Nissan Murano: Dtc/circuit Diagnosis / Ignition Signal

INSPECTION START

Turn ignition switch OFF, and restart engine.

Does the engine start?

YES>>With CONSULT: GO TO 2.

YES>>Without CONSULT: GO TO 3.

NO>>Proceed to Diagnosis Procedure.

CHECK IGNITION SIGNAL FUNCTION

With CONSULT

With CONSULT

-

Perform “POWER BALANCE” in “ACTIVE TEST” mode with CONSULT.

-

Check that each circuit produces a momentary engine speed drop.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Proceed to Diagnosis Procedure.

CHECK IGNITION SIGNAL FUNCTION

Without CONSULT

Without CONSULT

-

Let engine idle.

-

Read the voltage signal between ECM harness connector terminals with an oscilloscope.

ECM Voltage signal + – Connector Terminal Connector Terminal F79 103 E32 152

104 106 107 113 114  NOTE:

NOTE:

The pulse cycle changes depending on rpm at idle.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Proceed to Diagnosis Procedure.

CHECK ECM POWER SUPPLY

-

Turn ignition switch OFF, wait at least 10 seconds and then turn it ON.

-

Check the voltage between ECM harness connector terminals.

ECM Voltage Connector Terminal Connector Terminal F79 86 E32 152 Battery voltage

Is the inspection result normal?

YES>>GO TO 2.

NO>>Refer to Diagnosis Procedure.

CHECK CONDENSER-1 POWER SUPPLY

-

Turn ignition switch OFF.

-

Disconnect condenser-1 harness connector.

-

Turn ignition switch ON.

-

Check the voltage between condenser-1 harness connector and ground.

Condenser-1 Ground Voltage Connector Terminal F26 1 Ground Battery voltage

Is the inspection result normal?

YES>>GO TO 4.

NO>>GO TO 3.

CHECK CONDENSER-1 POWER SUPPLY CIRCUIT

-

Turn ignition switch OFF.

-

Disconnect IPDM E/R harness connector.

-

Check the continuity between IPDM E/R harness connector and condenser-1 harness connector.

IPDM E/R Condenser-1 Continuity Connector Terminal Connector Terminal F19 55 F26 1 Existed -

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES>>Refer to Diagnosis Procedure.

NO>>Repair open circuit, short to ground or short to power in harness or connectors.

CHECK CONDENSER-1 GROUND CIRCUIT

-

Turn ignition switch OFF.

-

Check the continuity between condenser-1 harness connector and ground.

Condenser-1 Ground Continuity Connector Terminal F26 2 Ground Existed -

Also check harness for short to power.

Is the inspection result normal?

YES>>GO TO 5.

NO>>Repair open circuit or short to power in harness or connectors.

CHECK CONDENSER-1

Check condenser-1. Refer to Component Inspection (Condenser-1)

Is the inspection result normal?

YES>>GO TO 6.

NO>>Replace condenser-1.

CHECK IGNITION COIL POWER SUPPLY

-

Reconnect all harness connectors disconnected.

-

Disconnect ignition coil harness connector-1.

-

Turn ignition switch ON.

-

Check the voltage between ignition coil harness connector and ground.

Ignition coil Ground Voltage Cylinder Connector Terminal 1 F47 3 Ground Battery voltage 2 F8 3 3 F48 3 4 F9 3 5 F49 3 6 F10 3

Is the inspection result normal?

YES>>GO TO 7.

NO>>Repair or replace harness or connectors.

CHECK IGNITION COIL GROUND CIRCUIT FOR OPEN AND SHORT

-

Turn ignition switch OFF.

-

Check the continuity between ignition coil harness connector and ground.

Ignition coil Ground Continuity Cylinder Connector Terminal 1 F47 2 Ground Existed 2 F8 2 3 F48 2 4 F9 2 5 F49 2 6 F10 2 -

Also check harness for short to power.

Is the inspection result normal?

YES>>GO TO 8.

NO>>Repair open circuit or short to power in harness or connectors.

CHECK IGNITION COIL OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

-

Disconnect ECM harness connector.

-

Check the continuity between ignition coil harness connector and ECM harness connector.

Ignition coil ECM Continuity Cylinder Connector Terminal Connector Terminal 1 F47 1 F79 113 Existed 2 F8 1 106 3 F48 1 103 4 F9 1 114 5 F49 1 107 6 F10 1 104 -

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES>>GO TO 9.

NO>>Repair open circuit, short to ground or short to power in harness or connectors.

CHECK IGNITION COIL WITH POWER TRANSISTOR

Check ignition coil with power transistor. Refer to Component Inspection (Ignition Coil with Power Transistor).

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO>>Replace malfunctioning ignition coil with power transistor. Refer to Removal and Installation (bank 2), Removal and Installation (bank 1).

CHECK IGNITION COIL WITH POWER TRANSISTOR-I

-

Turn ignition switch OFF.

-

Disconnect ignition coil harness connector.

