Nissan Murano: Repairing Procedures and Precautions / Checking Damage

When completing body and frame repairs, the front body and underbody dimensions must be correct, because these dimensions directly affect wheel alignment and steering angles.

The degree of damage should be determined by using a steel tape, tram tracking gauge and centering gauge or other measuring device. The measuring points are shown in the Body Repair Manual for each model. Wheel alignments are shown in the Service Manual for each model.

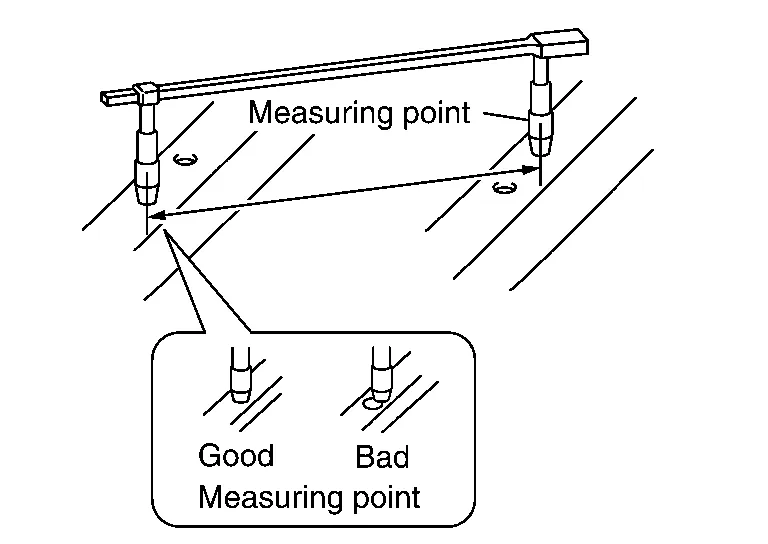

Measure the distance between two points. Before using the tracking gauge, check the measuring points with the steel tape.

(1) TRACKING GAUGE

-

Fit the tracking gauge correctly to the measuring point.

-

The dimension is indicated between the hole center.

If measurement is unavailable, use the method shown below.

