Nissan Murano: General Information :: How to Use This Manual / Tightening Torque of Standard Bolts

This vehicle has both new standard based on ISO* and previous standard bolts/nuts. There are some differences between these two types of bolts/ nuts; shape of the head, grade of strength, hexagonal width across flats and the standard tightening torque.

-

For guidance in discriminating, refer to Tightening Torque Table (New Standard Included).

-

If the tightening torque is not described in the description or figure, refer to Tightening Torque Table (New Standard Included).

*ISO: International Organization for Standardization

CAUTION:

-

The special parts are excluded.

-

The bolts/nuts in these tables have a strength (discrimination) number/symbol assigned to the head or the like. As to the relation between the strength grade in these tables and the strength (discrimination) number/symbol, refer to “DISCRIMINATION OF BOLTS AND NUTS”.

PREVIOUS STANDARD

| Grade (Strength grade) | Bolt size |

Bolt diameter mm |

Hexagonal width across flats mm |

Pitch mm | Tightening torque (Without lubricant) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hexagon head bolt | Hexagon flange bolt | |||||||||||

| N·m | kg-m | ft-lb | in-lb | N·m | kg-m | ft-lb | in-lb | |||||

| 4T | M6 | 6.0 | 10 | 1.0 | 5.5 | 0.56 | 4 | 49 | 7 | 0.71 | 5 | 62 |

| M8 | 8.0 | 12 | 1.25 | 13.5 | 1.4 | 10 | — | 17 | 1.7 | 13 | — | |

| 1.0 | 13.5 | 1.4 | 10 | — | 17 | 1.7 | 13 | — | ||||

| M10 | 10.0 | 14 | 1.5 | 28 | 2.9 | 21 | — | 35 | 3.6 | 26 | — | |

| 1.25 | 28 | 2.9 | 21 | — | 35 | 3.6 | 26 | — | ||||

| M12 | 12.0 | 17 | 1.75 | 45 | 4.6 | 33 | — | 55 | 5.6 | 41 | — | |

| 1.25 | 45 | 4.6 | 33 | — | 65 | 6.6 | 48 | — | ||||

| M14 | 14.0 | 19 | 1.5 | 80 | 8.2 | 59 | — | 100 | 10 | 74 | — | |

| 7T | M6 | 6.0 | 10 | 1.0 | 9 | 0.92 | 7 | 80 | 11 | 1.1 | 8 | 97 |

| M8 | 8.0 | 12 | 1.25 | 22 | 2.2 | 16 | — | 28 | 2.9 | 21 | — | |

| 1.0 | 22 | 2.2 | 16 | — | 28 | 2.9 | 21 | — | ||||

| M10 | 10.0 | 14 | 1.5 | 45 | 4.6 | 33 | — | 55 | 5.6 | 41 | — | |

| 1.25 | 45 | 4.6 | 33 | — | 55 | 5.6 | 41 | — | ||||

| M12 | 12.0 | 17 | 1.75 | 80 | 8.2 | 59 | — | 100 | 10 | 74 | — | |

| 1.25 | 80 | 8.2 | 59 | — | 100 | 10 | 74 | — | ||||

| M14 | 14.0 | 19 | 1.5 | 130 | 13 | 96 | — | 170 | 17 | 125 | — | |

| 9T | M6 | 6.0 | 10 | 1.0 | 11 | 1.1 | 8 | — | 13.5 | 1.4 | 10 | — |

| M8 | 8.0 | 12 | 1.25 | 28 | 2.9 | 21 | — | 35 | 3.6 | 26 | — | |

| 1.0 | 28 | 2.9 | 21 | — | 35 | 3.6 | 26 | — | ||||

| M10 | 10.0 | 14 | 1.5 | 55 | 5.6 | 41 | — | 80 | 8.2 | 59 | — | |

| 1.25 | 55 | 5.6 | 41 | — | 80 | 8.2 | 59 | — | ||||

| M12 | 12.0 | 17 | 1.75 | 100 | 10 | 74 | — | 130 | 13 | 96 | — | |

| 1.25 | 100 | 10 | 74 | — | 130 | 13 | 96 | — | ||||

| M14 | 14.0 | 19 | 1.5 | 170 | 17 | 125 | — | 210 | 21 | 155 | — | |

CAUTION:

The parts with aluminum or the cast iron washer surface/thread surface are excluded.

