Nissan Murano: Removal and Installation / Water Pump

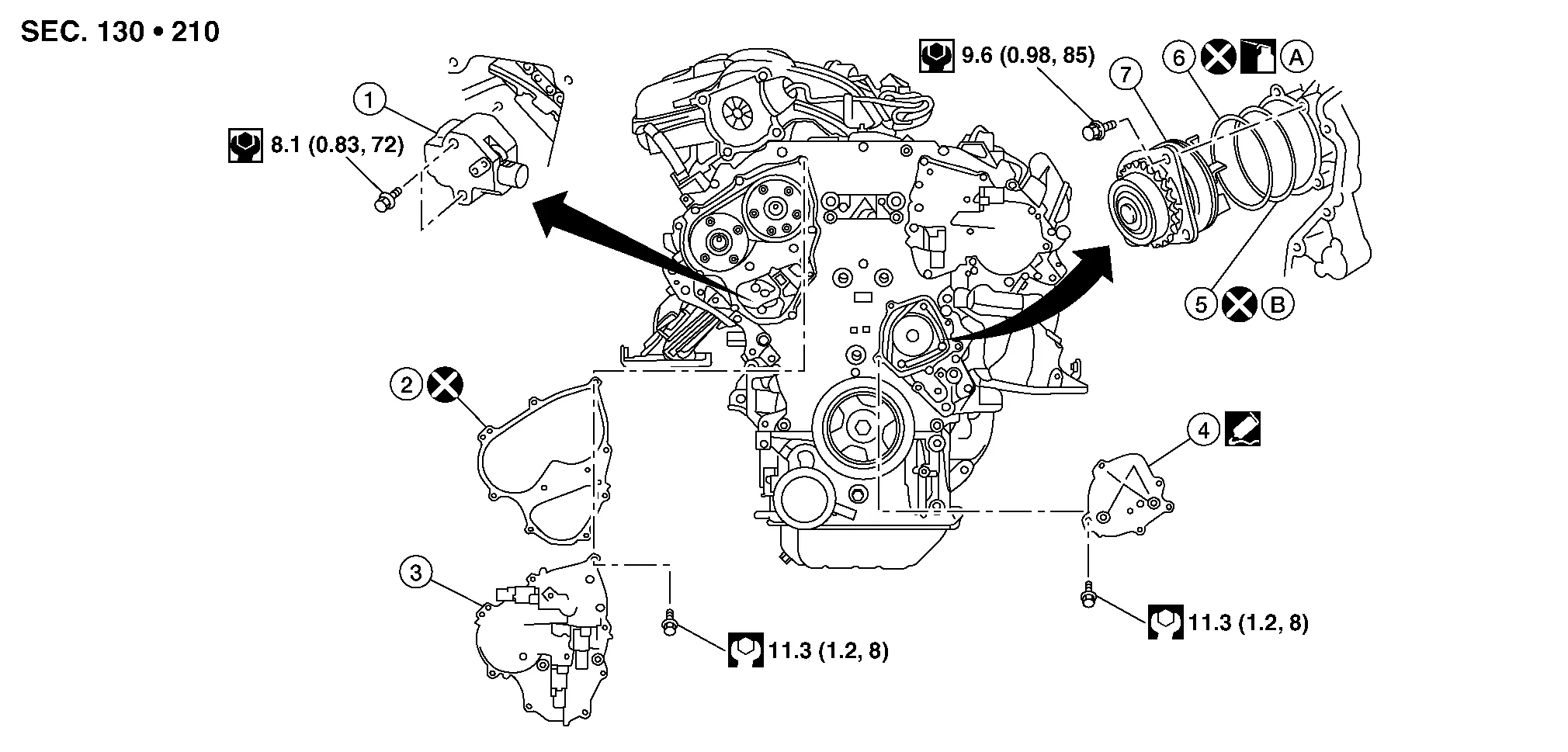

| 1. | Timing chain tensioner (primary) | 2. | Valve timing control cover gasket (bank 1) | 3. | Valve timing control cover (bank 1) |

| 4. | Water pump cover | 5. | O-ring | 6. | O-ring (Identify with white mark) |

| 7. | Water pump | A. | Apply engine oil | B. | Apply engine coolant |

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high pressure engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by turning it all the way.

CAUTION:

-

When removing water pump assembly, be careful not to get engine coolant on drive belt.