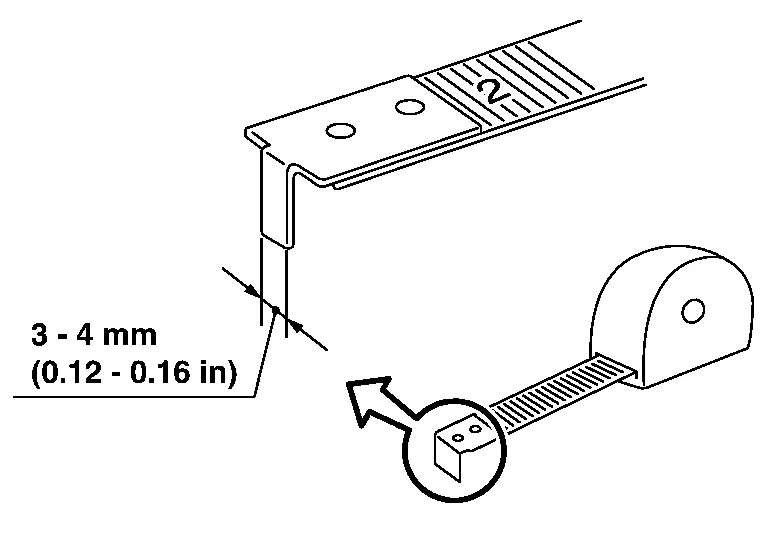

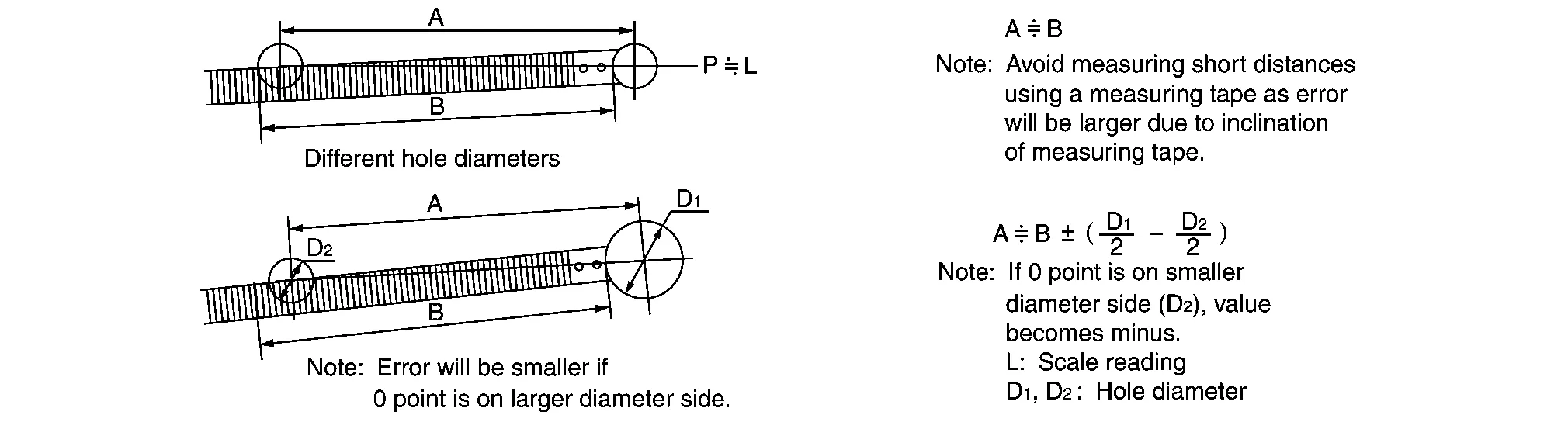

(2) STEEL TAPE

-

Shape the end of the rule for ease of measurement.

-

If the measuring point hole diameter is different, use the following measuring method.

The equipment has function of the measurement to display the vehicle measuring points in three dimensions: height, width and length.