NEW STANDARD BASED ON ISO

| Grade (Strength grade) | Bolt size |

Bolt diameter mm |

Hexagonal width across flats mm |

Pitch mm | Tightening torque | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hexagon head bolt | Hexagon flange bolt | |||||||||||

| N·m | kg-m | ft-lb | in-lb | N·m | kg-m | ft-lb | in-lb | |||||

|

4.8 (Without lubricant) |

M6 | 6.0 | 10 | 1.0 | 5.5 | 0.56 | 4 | 49 | 7 | 0.71 | 5 | 62 |

| M8 | 8.0 | 13 | 1.25 | 13.5 | 1.4 | 10 | — | 17 | 1.7 | 13 | — | |

| 1.0 | 13.5 | 1.4 | 10 | — | 17 | 1.7 | 13 | — | ||||

| M10 | 10.0 | 16 | 1.5 | 28 | 2.9 | 21 | — | 35 | 3.6 | 26 | — | |

| 1.25 | 28 | 2.9 | 21 | — | 35 | 3.6 | 26 | — | ||||

| M12 | 12.0 | 18 | 1.75 | 45 | 4.6 | 33 | — | 55 | 5.6 | 41 | — | |

| 1.25 | 45 | 4.6 | 33 | — | 65 | 6.6 | 48 | — | ||||

| M14 | 14.0 | 21 | 1.5 | 80 | 8.2 | 59 | — | 100 | 10 | 74 | — | |

|

4.8 (With lubricant) |

M6 | 6.0 | 10 | 1.0 | 4 | 0.41 | 3 | 35 | 5.5 | 0.56 | 4 | 49 |

| M8 | 8.0 | 13 | 1.25 | 11 | 1.1 | 8 | — | 13.5 | 1.4 | 10 | — | |

| 1.0 | 11 | 1.1 | 8 | — | 13.5 | 1.4 | 10 | — | ||||

| M10 | 10.0 | 16 | 1.5 | 22 | 2.2 | 16 | — | 28 | 2.9 | 21 | — | |

| 1.25 | 22 | 2.2 | 16 | — | 28 | 2.9 | 21 | — | ||||

| M12 | 12.0 | 18 | 1.75 | 35 | 3.6 | 26 | — | 45 | 4.6 | 33 | — | |

| 1.25 | 35 | 3.6 | 26 | — | 45 | 4.6 | 33 | — | ||||

| M14 | 14.0 | 21 | 1.5 | 65 | 6.6 | 48 | — | 80 | 8.2 | 59 | — | |

|

8.8 (With lubricant) |

M6 | 6.0 | 10 | 1.0 | 8 | 0.82 | 6 | 71 | 10 | 1.0 | 7 | 89 |

| M8 | 8.0 | 13 | 1.25 | 21 | 2.1 | 15 | — | 25 | 2.6 | 18 | — | |

| 1.0 | 21 | 2.1 | 15 | — | 25 | 2.6 | 18 | — | ||||

| M10 | 10.0 | 16 | 1.5 | 40 | 4.1 | 30 | — | 50 | 5.1 | 37 | — | |

| 1.25 | 40 | 4.1 | 30 | — | 50 | 5.1 | 37 | — | ||||

| M12 | 12.0 | 18 | 1.75 | 70 | 7.1 | 52 | — | 85 | 8.7 | 63 | — | |

| 1.25 | 70 | 7.1 | 52 | — | 85 | 8.7 | 63 | — | ||||

| M14 | 14.0 | 21 | 1.5 | 120 | 12 | 89 | — | 140 | 14 | 103 | — | |

|

10.9 (With lubricant) |

M6 | 6.0 | 10 | 1.0 | 10 | 1.0 | 7 | 89 | 12 | 1.2 | 9 | 106 |

| M8 | 8.0 | 13 | 1.25 | 27 | 2.8 | 20 | — | 32 | 3.3 | 24 | — | |

| 1.0 | 27 | 2.8 | 20 | — | 32 | 3.3 | 24 | — | ||||

| M10 | 10.0 | 16 | 1.5 | 55 | 5.6 | 41 | — | 65 | 6.6 | 48 | — | |

| 1.25 | 55 | 5.6 | 41 | — | 65 | 6.6 | 48 | — | ||||

| M12 | 12.0 | 18 | 1.75 | 95 | 9.7 | 70 | — | 110 | 11 | 81 | — | |

| 1.25 | 95 | 9.7 | 70 | — | 110 | 11 | 81 | — | ||||

| M14 | 14.0 | 21 | 1.5 | 160 | 16 | 118 | — | 180 | 18 | 133 | — | |

CAUTION:

-

Use tightening torque with lubricant for the new standard bolts/nuts in principle. Friction coefficient stabilizer is applied to the new standard bolts/nuts.

-

However, use tightening torque without lubricant for the following cases. Friction coefficient stabilizer is not applied to the following bolts/nuts.

