Nissan Murano: Dtc/circuit Diagnosis / P0300 Misfire

DTC DETECTION LOGIC

When a misfire occurs, engine speed will fluctuate. If the engine speed fluctuates enough to cause the crankshaft position (CKP) sensor (POS) signal to vary, ECM can determine that a misfire is occurring.

| Sensor | Input signal to ECM | ECM function | |

|---|---|---|---|

| Crankshaft position sensor (POS) | Engine speed | On board diagnosis of misfire | |

The misfire detection logic consists of the following two conditions.

-

One Trip Detection Logic (Three Way Catalyst Damage)

On the 1st trip, when a misfire condition occurs that can damage the three way catalyst (TWC) due to overheating, the MIL will blink.

When a misfire condition occurs, the ECM monitors the CKP sensor signal every 200 engine revolutions for a change.

When the misfire condition decreases to a level that will not damage the TWC, the MIL will turn off.

If another misfire condition occurs that can damage the TWC on a second trip, the MIL will blink.

When the misfire condition decreases to a level that will not damage the TWC, the MIL will remain on.

If another misfire condition occurs that can damage the TWC, the MIL will begin to blink again.

-

Two Trip Detection Logic (Exhaust quality deterioration)

For misfire conditions that will not damage the TWC (but will affect Nissan Murano vehicle emissions), the MIL will only illuminate when the misfire is detected on a second trip. During this condition, the ECM monitors the CKP sensor signal every 1,000 engine revolutions.

A misfire malfunction can be detected in any one cylinder or in multiple cylinders.