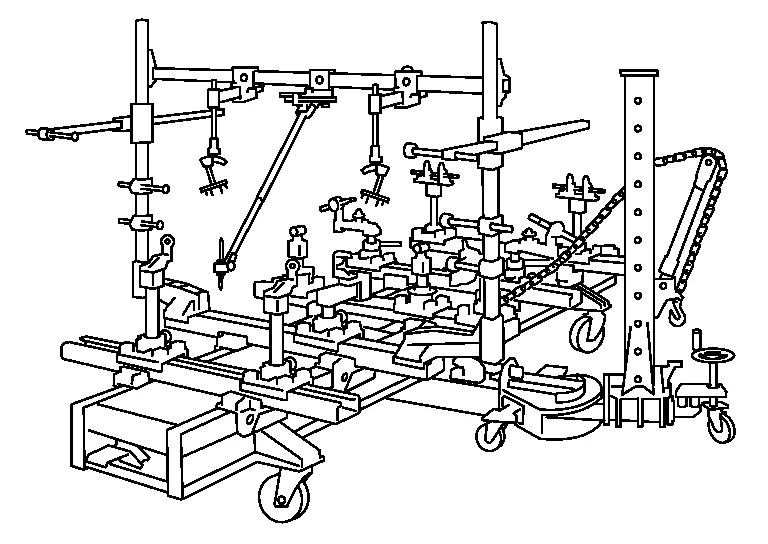

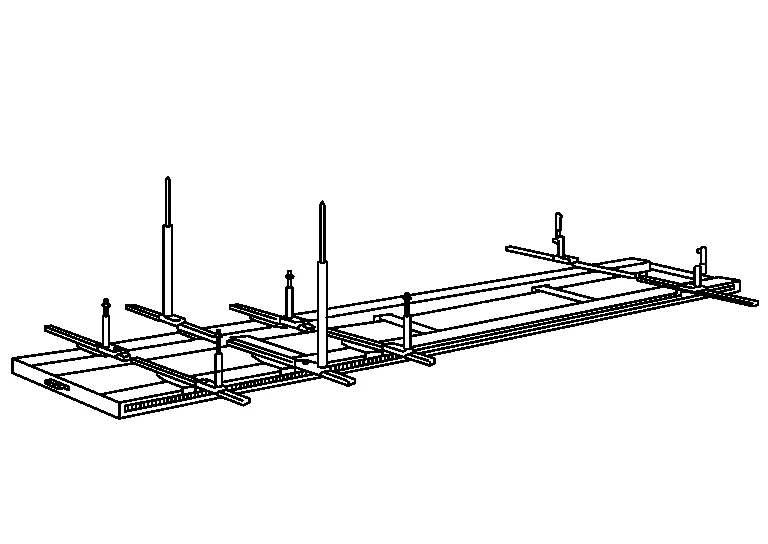

(1) UNIVERSAL JIG TYPE

This is one of the universal jig type body straightening equipment functions. The jig is assembled according to the instruction card specific to each Nissan Murano vehicle model. The jig, which can move forward/backward, left/right, and up/down, is anchored to each location on the underbody. The three-dimensional coordinates for the anchored point are read from the scale at the sliding base and jig head positions.

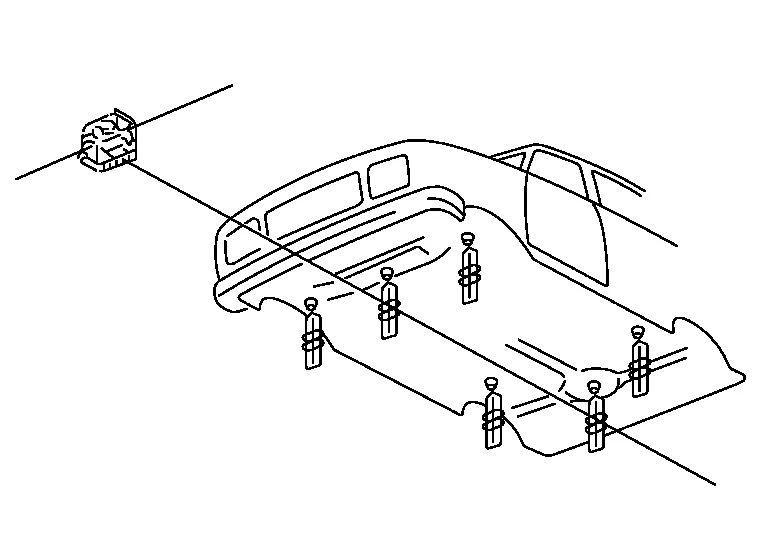

(2) UNIVERSAL MEASURING TYPE

The probe, which can move forward/backward, left/right, and up/down, is positioned on the frame. The three-dimensional coordinates at the measurement point and the distance between measurement holes can be measured by bringing the probe into contact with a locating hole on the body.

It is set on the straightening equipment for use.

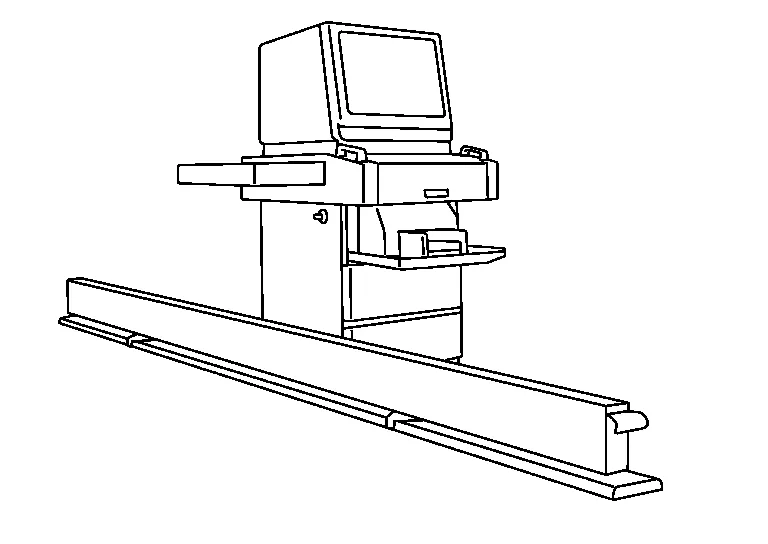

(3) LASER TYPE

The three-dimensional coordinates are read using convergence and straight-line stability of a laser beam.

