Nissan Murano: Engine Mechanical :: Removal and Installation / Exhaust Manifold and Three Way Catalyst

| 1. | Gasket | 2. | Exhaust manifold (bank 1) | 3. | Exhaust manifold cover (bank 1) |

| 4. | Air fuel ratio sensor 1 (bank 1) | 5. | Ring gasket | 6. | Three way catalyst (bank 1) |

| 7. | Three way catalyst support (bank 1) | 8. | Heated oxygen sensor 2 (bank 1) | 9. | Three way catalyst (bank 2) |

| 10. | Three way catalyst support (bank 2) | 11. | Heated oxygen sensor 2 (bank 2) | 12. | Ring gasket |

| 13. | Exhaust manifold (bank 2) | 14. | Exhaust manifold cover (bank 2) | 15. | Air fuel ratio sensor 1 (bank 2) |

| A. | To oil pan (upper). Refer to Exploded View. | B. | Upper mark |  |

Engine front |

REMOVAL

WARNING:

-

Perform the work when the exhaust system has completely cooled down.

-

When removing the front and rear engine mounting through bolts and nuts, lift the engine up slightly for safety.

NOTE:

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

Remove the air cleaner case (upper), air cleaner case (lower), and air duct hose and resonator assembly. Refer to Removal and Installation.

Remove the battery and battery tray assembly. Refer to Removal and Installation.

Remove the front wheels and tires using power tool. Refer to Removal and Installation.

Remove the front under cover. Refer to Removal and Installation.

Remove the fender protector side covers (LH and RH). Refer to Exploded View.

Remove the radiator assembly. Refer to Removal and Installation.

Remove the engine cooling fan shroud and motor assembly. Refer to Removal and Installation.

Remove the front exhaust tube. Refer to Exploded View.

Support the engine with a suitable tool.

Remove the engine mount bracket (front). Refer to Exploded View (FWD) or Exploded View (AWD).

Remove the three way catalyst support (bank 2).

Remove heated oxygen sensor 2 (bank 2), air fuel ratio (A/F) sensor 1 (bank 2).Disconnect harness connector from each sensor, and remove the harness from the bracket and middle clamp. Remove both heated oxygen sensor and air fuel ratio (A/F) sensor using Tool.

| Tool numbers | : KV10114400 (J-38365) |

| : KV991J0050 (J-44626) |

CAUTION:

-

Be careful not to damage heated oxygen sensors or air fuel ratio (A/F) sensors.

-

Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a hard surface such as a concrete floor; replace with a new sensor.

Remove exhaust manifold and three way catalyst heat shields with power tool.

Remove the three way catalyst (bank 2) by loosening the bolts first and then removing the nuts and through bolts.

Loosen and remove the exhaust manifold nuts in the reverse order as shown.

|

: Engine front |

NOTE:

NOTE:

Number 7 and 8 are not applicable to removal.

Remove the exhaust manifold (bank 2) and gasket.

INSPECTION AFTER REMOVAL

Surface Distortion

-

Use suitable tools (A/B) to check the flatness of the exhaust manifold mating surfaces.

Limit : 0.3 mm (0.012 in) -

Replace the exhaust manifold if the measurement exceeds specifications.

INSTALLATION

Installation is in the reverse order of removal.

Install the studs in the exhaust manifold (if removed), and tighten to specification.