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | |

| P0300 |

MULTI CYL MISFIRE (Random/Multiple cylinder misfire detected) |

Diagnosis condition | — |

| Signal (terminal) | — | ||

| Threshold | Multiple cylinders misfire | ||

| Diagnosis delay time | — | ||

| P0301 |

CYL 1 MISFIRE (Cylinder 1 misfire detected) |

Diagnosis condition | — |

| Signal (terminal) | — | ||

| Threshold | No. 1 cylinder misfires | ||

| Diagnosis delay time | — | ||

| P0302 |

CYL 2 MISFIRE (Cylinder 2 misfire detected) |

Diagnosis condition | — |

| Signal (terminal) | — | ||

| Threshold | No. 2 cylinder misfires | ||

| Diagnosis delay time | — | ||

| P0303 |

CYL 3 MISFIRE (Cylinder 3 misfire detected) |

Diagnosis condition | — |

| Signal (terminal) | — | ||

| Threshold | No. 3 cylinder misfires | ||

| Diagnosis delay time | — | ||

| P0304 |

CYL 4 MISFIRE (Cylinder 4 misfire detected) |

Diagnosis condition | — |

| Signal (terminal) | — | ||

| Threshold | No. 4 cylinder misfires | ||

| Diagnosis delay time | — | ||

| P0305 |

CYL 5 MISFIRE (Cylinder 5 misfire detected) |

Diagnosis condition | — |

| Signal (terminal) | — | ||

| Threshold | No. 5 cylinder misfires | ||

| Diagnosis delay time | — | ||

| P0306 |

CYL 6 MISFIRE (Cylinder 6 misfire detected) |

Diagnosis condition | — |

| Signal (terminal) | — | ||

| Threshold | No. 6 cylinder misfires | ||

| Diagnosis delay time | — | ||

POSSIBLE CAUSE

P0300

-

Improper spark plug

-

Insufficient compression

-

Incorrect fuel pressure

-

The fuel injector circuit is open or shorted

-

Fuel injector

-

Intake air leakage

-

The ignition signal circuit is open or shorted

-

Lack of fuel

-

Signal plate

-

A/F sensor 1

-

Incorrect PCV hose connection

P0301

-

Improper spark plug

-

Insufficient compression

-

Incorrect fuel pressure

-

The fuel injector circuit is open or shorted

-

Fuel injector

-

Intake air leakage

-

The ignition signal circuit is open or shorted

-

Lack of fuel

-

Signal plate

-

A/F sensor 1

-

Incorrect PCV hose connection

P0302

-

Improper spark plug

-

Insufficient compression

-

Incorrect fuel pressure

-

The fuel injector circuit is open or shorted

-

Fuel injector

-

Intake air leakage

-

The ignition signal circuit is open or shorted

-

Lack of fuel

-

Signal plate

-

A/F sensor 1

-

Incorrect PCV hose connection

P0303

-

Improper spark plug

-

Insufficient compression

-

Incorrect fuel pressure

-

The fuel injector circuit is open or shorted

-

Fuel injector

-

Intake air leakage

-

The ignition signal circuit is open or shorted

-

Lack of fuel

-

Signal plate

-

A/F sensor 1

-

Incorrect PCV hose connection

P0304

-

Improper spark plug

-

Insufficient compression

-

Incorrect fuel pressure

-

The fuel injector circuit is open or shorted

-

Fuel injector

-

Intake air leakage

-

The ignition signal circuit is open or shorted

-

Lack of fuel

-

Signal plate

-

A/F sensor 1

-

Incorrect PCV hose connection

P0305

-

Improper spark plug

-

Insufficient compression

-

Incorrect fuel pressure

-

The fuel injector circuit is open or shorted

-

Fuel injector

-

Intake air leakage

-

The ignition signal circuit is open or shorted

-

Lack of fuel

-

Signal plate

-

A/F sensor 1

-

Incorrect PCV hose connection

P0306

-

Improper spark plug

-

Insufficient compression

-

Incorrect fuel pressure

-

The fuel injector circuit is open or shorted

-

Fuel injector

-

Intake air leakage

-

The ignition signal circuit is open or shorted

-

Lack of fuel

-

Signal plate

-

A/F sensor 1

-

Incorrect PCV hose connection

FAIL-SAFE

Not applicable

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF and wait at least 10 seconds.

>>

GO TO 2.

PERFORM DTC CONFIRMATION PROCEDURE-I

-

Start engine and warm it up to normal operating temperature.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Restart engine and let it idle for approximately 15 minutes.

-

Check 1st trip DTC.

Is 1st trip DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO>>GO TO 3.

PERFORM DTC CONFIRMATION PROCEDURE-II

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Start engine and drive the Nissan Murano vehicle under similar conditions to (1st trip) Freeze Frame Data for a certain time. Refer to the table below.

Hold the accelerator pedal as steady as possible.

Similar conditions to (1st trip) Freeze Frame Data mean that the following conditions should be satisfied at the same time.

CAUTION:

Always drive Nissan Murano vehicle in safe manner according to traffic conditions and obey all traffic laws when driving.

Engine speed Engine speed in the freeze frame data ± 400 rpm Nissan Murano Vehicle speed Vehicle speed in the freeze frame data ± 10 km/h (6 MPH) Basic fuel schedule Basic fuel schedule in freeze frame data × (1 ± 0.1) Engine coolant temperature (T) condition When the freeze frame data shows lower than 70°C (158°F),

T should be lower than 70°C (158°F).When the freeze frame data shows higher than or equal to 70°C (158°F),

T should be higher than or equal to 70°C (158°F).Driving time varies according to the engine speed in the freeze frame data.

Engine speed Time Around 1,000 rpm Approximately 10 minutes Around 2,000 rpm Approximately 5 minutes More than 3,000 rpm Approximately 3.5 minutes -

Check 1st trip DTC.

Is 1st trip DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: INSPECTION END

CHECK GROUND CONNECTION

Check the following.

-

Connection condition of the ground F15 and F59

-

Connection condition of the ground harness between engine assembly and Nissan Murano vehicle body (If equipped)

Is the inspection result normal?

YES>>GO TO 2

NO>>Repair or replace error-detected parts.

CHECK FOR INTAKE AIR LEAKAGE AND PCV HOSE

-

Start engine and run it at idle speed.

-

Listen for the sound of the intake air leakage.

-

Check PCV hose connection.

Is intake air leakage detected?

YES>>Discover air leakage location and repair.

NO>>GO TO 3.