A laser beam is used for measurement. Once set, repair work can be performed during measurement.

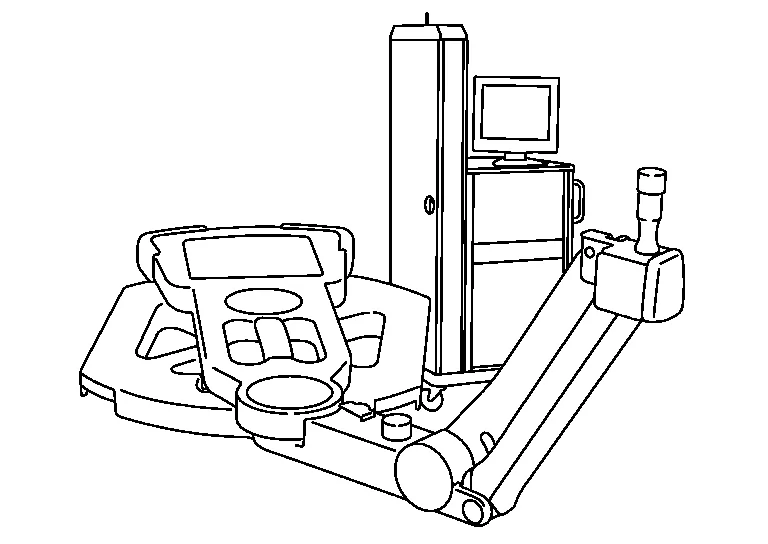

(4) COMPUTER MEASURING TYPE

This is set on the straightening equipment. The probe which is mounted on flexible arm is positioned at each point of the Nissan Murano vehicle body for measurement.

The computer compares the vehicle model data and the actual measurement data to identify the damage range and determine acceptability.

(5) ULTRASOUND TYPE

Ultrasound is transmitted from the probe, installed at the measurement point on the vehicle body, to the beam placed under the body in order to measure the three-dimensional coordinates at each measurement point.

Damage Diagnosis

Damage Diagnosis

Damage Diagnosis: Fundamental

What is forceForce causes the shape of objects and state of motion to change.

Equation that expresses force [F]

F= m + a

[m: mass in kg, a: rate of acceleration in m/s2]

The equation explains the factors that affect the force strength in a collision...

Body Straightening Equipment

Body Straightening Equipment

Comparison of Pulling Methods

(1) HYDRAULIC RAM TYPEIn this method, the pressing force of a hydraulic ram is converted to a pulling force by a chain.

Pulling points on the body may be added easily, and there is more freedom to select the pulling direction...

Other information:

Nissan Murano (Z52) 2015-2024 Owners Manual: Precautions on child restraints

WARNING Failure to follow the warnings and instructions for proper use and installation of child restraints could result in serious injury or death of a child or other passengers in a sudden stop or collision: The child restraint must be used and installed properly...

Nissan Murano (Z52) 2015-2024 Service Manual: Periodic Maintenance. Rear Differential Gear Oil

Inspection OIL LEAKAGEMake sure that oil is not leaking from final drive assembly or around it.OIL LEVELCheck oil level from filler plug mounting hole as shown in the figure after removing filler plug (1) and gasket from final drive assembly. CAUTION: Turn the ignition switch OFF while checking oil level...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Checking engine oil level

- GAS STATION INFORMATION

- How to enable/disable the LDW system

- New on site

- Most important about car

Driver and passenger supplemental knee air bag

Driver’s side

The knee air bag is located in the knee bolster, on the driver’s and passenger’s side. All of the information, cautions and warnings in this manual apply and must be followed. The knee air bag is designed to inflate in higher severity frontal collisions, although it may inflate if the forces in another type of collision are similar to those of a higher severity frontal impact. It may not inflate in certain collisions.

Passenger’s side