-

Water pump cannot be disassembled and must be replaced as a unit.

-

After installing the water pump, connect hose and clamp securely, then check for leaks. Repair as necessary.

NOTE:

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

Disconnect the negative battery terminal. Refer to Removal and Installation.

Remove the engine room cover. Refer to Removal and Installation.

Remove front under cover. Refer to Removal and Installation.

Drain engine coolant from the radiator. Refer to Changing Engine Coolant.

CAUTION:

Perform when the engine is cold.

Drain power steering fluid. Refer to Draining and Refilling.

Remove the cowl top cover and the cowl top extension. Refer to Exploded View.

Remove sub tank bracket from cowl top extension.

Remove brake fluid level sensor harness connector from brake fluid level sensor.

Remove strut tower brace.

Remove front air duct. Refer to Removal and Installation.

Remove the front road wheel and tire (RH) using a power tool. Refer to Removal and Installation.

Remove the fender protector (RH). Refer to Removal and Installation.

Disconnect engine coolant reservoir hose and remove engine coolant reservoir tank.

Set No. 1 cylinder at TDC on its compression stroke.

-

Align pointer with TDC mark on crankshaft pulley.

Remove drive belt. Refer to Removal and Installation.

Remove the drive belt auto-tensioner assembly. Refer to Removal and Installation of Drive Belt Auto-Tensioner.

Drain engine coolant from cylinder block (if necessary). Refer to Changing Engine Coolant.

Remove the E-PSF cover, bracket and motor. Refer to Removal and Installation.

Support engine and remove the RH engine insulator and bracket. Refer to Exploded View.

Disconnect the A/C lines at the junction. Refer to Exploded View.

Disconnect RH valve timing control connectors and remove valve timing control cover (bank 1). Refer to Exploded View.

Remove water pump cover. Refer to Exploded View.

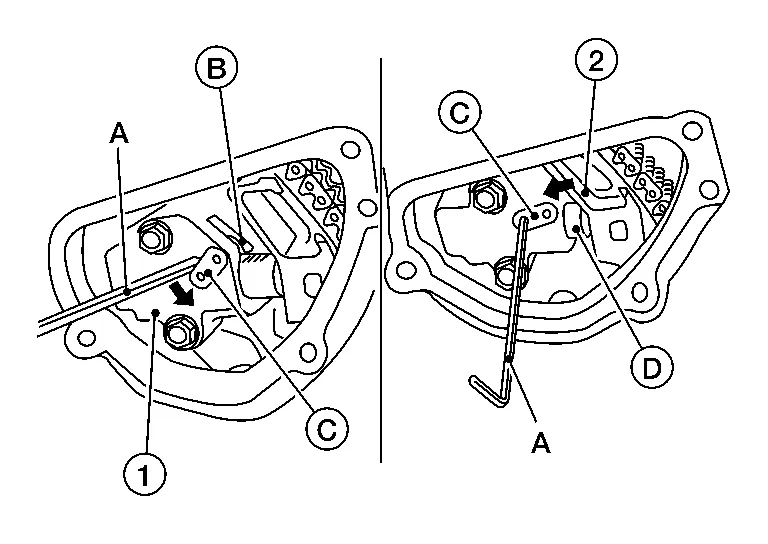

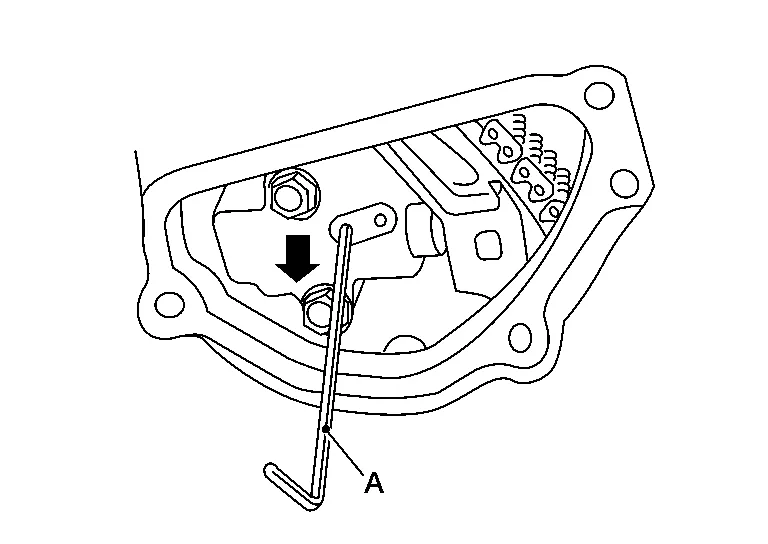

Remove the timing chain tensioner (primary) as follows:Pull the lever (C) down to release the plunger stopper tab (B).