CHECK FOR EXHAUST SYSTEM CLOGGING

Stop engine and visually check exhaust tube, three way catalyst and muffler for dents.

Is the inspection result normal?

YES>>With CONSULT: GO TO 4.

YES>>Without CONSULT: GO TO 5.

NO>>Repair or replace malfunctioning part.

PERFORM POWER BALANCE TEST

With CONSULT

With CONSULT

-

Start engine.

-

Perform “POWER BALANCE” in “ACTIVE TEST” mode with CONSULT.

-

Check that each circuit produces a momentary engine speed drop.

Is the inspection result normal?

YES>>GO TO 10.

NO>>GO TO 5.

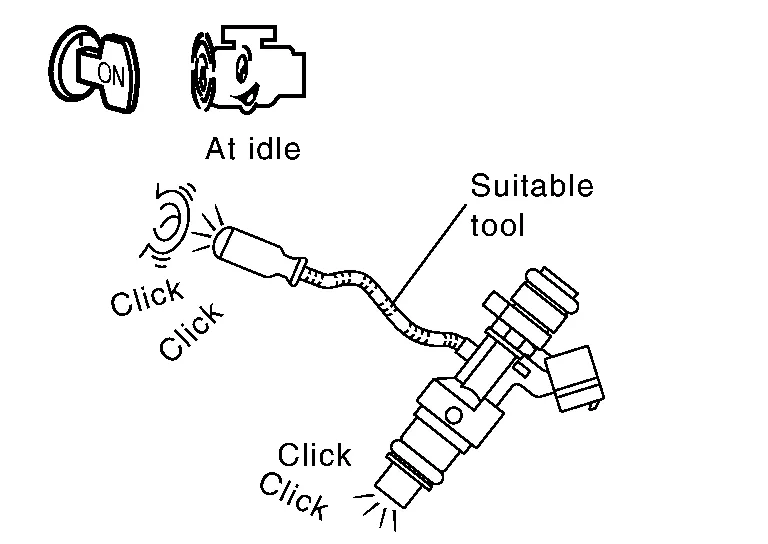

CHECK FUNCTION OF FUEL INJECTOR

-

Start engine and let it idle.

-

Listen to each fuel injector make operation sound.

Clicking sound should be heard.

Is the inspection result normal?

YES>>GO TO 6.

NO>>Perform trouble diagnosis for FUEL INJECTOR, refer to Diagnosis Procedure.

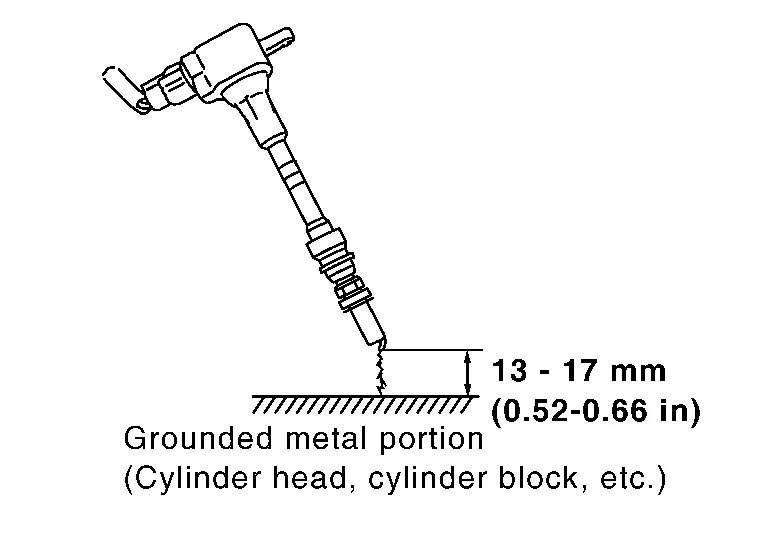

CHECK FUNCTION OF IGNITION COIL-I

CAUTION:

Perform the following procedure in a place with no combustible objects and good ventilation.

-

Turn ignition switch OFF.

