Nissan Murano: Dtc/circuit Diagnosis / P219a Air Fuel Ratio

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | |

| P219A |

AIR FUEL RATIO IMBALANCE B1 (Air-fuel ratio imbalance bank 1) |

Diagnosis condition | — |

| Signal (terminal) | — | ||

| Threshold | ECM detects a lean/rich air fuel ratio state in any cylinder for a specified length of time | ||

| Diagnosis delay time | — | ||

| P219B |

AIR FUEL RATIO IMBALANCE B2 (Air-fuel ratio imbalance bank 2) |

Diagnosis condition | — |

| Signal (terminal) | — | ||

| Threshold | ECM detects a lean/rich air fuel ratio state in any cylinder for a specified length of time | ||

| Diagnosis delay time | — | ||

POSSIBLE CAUSE

DTC P219A

-

Fuel injector

-

Exhaust gas leaks

-

Incorrect fuel pressure

-

Mass air flow sensor

-

Intake air leaks

-

Lack of fuel

-

Incorrect PCV hose connection

-

Improper spark plug

-

Insufficient compression

-

The fuel injector circuit is open or shorted

-

Ignition coil

-

The ignition signal circuit is open or shorted

DTC P219B

-

Fuel injector

-

Exhaust gas leaks

-

Incorrect fuel pressure

-

Mass air flow sensor

-

Intake air leaks

-

Lack of fuel

-

Incorrect PCV hose connection

-

Improper spark plug

-

Insufficient compression

-

The fuel injector circuit is open or shorted

-

Ignition coil

-

The ignition signal circuit is open or shorted

FAIL-SAFE

Not applicable

CHECK DTC PRIORITY

If DTC P219A or P219B is displayed with other DTC, first perform the trouble diagnosis for the other DTC.

Is applicable DTC detected?

YES>>Perform diagnosis of applicable. Refer to DTC Index.

NO>>GO TO 2.

PRECONDITIONING-1

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF and wait at least 10 seconds.

NOTE:

NOTE:

Before performing the following procedure, confirm that battery voltage is 11 V or more at idle.

>>

GO TO 3.

PRECONDITIONING-2

-

Turn ignition switch ON.

-

Clear the mixture ratio self-learning value. Refer to Description.

Will CONSULT be used?

YES>>GO TO 4.

NO>>GO TO 7.

PERFORM DTC CONFIRMATION PROCEDURE-1

-

Turn ignition switch ON.

-

Select “COOLAN TEMP/S” in “DATA MONITOR” mode of “ENGINE” using CONSULT.

-

Start engine.

-

Make sure that “COOLAN TEMP/S” indicates more than 65°C (149°F).

>>

GO TO 5.

PERFORM DTC CONFIRMATION PROCEDURE-2

With CONSULT

With CONSULT

-

Select “SYSTEM 1 DIAGNOSIS B B1” and “SYSTEM 1 DIAGNOSIS A B1” in “DATA MONITOR” mode of “ENGINE” using CONSULT.

-

Drive Nissan Murano vehicle under the following conditions for at least 5 consecutive seconds.

CAUTION:

-

Always drive Nissan Murano vehicle at a safe speed.

ENG SPEED 1,000 – 1,600rpm COOLAN TEMP/S More than 65°C (149°F) B/FUEL SCHDL 5 – 12 msec Selector lever D position SYSTEM 1 DIAGNOSIS B B1 PRSENT  NOTE:

NOTE:

-

Drive the Nissan Murano vehicle at approximately 88 km/h (55MPH) allows easy diagnosis.

-

Keep the accelerator pedal as possible during crusing.

-

-

Check “SYSTEM 1 DIAGNOSIS A B1” indication.

Is “CMPLT” displayed?

YES>>GO TO 6.

NO>>GO TO 3.

PERFORM DTC CONFIRMATION PROCEDURE-3

Check 1st trip DTC.

Is 1st trip DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: INSPECTION END

PERFORM DTC CONFIRMATION PROCEDURE-4

Without CONSULT

Without CONSULT

-

Start the engine and warm it up to normal operating temperature.

-

Drive Nissan Murano vehicle under the following conditions for at least 5 consecutive seconds.