-

Grade 4.8, M6 size bolt, Conical spring washer installed

-

Paint removing nut (Size M6 and M8) for fixing with weld bolt

-

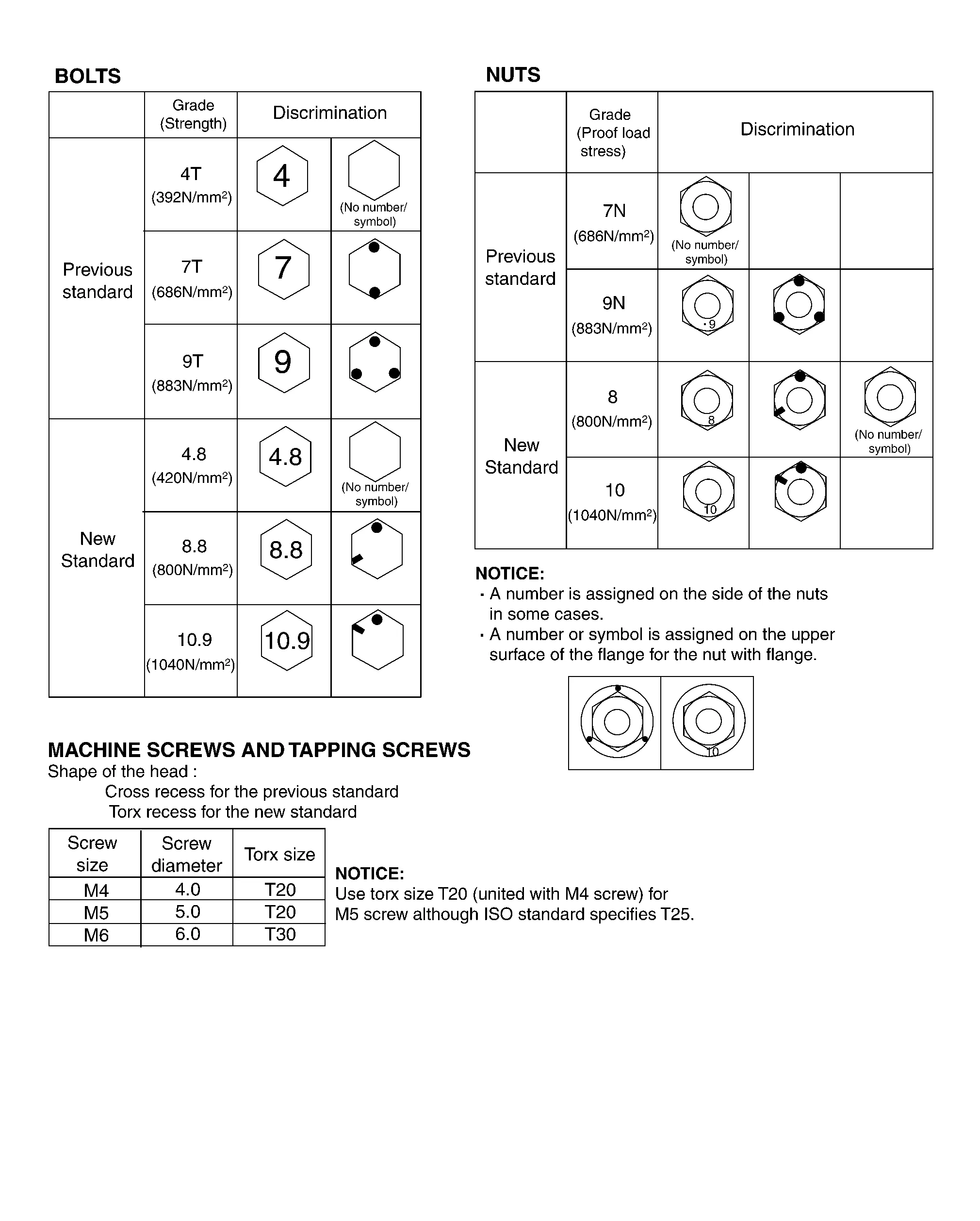

DISCRIMINATION OF BOLTS AND NUTS

Abbreviations

Abbreviations

Abbreviation List

The following ABBREVIATIONS are used:A ABBREVIATION DESCRIPTION

A/C

Air conditioner

Air conditioning

A/F sensor

Air fuel ratio sensor

A/T

Automatic transaxle/transmission

ABS

Anti-lock braking system

ACCS

Advance climate control system

ACL

Air cleaner

AEB

Automatic Emergency Braking

AP

Accelerator pedal

APP

Accelerator pedal position

ATF

Automatic transmission fluid

ATR

Active torque rod

AV

Audio visual

AVM

Around view monitor

AWD

All wheel drive

B ABBREVIATION DESCRIPTION

BARO

Barometric pressure

BCI

Backup collision intervention

BCM

Body control module

BLSD

Brake limited slip differential

BPP

Brake pedal position

BSI

Blind spot intervention

BSW

Blind spot warning

C ABBREVIATION DESCRIPTION

CGW

Can Gateway

CKP

Crankshaft position

CL

Closed loop

CMP

Camshaft position

CPP

Clutch pedal position

CTP

Closed throttle position

CVT

Continuously variable transaxle/transmission

D ABBREVIATION DESCRIPTION

D1

Drive range first gear

D2

Drive range second gear

D3

Drive range third gear

D4

Drive range fourth gear

DCA

Distance control assist

DDS

Downhill drive support

DFI

Direct fuel injection system

DLC

Data link connector

DTC

Diagnostic trouble code

E ABBREVIATION DESCRIPTION

E/T

Exhaust temperature

EBD

Electric brake force distribution

EC

Engine control

ECD

Electronic controlled deceleration

ECL

Engine coolant level

ECM

Engine control module

ECT

Engine coolant temperature

ECV

Electrical control valve

EEPROM

Electrically erasable programmable read only memory

EFT

Engine fuel temperature

EGR

Exhaust gas recirculation

EGRT

Exhaust gas recirculation temperature

EGT

Exhaust gas temperature

ELD

Electronic locking differential

EOP

Engine oil pressure

EP

Exhaust pressure

EPR

Exhaust pressure regulator

EPS

Electronically controlled power steering