NOTE:

NOTE:

An allen wrench (1.2 mm (0.047 in) is used for a stopper pin (A) as an example.

Compress the plunger (D) into the tensioner body (1) by pressing the slack guide (2). Keep the slack guide (2) pressed and lock the plunger (D) in by pushing the stopper pin (A) through the lever (C) and into the chain tensioner body hole. Remove timing chain tensioner bolts and then remove the timing chain tensioner.CAUTION:

Be careful not to drop timing chain tensioner bolts inside timing chain case.

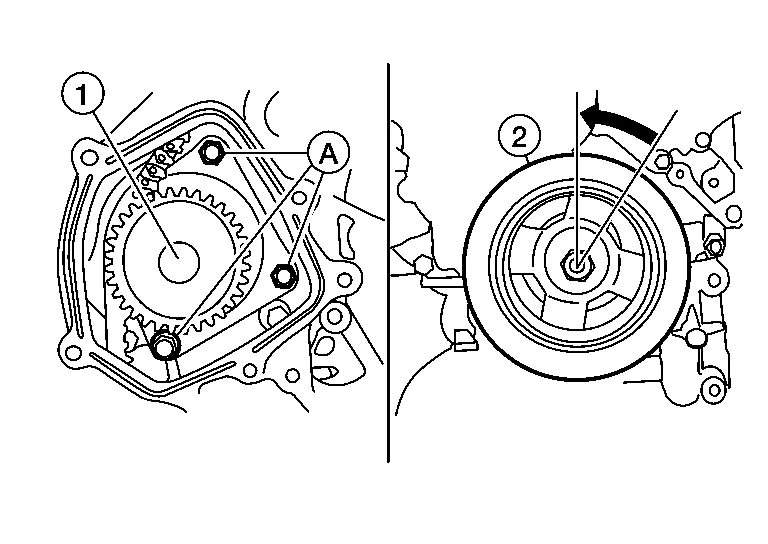

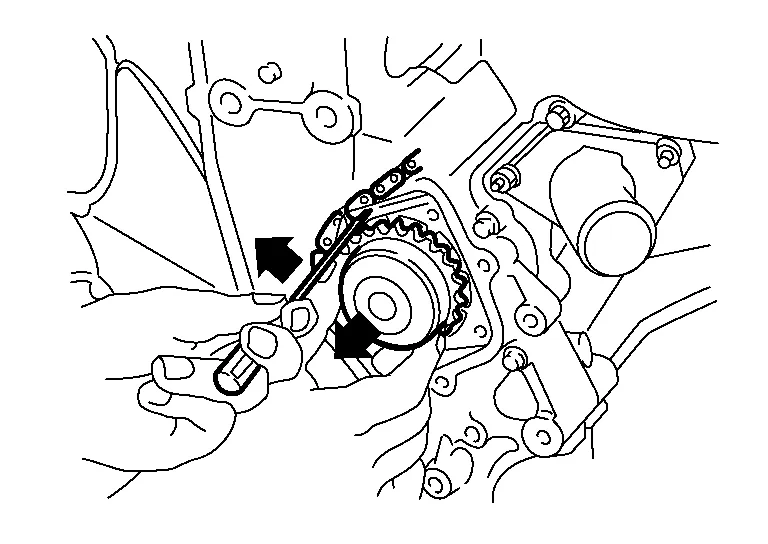

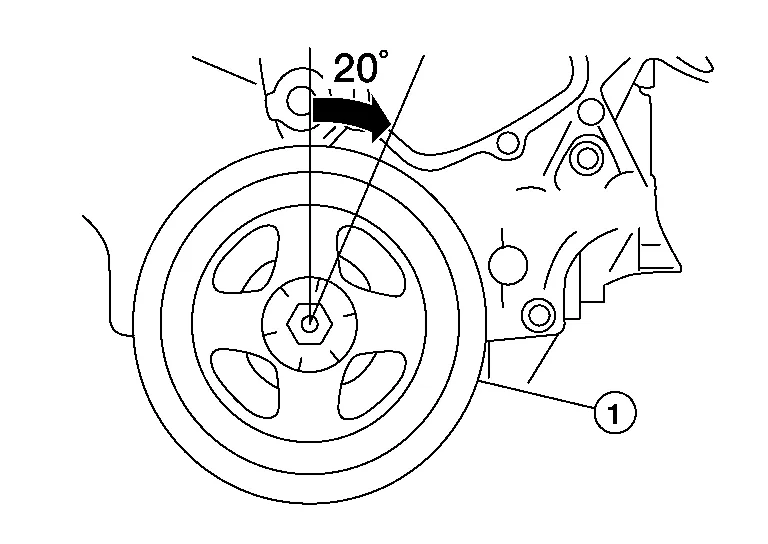

Remove the three water pump bolts (A). Make a gap between water pump sprocket (1) and timing chain by carefully turning crankshaft pulley (2) counterclockwise until timing chain loosens on water pump sprocket (1).

CAUTION:

Be careful not to drop water pump bolts inside timing chain case.

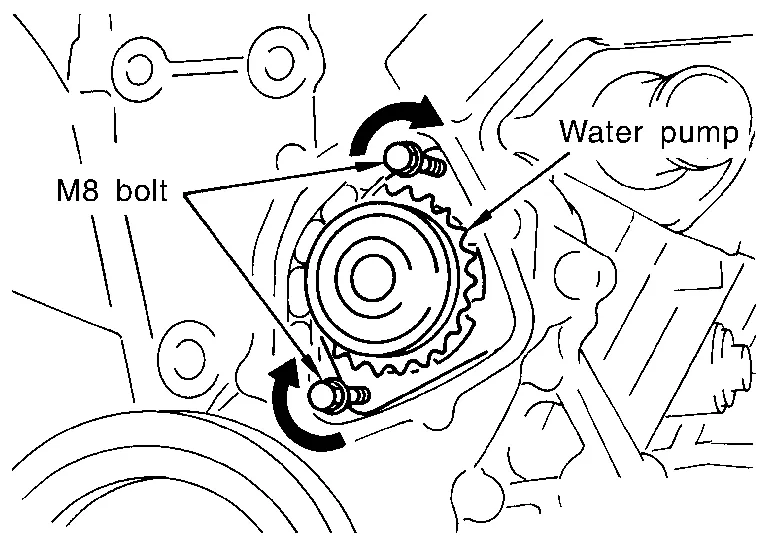