CAUTION:

-

Always drive Nissan Murano vehicle at a safe speed.

Engine speed 1,000 – 1,600 rpm Calculated load value 27 – 63 % Selector lever D position  NOTE:

NOTE:

-

Drive the Nissan Murano vehicle at approximately 88 km/h (55MPH) allows easy diagnosis.

-

Keep the accelerator pedal as possible during crusing.

-

-

Check 1st trip DTC.

Is 1st trip DTC detected?

YES>>Proceed to Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: INSPECTION END

NOTE:

NOTE:

Do not replace A/F sensor when DTC P219A is detected.

A/F sensor malfunction is not related to DTC P219A.

CHECK DTC PRIORITY

If DTC P219A or P219B is displayed with other DTC, first perform the trouble diagnosis for the other DTC.

Is applicable DTC detected?

YES>>Perform diagnosis of applicable. Refer to DTC Index.

NO>>GO TO 2.

CHECK FOR INTAKE AIR LEAK

-

Stop engine and check the following for connection.

-

Air duct

-

Vacuum hoses

-

PCV hose

-

Intake air passage between air duct to intake manifold

-

-

Start engine and let it idle.

-

Listen for an intake air leak after the mass air flow sensor.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace error-detected parts.

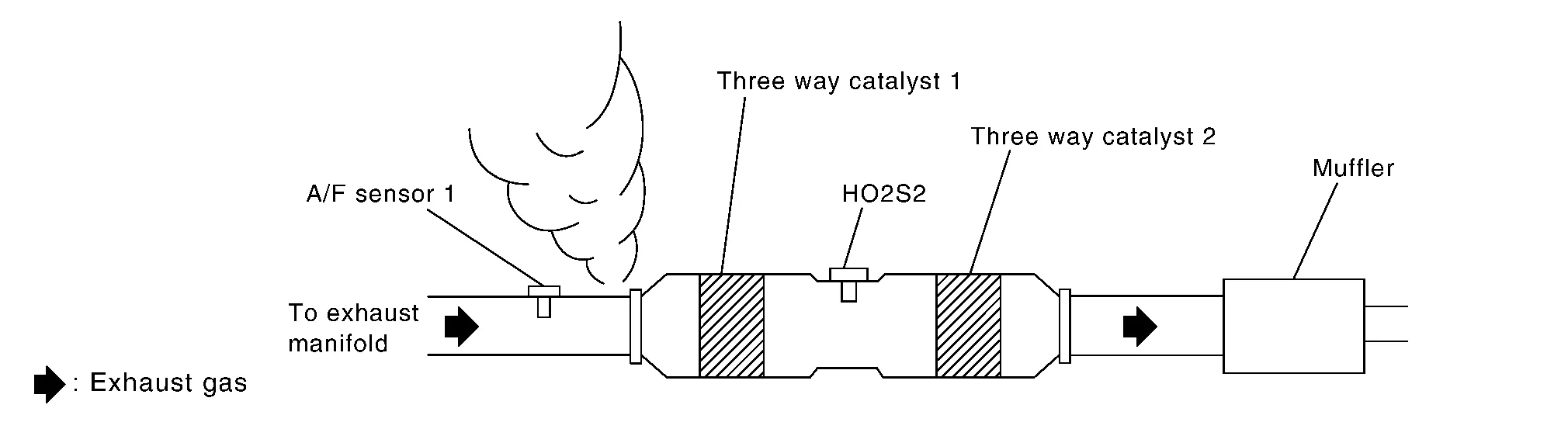

CHECK EXHAUST GAS LEAK

-

Stop engine and visually check exhaust tube, three way catalyst and muffler for dents connection.

-

Start engine and let it idle.

-

Listen for an exhaust gas leak before three way catalyst (manifold).

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace error-detected parts.

CHECK FUEL PRESSURE

-

Release fuel pressure to zero. Refer to Work Procedure.

-

Check fuel pressure. Refer to Work Procedure.

Is the inspection result normal?

YES>>GO TO 5.

NO>>GO TO 10.

