Nissan Murano: Dtc/circuit Diagnosis / P0011 Ivt Control

DTC DETECTION LOGIC

There is a gap between angle of target and phase-control angle degree.

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | |

| P0011 |

INT/V TIM CONT-B1 (“A” Camshaft Position - Timing Over-Advanced or System Performance bank 1) |

Diagnosis condition | — |

| Signal (terminal) | Camshaft position sensor signal | ||

| Threshold | During the advanced control of intake valve timing control, the angle difference between actual angle and target angle is 13 degrees or more. | ||

| Diagnosis delay time | 6 seconds or more | ||

| P0021 |

INT/V TIM CONT-B2 (“B” Camshaft Position - Timing Over-Advanced or System Performance bank 2) |

Diagnosis condition | — |

| Signal (terminal) | Camshaft position sensor signal | ||

| Threshold | During the advanced control of intake valve timing control, the angle difference between actual angle and target angle is 13 degrees or more. | ||

| Diagnosis delay time | 6 seconds or more | ||

POSSIBLE CAUSE

-

Crankshaft position sensor (POS)

-

Camshaft position sensor (PHASE)

-

Intake valve timing control solenoid valve

-

Accumulation of debris to the signal pick-up portion of the camshaft

-

Timing chain installation

-

Foreign matter caught in the oil groove for intake valve timing control

FAIL-SAFE

| Engine operating condition in fail-safe mode | ||

|---|---|---|

| Fail safe mode | Nissan Murano Vehicle behavior | |

| Intake valve timing control |

|

|

CHECK DTC PRIORITY

If DTC P0011 or P0021 is displayed with DTC P0075 or P0081, first perform the trouble diagnosis for DTC P0075 or P0081.

Is applicable DTC detected?

YES>>Perform diagnosis of applicable.

-

DTC P0075: Refer to DTC Description.

-

DTC P0081: Refer to DTC Description.

GO TO 2.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is between 10 V and 16 V at idle.

>>

GO TO 3.

PERFORM DTC CONFIRMATION PROCEDURE-I

With CONSULT

With CONSULT

-

Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT.

-

Start engine and warm it up to the normal operating temperature.

-

Maintain the following conditions for at least 13 consecutive seconds. Hold the accelerator pedal as steady as possible.

ENG SPEED 1,200 - 2,000 rpm COOLANT TEMP/S More than 60°C (140°F) Selector lever P or N position -

Stop Nissan Murano vehicle with engine running and let engine idle for 13 seconds.

-

Check 1st trip DTC.

With GST

With GST

Follow the procedure “With CONSULT” above.

Is 1st trip DTC detected?

YES>>Proceed to Diagnosis Procedure

NO>>GO TO 4.

PERFORM DTC CONFIRMATION PROCEDURE-II

With CONSULT

With CONSULT

-

Maintain the following conditions for at least 20 consecutive seconds.

ENG SPEED 1,200 - 3,175 rpm (A constant rotation is maintained.) COOLANT TEMP/S More than 64°C (147°F) Selector lever D position Driving location uphill Driving Nissan Murano vehicle uphill

(Increased engine load will help maintain the driving conditions required for this test.)CAUTION:

Always drive at a safe speed.

-

Check 1st trip DTC.

With GST

With GST

Follow the procedure “With CONSULT” above.

Is 1st trip DTC detected?

YES>>Proceed to Diagnosis Procedure

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: INSPECTION END

CHECK DTC PRIORITY

If DTC P0011 or P0021 is displayed with DTC P0075 or P0081, first perform the trouble diagnosis for DTC P0075 or P0081.

Is applicable DTC detected?

YES>>Perform diagnosis of applicable.

-

DTC P0075: Refer to DTC Description.

-

DTC P0081: Refer to DTC Description.

GO TO 2.

CHECK OIL PRESSURE WARNING LAMP

-

Start engine.

-

Check oil pressure warning lamp and confirm it is not illuminated.

Is oil pressure warming lamp illuminated?

YES>>Check the engine oil level. Refer to Inspection.

NO>>GO TO 3.

CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE

Check intake valve timing control solenoid valve. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 4.

NO>>Replace malfunctioning intake valve timing control solenoid valve. Refer to Exploded View.

CHECK CRANKSHAFT POSITION SENSOR (POS)

Check crankshaft position sensor (POS). Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 5.

NO>>Replace crankshaft position sensor (POS). Refer to Exploded View.

CHECK CAMSHAFT POSITION SENSOR (PHASE)

Check camshaft position sensor (PHASE). Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 6.

NO>>Replace malfunctioning camshaft position sensor (PHASE). Refer to Exploded View.

CHECK CAMSHAFT (INTAKE)

Check the following.

-

Accumulation of debris on the signal plate of camshaft rear end

-

Chipping signal plate of camshaft rear end

Is the inspection result normal?

YES>>GO TO 7.

NO>>Remove debris and clean the signal plate of camshaft rear end or replace camshaft. Refer to Removal and Installation.