-

Check resistance between ignition coil terminals as per the following.

Terminal No. (Polarity) Resistance Ω [at 25°C (77°F)] 1 and 2 Except 0 or ∞ 1 and 3 Except 0 2 and 3

Is the inspection result normal?

YES>>GO TO 2.

NO>>Replace malfunctioning ignition coil with power transistor. Refer to Removal and Installation (bank 2), Removal and Installation (bank 1).

CHECK IGNITION COIL WITH POWER TRANSISTOR-II

CAUTION:

Perform the following procedure in a place with no combustible objects and good ventilation.

-

Turn ignition switch OFF.

-

Reconnect all harness connectors disconnected.

-

Remove fuel pump fuse in IPDM E/R to release fuel pressure.

NOTE:

NOTE:

Do not use CONSULT to release fuel pressure, or fuel pressure applies again during the following procedure.

-

Start engine.

-

After engine stalls, crank it 2 or 3 times to release all fuel pressure.

-

Turn ignition switch OFF.

-

Remove all ignition coil harness connectors to avoid the electrical discharge from the ignition coils.

-

Remove ignition coil and spark plug of the cylinder to be checked.

-

Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

-

Connect spark plug and harness connector to ignition coil.

-

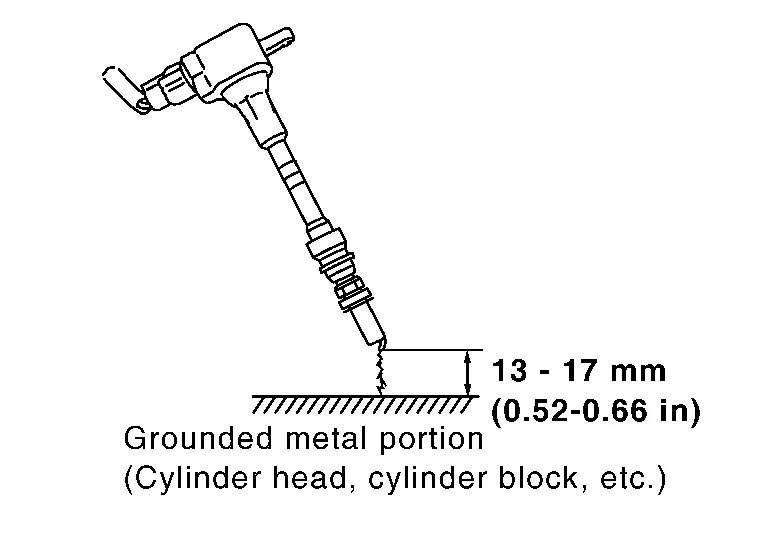

Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 - 0.66 in) between the edge of the spark plug and grounded metal portion as shown in the figure.

-

Crank engine for approximately 3 seconds, and check whether spark is generated between the spark plug and the grounded metal portion.

Spark should be generated. CAUTION:

-

During the operation, always stay 0.5 m (19.7 in) or more away from the spark plug and the ignition coil. Be careful not to get an electrical shock while checking, because the electrical discharge voltage becomes 20 kV or more.

-

It might cause to damage the ignition coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

NOTE:

When the gap is less than 13 mm (0.52 in), the spark might be generated even if the coil is malfunctioning.

-

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace malfunctioning ignition coil with power transistor. Refer to Removal and Installation (bank 2), Removal and Installation (bank 1).

CHECK CONDENSER-1

-

Turn ignition switch OFF.

-

Disconnect condenser-1 harness connector.

-

Check resistance between condenser-1 terminals as per the following.

Terminals Resistance 1 and 2 Above 1 MΩ [at 25C° (77C°)]

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace condenser-1.

Fuel Injector

Fuel Injector

Component Function Check

INSPECTION START

Turn ignition switch to START.

Are any cylinders ignited?

YES>>

GO TO 2.

NO>>

Proceed to Diagnosis Procedure...

Information Display (ascd)

Information Display (ascd)

Component Function Check

CHECK INFORMATION DISPLAY

Start engine.

Press MAIN switch on ASCD steering switch.

Drive the Nissan Murano vehicle at more than 40 km/h (25 MPH)...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: P1612 Chain of Ecm-Immu

DTC Description DTC DETECTION LOGICNOTE: If DTC P1612 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to DTC Description. If DTC P1612 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010...

Nissan Murano (Z52) 2015-2024 Owners Manual: Tilt and telescopic operation

To adjust the steering wheel move the switch in the following directions: Adjust the steering wheel up or down in direction to the desired tilt position. Adjust the steering wheel forward or backward in direction to the desired telescopic position...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Rear bench seat adjustment

- Warning lights

- Passenger compartment

- New on site

- Most important about car

Luggage hooks

When securing items using luggage hooks located on the back of the seat or side finisher do not apply a load over more than 6.5 lbs. (29 N) to a single hook.

The luggage hooks that are located on the floor should have loads less than 110 lbs. (490 N) to a single hook.