Nissan Murano: Dtc/circuit Diagnosis / On Board Refueling Vapor Recovery (orvr)

CHECK ORVR FUNCTION

Check whether the following symptoms are present.

-

Fuel odor from EVAP canister is strong.

-

Cannot refuel/Fuel odor from the fuel filler opening is strong while refueling.

Are any symptoms present?

YES>>Proceed to Diagnosis Procedure.

NO>>INSPECTION END

INSPECTION START

Check whether the following symptoms are present.

A: Fuel odor from EVAP canister is strong.

B: Cannot refuel/Fuel odor from the fuel filler opening is strong while refueling.

A or B

A>>GO TO 2.

B>>GO TO 7.

CHECK EVAP CANISTER

-

Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor attached. Refer to Removal and Installation.

-

Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor attached.

The weight should be less than 2.1 kg (4.6 lb).

Is the inspection result normal?

YES>>GO TO 3.

NO>>GO TO 4.

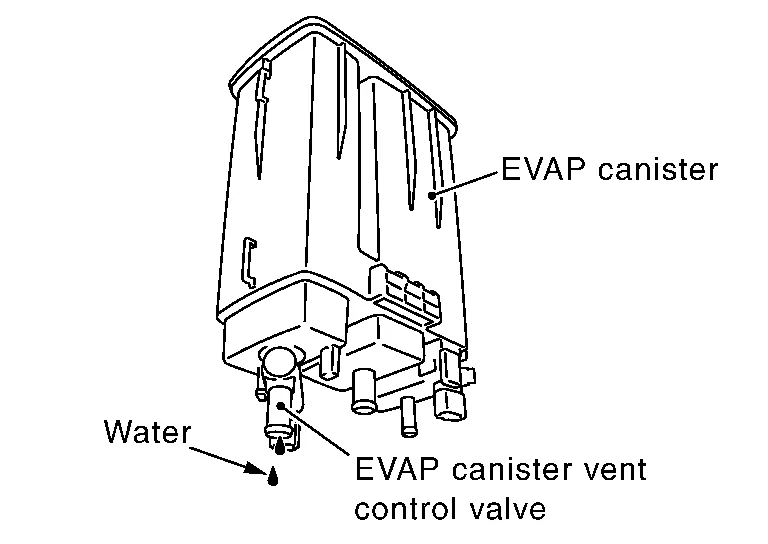

CHECK IF EVAP CANISTER IS SATURATED WITH WATER

Check if water will drain from EVAP canister

Does water drain from the EVAP canister?

YES>>GO TO 4.

NO>>GO TO 6.

REPLACE EVAP CANISTER

Replace EVAP canister with a new one. Refer to Removal and Installation.

>>

GO TO 5.

DETECT MALFUNCTIONING PART

Check the EVAP hose between EVAP canister and Nissan Murano vehicle frame for clogging or poor connection.

>>

Repair or replace EVAP hose. Refer to Exploded View.

CHECK REFUELING EVAP VAPOR CUT VALVE

Check refueling EVAP vapor cut valve. Refer to Component Inspection.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace refueling EVAP vapor cut valve with fuel tank. Refer to Removal and Installation (FWD models) or Removal and Installation (AWD models).

CHECK EVAP CANISTER

-

Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor attached. Refer to Removal and Installation.

-

Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor attached.

The weight should be less than 2.1 kg (4.6 lb).

Is the inspection result normal?

YES>>GO TO 8.

NO>>GO TO 9.

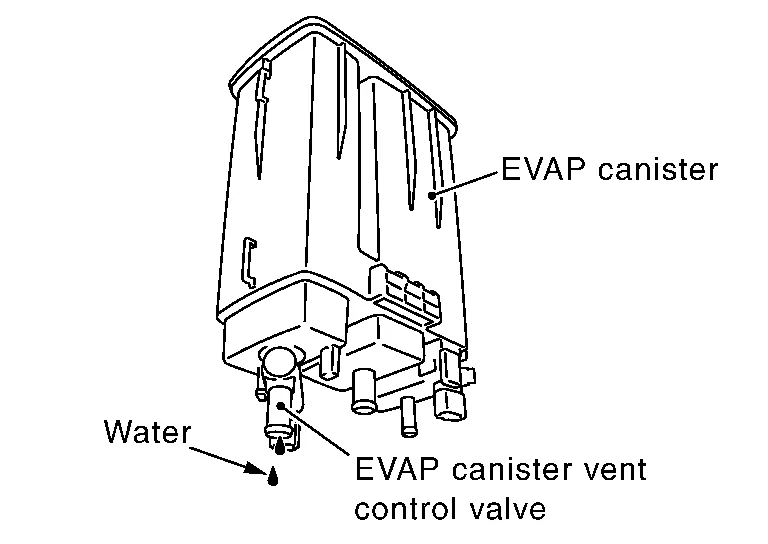

CHECK IF EVAP CANISTER IS SATURATED WITH WATER

Check if water will drain from EVAP canister.

Does water drain from the EVAP canister?

YES>>GO TO 6.

NO>>GO TO 11.

REPLACE EVAP CANISTER

Replace EVAP canister with a new one. Refer to Removal and Installation.

>>

GO TO 10.

DETECT MALFUNCTIONING PART

Check the EVAP hose between EVAP canister and Nissan Murano vehicle frame for clogging or poor connection.

>>

Repair or replace EVAP hose. Refer to Exploded View.

CHECK VENT HOSES AND VENT TUBES

Check hoses and tubes between EVAP canister and refueling control valve for clogging, kinks, looseness and improper connection.

Is the inspection result normal?

YES>>GO TO 12.

NO>>Repair or replace hoses and tubes.