CHECK TIMING CHAIN INSTALLATION

Check service records for any recent repairs that may cause timing chain misalignment.

Are there any service records that may cause timing chain misalignment?

YES>>Check timing chain installation. Refer to Removal and Installation.

NO>>GO TO 8.

CHECK LUBRICATION CIRCUIT

Check lubrication circuit. Refer to Inspection.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Clean lubrication line.

CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE-I

-

Turn ignition switch OFF.

-

Disconnect intake valve timing control solenoid valve harness connector.

-

Check resistance between intake valve timing control solenoid valve terminals as per the following.

Intake valve timing control solenoid valve Condition

Resistance + − Terminal 1 2 Temperature 20°C (68°F) 7.0 – 7.8 Ω 1 Ground ∞

(Continuity should not exist)2

Is the inspection result normal?

YES>>GO TO 2.

NO>>Replace malfunctioning intake valve timing control solenoid valve. Refer to Exploded View.

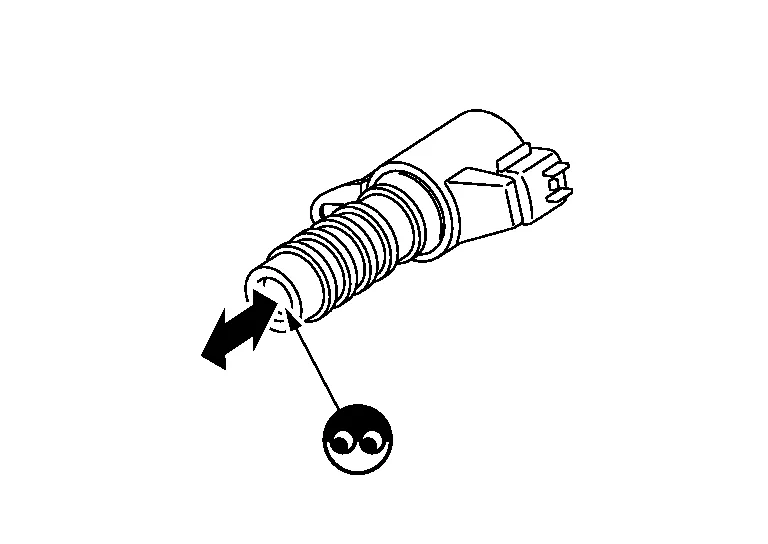

CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE-II

-

Remove intake valve timing control solenoid valve. Refer to Exploded View.

-

Provide 12 V DC between intake valve timing control solenoid valve terminals 1 and 2, and then interrupt it. Check that the plunger moves as shown in the figure.

CAUTION:

Never apply 12 V DC continuously for 5 seconds or more. Doing so may result in damage to the coil in intake valve timing control solenoid valve.

NOTE:

NOTE:

Always replace O-ring when intake valve timing control solenoid valve is removed.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace malfunctioning intake valve timing control solenoid valve. Refer to Exploded View.

U1044 Eng Comm Circuit

U1044 Eng Comm Circuit

DTC Description

DTC DETECTION LOGICA signal voltage of LIN communication between ECM and generator is excessively low or excessively high. DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

U1044

ENG COMM CIRCUIT

(Engine communication circuit)

Diagnosis condition

Ignition switch ON

Signal (terminal)

Signal voltage of LIN communication

Threshold

Signal voltage between ECM and generator is excessively low or excessively high

Diagnosis delay time

—

POSSIBLE CAUSE

Harness or connectors

(LIN communication circuit is open or shorted...

P0014 Evt Control

P0014 Evt Control

DTC Description

DTC DETECTION LOGICThere is a gap between angle of target and phase-control angle degree. DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P0014

EXH/V TIM CONT-B1

[Exhaust valve timing control performance (bank 1)]

Diagnosis condition

—

Signal (terminal)

Exhaust valve timing control position sensor signal

Threshold

During the advanced control of exhaust valve timing control, the angle difference between actual angle and target angle is 13 degrees or more...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Fusible Link Inspection

Fusible Link A melted fusible link can be detected either by visual inspection or by feeling with a finger tip. If its condition is questionable, use circuit tester or test lamp. 1 : Fusible link CAUTION: If fusible link should melt, it is possible that critical circuit (power supply or large current carrying circuit) is shorted...

Nissan Murano (Z52) 2015-2024 Service Manual: B2560 Starter Cont Relay

DTC Description Starter control relay, integrated in IPDM E/R, permits the starter relay operation when in N (Neutral) or P (Park) position.DTC DETECTION LOGICNOTE: If DTC B2560 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- How to enable/disable the LDW system

- Tire rotation

- GAS STATION INFORMATION

- New on site

- Most important about car

Fuel gauge

The gauge indicates the approximate fuel level in the tank.

The gauge may move slightly during braking, turning, acceleration, or going up or down hills.

The gauge needle returns to 0 (Empty) after the ignition switch is placed in the OFF position.