Electronic power steering

ESP

Electronic stability program system

EVAP canister

Evaporative emission canister

EVSE

Electric Nissan Murano vehicle supply equipment

EXC

Exhaust control

F ABBREVIATION DESCRIPTION

FC

Fan control

FCW

Forward collision warning

FEB

Forward Emergency Braking

FIC

Fuel injector control

FP

Fuel pump

FR

Front

FRP

Fuel rail pressure

FRT

Fuel rail temperature

FTP

Fuel tank pressure

FTT

Fuel tank temperature

G ABBREVIATION DESCRIPTION

GND

Ground

GPS

Global positioning system

GST

Generic scan tool

H ABBREVIATION DESCRIPTION

HBMC

Hydraulic body-motion control system

HDD

Hard disk drive

HO2S

Heated oxygen sensor

HOC

Heated oxidation catalyst

HPCM

Hybrid powertrain control module

I ABBREVIATION DESCRIPTION

I/M

Inspection and maintenance

IA

Intake air

IAC

Idle air control

IAT

Intake air temperature

IBA

Intelligent brake assist

IC

Ignition control

ICC

Intelligent cruise control

ICM

Ignition control module

IPDM E/R

Intelligent power distribution module engine room

ISC

Idle speed control

ISS

Input shaft speed

ITS

Information technology suite

IVC

In-Nissan Murano vehicle communications

K ABBREVIATION DESCRIPTION

KS

Knock sensor

L ABBREVIATION DESCRIPTION

LBC

Li-ion battery controller

LCD

Liquid crystal display

LCU

Local control unit

LDP

Lane departure prevention

LDW

Lane departure warning

LED

Light emitting diode

LH

Left-hand

LHD

Left-hand drive

LIN

Local interconnect network

M ABBREVIATION DESCRIPTION

M/T

Manual transaxle/transmission

MAF

Mass airflow

MAP

Manifold absolute pressure

MDU

Multi display unit

MI

Malfunction indicator

MIL

Malfunction indicator lamp

MOD

Moving object detection

N ABBREVIATION DESCRIPTION

NOX

Nitrogen oxides

O ABBREVIATION DESCRIPTION

O2

Oxygen

O2S

Oxygen sensor

OBD

On board diagnostic

OC

Oxidation catalytic converter

OD

Overdrive

OL

Open loop

OSS

Output shaft speed

P ABBREVIATION DESCRIPTION

P/S

Power steering

PBR

Potentio balance resistor

PCV

Positive crankcase ventilation

PFCW