Screw M8 bolts [pitch: 1.25 mm (0.49 in) length: approx. 50 mm (1.97in)] into water pumps upper and lower bolt holes until they reach the timing chain case.

Hold the timing chain to the side using a suitable tool and alternately tighten the M8 bolts for a half turn until the water pump can be removed.

CAUTION:

-

Place a suitable shop cloth below the water pump housing to prevent any engine coolant from dripping into the timing chain case.

-

Remove water pump without causing sprocket to contact timing chain.

-

Pull water pump straight out while preventing vane from contacting the engine block and timing chain case.

-

It may be necessary to adjust the timing chain until it loosens enough to remove the water pump.

Remove M8 bolts and O-rings from water pump.

CAUTION:

Do not reuse O-rings.

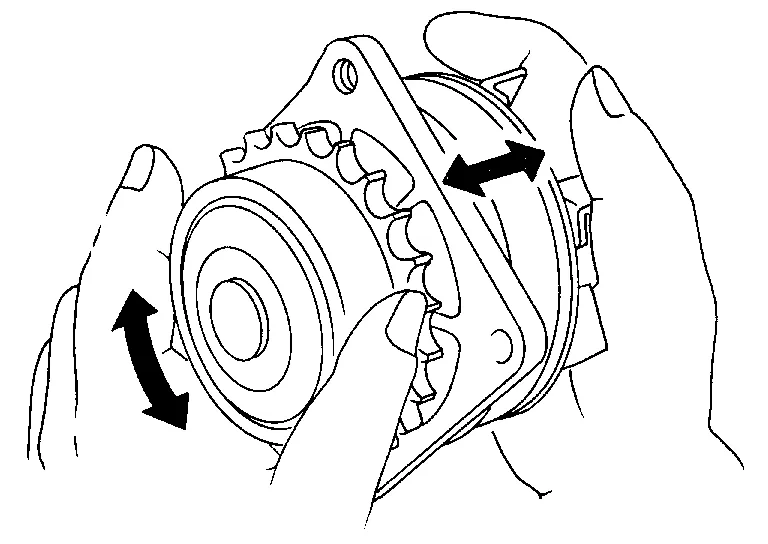

INSPECTION AFTER REMOVAL

-

Visually check for significant dirt or rust on the water pump body and vane.