| Exhaust manifold studs | : 15.4 N·m (1.6 kg-m, 11 ft-lb) |

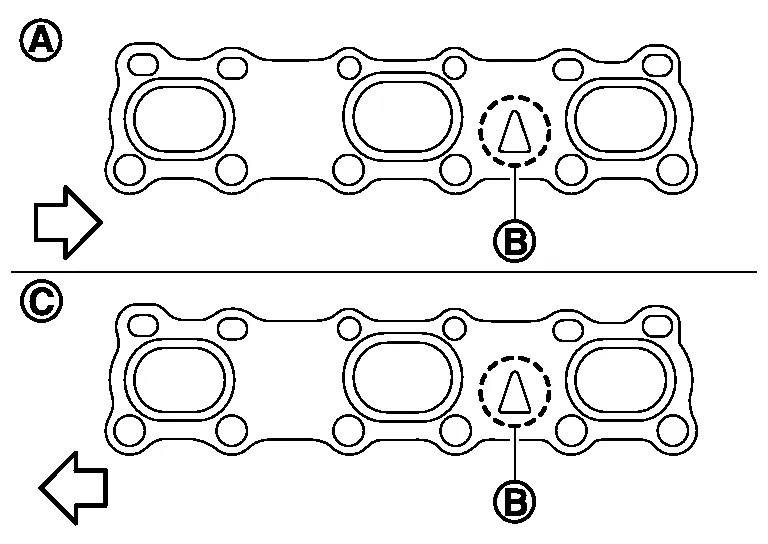

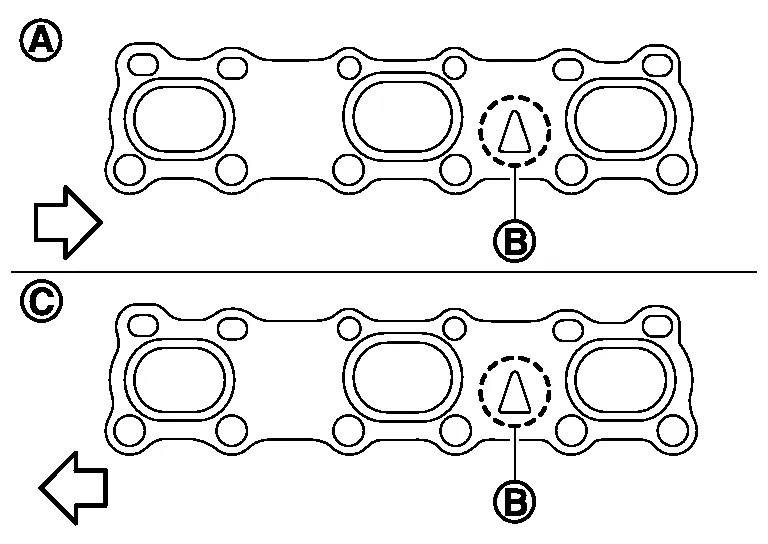

Install the exhaust manifold gasket in the direction shown.

CAUTION:

Do not reuse exhaust manifold gasket.

| (A) | : Bank 1 |

| (B) | : Triangle press |

| (C) | : Bank 2 |

|

: Engine front |

Install the exhaust manifold (bank 2) nuts and tighten to specification in the order shown.

|

: Engine front |

NOTE:

NOTE:

Number 7 and 8 are tightened a second time.

CAUTION:

-

Before installing a heated oxygen sensor or air fuel ratio (A/F) sensor, clean the exhaust manifold threads using the oxygen sensor thread cleaner tool and apply anti-seize lubricant.

Oxygen sensor thread cleaner : — (J-43897-18) -

Do not over-tighten the air fuel ratio (A/F) sensor or heated oxygen sensors. Doing so may cause damage.

Tool numbers : KV10114400 (J-38365) : KV991J0050 (J-44626)

NOTE:

NOTE:

After installation, it is necessary to re-calibrate the electric throttle control actuator as follows:

-

Perform the "Throttle Valve Closed Position Learning" when harness connector of the ECM is disconnected. Refer to Description.

-

Perform the "Accelerator Pedal Released Position Learning" when harness connector of the ECM is disconnected. Refer to Description.

REMOVAL

WARNING:

-

Perform the work when the exhaust system has completely cooled down.

-

When removing the front and rear engine mounting through bolts and nuts, lift the engine up slightly for safety.

NOTE:

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

Remove the cowl top and the lower cowl top extension. Refer to Exploded View.

Remove the front wheel and tire (RH) (AWD models only) using a power tool. Refer to Removal and Installation.

Remove the front under cover. Refer to Removal and Installation.

Remove the fender protector side cover (RH) (AWD models only). Refer to Removal and Installation.

Remove transmission air breather hose. Refer to Exploded View.

Remove the front exhaust tube, hanger and heat insulator. Refer to Exploded View.

Remove the propeller shaft and propeller shaft center bearing (AWD models only). Refer to Removal and Installation.

Remove the RH front axle shaft (AWD models only). Refer to Removal and Installation (RH).

Remove the three way catalyst support (bank 1).

