diagnosis condition | — | ||

| Signal (terminal) | — | |||

| Threshold | Engine coolant was not added to the system using the proper filling method | |||

| Diagnosis delay time | — | |||

| 4 | Diagnosis condition | — | ||

| Signal (terminal) | — | |||

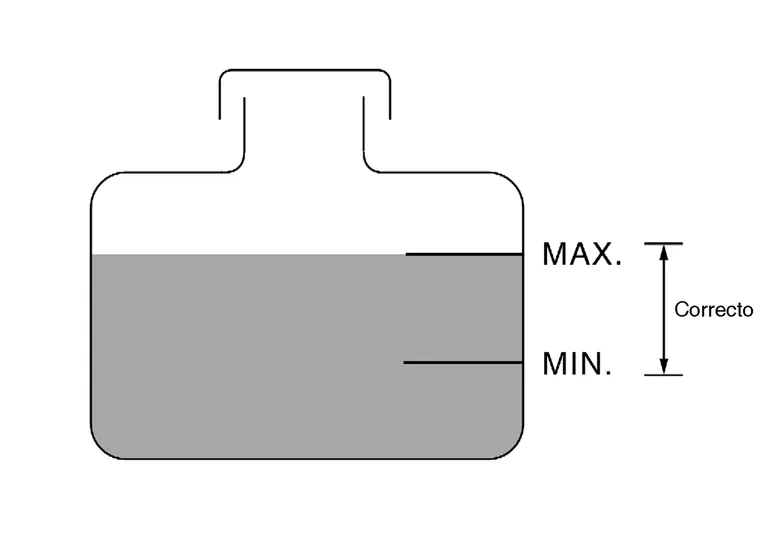

| Threshold | Engine coolant is not within the specified range | |||

| Diagnosis delay time | — | |||

CAUTION:

When a malfunction is indicated, be sure to replace the coolant. Refer to Changing Engine Coolant. Also, replace the engine oil. Refer to Changing Engine Oil.

-

Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to use coolant with the proper mixture ratio. Refer to Engine Coolant Mixture.

-

After refilling coolant, run engine to ensure that no water-flow noise is emitted.

POSSIBLE CAUSE

-

Harness or connectors

(Cooling fan circuit is open or shorted.)

-

IPDM E/R

-

Cooling fan motor

-

Radiator hose

-

Radiator

-

Radiator cap

-

Reservoir tank

-

Water pump

-

Thermostat

-

Water control valve

FAIL-SAFE

Not applicable

CHECK DTC PRIORITY

If DTC P1217 is displayed with DTC UXXXX or P0607, first perform the confirmation procedure for DTC UXXXX or P0607.

Is applicable DTC detected?

YES>>Perform diagnosis of applicable.

-

DTC UXXXX: Refer to DTC Index.

-

DTC P0607: Refer to DTC Description.

GO TO 2.

PERFORM COMPONENT FUNCTION CHECK-I

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pressure fluid escaping from the radiator.

Wrap a thick cloth around cap. Carefully remove the cap by turning it a quarter turn to allow built-up pressure to escape. Then turn the cap all the way off.

Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

Is the coolant level in the reservoir tank and/or radiator below the proper range?

YES>>Proceed to Diagnosis Procedure.

NO>>GO TO 3.

PERFORM COMPONENT FUNCTION CHECK-II

Confirm whether customer filled the coolant or not.

Did customer fill the coolant?

YES>>Proceed to Diagnosis Procedure.

NO>>GO TO 4.

PERFORM COMPONENT FUNCTION CHECK-III

With CONSULT

With CONSULT

-

Turn ignition switch ON.

-

Perform “FAN DUTY CONTROL” in “ACTIVE TEST” mode of “ENGINE” using CONSULT.

-

Check that cooling fan speed varies according to the percentage.

Without CONSULT

Without CONSULT

-

Activate IPDM E/R auto active test and check cooling fan motors operation. Refer to Diagnosis Description.