-

Check that the vane shaft turns smoothly by hand and is not excessively loose.

-

Replace the water pump assembly if the water pump does not perform properly.

INSTALLATION

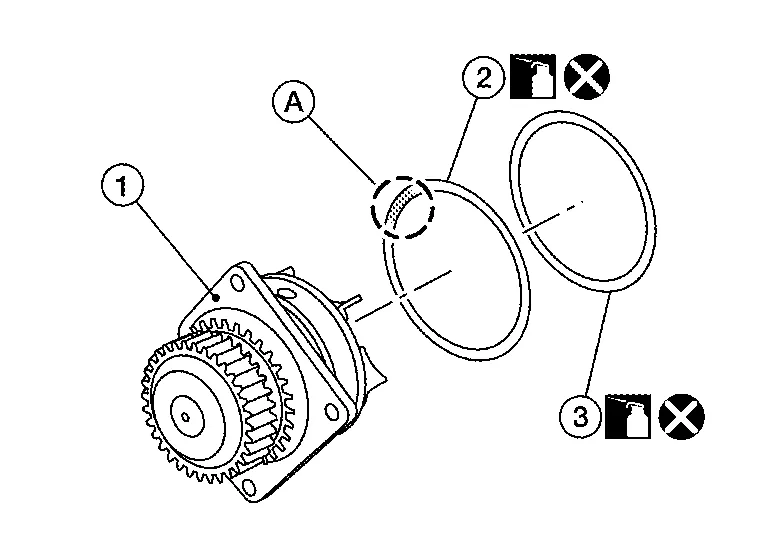

Install new O-rings to water pump (1).

CAUTION:

Do not reuse O-rings.

Apply engine coolant to the O-rings (2,3) as shown. Locate the O-ring (2) with white paint mark (A) to engine front side.Hold timing chain to the side and install the water pump.

CAUTION:

-

Install water pump without causing sprocket to contact timing chain.

-

It may be necessary to adjust the timing chain until it loosens enough to install the water pump.

-

Install water pump straight in while preventing vane from contacting the engine block and timing chain case.

-

Be careful not to damage the O-rings when installing the water pump.

-

Check that timing chain and water pump sprocket are engaged.

-

Tighten water pump bolts alternately and evenly to specification.

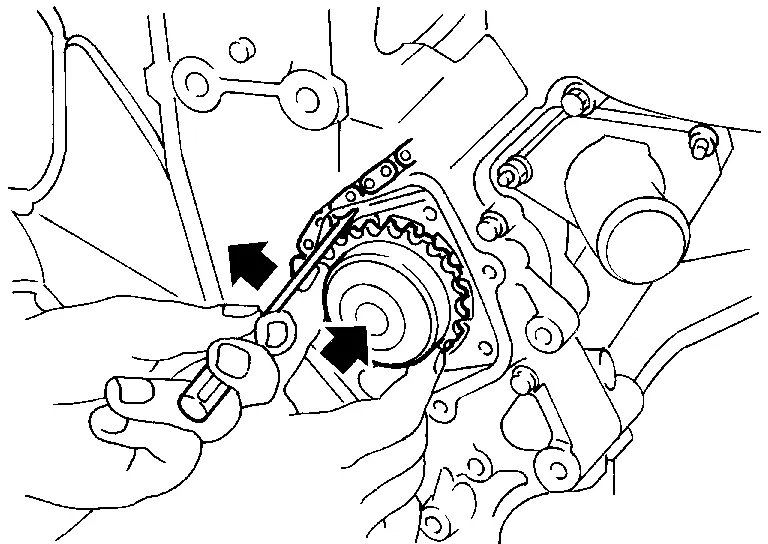

Remove dust and foreign material completely from installation area of timing chain tensioner and rear timing chain case.