Remove heated oxygen sensor 2 (bank 1), air fuel ratio (A/F) sensor 1 (bank 1).disconnect harness connector from each sensor, and remove the harness from the bracket and middle clamp. Remove both heated oxygen sensors and air fuel ratio (A/F) sensors using Tool.

| Tool numbers | : KV10114400 (J-38365) |

| : KV991J0050 (J-44626) |

CAUTION:

-

Be careful not to damage heated oxygen sensors or air fuel ratio (A/F) sensors.

-

Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a hard surface such as a concrete floor; replace with a new sensor.

Remove exhaust manifold and three way catalyst heat shields with power tool.

Remove the three way catalyst (bank 1) by loosening the bolts first and then removing the nuts and through bolts.

Loosen the exhaust manifold nuts in the reverse order as shown.

|

: Engine front |

NOTE:

NOTE:

Number 7 and 8 are not applicable to removal.

Remove the exhaust manifold (bank 1) and gasket.

INSPECTION AFTER REMOVAL

Surface Distortion

-

Use suitable tools (A/B) to check the flatness of the exhaust manifold mating surfaces.

Limit : 0.3 mm (0.012 in) -

Replace the exhaust manifold if the measurement exceeds specifications.

INSTALLATION

Installation is in the reverse order of removal.

Install the studs in the exhaust manifold (if removed), and tighten to specification.

| Exhaust manifold studs | : 15.4 N·m (1.6 kg-m, 11 ft-lb) |

Install the exhaust manifold gasket in the direction shown.

CAUTION:

Do not reuse exhaust manifold gasket.

| (A) | : Bank 1 |

| (B) | : Triangle press |

| (C) | : Bank 2 |

|

: Engine front |

Install the exhaust manifold (bank 1) nuts and tighten to specification in the order shown.

|

: Engine front |

NOTE:

NOTE:

Number 7 and 8 are tightened a second time.

CAUTION:

-

Before installing a heated oxygen sensor or air fuel ratio (A/F) sensor, clean the exhaust manifold threads using the oxygen sensor thread cleaner tool and apply anti-seize lubricant.

Oxygen sensor thread cleaner : — (J-43897-18) -

Do not over-tighten the air fuel ratio (A/F) sensor or heated oxygen sensors. Doing so may cause damage.

Tool numbers : KV10114400 (J-38365) : KV991J0050 (J-44626)

Intake Manifold

Intake Manifold

Exploded View

1.

Intake manifold

2.

Intake manifold gasket

A.

Refer to Removal and Installation.

Removal and Installation

REMOVALWARNING:

To avoid the danger of being scalded, do not drain the coolant when the engine is hot...

Oil Pan and Oil Strainer

Oil Pan and Oil Strainer

Exploded View

1.

Oil pan baffle

2.

O-ring

3.

Upper oil pan gasket

4.

Blind plug O-ring

5.

Blind plug

6.

Oil cooler O-ring

7...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Door Does Not Lock/unlock and Engine Does Not Start (req Sw/push Sw) (one Key)

Diagnosis Procedure Door does not lock/unlock with door request switch, and engine does not start when ignition switch is pressed while carrying Intelligent Key. (One Intelligent Key has the symptom, other keys operate normally.)SYMPTOM TABLE (ONE INTELLIGENT KEY HAS THE SYMPTOM, OTHER KEYS OPERATE NORMALLY) Door lock operation (remote keyless entry) Door lock operation (request switch) or back door open operation (opener switch of back door panel) Engine started with push-button ignition switch operation (Intelligent Key is within the detection area of inside key antenna) Engine started with push-button ignition switch operation (registered Intelligent Key placed next to push-button ignition switch) OK NG No crank, No start OK DIAGNOSIS PROCEDURERefer to Diagnosis Procedure...

Nissan Murano (Z52) 2015-2024 Service Manual: Main Line Between Hvac and M&a Circuit

Diagnosis Procedure CHECK CONNECTOR Turn the ignition switch OFF. Disconnect the battery cable from the negative terminal. Check the following terminals and connectors for damage, bend and loose connection (connector side and harness side). Harness connector M84 Harness connector B101 Is the inspection result normal? YES>> GO TO 2...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Intelligent Forward Collision Warning (I-FCW)

- High Beam Assist (if so equipped)

- Passenger compartment

- New on site

- Most important about car