-

Check that cooling fan operates.

Is the inspection result normal?

YES>>To check malfunction symptom before repair: Refer to Intermittent Incident.

YES>>Confirmation after repair: INSPECTION END

NO>>Proceed to Diagnosis Procedure.

CHECK DTC PRIORITY

If DTC P1217 is displayed with DTC UXXXX or P0607, first perform the confirmation procedure for DTC UXXXX or P0607.

Is applicable DTC detected?

YES>>Perform diagnosis of applicable.

-

DTC UXXXX: Refer to DTC Index.

-

DTC P0607: Refer to DTC Description.

GO TO 2.

CHECK COOLING FAN OPERATION

With CONSULT

With CONSULT

-

Turn ignition switch ON.

-

Perform “FAN DUTY CONTROL” in “ACTIVE TEST” mode of “ENGINE” using CONSULT.

-

Check that cooling fan speed varies according to the percentage.

Without CONSULT

Without CONSULT

-

Activate IPDM E/R auto active test and check cooling fan motors operation. Refer to Diagnosis Description.

-

Check that cooling fan operates.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Proceed to Diagnosis Procedure.

CHECK COOLING SYSTEM FOR LEAK-I

Check cooling system for leak. Refer to System Inspection.

Is leakage detected?

YES>>GO TO 4.

NO>>GO TO 5.

CHECK COOLING SYSTEM FOR LEAK-II

Check the following for leak.

-

Hose (Refer to System Inspection.)

-

Radiator (Refer to System Inspection.)

-

Water pump (Refer to Removal and Installation.)

>>

Repair or replace malfunctioning part.

CHECK RADIATOR CAP

Check radiator cap. Refer to System Inspection.

Is the inspection result normal?

YES>>GO TO 6.

NO>>Replace radiator cap. Refer to Exploded View.

CHECK THERMOSTAT

Check thermostat. Refer to Removal and Installation.

Is the inspection result normal?

YES>>GO TO 7.

NO>>Replace thermostat. Refer to Removal and Installation.

CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 8.

NO>>Replace engine coolant temperature sensor. Refer to Exploded View.

OVERHEATING CAUSE ANALYSIS

If the cause cannot be isolated, check the Troubleshooting Chart.

>>

INSPECTION END

P1212 Tcs Communication Line

P1212 Tcs Communication Line

DTC Description

DESCRIPTIONThis CAN communication line is used to control the smooth engine operation during the TCS operation. Pulse signals are exchanged between ECM and “ABS actuator and electric unit (control unit)”...

P1220 Fuel Pump Control Module (fpcm)

P1220 Fuel Pump Control Module (fpcm)

DTC Description

DTC DETECTION LOGIC DTC No.

Trouble diagnosis name

(Trouble diagnosis content) DTC detecting condition Possible cause

P1220

FPCM

(Fuel pump control module)

During engine cranking, the signal voltage of the FPCM to the ECM is too low...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Additional Service When Replacing Control Unit (bcm)

Description BEFORE REPLACEMENTWhen replacing BCM, save or print current vehicle specification with CONSULT configuration before replacement.CAUTION: When replacing the BCM, a new BCM must be used. The functions controlled by the BCM do not operate properly if a BCM from another Nissan Murano vehicle is used...

Nissan Murano (Z52) 2015-2024 Service Manual: Open/closure Function

Diagnosis Procedure Back door auto closure function does not operate when back door opening and closing operations are performed.CHECK DTC WITH AUTOMATIC BACK DOOR CONTROL MODULE Check that DTC is not detected with automatic back door control module. Is the inspection result normal? YES>> GO TO 2...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Settings

- How to enable/disable the LDW system

- Shift lock release

- New on site

- Most important about car

Seatback pockets

Theremaybe one or two seatback pockets located on the back of the driver and passenger seats. The pockets can be used to store maps.

WARNING