Predictive forward collision warning

PNP

Park/Neutral position

PSP

Power steering pressure

PTC

Positive temperature coefficient

PTO

Power takeoff

PWM

Pulse width modulation

R ABBREVIATION DESCRIPTION

RAM

Random access memory

RAS

Rear active steer

RH

Right-hand

RHD

Right-hand drive

ROM

Read only memory

RPM

Engine speed

RR

Rear

S ABBREVIATION DESCRIPTION

SAE

Society of Automotive Engineers, Inc...

Recommended Chemical Products and Sealants

Recommended Chemical Products and Sealants

Recommended Chemical Products and Sealants

Refer to the following chart for help in selecting the appropriate chemical product or sealant. Product Description Purpose Nissan North America Part No...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Rcta

System Description SYSTEM DIAGRAMADAS CONTROL UNIT INPUT/OUTPUT SIGNAL ITEMInput Signal Item Transmit unit Signal name Description TCM CAN communication Current gear position signal Receives a current gear position. Shift position signal Receives a select lever position...

Nissan Murano (Z52) 2015-2024 Service Manual: Front Seat Belt Buckle

Removal and Installation REMOVALRemove front seat. Refer to Removal and Installation. Disconnect seat belt buckle harness connector. Remove seat belt buckle anchor bolt and seat belt buckle. CAUTION: Before removing the seat belt buckle anchor bolt, note the positions of washers and spacers for correct installation...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Fuel recommendation

- High Beam Assist (if so equipped)

- Checking engine oil level

- New on site

- Most important about car

Driver and passenger supplemental knee air bag

Driver’s side

The knee air bag is located in the knee bolster, on the driver’s and passenger’s side. All of the information, cautions and warnings in this manual apply and must be followed. The knee air bag is designed to inflate in higher severity frontal collisions, although it may inflate if the forces in another type of collision are similar to those of a higher severity frontal impact. It may not inflate in certain collisions.

Passenger’s side