CHECK MASS AIR FLOW SENSOR

With CONSULT

With CONSULT

Check “MASS AIR FLOW” in “DATA MONITOR” mode of “ENGINE” using CONSULT.

For specification, refer to Mass Air Flow Sensor.

With GST

With GST

Check mass air flow sensor signal in Service $01 using GST.

For specification, refer to Mass Air Flow Sensor.

Is the inspection result normal?

YES>>GO TO 6.

NO>>Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or grounds. Refer to Diagnosis Procedure.

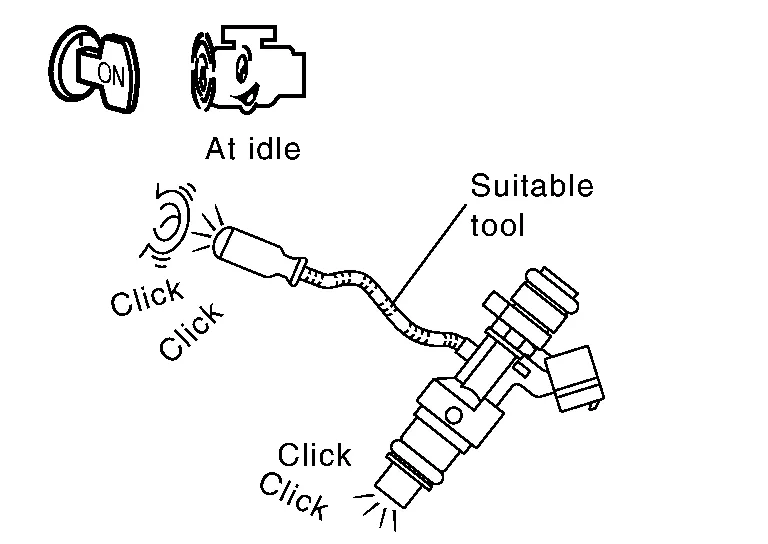

CHECK FUNCTION OF FUEL INJECTOR-1

With CONSULT

With CONSULT

-

Start engine.

-

Perform “POWER BALANCE” in “ACTIVE TEST” mode of “ENGINE” using CONSULT.

-

Check that each circuit produces a momentary engine speed drop.

Without CONSULT

Without CONSULT

-

Let engine idle.

-

Listen to each fuel injector operating sound.

Clicking noise should be heard.

Is the inspection result normal?

YES>>GO TO 7.

NO>>Perform trouble diagnosis for fuel injector, refer to Component Inspection.

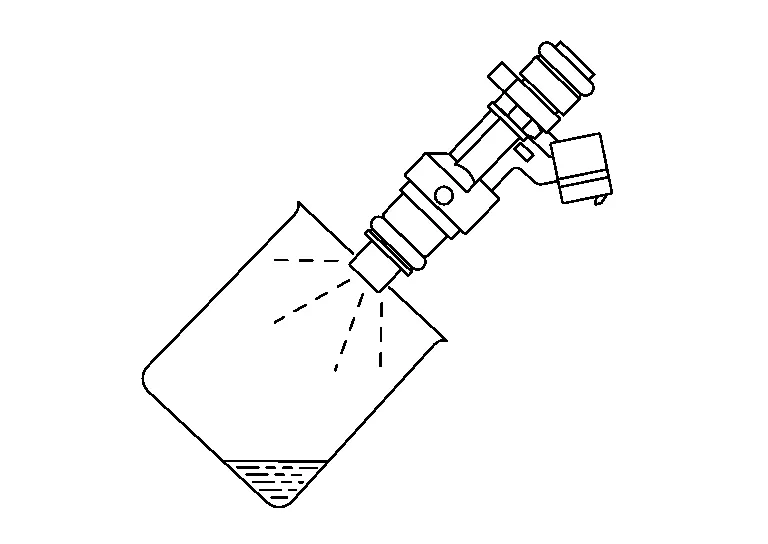

CHECK FUNCTION OF FUEL INJECTOR-2

CAUTION:

Perform the following procedure in a place with no combustible objects and good ventilation.

-

Turn ignition switch OFF.

-

Confirm that the engine is cooled down and there are no fire hazards near the Nissan Murano vehicle.