Turn crankshaft pulley (1) approximately 20° clockwise so that timing chain on timing chain tensioner side is loose.

Apply engine oil to the oil feed hole and timing chain tensioner and install the timing chain tensioner.

Remove the stopper pin (A).

Install valve timing control cover (bank 1) and water pump cover.Before installing, remove all traces of liquid gasket from mating surface of water pump cover and IVT cover using a scraper.

Also remove traces of liquid gasket from the mating surface of the front cover.

Apply a continuous bead of liquid gasket to mating surface of IVT cover and water pump cover. Use Genuine RTV Silicone Sealant or equivalent. Refer to Recommended Chemical Products and Sealants.CAUTION:

-

Installation should be done within 5 minutes after applying liquid gasket.

-

Do not fill the engine with engine oil for at least 30 minutes after the components are installed to allow the sealant to cure.

Installation of remaining components is in the reverse order of removal.

-

After installation, refill engine coolant and check for leaks. Refer to Changing Engine Coolant and System Inspection.

CAUTION:

Do not spill engine coolant in engine compartment. Use a shop cloth to absorb engine coolant.

-

Refill power steering fluid. Refer to Draining and Refilling.

-

After starting engine, let idle for three minutes then rev engine up to 3,000 rpm under no load to purge air from the high-pressure chamber of the chain tensioner. The engine may produce a rattling noise. This indicates that air still remains in the chamber and is not a matter of concern.

INSPECTION AFTER INSTALLATION

-

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required quantity, fill to the specified level. Refer to Fluids and Lubricants.

-

Use procedure below to check for fuel leaks.

-

Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leaks at connection points.

-

Start engine. With engine speed increased, check again for fuel leaks at connection points.

-

Run engine to check for unusual noise and vibration.

NOTE:

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after hydraulic pressure rises.

-

Warm up engine thoroughly to make sure there are no leaks of fuel, exhaust gas, or any oils/fluids including engine oil and engine coolant.

-

Bleed air from passages in lines and hoses, such as in cooling system.

-

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to specified level, if necessary.

-

Summary of the inspection items:

Item Before starting engine Engine running After engine stopped Engine coolant Level Leakage Level Engine oil Level Leakage Level Transmission/transaxle fluid A/T and CVT Models Leakage Level/Leakage Leakage M/T Models Level/Leakage Leakage Level/Leakage Other oils and fluids* Level Leakage Level Fuel Leakage Leakage Leakage Exhaust gas — Leakage — *Power steering fluid, brake fluid, etc.

Cooling Fan

Cooling Fan

Exploded View

1.

Radiator core support

2.

Fan

3.

Fan motor

4.

Fan shroud and motor assembly

5.

Isolator (lower)

6.

Grommet

Front

Removal and Installation

WARNING:

Do not remove the radiator cap when the engine is hot...

Thermostat and Thermostat Housing

Thermostat and Thermostat Housing

Exploded View

1.

Gasket

2.

Thermostat assembly (water inlet)

Removal and Installation

WARNING:

Do not remove the radiator cap when the engine is hot...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Component Parts. Charging System

Component Parts Location A. Engine room left side B. Combination meter No. Component Description 1. Generator (IC regulator) Refer to Generator. 2. Combination meter (charge warning lamp) The IC regulator warning function activates to illuminate the charge warning lamp if any of the following symptoms occur while generator is operating: ·Excessive voltage is produced...

Nissan Murano (Z52) 2015-2024 Service Manual: Main Switch Does Not Turn On, Main Switch Does Not Turn Off

Diagnosis Procedure MAIN switch does not turn ON ICC system display does not appear even when MAIN switch is pressed. MAIN switch does not turn OFF When ICC system display is ON, display does not turn OFF even if MAIN switch is pressed. NOTE: When ICC system warning lamp illuminates, perform the self-diagnosis of ICC system, and then repair or replace the malfunctioning parts...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- High Beam Assist (if so equipped)

- Tire rotation

- Fuel recommendation

- New on site

- Most important about car

Vehicle security system

Your vehicle has two types of security systems:

Vehicle security system NISSAN Vehicle Immobilizer SystemThe vehicle security system provides visual and audible alarm signals if someone opens the doors, liftgate or the hood when the system is armed. It is not, however, a motion detection type system that activates when a vehicle is moved or when a vibration occurs.