CHECK FILLER NECK TUBE

Check recirculation line for clogging, dents and cracks.

Is the inspection result normal?

YES>>GO TO 13.

NO>>Replace filler neck tube.

CHECK REFUELING EVAP VAPOR CUT VALVE

Check refueling EVAP vapor cut valve. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 14.

NO>>Replace refueling EVAP vapor cut valve with fuel tank. Refer to Removal and Installation (FWD models) or Removal and Installation (AWD models).

CHECK FUEL FILLER TUBE

Check filler neck tube and hose connected to the fuel tank for clogging, dents and cracks.

Is the inspection result normal?

YES>>GO TO 15.

NO>>Replace fuel filler tube. Refer to Exploded View (FWD models) or Exploded View (AWD models).

CHECK ONE-WAY FUEL VALVE-I

Check one-way valve for clogging.

Is the inspection result normal?

YES>>GO TO 16.

NO>>Replace refueling EVAP vapor cut valve with fuel tank. Refer to Removal and Installation (FWD models) or Removal and Installation (AWD models).

CHECK ONE-WAY FUEL VALVE-II

-

Check that fuel is drained from the tank.

-

Remove fuel filler tube and hose. Refer to Exploded View (FWD models) or Exploded View (AWD models).

-

Check one-way fuel valve for operation as per the following.

When a stick is inserted, the valve should open, when removing stick it should close.

Do not drop any material into the tank.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace fuel filler tube or replace one-way fuel valve with fuel tank. Refer to Exploded View (FWD models) or Exploded View (AWD models).

INSPECTION START

Will CONSULT be used?

Will CONSULT be used?

YES>>GO TO 2.

NO>>GO TO 3.

CHECK REFUELING EVAP VAPOR CUT VALVE

With CONSULT

With CONSULT

-

Turn ignition switch OFF.

-

Remove fuel tank. Refer to Removal and Installation.

-

Drain fuel from the tank as per the following:

-

Remove fuel feed hose located on the fuel gauge retainer. Refer to Removal and Installation.

-

Connect a spare fuel hose, one side to fuel gauge retainer where the hose was removed and the other side to a fuel container.

-

Drain fuel using “FUEL PUMP RELAY” in “ACTIVE TEST” mode with CONSULT.

-

-

Check refueling EVAP vapor cut valve for being stuck to close as per the following.

Blow air into the refueling EVAP vapor cut valve (from the end of EVAP/ORVR line hose), and check that the air flows freely into the tank.

-

Check refueling EVAP vapor cut valve for being stuck to open as per the following.

-

Connect vacuum pump to hose end.

-

Remove fuel gauge retainer with fuel gauge unit.

Always replace O-ring with new one.

-

Turn fuel tank upside down.

-

Apply vacuum pressure to hose end [−13.3 kPa (−0.136 kg/cm2, −1.93 psi)] with fuel gauge retainer remaining open and check that the pressure is applicable.

-

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace refueling EVAP vapor cut valve with fuel tank. Refer to Removal and Installation.

CHECK REFUELING EVAP VAPOR CUT VALVE

Without CONSULT

Without CONSULT

-

Turn ignition switch OFF.

-

Remove fuel tank. Refer to Removal and Installation.

-

Drain fuel from the tank as per the following:

-

Remove fuel gauge retainer.

-

Drain fuel from the tank using a handy pump into a fuel container.

-

-

Check refueling EVAP vapor cut valve for being stuck to close as per the following.

Blow air into the refueling EVAP vapor cut valve (from the end of EVAP/ORVR line hose), and check that the air flows freely into the tank.

-

Check refueling EVAP vapor cut valve for being stuck to open as per the following.

-

Connect vacuum pump to hose end.

-

Remove fuel gauge retainer with fuel gauge unit.

Always replace O-ring with new one.

-

Turn fuel tank upside down.

-

Apply vacuum pressure to hose end [−13.3 kPa (−0.136 kg/cm2, −1.93 psi)] with fuel gauge retainer remaining open and check that the pressure is applicable.

-

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace refueling EVAP vapor cut valve with fuel tank. Refer to Removal and Installation.

Information Display (ascd)

Information Display (ascd)

Component Function Check

CHECK INFORMATION DISPLAY

Start engine.

Press MAIN switch on ASCD steering switch.

Drive the Nissan Murano vehicle at more than 40 km/h (25 MPH)...

Refrigerant Pressure Sensor

Refrigerant Pressure Sensor

Component Function Check

CHECK REFRIGERANT PRESSURE SENSOR FUNCTION

Start engine and warm it up to normal operating temperature.

Turn A/C switch and blower fan switch ON...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: U1000 Can Comm Circuit

DTC Description DescriptionCAN (Controller Area Network) is a serial communication line for real time applications. It is an on-Nissan Murano vehicle multiplex communication line with high data communication speed and excellent error detection ability...

Nissan Murano (Z52) 2015-2024 Owners Manual: Checking tire pressure

Remove the valve stem cap from the tire. Press the pressure gauge squarely onto the valve stem. Do not press too hard or force the valve stem sideways, or air will escape. If the hissing sound of air escaping from the tire is heard while checking the pressure, reposition the gauge to eliminate this leakage...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Vehicle Dynamic Control (VDC) OFF switch

- Settings

- How to enable/disable the LDW system

- New on site

- Most important about car

Driver and passenger supplemental knee air bag

Driver’s side

The knee air bag is located in the knee bolster, on the driver’s and passenger’s side. All of the information, cautions and warnings in this manual apply and must be followed. The knee air bag is designed to inflate in higher severity frontal collisions, although it may inflate if the forces in another type of collision are similar to those of a higher severity frontal impact. It may not inflate in certain collisions.

Passenger’s side