-

Disconnect all fuel injector harness connectors.

-

Remove fuel tube assembly. Refer to Removal and Installation.

Keep fuel hose and all fuel injectors connected to fuel tube.

-

Disconnect all ignition coil harness connectors.

-

Prepare pans or saucers under each fuel injector.

-

Crank engine for approximately 3 seconds.

-

Fuel should be sprayed evenly for each fuel injector.

-

Fuel must not drip from the tip of fuel injector.

-

Is the inspection result normal?

YES>>GO TO 8.

NO>>Replace fuel injector. Refer to Removal and Installation.

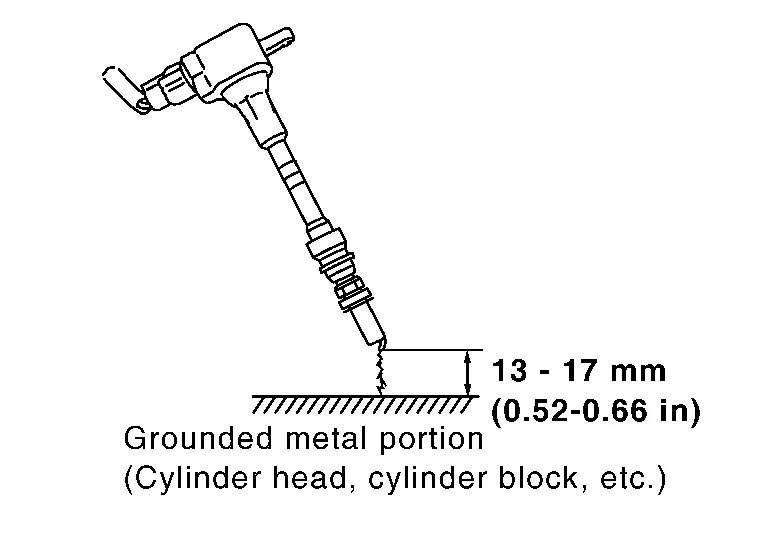

CHECK FUNCTION OF IGNITION COIL-1

CAUTION:

Perform the following steps in a well-ventilated area with no combustibles.

-

Turn ignition switch OFF.

-

Remove fuel pump fuse from IPDM E/R to release fuel pressure.

NOTE:

NOTE:

CONSULT must not be used to release fuel pressure. It develops again during the following steps, if released by using CONSULT.

-

Start the engine.

-

After an engine stall, crank the engine two or three times to release all the fuel pressure.

-

Turn ignition switch OFF.

-

Disconnect all the harness connectors of ignition coil to prevent electric discharge from occurring in ignition coil.

-

Remove ignition coil assembly and spark plug of cylinder. Refer to Removal and Installation (bank 2), Removal and Installation (bank 1).

-

Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

-

Connect spark plug and harness connector to ignition coil.

-

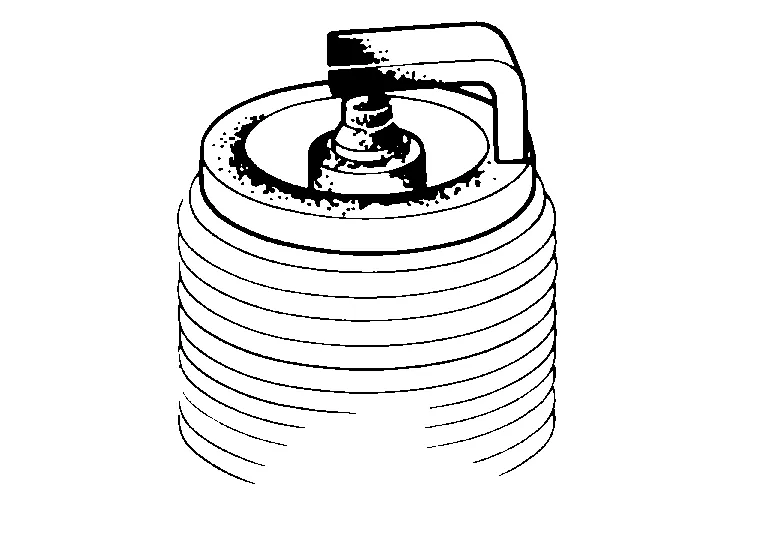

Allow a 13-17mm (0.52-0.66 in) spacing between spark plug and grounded metal portion as shown in the figure to fix the ignition coil with a rope or an equivalent.