-

Remove fuel pump fuse in IPDM E/R to release fuel pressure.

NOTE:

NOTE:

Do not use CONSULT to release fuel pressure, or fuel pressure applies again during the following procedure.

-

Start engine.

-

After engine stalls, crank it 2 or 3 times to release all fuel pressure.

-

Turn ignition switch OFF.

-

Remove all ignition coil harness connectors to avoid the electrical discharge from the ignition coils.

-

Remove ignition coil and spark plug of the cylinder to be checked.

-

Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

-

Connect spark plug and harness connector to ignition coil.

-

Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 - 0.66 in) between the edge of the spark plug and grounded metal portion as shown in the figure.

-

Crank engine for approximately 3 seconds, and check whether spark is generated between the spark plug and the grounded metal portion.

Spark should be generated. CAUTION:

-

During the operation, always stay 0.5 m (19.7 in) or more away from the spark plug and the ignition coil. Be careful not to get an electrical shock while checking, because the electrical discharge voltage becomes 20 kV or more.

-

It might damage the ignition coil if the gap of more than 17 mm (0.66 in) is made.

NOTE:

NOTE:

When the gap is less than 13 mm (0.52 in), a spark might be generated even if the coil is malfunctioning.

-

Is the inspection result normal?

YES>>GO TO 10.

NO>>GO TO 7.

CHECK FUNCTION OF IGNITION COIL-II

-

Turn ignition switch OFF.

-

Disconnect spark plug and connect a non-malfunctioning spark plug.

-

Crank engine for approximately 3 seconds, and recheck whether spark is generated between the spark plug and the grounded metal portion.

Spark should be generated.

Is the inspection result normal?

YES>>GO TO 8.

NO>>Check ignition coil, power transistor and their circuits. Refer to Diagnosis Procedure.

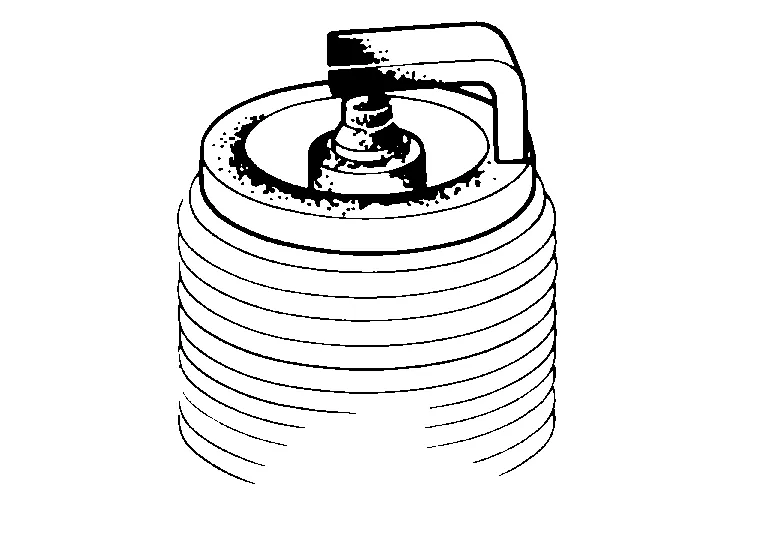

CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal?

YES>>Replace spark plug(s) with standard type one(s). For spark plug type, refer to Spark Plug.

NO>>Repair or clean spark plug. Then GO TO 9.

CHECK FUNCTION OF IGNITION COIL-III

-

Reconnect the initial spark plugs.

-

Crank engine for approximately 3 seconds, and recheck whether spark is generated between the spark plug and the grounded portion.

Spark should be generated.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace spark plug(s) with standard type one(s). For spark plug type, refer to Spark Plug.

CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to On-Nissan Murano Vehicle Service.

Is the inspection result normal?

YES>>GO TO 11.

NO>>Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

CHECK FUEL PRESSURE

-

Install all removed parts.

-

Release fuel pressure to zero. Refer to Work Procedure.

-

Install fuel pressure gauge kit [SST: — (J-44321)] and check fuel pressure. Refer to Work Procedure.

At idle: Approximately 350 kPa (3.57 kg/cm2, 51 psi)

Is the inspection result normal?

YES>>GO TO 13.

NO>>GO TO 12.

DETECT MALFUNCTIONING PART

Check fuel hoses and fuel tubes for clogging.

Is the inspection result normal?

YES>>Replace “fuel filter and fuel pump assembly”. Refer to Removal and Installation.

NO>>Repair or replace malfunctioning part.

CHECK IGNITION TIMING

Check idle speed and ignition timing.

For procedure, refer to Work Procedure.

For specification, refer to Idle Speed and Ignition Timing.

Is the inspection result normal?

YES>>GO TO 14.

NO>>Follow the Work Procedure.

CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT

-

Turn ignition switch OFF.

-

Disconnect corresponding A/F sensor 1 harness connector.

-

Disconnect ECM harness connector.

-

Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

A/F sensor 1 ECM Continuity Bank Connector Terminal Connector Terminal 1 F12 3 F79 66 Existed 4 67 2 F61 3 76 4 77 -

Check the continuity between A/F sensor 1 harness connector and ground, or ECM harness connector and ground.

A/F sensor 1 Ground Continuity Bank Connector Terminal 1 F12 3 Ground Not existed 4 2 F61 3 4 ECM Ground Continuity Connector Terminal F79 66 Ground Not existed 67 76 77 -

Also check harness for short to power.

Is the inspection result normal?

YES>>GO TO 15.

NO>>Repair open circuit, short to ground or short to power in harness or connectors.

CHECK A/F SENSOR 1 HEATER

Check A/F sensor 1 heater. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 16.

NO>>Replace malfunctioning A/F sensor 1. Refer to Removal and Installation (bank 2), Removal and Installation (bank 2).

CHECK MASS AIR FLOW SENSOR

With CONSULT

With CONSULT

-

Check “MASS AIR FLOW” in “DATA MONITOR” mode with CONSULT.

-

For specification, refer to Component Inspection.

With GST

With GST

-

Check mass air flow sensor signal in Service $01 with GST.

-

For specification, refer to Mass Air Flow Sensor.

Is the measurement value within the specification?

YES>>GO TO 17.

NO>>Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or ground. Refer to Diagnosis Procedure.

CHECK SYMPTOM TABLE

Check items on the rough idle symptom in Symptom Table.

Is the inspection result normal?

YES>>GO TO 18.

NO>>Repair or replace malfunctioning part.

ERASE THE 1ST TRIP DTC

Some tests may cause a 1st trip DTC to be set.

Erase the 1st trip DTC from the ECM memory after performing the tests. Refer to CONSULT Function.

>>

INSPECTION END

P0222 Tp Sensor

P0222 Tp Sensor

DTC Description

DTC DETECTION LOGIC

An excessively low voltage from the TP sensor 1 is sent to ECM.

An excessively high voltage from the TP sensor 1 is sent to ECM...

P0315 Crankshaft Position

P0315 Crankshaft Position

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P0315

Crankshaft position

(Crankshaft Position System Variation Not Learned)

Diagnosis condition

Engine run and fuel shut off

Signal

—

Threshold

Learning value of signal plate variation is abnormal or not learned...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Component Parts. Rear Window Defogger

Component Parts Location A. Center of instrument panel B. Left side of instrument panel (View with fuse block (J/B) removed) C. Back door lower finisher inside (View with back door lower finisher removed) No. Component Function 1. BCM (Body Control Module) Operates the rear window defogger with the operation of rear window defogger switch...

Nissan Murano (Z52) 2015-2024 Service Manual: Precaution. Precautions

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER" The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of collisions...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Indicator lights

- Checking engine oil level

- Jacking up vehicle and removing the damaged tire

- New on site

- Most important about car

Fuel gauge

The gauge indicates the approximate fuel level in the tank.

The gauge may move slightly during braking, turning, acceleration, or going up or down hills.

The gauge needle returns to 0 (Empty) after the ignition switch is placed in the OFF position.