-

Crank the engine for approximately 3 seconds to see if sparking occurs between spark plug and the grounded metal portion.

Spark should be generated. CAUTION:

-

The discharge voltage becomes 20 kV or higher. Therefore, always stay away from the spark plug and ignition coil at least 50 cm (19.7 in) during the inspection.

-

Leaving a space of more than 17mm (0.66 in) may damage the ignition coil.

NOTE:

NOTE:

When the gap is less than 13 mm (0.52 in), a the spark might be generated even if the coil is malfunctioning.

-

Is the inspection result normal?

YES>>GO TO 9.

NO>>GO TO 11.

CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to Work Procedure.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

DETECT MALFUNCTIONING PART

Check fuel hoses and fuel tubes for clogging.

Is the inspection result normal?

YES>>Replace fuel filter and fuel pump assembly. Refer to Removal and Installation.

NO>>Repair or replace error-detected parts.

CHECK FUNCTION OF IGNITION COIL-2

-

Turn ignition switch OFF.

-

Disconnect spark plug and connect a non-malfunctioning spark plug.

-

Crank engine for approximately 3 seconds, and recheck whether spark is generated between the spark plug and the grounded metal portion.

Spark should be generated.

Is the inspection result normal?

YES>>GO TO 12.

NO>>Check ignition coil, power transistor and their circuits. Refer to Component Function Check.

CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal?

YES>>-

Repair or clean spark plug. Refer to Removal and Installation.

-

GO TO 13.

Replace spark plug(s) with standard type one(s). For spark plug type, refer to Removal and Installation.

CHECK FUNCTION OF IGNITION COIL-3

-

Reconnect the initial spark plugs.

-

Crank engine for approximately 3 seconds, and recheck whether spark is generated between the spark plug and the grounded portion.

Spark should be generated.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace spark plug(s) with standard type one(s). For spark plug type, refer to Spark Plug.

P2138 App Sensor

P2138 App Sensor

DTC Description

DTC DETECTION LOGICRationally incorrect voltage is sent to ECM compared with the signals from APP sensor 1 and APP sensor 2. DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P2138

APP SENSOR

(Throttle/Pedal position sensor/switch “D” / “E” voltage correlation)

Diagnosis condition

Start engine and let it idle

Signal (terminal)

APP sensor 1 signal and APP sensor 2 signal

Threshold

Rationally incorrect voltage is sent to ECM compared with the signals from APP sensor 1 and APP sensor 2

Diagnosis delay time

—

POSSIBLE CAUSE

Harness or connector

(APP sensor 1 or 2 circuit is open or shorted...

P2237 A/f Sensor 1

P2237 A/f Sensor 1

DTC Description

DTC DETECTION LOGICTo judge malfunctions, the diagnosis checks that the A/F signal computed by ECM from the A/F sensor 1 signal fluctuates according to fuel feedback control...

Other information:

Nissan Murano (Z52) 2015-2024 Service Manual: Ventilation System :: Precaution. Precautions

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER" The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of collisions...

Nissan Murano (Z52) 2015-2024 Service Manual: Door Lock Actuator. Front Lh

Component Function Check CHECK FUNCTION CONSULT Select “DOOR LOCK” in “Active Test” mode of “BCM(DOOR LOCK)”. Select “ALL LOCK” or “ALL UNLK” to check that it works normally. Is the inspection result normal? YES>> Door lock actuator is OK...

Categories

- Manuals Home

- Nissan Murano Owners Manual

- Nissan Murano Service Manual

- Shift lock release

- Indicator lights

- Settings

- New on site

- Most important about car

Luggage hooks

When securing items using luggage hooks located on the back of the seat or side finisher do not apply a load over more than 6.5 lbs. (29 N) to a single hook.

The luggage hooks that are located on the floor should have loads less than 110 lbs. (490 N) to a single hook.